Stain-resistant release film with small release force

A release film, light release technology, applied in the direction of coating, etc., can solve the problems affecting the processing and use of the release film, the use and storage of the release film, and the poor pollution resistance of the release film. Stabilizes release force, increases three-dimensionality and gloss, and improves scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

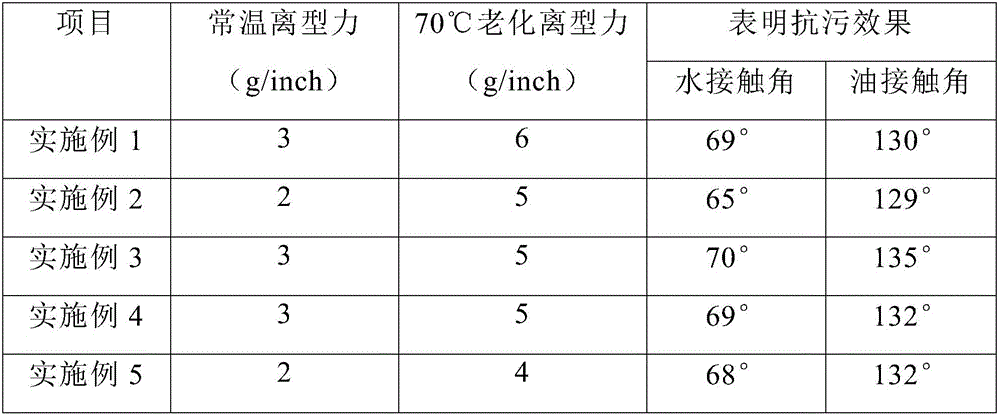

Examples

Embodiment 1

[0018] A light release force stain-resistant release film, comprising a base film layer, the base film layer is provided with a release layer, the release layer is coated with a release agent, and the release agent contains the following Each component of the stated mass parts: polyethylene wax particles: 6 parts; vinyl silicone resin: 18 parts; fluorine-containing polysiloxane: 5 parts; polyvinyl alcohol: 3 parts; pigment: 0.4 parts; antioxidant : 2 parts; coupling agent: 2.5 parts; defoamer: 0.5 parts; solvent: 16 parts.

[0019] Wherein, the material of the base film layer is PET, the particle diameter of the polyethylene wax particles is 2 μm, the antioxidant is di-tert-butylphenol, and the coupling agent is a silane coupling agent; the defoamer It is ethylene glycol distearate.

Embodiment 2

[0021] A light release force stain-resistant release film, comprising a base film layer, the base film layer is provided with a release layer, the release layer is coated with a release agent, and the release agent contains the following Each component of the stated mass parts: polyethylene wax particles: 5 parts; vinyl silicone resin: 23 parts; fluorine-containing polysiloxane: 7 parts; polyvinyl alcohol: 2 parts; pigment: 0.1 part; antioxidant : 2.5 parts; coupling agent: 3 parts; defoamer: 1.5 parts; solvent: 19 parts.

[0022] Wherein, the material of the base film layer is PMMA, the particle diameter of the polyethylene wax particles is 2 μm, the antioxidant is di-tert-butylphenol, the coupling agent is a silane coupling agent, and the defoaming agent It is polyoxypropylene polyoxyethylene glyceryl ether.

Embodiment 3

[0024] A light release force stain-resistant release film, comprising a base film layer, the base film layer is provided with a release layer, the release layer is coated with a release agent, and the release agent contains the following Each component of the stated weight percentage content: polyethylene wax particles: 7 parts; vinyl silicone resin: 31 parts; fluorine-containing polysiloxane: 10 parts; polyvinyl alcohol: 6 parts; pigment: 1.5 parts; Oxidizing agent: 2.5 parts; coupling agent: 3 parts; defoamer: 1.5 parts; solvent: 19 parts.

[0025] Wherein, the material of the base film layer is PMMA, the particle diameter of the polyethylene wax particles is 3 μm, the antioxidant is butyl hydroxyanisole, the coupling agent is a silane coupling agent, and the defoaming The agent is ethylene glycol distearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com