Thermochromic polyester release film and preparation method thereof

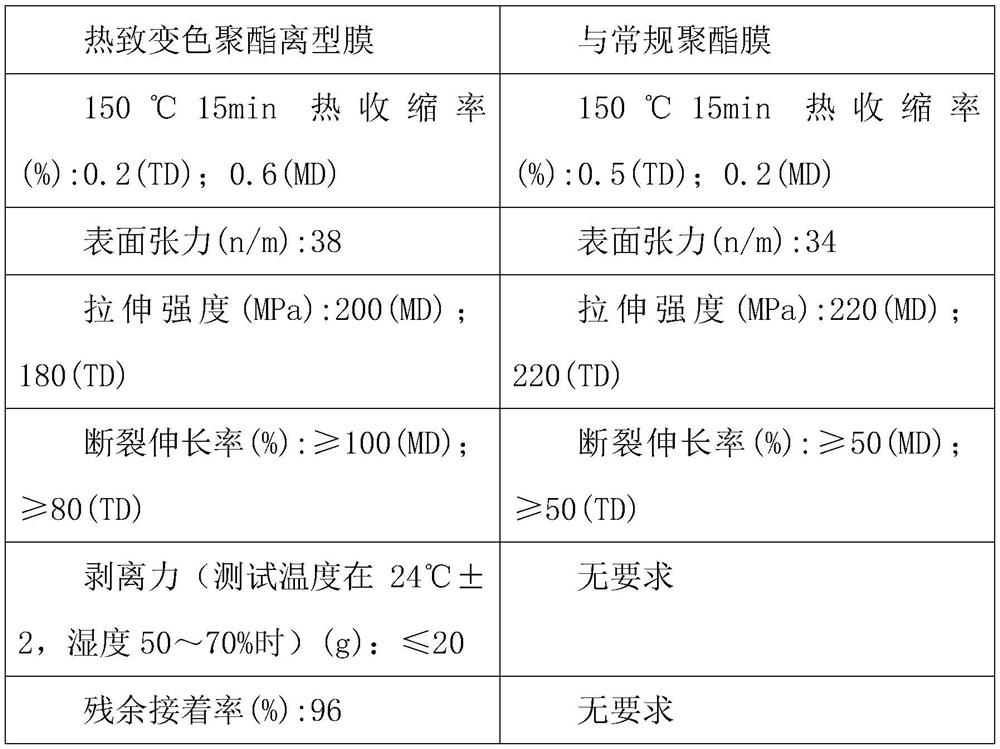

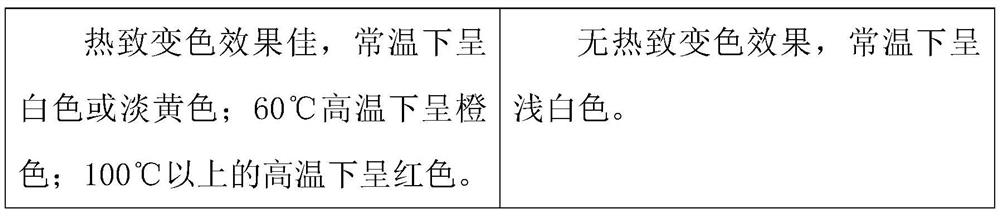

A thermochromic and release film technology, applied in the direction of coating, can solve the problems of irreversible color and unfavorable product application, and achieve the effect of good heat resistance, good camouflage and warning effect, and stable release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A thermochromic polyester release film, comprising a polyester base film and a release coating coated on one side of the polyester base film, the polyester base film is made of anti-aging polyester resin, antistatic polyester resin It is composed of thermochromic polyester resin, and the weight percentage of each component is: 80% of anti-aging polyester resin, 10% of antistatic polyester resin and 10% of thermochromic polyester resin.

[0025] The polyester base film has a single-layer structure, which is prepared by melt extrusion and biaxial stretching, and has a thickness of 40 microns.

[0026] The release coating is formed by coating the release coating liquid, and then baked and cured, with a thickness of 2 microns.

[0027] The release coating liquid is prepared by main agent, auxiliary agent and solvent, wherein the main agent is polyacrylate resin, octadecyltrimethoxysilane, fluorine-containing polymer, and the weight percentage accounts for about 20% of the r...

Embodiment 2

[0033]A thermochromic polyester release film, comprising a polyester base film and a release coating coated on one side of the polyester base film, the polyester base film is made of anti-aging polyester resin, antistatic polyester resin It is composed of thermochromic polyester resin, and the weight percentage of each component is: 85% of anti-aging polyester resin, 8% of antistatic polyester resin and 7% of thermochromic polyester resin.

[0034] The polyester base film has a single-layer structure, which is prepared by melt extrusion and biaxial stretching, and has a thickness of 60 microns.

[0035] The release coating is formed by coating the release coating solution, and then baked and cured, with a thickness of 5 microns.

[0036] The release coating liquid is prepared by main agent, auxiliary agent and solvent, wherein the main agent is polyacrylate resin, octadecyltrimethoxysilane, fluorine-containing polymer, and the weight percentage accounts for about 25% of the re...

Embodiment 3

[0042] A thermochromic polyester release film, comprising a polyester base film and a release coating coated on one side of the polyester base film, the polyester base film is made of anti-aging polyester resin, antistatic polyester resin It is composed of thermochromic polyester resin, and the weight percentage of each component is: 90% of antiaging polyester resin, 5% of antistatic polyester resin and 5% of thermochromic polyester resin.

[0043] The polyester base film has a single-layer structure, which is prepared by melt extrusion and biaxial stretching, and has a thickness of 100 microns.

[0044] The release coating is formed by coating the release coating solution, and then baked and cured, with a thickness of 10 microns.

[0045] The release coating liquid is prepared by main agent, auxiliary agent and solvent, wherein the main agent is polyacrylate resin, octadecyltrimethoxysilane, fluorine-containing polymer, and the weight percentage accounts for about 30% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com