Anti-scuffing matt-surface antistatic release paper

A technology of anti-static and release paper, applied in the direction of anti-sticking paper, papermaking, paper, etc., can solve the problems of unstable peeling force, low bonding force between the coating layer and the release agent coating, and improve the anti-static effect , Improve anti-static performance, improve the effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

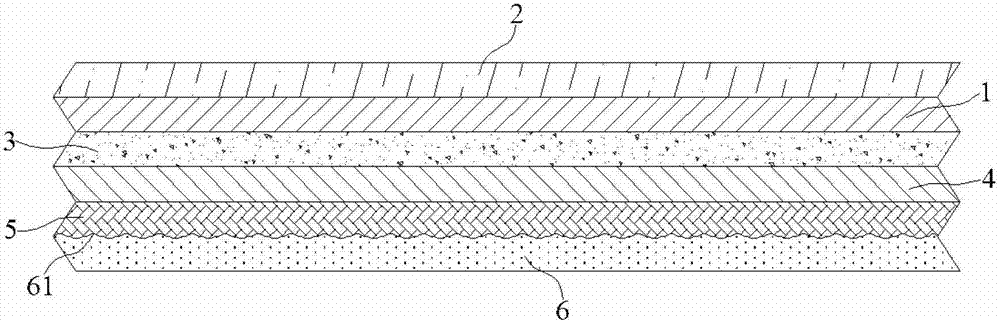

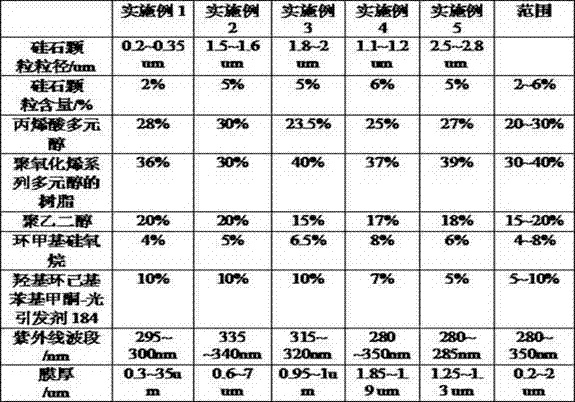

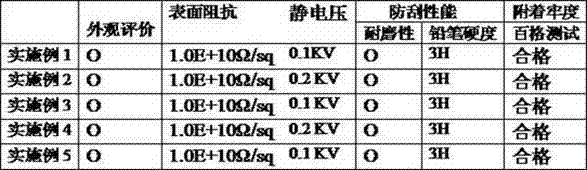

[0026] Embodiments 1 to 5: A kind of anti-scratch matte surface antistatic release paper, the anti-scratch matte surface antistatic release paper includes a release paper base paper 1 with a coating layer 2 on the surface, the release paper The other surface of the base paper 1 is coated with an adhesive layer 3, the other surface of the adhesive layer 3 is bonded with a film layer 4, and the other surface of the film layer 4 is coated with a layer of anti-fog layer with a thickness of 0.2-2 microns. An electrostatic coating 5, the other surface of the matte antistatic coating 5 is coated with a silicone oil layer 6; the surface of the matte antistatic coating 5 in contact with the silicone oil layer 6 has several concave and convex points 61;

[0027] The matte antistatic coating 5 is composed of the following components in mass percentage:

[0028] Silica particles 2~6%,

[0029] Acrylic polyols with an average molecular weight of 500~2000 20~30%,

[0030] Resin of polyoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com