Patents

Literature

37results about How to "Stable release force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

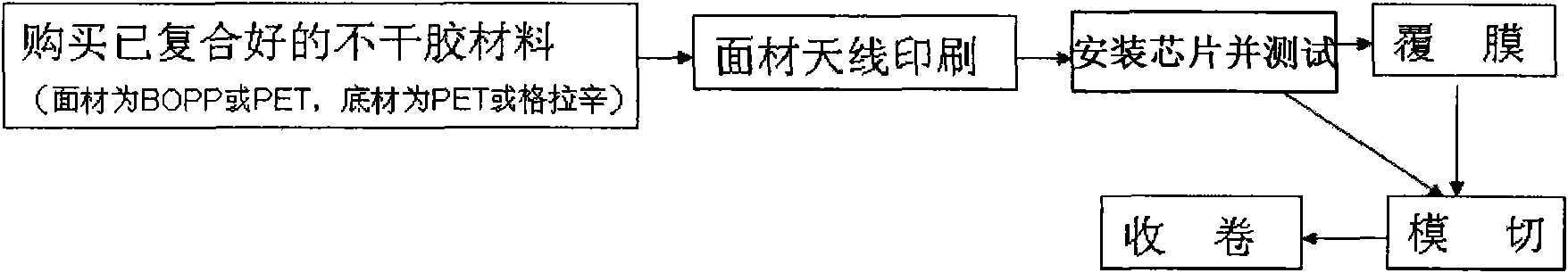

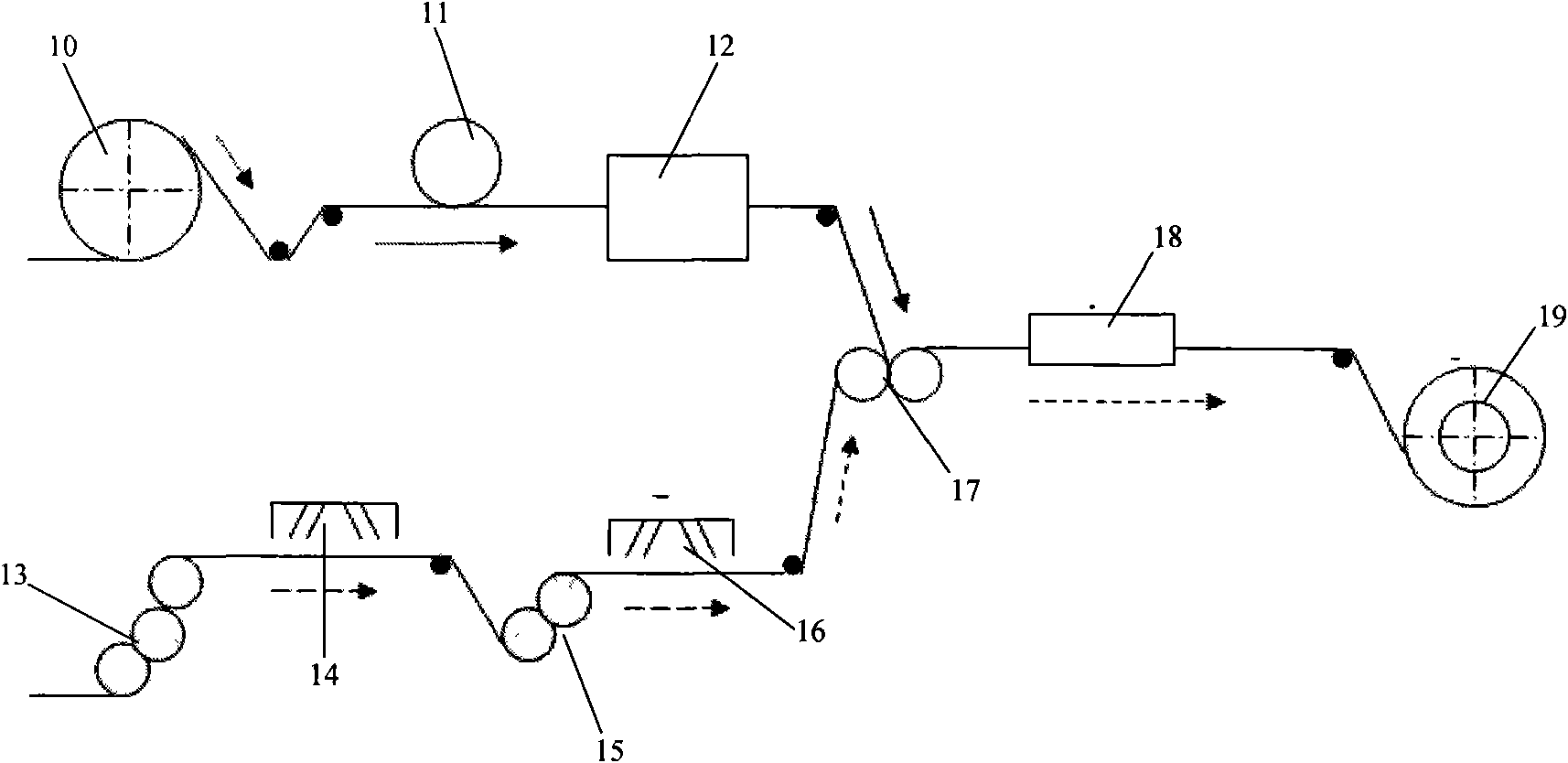

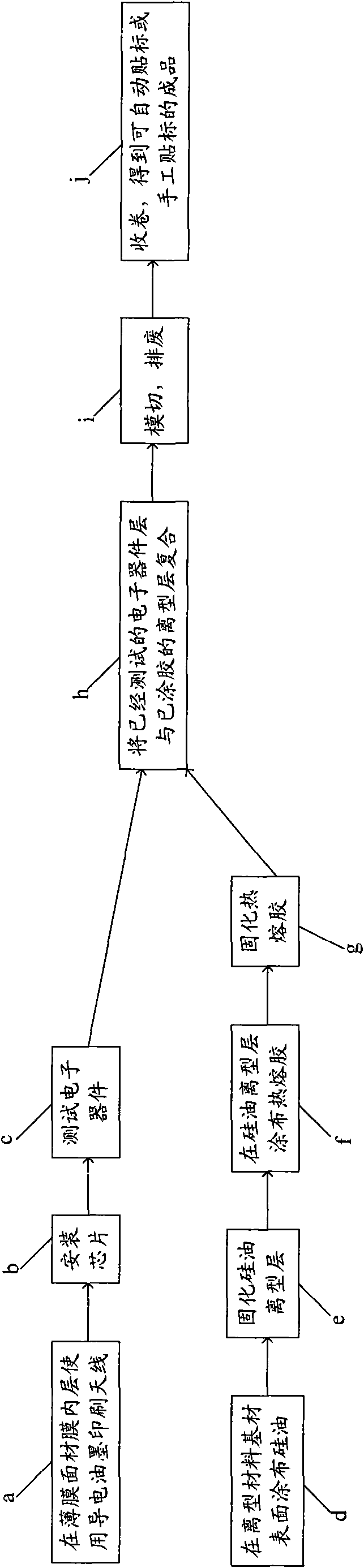

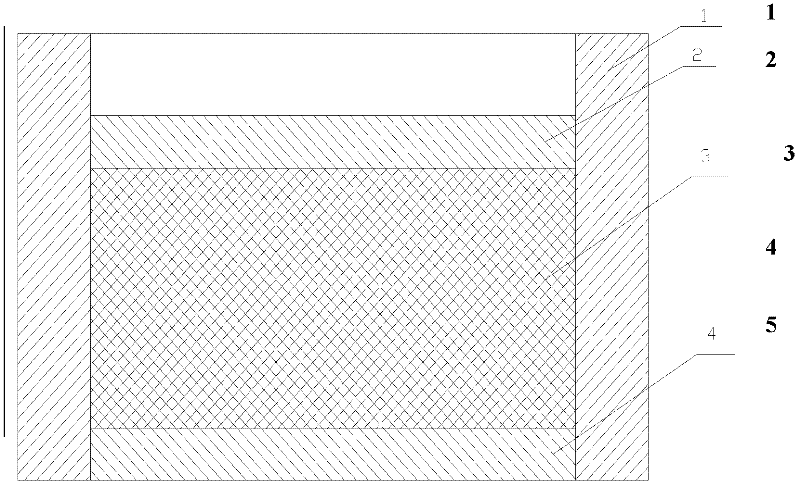

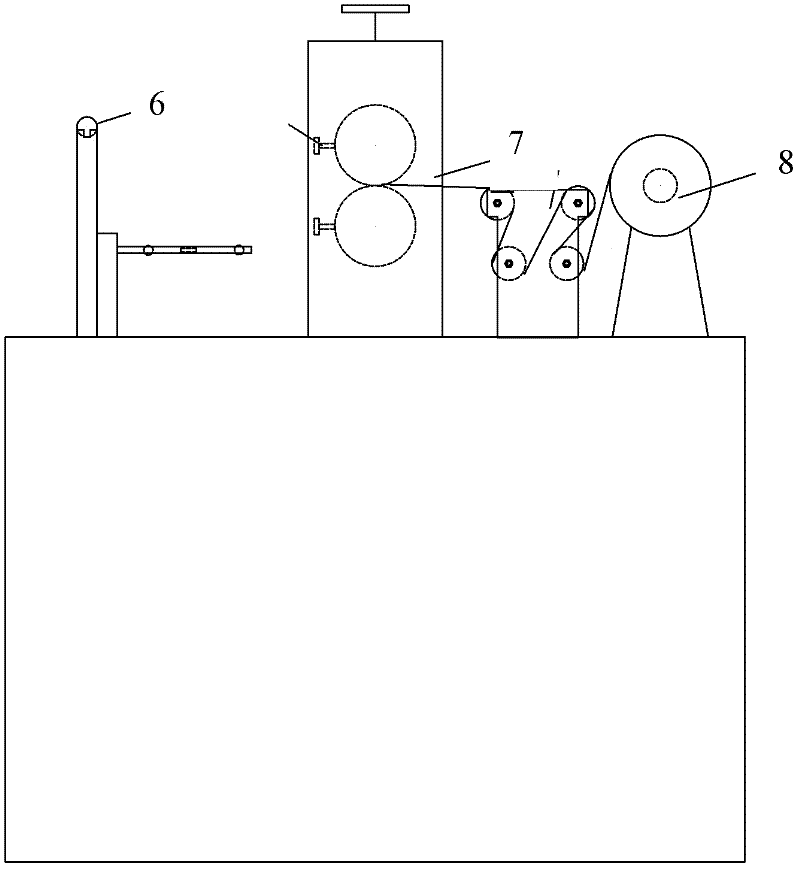

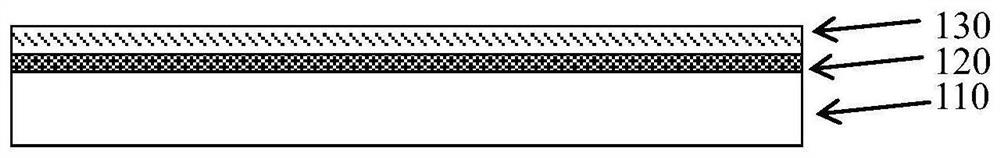

Manufacturing method and system of radio frequency self-adhesive label

ActiveCN101877072AAvoid scratchesPrevent oxidationSemiconductor/solid-state device manufacturingRecord carriers used with machinesEngineeringSilicone oil

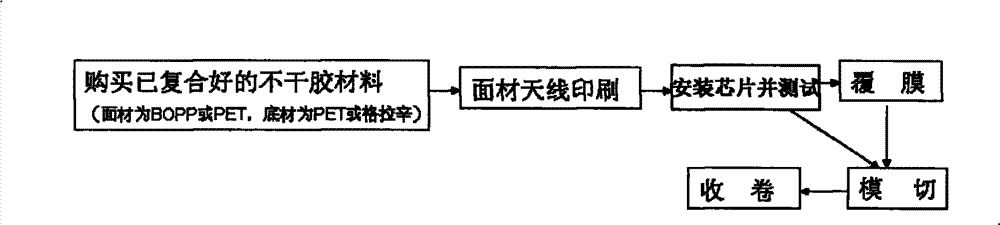

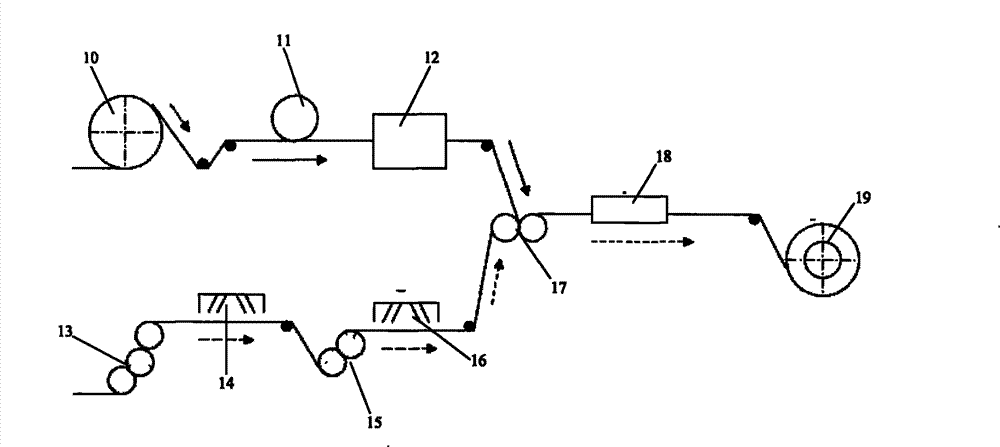

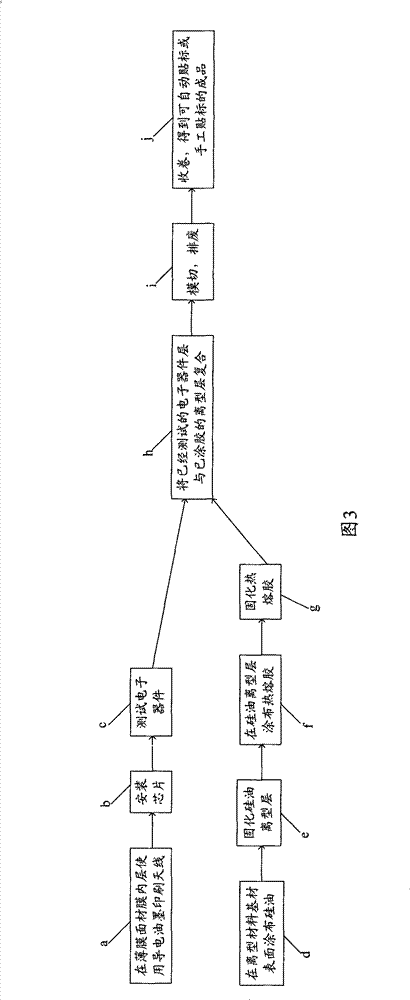

The invention relates to a manufacturing method and a system of a radio frequency self-adhesive label, and the manufacturing method of the radio frequency self-adhesive label comprises the following steps: a) using conductive ink to print an antenna on an inner layer of a surface material film of a thin film; b) mounting a chip; c) testing an electronic device; d) coating silicone oil on the surface of a release material substrate; e) curing a silicone oil release layer; f) coating hot melt adhesive on the silicone oil release layer; g) curing the hot melt adhesive; h) compounding the tested electronic device layer with the release layer coated with the adhesive; i) carrying out die cutting and waste discharge; and j) taking up and obtaining a finished product which can be stuck automatically or manually. The manufacturing method of the radio frequency self-adhesive label can meet the technical requirements of the market on the radio frequency self-adhesive label, has significant advantages in the aspects of manufacturing efficiency, product yield, durability and economy, and can solve the shortcomings of the existing process, and the popularization of the manufacturing method of the radio frequency self-adhesive label is conductive to the wide applications of the radio frequency technology.

Owner:浙江龙游道明光学有限公司

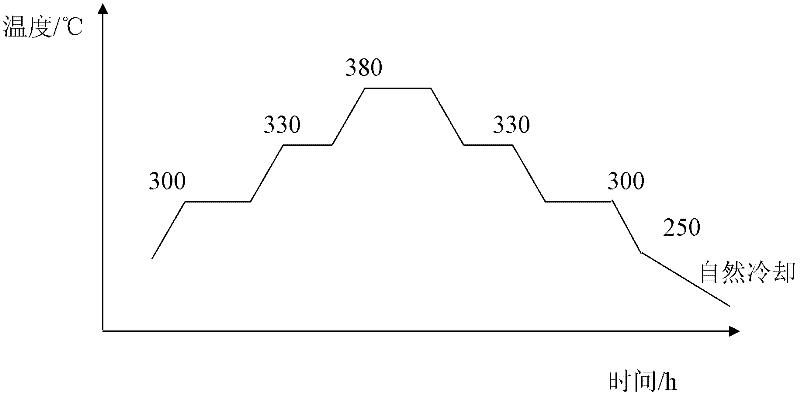

Color polytetrafluoroethylene release film and preparation method thereof

InactiveCN102532759AGood anti-sticking effectImprove flatnessFlat articlesTetrafluoroethyleneWeather resistance

The invention discloses a color polytetrafluoroethylene release film and a preparation method thereof. The color polytetrafluoroethylene release film is prepared through the following steps: blending polytetrafluoroethylene resin and a pigment according to a weight ratio of 100:1-10, and carrying out treatments of pre-forming, sintering, turning and rolling to prepare the color polytetrafluoroethylene release film. According to the present invention, the color polytetrafluoroethylene release film of the present invention has excellent anti-sticking property and surface smoothness of the polytetrafluoroethylene, and can provide light and stable release force during stripping; the color polytetrafluoroethylene release film of the present invention further has characteristics of weathering resistance, temperature resistance, chemical stability, and other excellent properties of the polytetrafluoroethylene, and has bright color, such that the application range is wide; the preparation method is simple, and is convenient to operate.

Owner:TIANJIN TIANSUBINHAI PTFE PLASTIC PROD

Manufacturing process of fluorine element release film

ActiveCN104057669AUniform coatingThe deployment steps are rigorousSynthetic resin layered productsIsolation effectHigh humidity

The invention discloses a manufacturing process of a fluorine element release film, which comprises the following steps: 1) preparing a coating, that is, mixing a fluorine element coating main agent with a n-heptane solvent according to a ratio of 1:6-1:8, adding a bridging agent and an anchoring agent, then adding a catalyst and stirring; 2) preparing the fluorine element release film, that is, coating the above coating on a PET raw film in a precise coating manner, performing an curing reaction in an oven, then cooling and rolling to obtain the finished product. The PET film used in the invention is strict in material selection criterion; the selected main material is available on the market; the blending and preparation steps of the coating solution are strict; a precise coating mode is adopted to allow the coating of the whole film to be quite uniform; after curing and drying, the release force of the product is very stable; the product is good in aging resistance, is very suitable for all organic silica gel protection adhesive tapes, and can be used in high-temperature high-humidity environment with good isolation effect.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

Film material for PE coated paper

Disclosed is a film material for PE coated paper. Raw material formula of the film material is composed of 71.2-90.8% of a polymer, 0.2-1.2% of a lubricant and 9-27.6% of a fogging filler, wherein the polymer is selected from the group consisting of polyethylene, polypropylene, PVC and PET; and the filler is solid particles with the particle size being 3-20 micrometers. A fogging-surface release film with stable release force and good pressure-sensitive adhesive surface fogging effect can be produced, thus reaching low reflection effect of transfer adhesive surface. The production technology is simple, equipment investment cost is low and equipment is convenient to operate.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

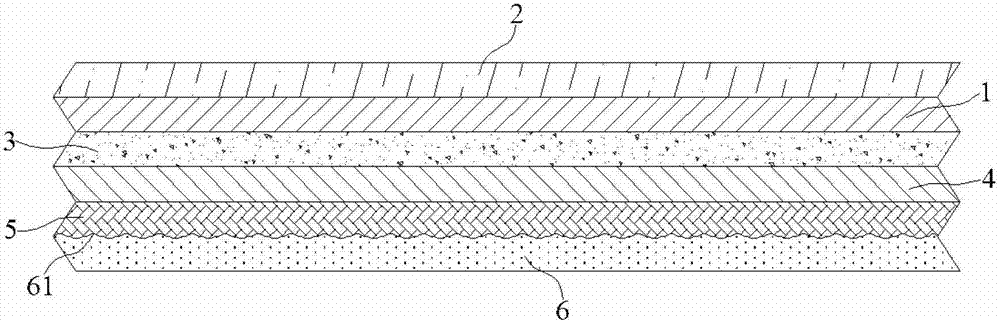

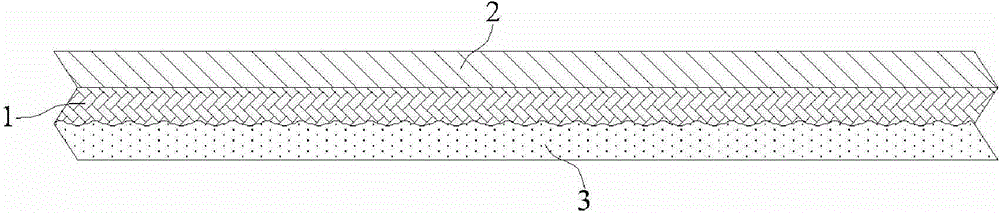

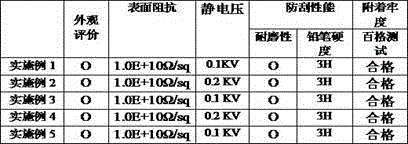

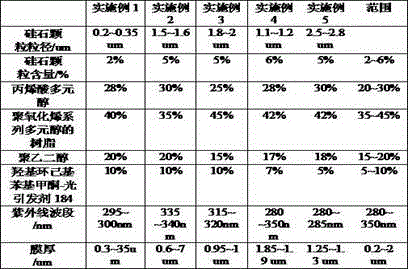

Anti-scuffing matt-surface antistatic release paper

ActiveCN103074819ALow wear resistanceImprove surface antistatic performanceNon-fibrous pulp additionSynthetic resin layered productsElectrostatic coatingPolyethylene glycol

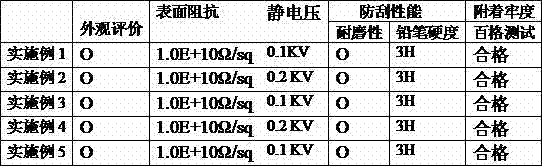

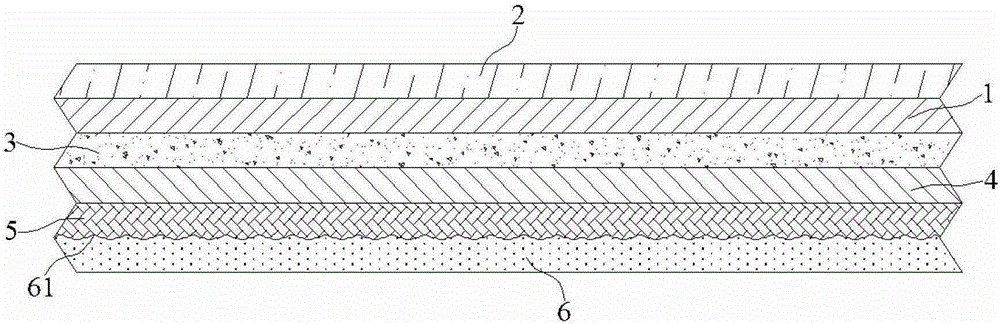

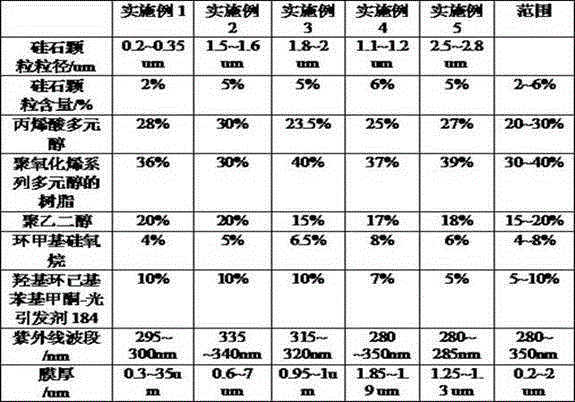

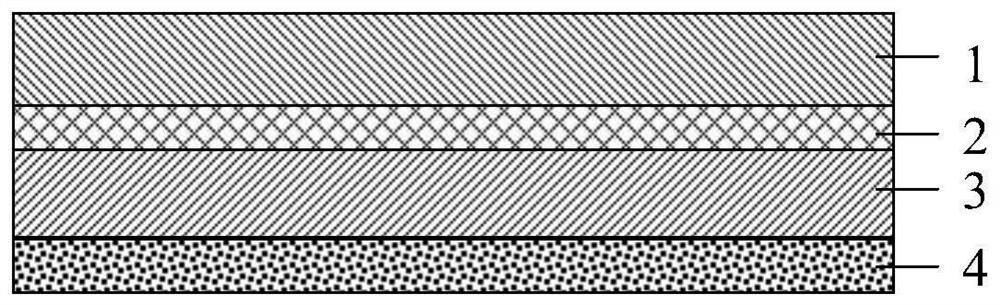

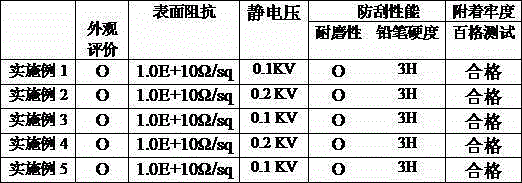

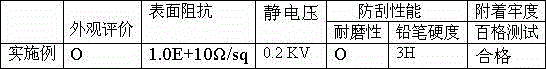

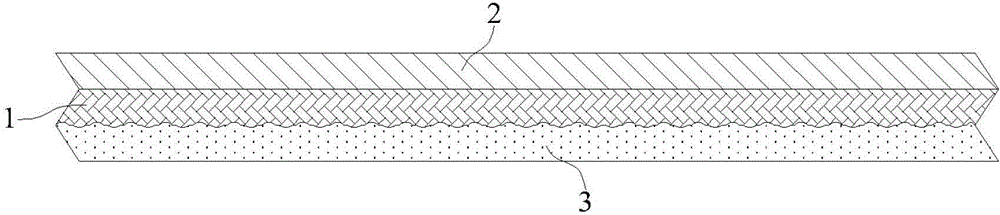

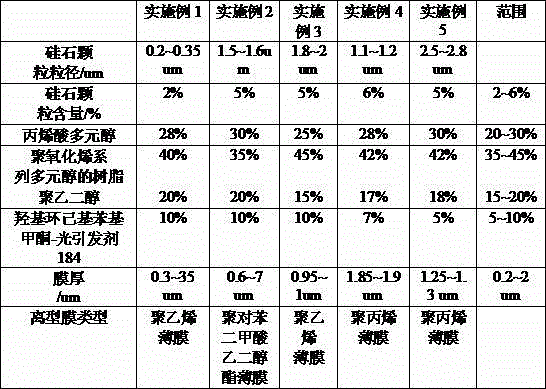

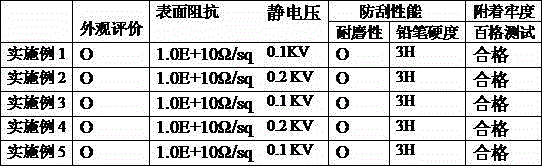

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

Matte release paper

InactiveCN102619142AEnhance hazeImprove bonding fastnessSurface covering paperCoatings with pigmentsPolymer sciencePolyethylene terephthalate glycol

The invention relates to matte release paper, comprising a substrate, wherein coating material is coated on the surface of at least one side of the substrate, raw material formula of the coating material comprises 71.2-90.8% of polymer, 0.2-1.2% of lubricating agent and 9-27.6% of fogging filler; the polymer is selected from polyethylene, polypropylene, PVC (polyvinyl chloride) and PET (polyethylene terephthalate); and the filler is solid particles with particle size of 3-20 microns. According to the invention, the matte release paper with stable release force and a pressure sensitive adhesive surface having a good haze effect can be produced, thus an adhesive moving surface can achieve low reflective effect. The matte release paper has the advantages that the production process is simple, equipment investment cost is low and operation is easy to carry out.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

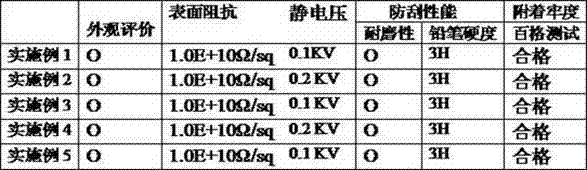

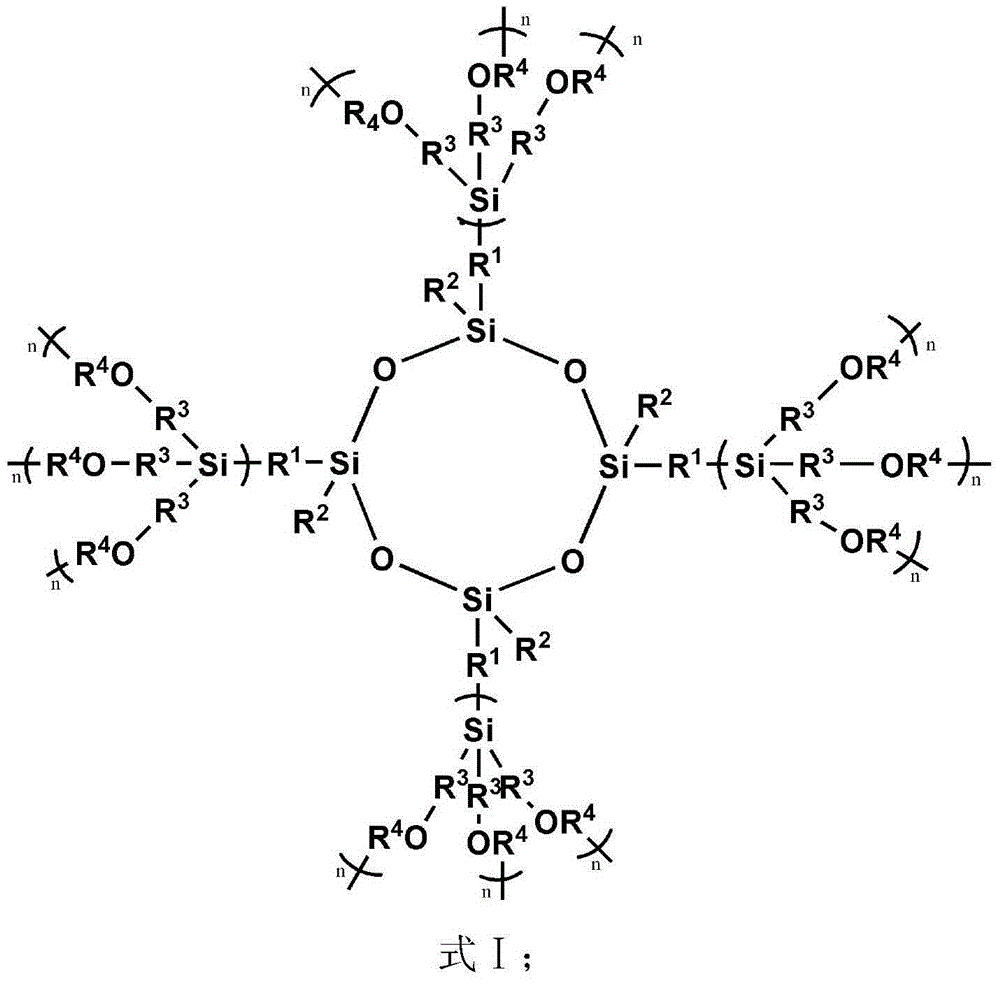

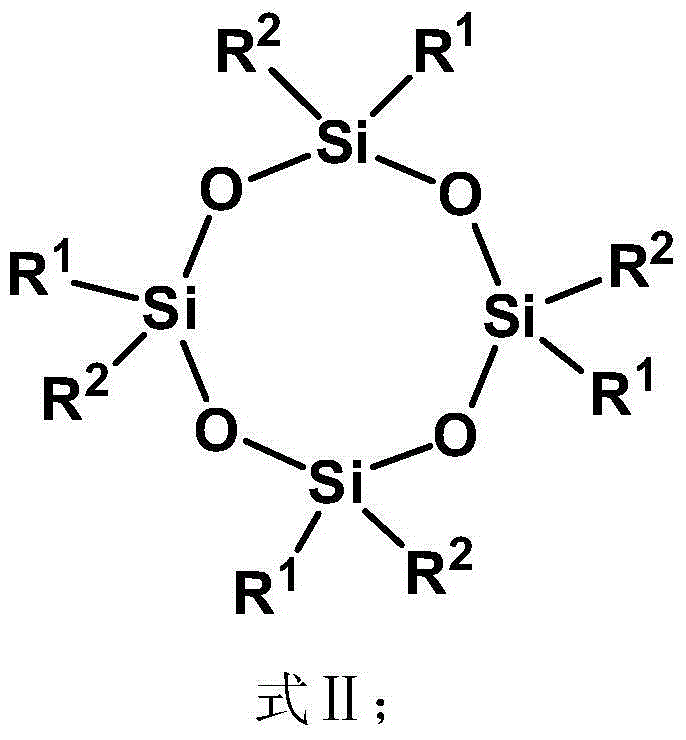

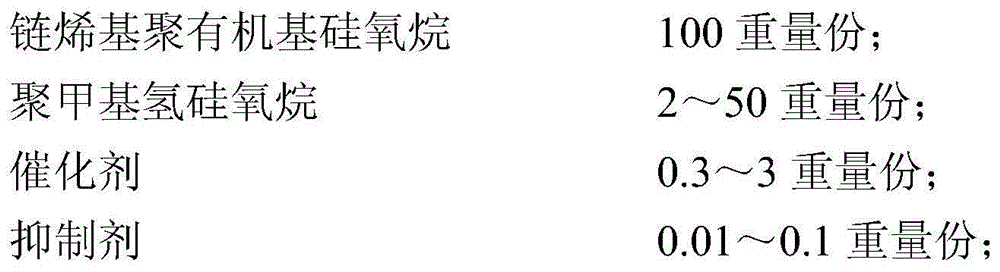

Spherical dendritic organic silicon macromolecule, preparation method thereof and application

The invention belongs to the field of chemical synthesis, and particularly relates to a spherical dendritic organic silicon macromolecule, a preparation method thereof and an application. The structural formula of the spherical dendritic organic silicon macromolecule is indicated in a formula I. The spherical dendritic organic silicon macromolecule is synthesized by a two-step circulation method, and then the synthesized spherical dendritic organic silicon macromolecule serves as a cross-linking compensation point and is applied to a solvent-free polysiloxane compound SL. The two-step circulation method includes hydrosilylation and nucleophilic substitution. Active sites capable of diverging are led into annular siloxane in the hydrosilylation. The nucleophilic substitution aims to lead in more cross-linking reaction sites and ensure that the solvent-free polysiloxane compound obtains a curing coating with a perfect cross-linking network structure when cured on a sheet substrate, so that stable performance of an anti-adhesion coating is ensured.

Owner:国科广化(南雄)新材料研究院有限公司 +2

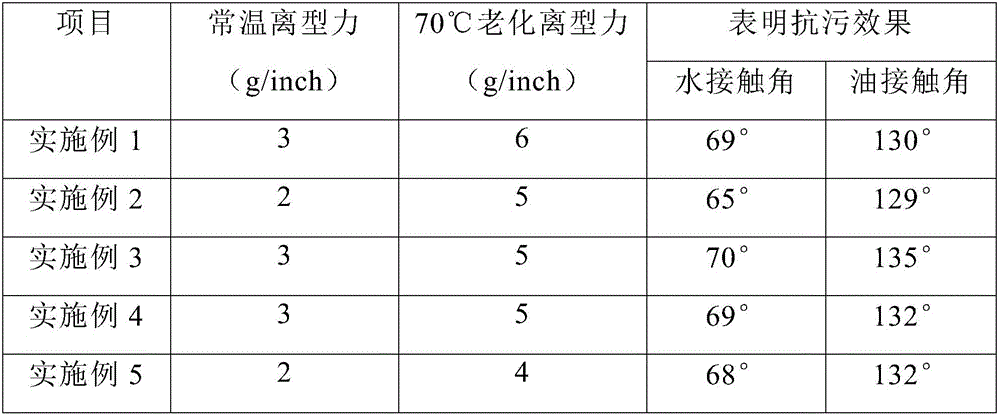

Stain-resistant release film with small release force

InactiveCN106243372AStable release forceImprove stain resistanceCoatingsPolyvinyl alcoholAntioxidant

The invention discloses a stain-resistant release film with small release force. The stain-resistant release film comprises a base film layer; the base film layer is provided with a release layer; the release layer is formed via coating of a release agent; and the release agent comprises, by mass, 5 to 10 parts of polyethylene wax particle, 18 to 38 parts of vinyl organosilicone resin, 5 to 12 parts of fluorine-containing polysiloxane, 2 to 7 parts of polyvinyl alcohol, 0.1 to 2.5 parts of a pigment, 2 to 5 parts of an antioxidant, 2.5 to 5 parts of a coupling agent, 0.5 to 3 parts of an antifoaming agent, and 16 to 32 parts of a solvent. Cooperation of the ingredients is capable of providing the stain-resistant release film with excellent stain resistance; adding of the polyethylene wax particle is capable of changing surface composition of the stain-resistant release film, improving the lubricating properties, the stereoscopic impression, and the lustrousness of the surface of the stain-resistant release film, and providing the stain-resistant release film with small and stable release force; and at the same time, the polyethylene wax particle possesses excellent wear resistance, so that the scrath resistance of the stain-resistant release film is improved.

Owner:苏州睿利斯电子材料科技有限公司

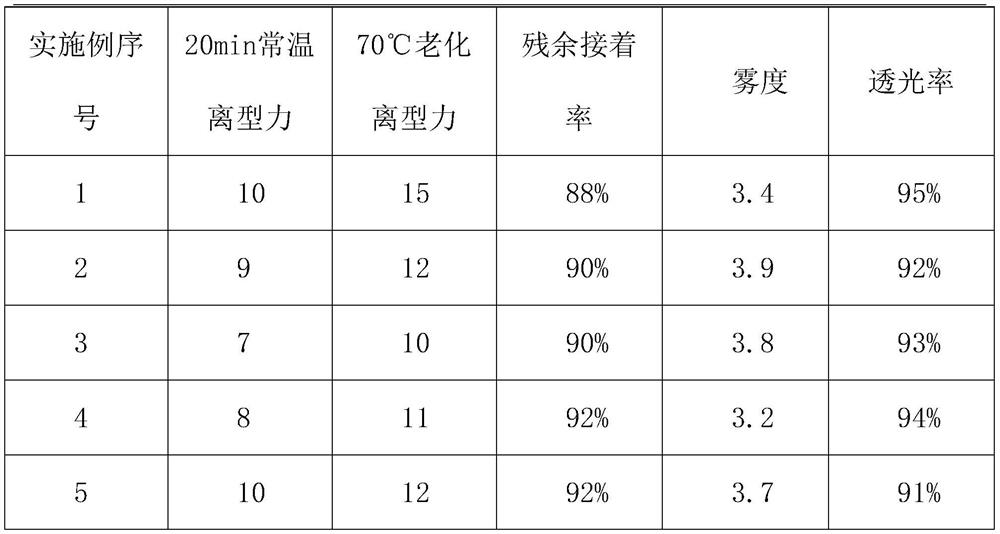

Release film special for MLCC and preparation method

The invention provides a special release film for an MLCC, which is specifically composed of the following components: 100 parts of vinyl-terminated organic silicon resin, 1-10 parts of methyl hydrogen silicone oil, 0.3-3 parts of fluorine-containing polysiloxane, 1-5 parts of anchoring agent, 1-5 parts of catalyst and 500-1000 parts of solvent. Compared with a common release film, the special release film for the MLCC is stable in release force and has the characteristics of excellent aging resistance, high light transmittance, low haze and the like; the residual adhesion rate is greater than 85%, the functionality is stronger during use, and the practical effect is improved.

Owner:苏州市星辰科技有限公司

Fluorine release coating and preparation method thereof

InactiveCN113185872AStable release forceAdjustable release forceCoatingsPolymer sciencePtru catalyst

The invention discloses a fluorine release coating and a preparation method thereof, and relates to the technical field of release liners.The fluorine release coating is obtained by mixing a main adhesive A and a main adhesive B according to the weight ratio of (1-10): 1; the main adhesive A is prepared from the following raw materials in percentage by weight: 5 to 10 percent of fluorine release agent I, 0.1 to 0.5 percent of cross-linking agent, 0.01 to 0.05 percent of catalyst I and the balance of organic solvent; and the main adhesive B is prepared from the following raw materials in percentage by weight: 25 to 40 percent of fluorine release agent II, 0.1 to 0.4 percent of catalyst II and the balance of fluorine-containing solvent. The invention provides a double-component formula, the main adhesive B with low release force is obtained by selecting the fluorine release agent and the solvent in the main adhesive B, the main adhesive B is added to fill the microcosmic flatness problem formed by the main adhesive A, and the compounded fluorine release coating is stable in release force and adjustable in release force.

Owner:TAIHU JINZHANG TECH CO LTD

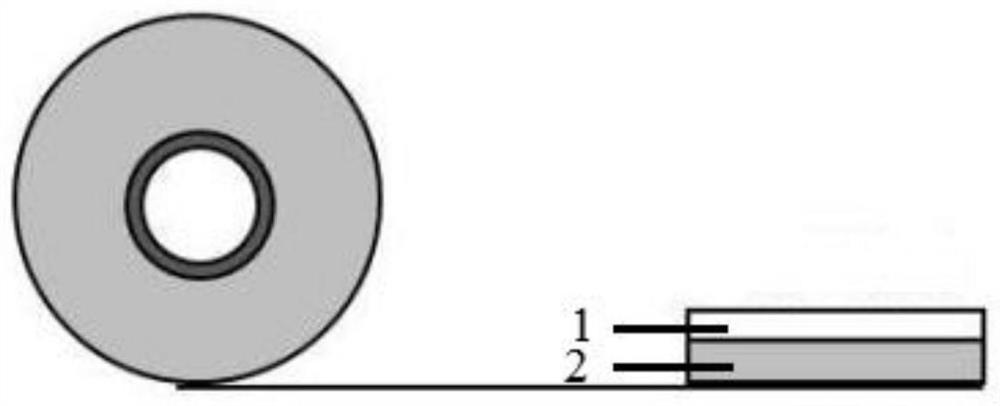

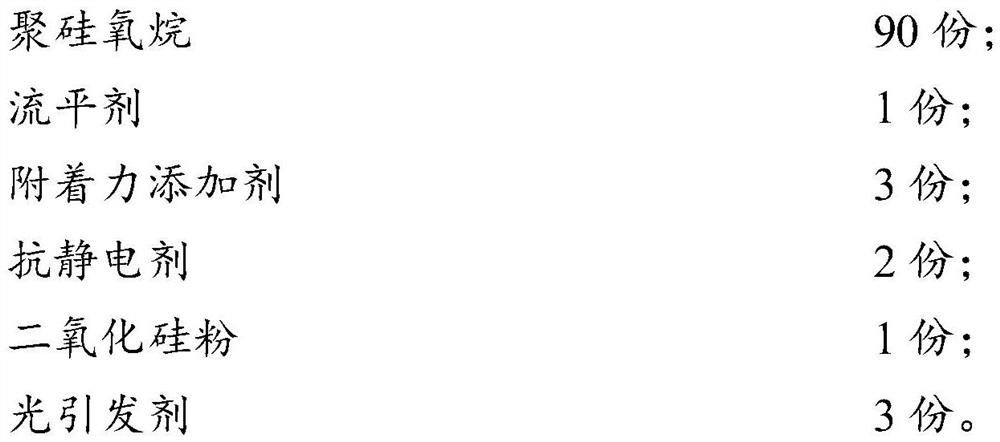

Ultralight release force free radical photocuring release film and preparation method thereof

ActiveCN111621156AStable chemical and physical propertiesStable release forceFilm/foil adhesive release linersPolymer scienceFumed silica

The invention belongs to the technical field of release films, and provides an ultralight release force free radical photocuring release film which comprises the following components in parts by weight: 40-140 parts of polysiloxane, 0.8-1.5 parts of a leveling agent, 0-5 parts of an adhesion additive, 1-5 parts of an antistatic agent, 1-2 parts of fumed silica powder and 3-4 parts of a photoinitiator. The invention also provides a preparation method of the ultralight release force free radical photocuring release film. The release film disclosed by the invention is stable in chemical and physical properties, stable in release force and anti-static capability, good in adhesive force and less in silicon transfer; 20-minute release force and aging release force of the release film can be stably and accurately controlled to be 1-2.5 cN / 2.5 cm, and 24-hour residual adhesive force is larger than 85%. The process is simple, one-time operation is completed, the production efficiency is high, the cost is low, and few waste materials are generated in production.

Owner:苏州鸿科新材料科技有限公司

Antistatic coating, antistatic release film with high adhesion and stability and preparation method of antistatic release film

PendingCN113604088AImprove antistatic performanceSolve the problem of poor anti-static effectCellulose coatingsElectrically-conductive paintsPolymer scienceEthyl acetate

The invention discloses an antistatic coating, an antistatic release film with high adhesion and stability and a preparation method of the antistatic release film. The antistatic coating is an aqueous dispersion liquid or an ethyl acetate dispersion liquid containing an antistatic material; the antistatic coating is used as an external additive or an internal additive, the prepared antistatic release film has a lasting antistatic effect, the surface resistance can reach 103 omega / sq, the adhesion is high, the release force is stable, the transparency is good, and the problems of pollution, stripping failure and the like caused by static electricity when the release film is separated from an adhesive can be reduced.

Owner:SICHUAN UNIV

Release film with anti-counterfeiting marks

The invention discloses a release film with anti-counterfeiting marks. The release film is characterized by comprising a base film layer, a middle layer and a release layer, the middle layer is an anti-counterfeiting mark layer, the release layer is formed by coating a release agent, and the release agent is prepared from, by mass, 2-5 parts of polyethylene wax particles, 18-35 parts of vinyl silicone resin, 12-25 parts of melamine resin, 3-7 parts of nanometer titania, 2-4 parts of sodium polyacrylate, 1-3 parts of coupling agent, 1.5-3 parts of flatting agent and 12-28 parts of solvent. All the components of the release film are matched with one another, so the release layer can be evenly coated on the base film layer, the middle layer is the anti-counterfeiting mark layer and has an anti-counterfeiting effect, and counterfeiting of illegal merchants is avoided; polyethylene wax particles are contained, so the release film shows light and stable release force and has good scratch-resistant performance.

Owner:苏州睿利斯电子材料科技有限公司

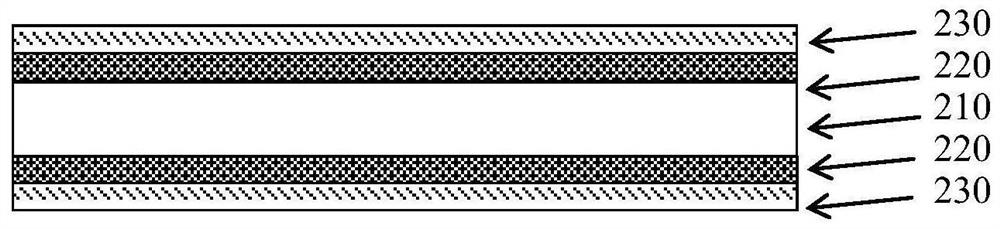

Fluorine-containing paint and preparation method thereof, and fluorine release film based on coating by fluorine-containing paint

InactiveCN108299923AImprove responseMild conditionsFireproof paintsSynthetic resin layered productsThermal insulationFluorine containing

The invention discloses a fluorine-containing paint and a preparation method thereof, and a fluorine release film based on coating by the fluorine-containing paint. The fluorine-containing paint usesa basic paint as a main body, and then fluorine-containing epoxy resin and diethanol amine are added; a reaction is carried out under the conditions of a pH value of 8 to 9 and a temperature of 40 to50 DEG C for 5 to 6 h so as to obtain the fluorine-containing paint; and reaction process is simple, reaction conditions are mild, and the reaction can be easily implemented. The fluorine release filmuses the fluorine-containing paint as a release layer; an adhesive layer, a first middle layer and a second middle layer are arranged between a base layer and the release layer; and the outer side ofthe base layer is provided with a thermal insulation layer. Through interaction among the above six structures, the fluorine release film has stable release force and resistance to high temperature and ageing, and does not produce chips and burrs during die cutting.

Owner:KUNSHAN QIAO WEI NEW MATERIAL

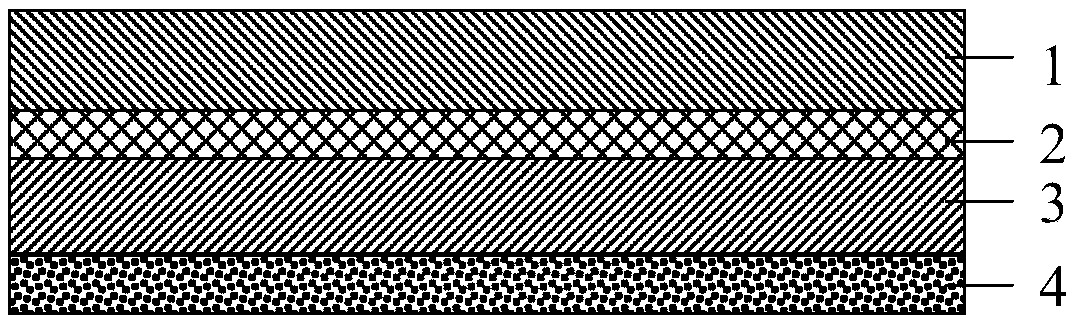

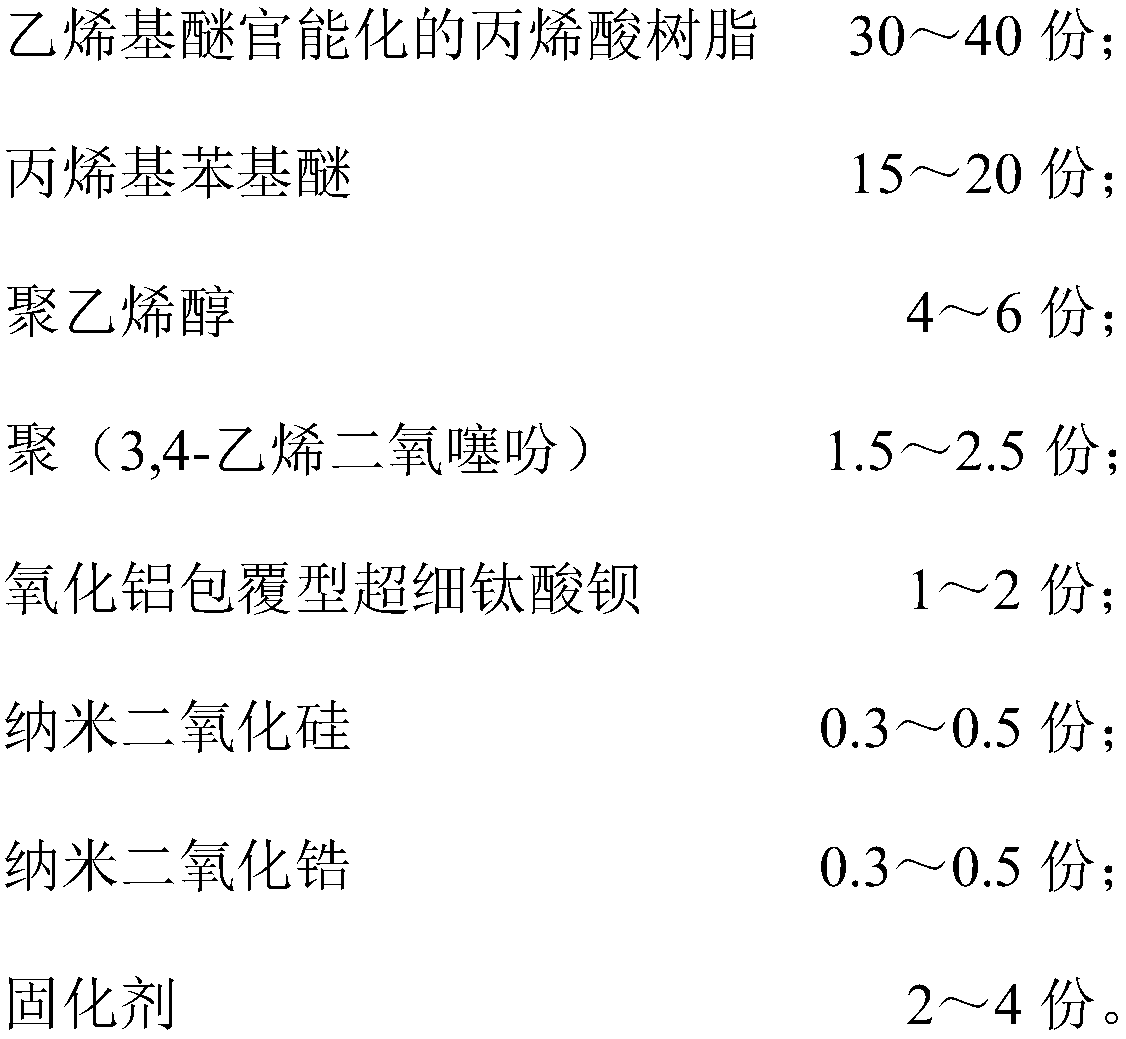

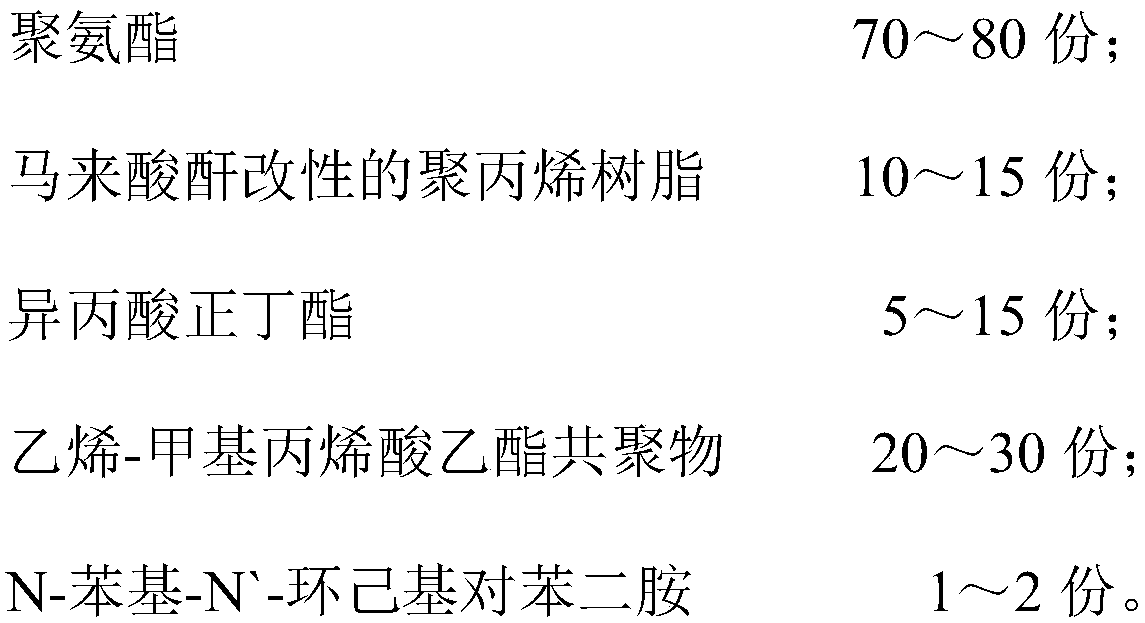

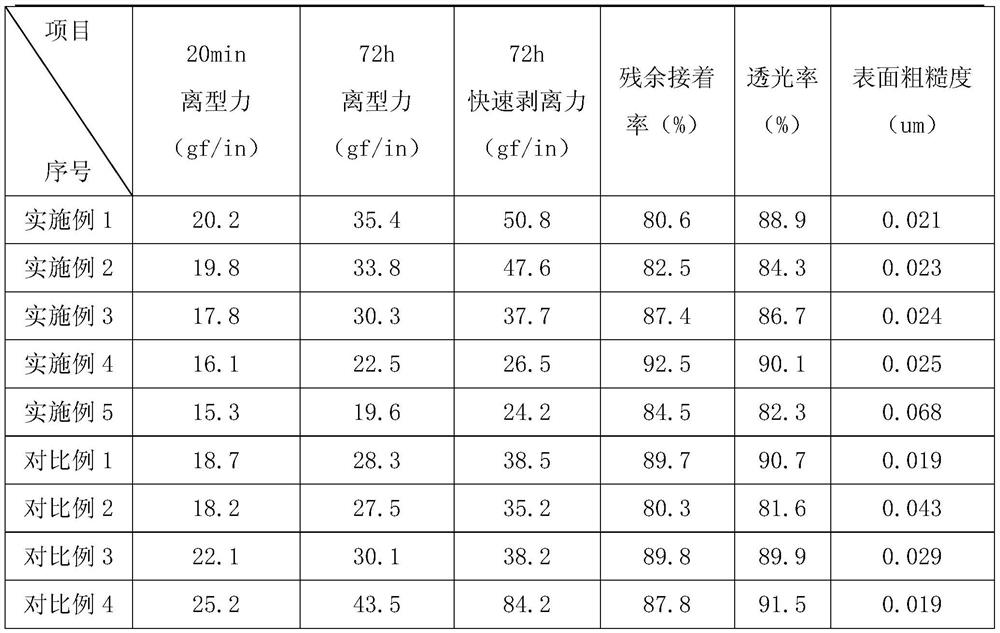

Release film for circuit board

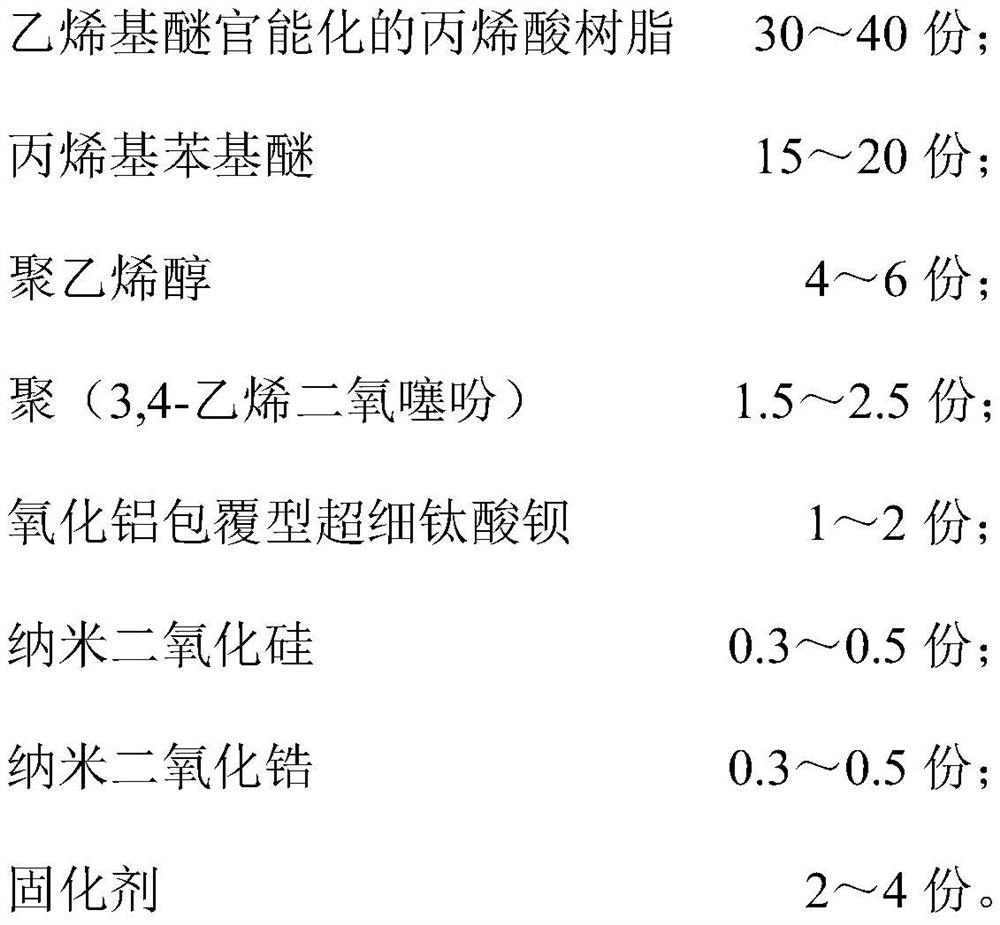

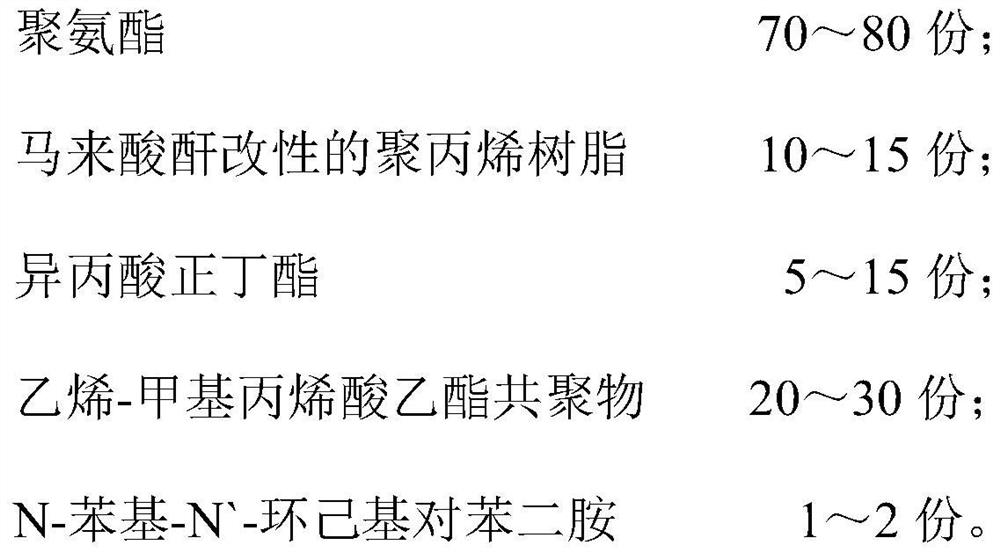

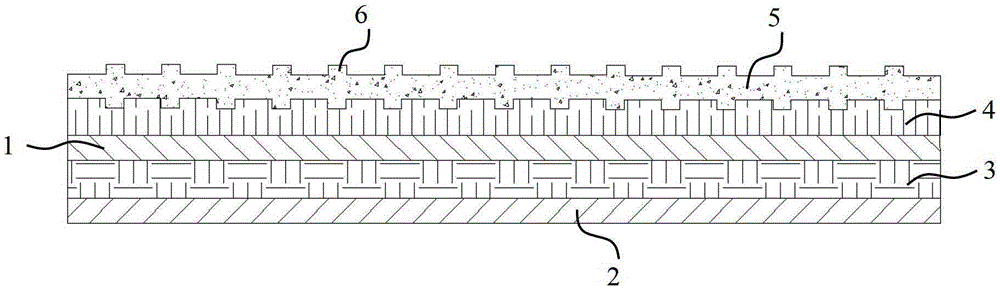

ActiveCN109435390AStable hot meltImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPolyvinyl alcohol

The invention belongs to the technical field of electronic materials, and particularly relates to a release film for a circuit board. The release film comprises a supporting layer, an adhesive layer,an aluminum foil layer and a release heat sealing layer. The release heat sealing layer comprises vinyl functionalized acrylic resin, allyl phenyl ether, polyvinyl alcohol, poly(3, 4-ethylene dioxythiophene), alumina coated superfine barium titanium, nano silicon dioxide, nano zirconium dioxide and curing agent. The release film has stable hot melting performance within a wide temperature range, thereby having high sealability with the circuit board; adhesion strength of the release heat sealing layer to the aluminum foil layer is higher than that of the same to the circuit board, so that stripping of the release heat sealing layer from the circuit board is facilitated, the release heat sealing layer cannot be transferred onto a circuit board material when being torn off, and appearance uniformity of the circuit board is ensured.

Owner:浙江海顺新材料有限公司 +1

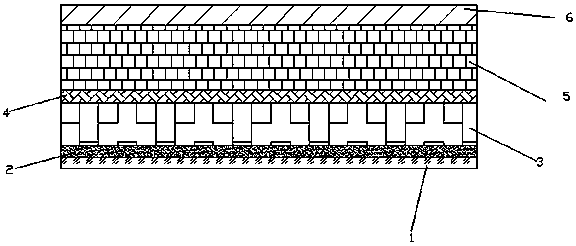

Antistatic optical release film for polaroid and preparation method of antistatic optical release film

PendingCN113308007AStable release forceQuick Peel LowElectrically-conductive paintsPtru catalystDimethyl siloxane

The invention discloses an antistatic optical release film for a polaroid. The antistatic optical release film comprises a release layer, a base material layer and an antistatic layer from top to bottom, and the release layer comprises the following components in parts by weight: 20-40 parts of vinyl polydimethylsiloxane, 3-8 parts of hydrogen-containing polysiloxane, 0.5-1.5 parts of an anchoring agent, 0.05-0.2 part of chemically modified inorganic particles, 3-8 parts of fluorine modified organic silicon resin, 2-4 parts of a platinum catalyst and 130 parts of an organic solvent. The release film has the characteristics of stable release force, low quick release force, antistatic property, high light transmittance, high residual adhesion rate and the like, is mainly used for protecting and transporting pressure-sensitive adhesive layers of polaroid products, does not generate static electricity to adsorb dust in polaroid transportation and downstream production, does not generate bad bubbles in use, and the release film cannot be quickly stripped in the downstream manufacturing process to cause poor stripping and influence the yield.

Owner:浙江日久新材料科技有限公司

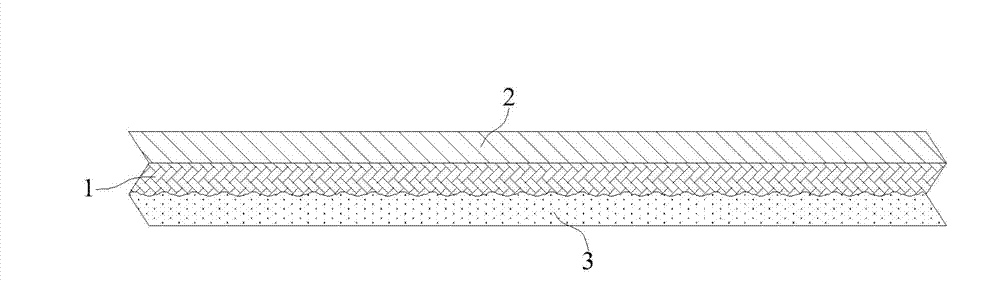

Release film with small release force

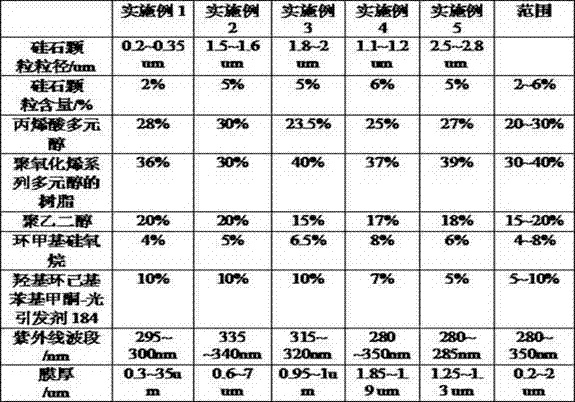

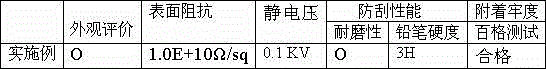

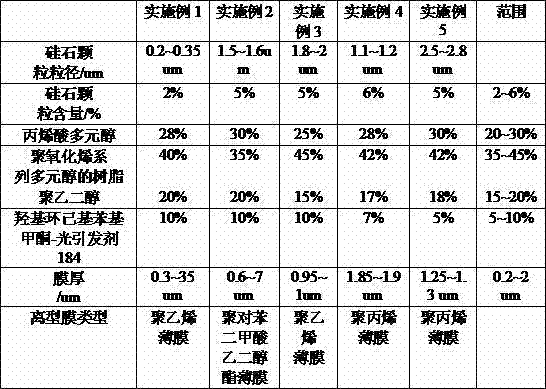

InactiveCN104788637AImprove surface antistatic performanceLow wear resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsBinding forcePhenyl ketone

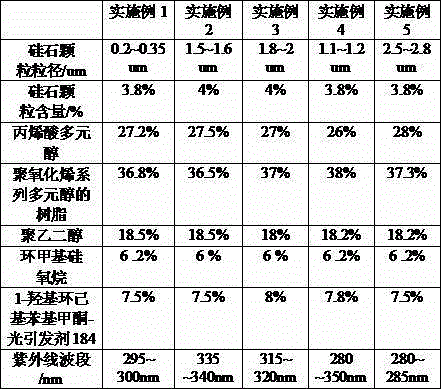

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Matte release agent used for mold release material

ActiveCN103046432AImprove surface antistatic performanceImprove anti-static performanceCoatingsCoatings without pigmentsSilica particlePolyol

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:太仓斯迪克新材料科技有限公司

Anti-scratch matte anti-static release paper

ActiveCN103074819BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionSynthetic resin layered productsSilica particlePolyol

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

Release film for circuit board

ActiveCN109435390BStable hot meltImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPolyvinyl alcohol

The invention belongs to the technical field of electronic materials, and particularly relates to a release film for a circuit board. The release film comprises a supporting layer, an adhesive layer,an aluminum foil layer and a release heat sealing layer. The release heat sealing layer comprises vinyl functionalized acrylic resin, allyl phenyl ether, polyvinyl alcohol, poly(3, 4-ethylene dioxythiophene), alumina coated superfine barium titanium, nano silicon dioxide, nano zirconium dioxide and curing agent. The release film has stable hot melting performance within a wide temperature range, thereby having high sealability with the circuit board; adhesion strength of the release heat sealing layer to the aluminum foil layer is higher than that of the same to the circuit board, so that stripping of the release heat sealing layer from the circuit board is facilitated, the release heat sealing layer cannot be transferred onto a circuit board material when being torn off, and appearance uniformity of the circuit board is ensured.

Owner:浙江海顺新材料有限公司 +1

Matte antistatic agent for release film

ActiveCN103103875BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionRelease paperPolyethylene glycolEngineering

Owner:斯迪克新型材料(江苏)有限公司

Anti-static matte release agent

InactiveCN104790252AImprove surface antistatic performanceLow wear resistanceCoatingsCoatings without pigmentsPeak valueBinding force

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Matte release agent for release materials

ActiveCN103046432BImprove surface antistatic performanceImprove anti-static performanceCoatingsCoatings without pigmentsSilica particlePolyol

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:TAICANG SIDIKE NEW MATERIALS SCI & TECH CO LTD

Manufacturing method and system of radio frequency self-adhesive label

ActiveCN101877072BAvoid scratchesPrevent oxidationSemiconductor/solid-state device manufacturingRecord carriers used with machinesEngineeringSilicone oil

The invention relates to a manufacturing method and a system of a radio frequency self-adhesive label, and the manufacturing method of the radio frequency self-adhesive label comprises the following steps: a) using conductive ink to print an antenna on an inner layer of a surface material film of a thin film; b) mounting a chip; c) testing an electronic device; d) coating silicone oil on the surface of a release material substrate; e) curing a silicone oil release layer; f) coating hot melt adhesive on the silicone oil release layer; g) curing the hot melt adhesive; h) compounding the tested electronic device layer with the release layer coated with the adhesive; i) carrying out die cutting and waste discharge; and j) taking up and obtaining a finished product which can be stuck automatically or manually. The manufacturing method of the radio frequency self-adhesive label can meet the technical requirements of the market on the radio frequency self-adhesive label, has significant advantages in the aspects of manufacturing efficiency, product yield, durability and economy, and can solve the shortcomings of the existing process, and the popularization of the manufacturing method of the radio frequency self-adhesive label is conductive to the wide applications of the radio frequency technology.

Owner:浙江龙游道明光学有限公司

A kind of manufacturing process of fluorine release film

ActiveCN104057669BUniform coatingThe deployment steps are rigorousSynthetic resin layered productsHigh humidityAging resistance

The invention discloses a manufacturing process of a fluorine element release film, which comprises the following steps: 1) preparing a coating, that is, mixing a fluorine element coating main agent with a n-heptane solvent according to a ratio of 1:6-1:8, adding a bridging agent and an anchoring agent, then adding a catalyst and stirring; 2) preparing the fluorine element release film, that is, coating the above coating on a PET raw film in a precise coating manner, performing an curing reaction in an oven, then cooling and rolling to obtain the finished product. The PET film used in the invention is strict in material selection criterion; the selected main material is available on the market; the blending and preparation steps of the coating solution are strict; a precise coating mode is adopted to allow the coating of the whole film to be quite uniform; after curing and drying, the release force of the product is very stable; the product is good in aging resistance, is very suitable for all organic silica gel protection adhesive tapes, and can be used in high-temperature high-humidity environment with good isolation effect.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

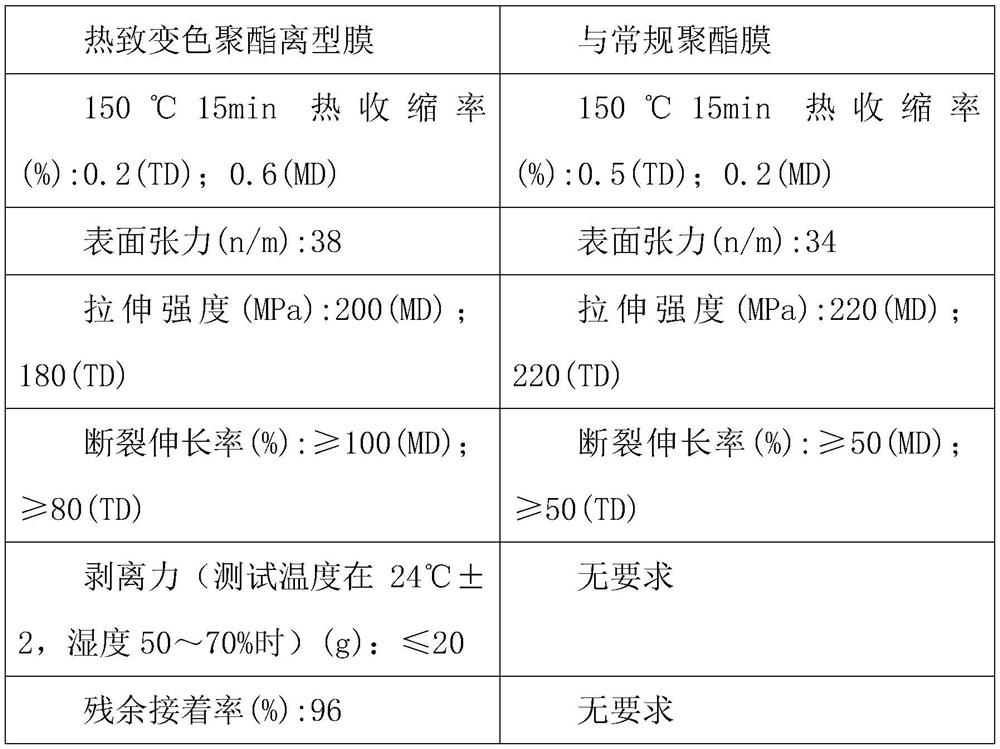

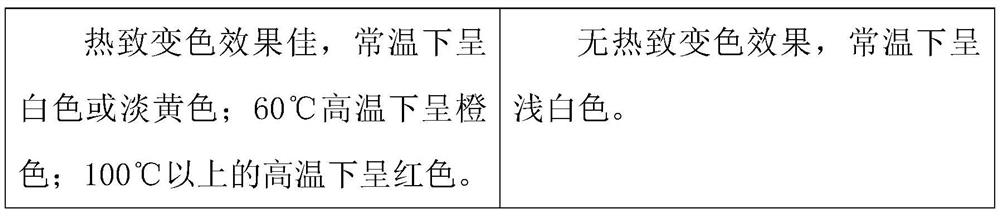

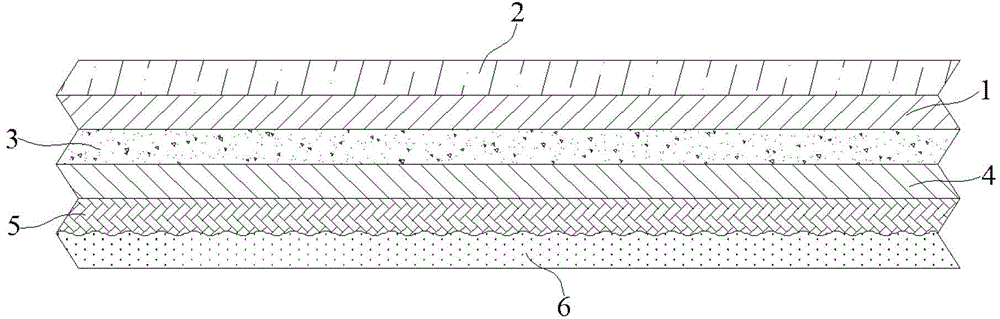

Thermochromic polyester release film and preparation method thereof

PendingCN113861473AImprove heat resistanceGood anti-aging performanceCoatingsPolymer sciencePolyester resin

The invention relates to a thermochromic polyester release film. The thermochromic polyester release film comprises a polyester base film and a release coating which coats the surface of one side of the polyester base film; the polyester base film is composed of anti-aging polyester resin, antistatic polyester resin and thermochromic polyester resin, the weight percentage of each component is as follows: 80-90% of anti-aging polyester resin, 5-10% of antistatic polyester resin and 5-10% of thermochromic polyester resin; the polyester base film is of a single-layer structure and is prepared through melt extrusion and two-way stretching, and the thickness of the polyester base film is 50-200 microns; and the release coating is formed by coating release coating liquid and carrying out baking and curing treatment, and the thickness of the release coating is 2-8 microns. The thermochromic polyester release film provided by the invention is prepared by the processes of preparation of the release coating liquid and the base film, single-layer extrusion, coating curing and the like, not only has better heat resistance, antistatic property, aging resistance and migration resistance, but also can develop and change color at normal temperature and high temperature.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

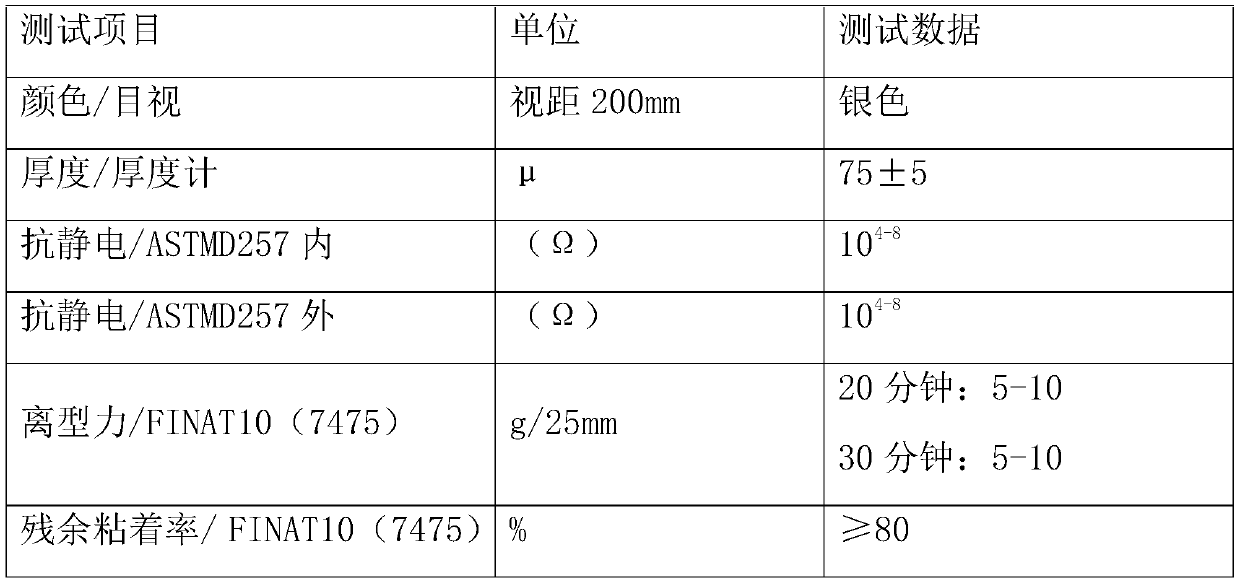

Extremely-high-conductivity release film and preparation method thereof

InactiveCN111205787AImprove cleanlinessHigh residual adhesionElectrically-conductive paintsFilm/foil adhesive release linersCyclohexanonePolymer science

The invention discloses a release film with extremely high conductivity. The formula of the release agent comprises the following components in parts by weight: 45-54 parts of silicone oil A, 46-52 parts of silicone oil B, 2-3 parts of a bridging agent, 2-3.5 parts of an adhesion promoter, 1.5-2.8 parts of a catalyst, 130-150 parts of n-heptane, 90-110 parts of D30, 45-52 parts of isopropanol and58-65 parts of cyclohexanone. The base material of the release film is subjected to a sputtering treatment; the release film is suitable for releasing and die cutting punching of various adhesive materials, is generally suitable for adhesion processing of protective films, double faced adhesive tapes and other adhesive materials, and has the advantages of high cleanliness, stable release force, high residual adhesion rate, favorable surface flatness, favorable machining property and extremely low surface resistance.

Owner:佛山市佳世达薄膜科技有限公司

Preparation method of novel matte anti-static release paper

ActiveCN103061207BImprove surface antistatic performanceLow wear resistanceSpecial paperPaper coatingUltravioletPolyethylene glycol

The invention discloses a preparation method of novel matte anti-static release paper. One surface of release paper body paper is coated with a coating layer through a coating machine, and one surface of a thin film layer is coated with a matte anti-static coating with a thickness of 0.2-2 micrometres. Under the influence of the used ultraviolet rays which are of a wave band of 280-350nm and of an illumination of 1200mW / cm<2>, components, contained in the matte anti-static coating, including 2-6% of silica particles, 20-30% of acrylic polyol with the average molecular weight of 500-2000, 35-45% of resin of polyoxyalkylene polyols with the average molecular weight of 200-2500, 15-20% of polyethylene glycol and 5-10% of 1-1-hydroxy-cyclohexyl phenyl ketone-photoinitiator 184 react to obtain the matte anti-static coating. The thickness of the matte anti-static coating is 4-10 micrometres. The preparation method of the novel matte anti-static release paper not only solves the problems that the binding force between the coating layer and the release agent coating of the release paper is not strong and the release force between the coating layer and the release agent coating of the release paper is not stable, but also promotes the anti-static performance of the surface of the film, and meanwhile promotes the anti-scraping performance.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Foggy surface release material for high-reliability adhesive tape

InactiveCN108149518ALow wear resistanceImprove surface antistatic performanceSpecial paperNon-macromolecular organic additionElectrostatic coatingUltraviolet

The invention discloses a foggy surface release material for a high-reliability adhesive tape. The foggy surface release material is characterized by being used in release paper of the adhesive tape;the foggy surface release material consists of the following components in percentage by weight: 5 percent of silica particles, 27 percent of acrylic polyol with an average molecular weight of 500-2000, 39 percent of resin of polyoxylene series polyol with an average molecular weight of 200-2500, 18 percent of polyethylene glycol, 6 percent of cyclomethylsiloxane and 5 percent of 1-hydroxycyclohexylphenylketone photoinitiator 184; a foggy surface antistatic coating layer adopts an ultraviolet waveband of 280-350 nm, and the diameter of each of the silica particles is 2.5-2.8 micrometers. The foggy surface release material disclosed by the invention can eliminate influences caused by static electricity on the silicone oil coating instability, is stable in release peeling force and also avoids the generation of electrostatic sparks in the production process.

Owner:邓明

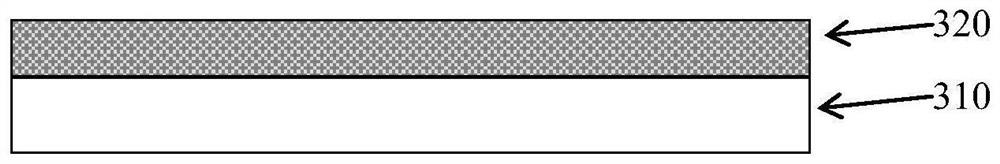

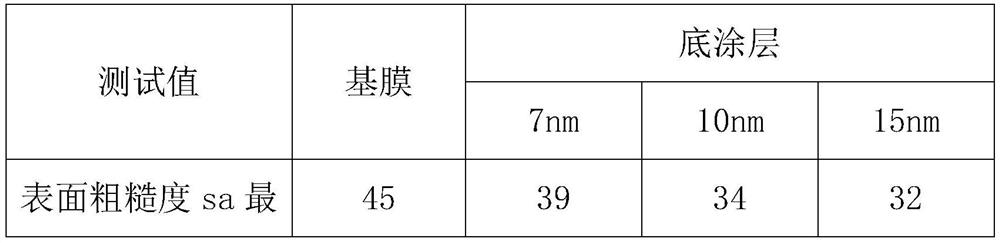

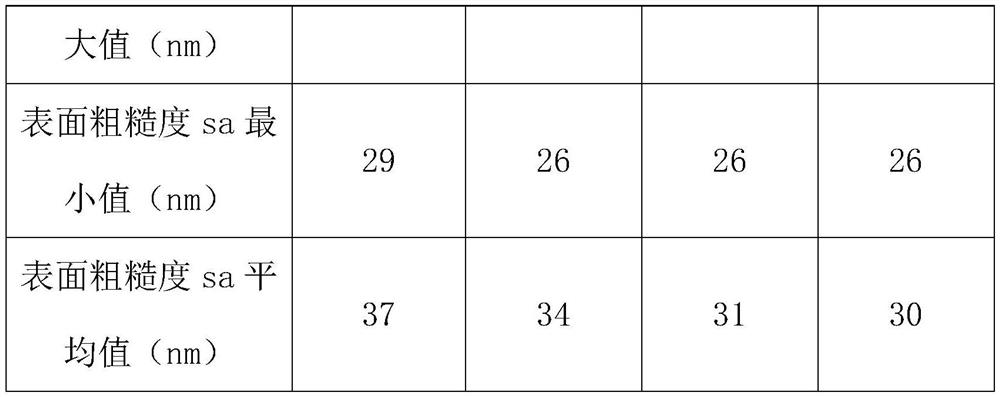

Bottom coating agent and film containing bottom coating layer

The invention discloses a primer. The primer comprises reactive silane and a solvent. The invention further discloses a thin film containing a primer layer. The thin film comprises a base film and the primer layer formed by curing the primer on the surface of the base film. A primer layer formed by the primer can improve the binding force between a film coating material and a film, so that the requirement of adhesiveness can be met without adding an anchoring agent in a silica gel and silicon release film formula, and the primer is simple in formula, suitable for various film coating materials such as a pressure-sensitive adhesive, silica gel and a silicon release agent and high in universality.

Owner:TAIHU JINZHANG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com