Extremely-high-conductivity release film and preparation method thereof

A conductive, release film technology, used in conductive coatings, film/sheet release liners, film/sheet adhesives, etc., to solve the problem of high surface resistance and poor release stability of release films and other problems, to achieve the effect of stable release force, high residual adhesion rate and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of extremely high conductivity release film, the formula of release agent comprises each component of following parts by weight:

[0036] Silicone oil A 45 parts

[0037] Silicone oil B 46 parts

[0038] Bridge agent 2 parts

[0039] Adhesive 2 parts

[0040] Catalyst 1.5 parts

[0041] 130 parts of white electric oil

[0042] D30 90 copies

[0043] 45 parts of isopropanol

[0044] 58 parts of cyclohexanone.

[0045] The preparation method of the extremely high conductivity release film comprises the following steps:

[0046] S1. Coating soluble conductive polymer on the corona surface of 75μm silver aluminized PET film, the speed is 60m / min, the temperature T1 / T2 / T3 / T4 / T5 / T6 / T7=80 / 130 / 145 / 155 / 155 / 130 / 70;

[0047] S2. Coating soluble conductive polymer on the back of 75μm silver aluminized film PET, the speed is 60m / min, the temperature T1 / T2 / T3 / T4 / T5 / T6 / T7=80 / 130 / 145 / 155 / 155 / 130 / 70;

[0048] S3 is released on the soluble conductive polymer layer on ...

Embodiment 2

[0050] A kind of extremely high conductivity release film, the formula of release agent comprises each component of following parts by weight:

[0051] Silicone oil A 54 parts

[0052] Silicone oil B 52 parts

[0053] 3 parts bridging agent

[0054] Adhesive 3.5 parts

[0055] Catalyst 2.8 parts

[0056] 150 parts of white electric oil

[0057] D30 110 copies

[0058] 52 parts of isopropanol

[0059] 65 parts of cyclohexanone.

[0060] The preparation method of the extremely high conductivity release film comprises the following steps:

[0061] S1. Coating soluble conductive polymer on the corona surface of 75μm silver aluminized PET film, the speed is 60m / min, the temperature T1 / T2 / T3 / T4 / T5 / T6 / T7=80 / 130 / 145 / 155 / 155 / 130 / 70;

[0062] S2. Coating soluble conductive polymer on the back of 75μm silver aluminized film PET, the speed is 60m / min, the temperature T1 / T2 / T3 / T4 / T5 / T6 / T7=80 / 130 / 145 / 155 / 155 / 130 / 70;

[0063] S3 is released on the soluble conductive polymer laye...

Embodiment 3

[0066] A kind of extremely high conductivity release film, the formula of release agent comprises each component of following parts by weight:

[0067] Silicone oil A 50 parts

[0068] Silicone oil B 50 parts

[0069] 2.3 parts of bridging agent

[0070] Adhesive 2.4 parts

[0071] Catalyst 2.4 parts

[0072] 140 parts of white electric oil

[0073] D30 100 copies

[0074] 49 parts of isopropanol

[0075] 61 parts of cyclohexanone.

[0076] The preparation method of this embodiment is the same as embodiment 2.

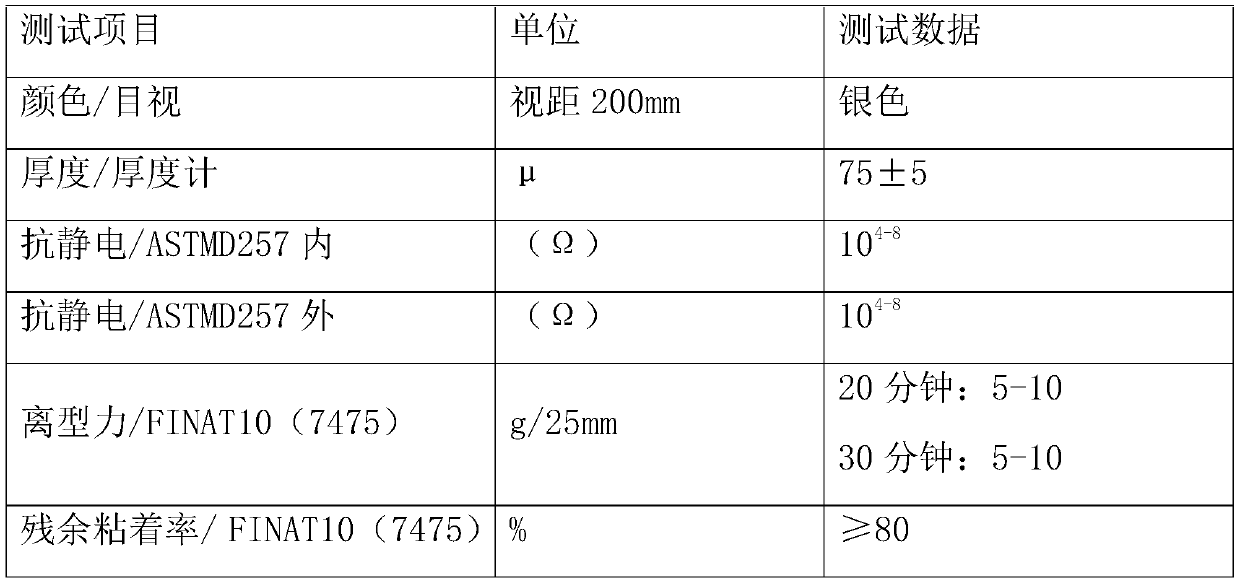

[0077] The test parameter of embodiment 3

[0078]

[0079] From the data in the above table, it can be seen that the highly conductive release film of the present invention has stable release force, high residual adhesion rate, good surface smoothness and mechanical processing, and extremely low surface resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com