Patents

Literature

282results about "Release paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

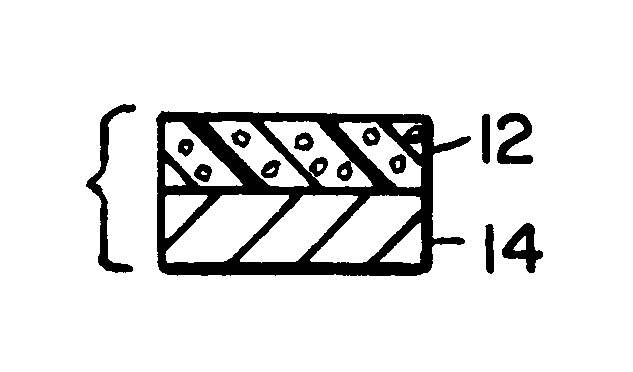

Release liners for pressure sensitive adhesive labels

InactiveUS6110552AReduce thicknessEasy transferCoatings with pigmentsSynthetic resin layered productsEngineeringFacial tissue

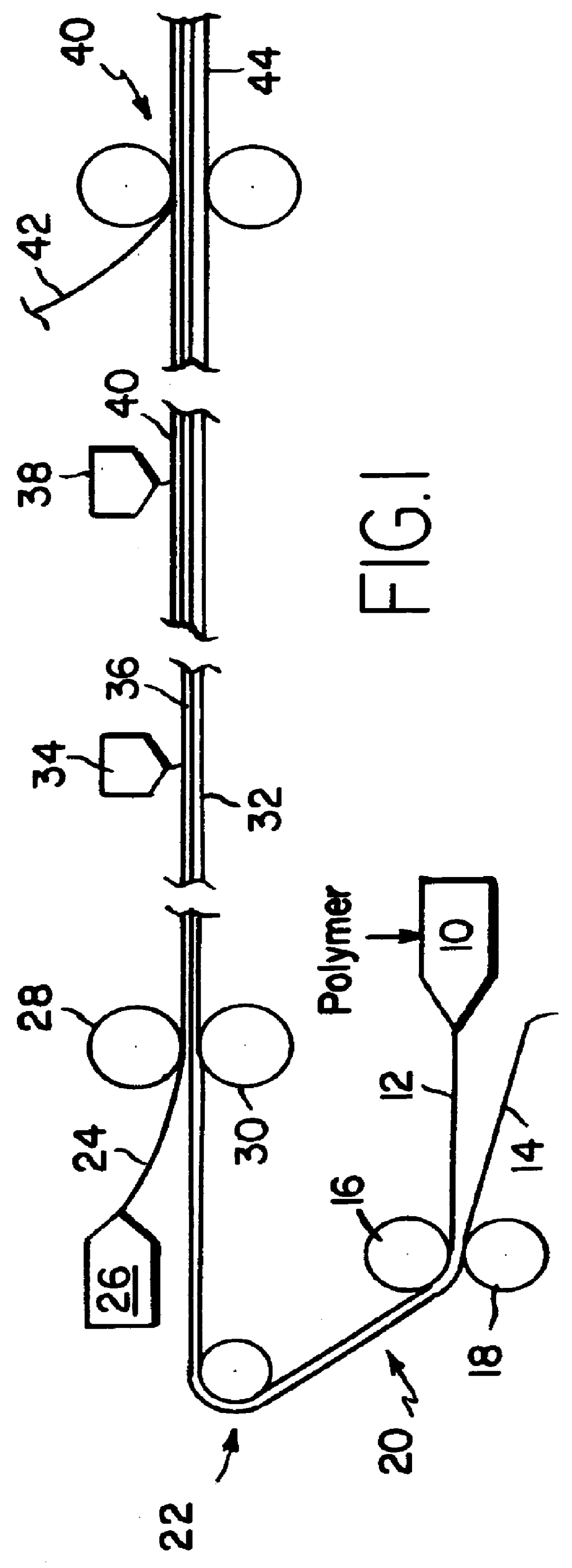

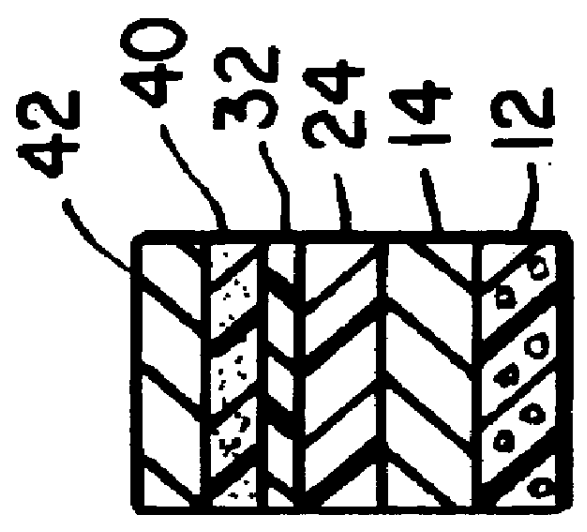

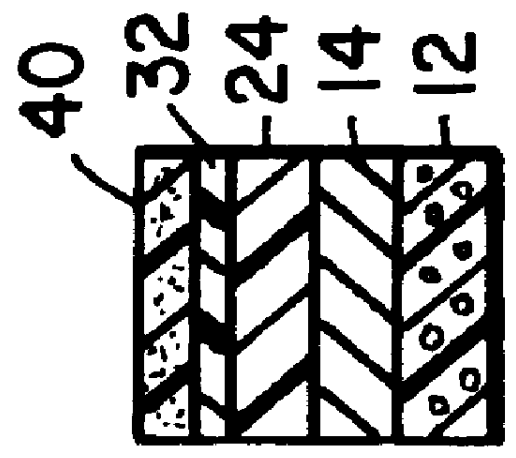

A release liner for use with face stocks for pressure sensitive labels, tapes, decals and other products formed from sheet and roll stock. A filled polymer is laminated to one side of a paper web. An extrudate is laminated to the other side of the paper substrate to form a release liner. The filled polymer has paper-like properties and replaces paper tissue back liners.

Owner:FLEXCON

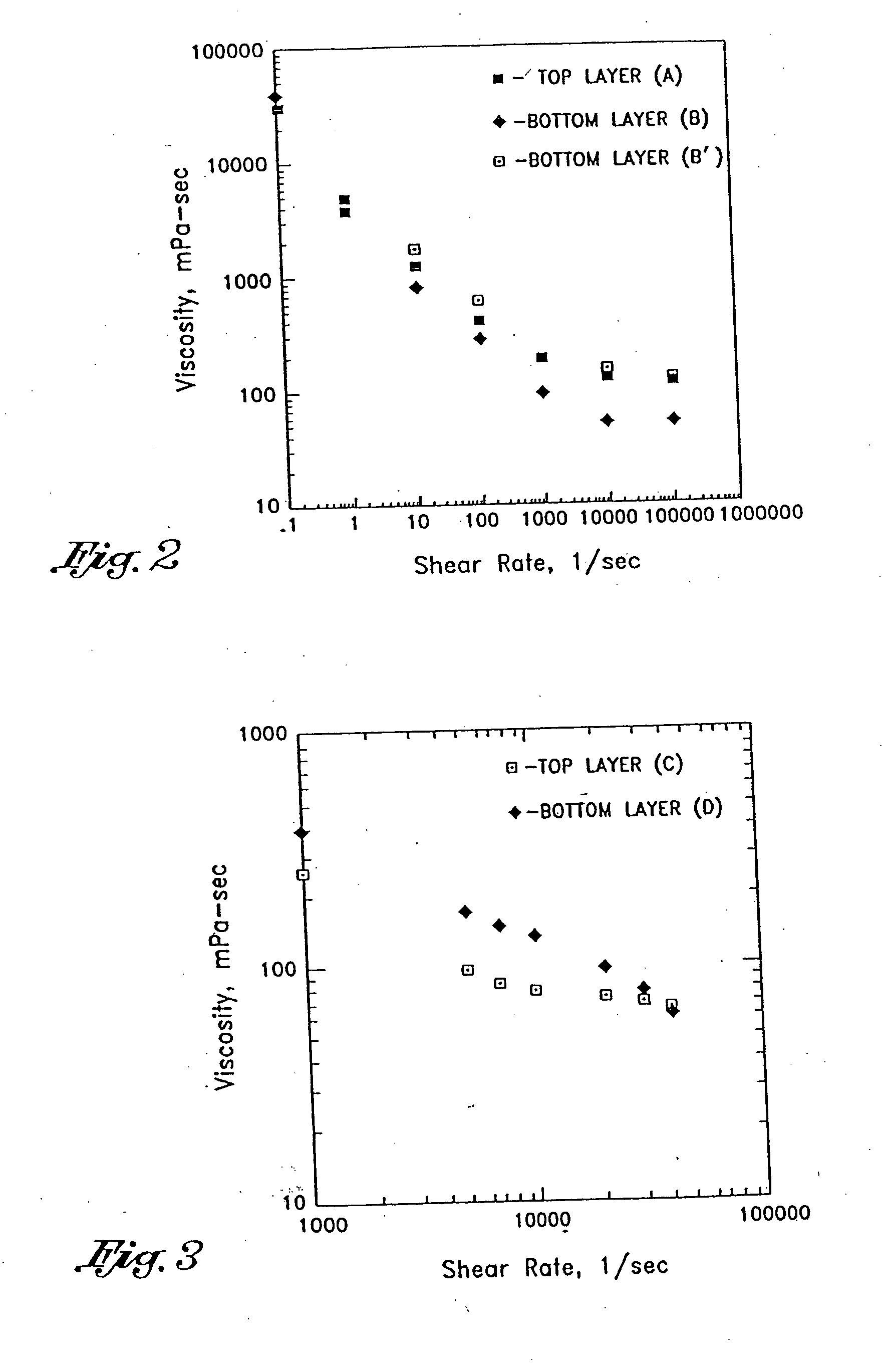

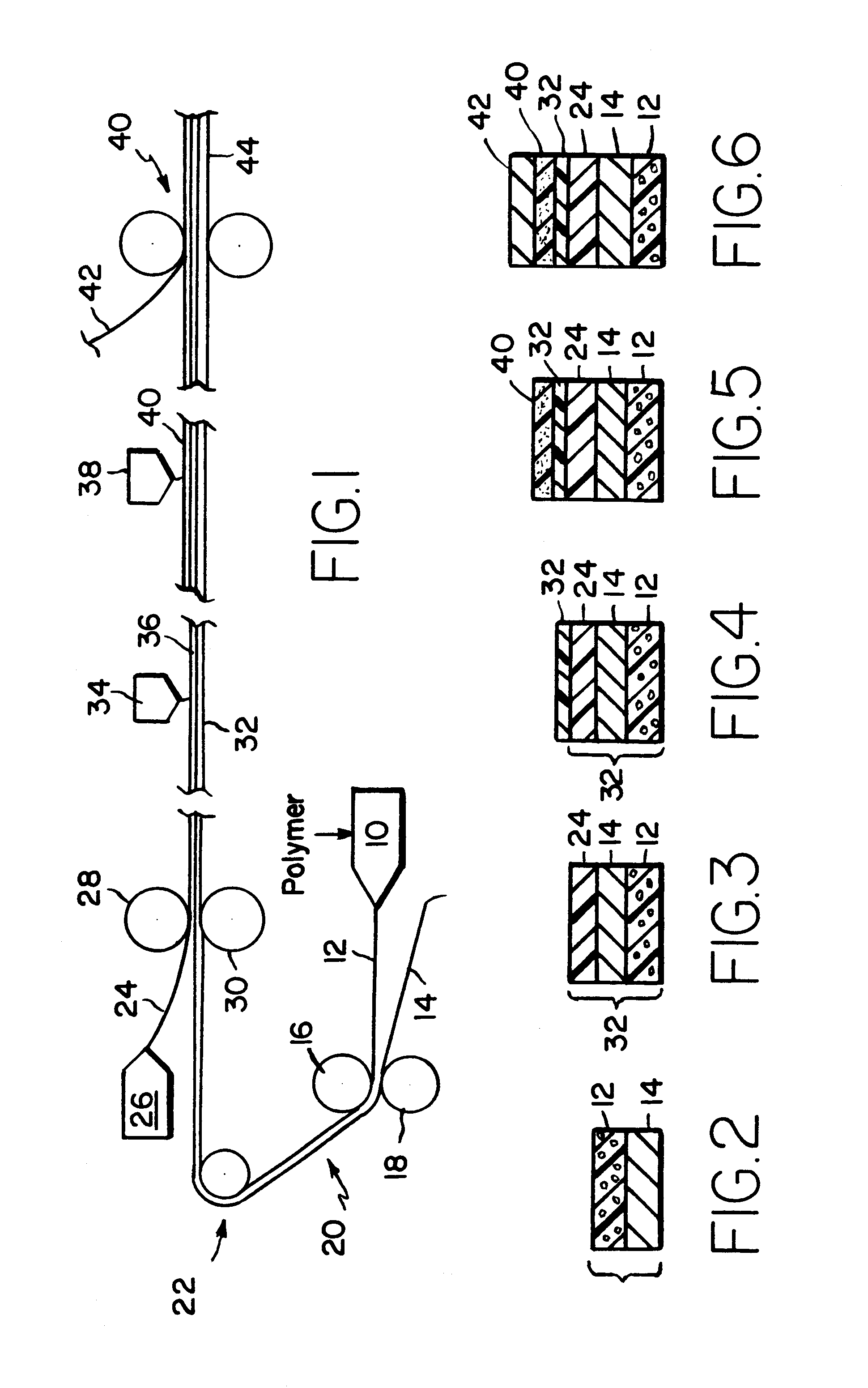

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050074549A1Easy to optimizeLow costFilm/foil adhesivesLayered productsBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

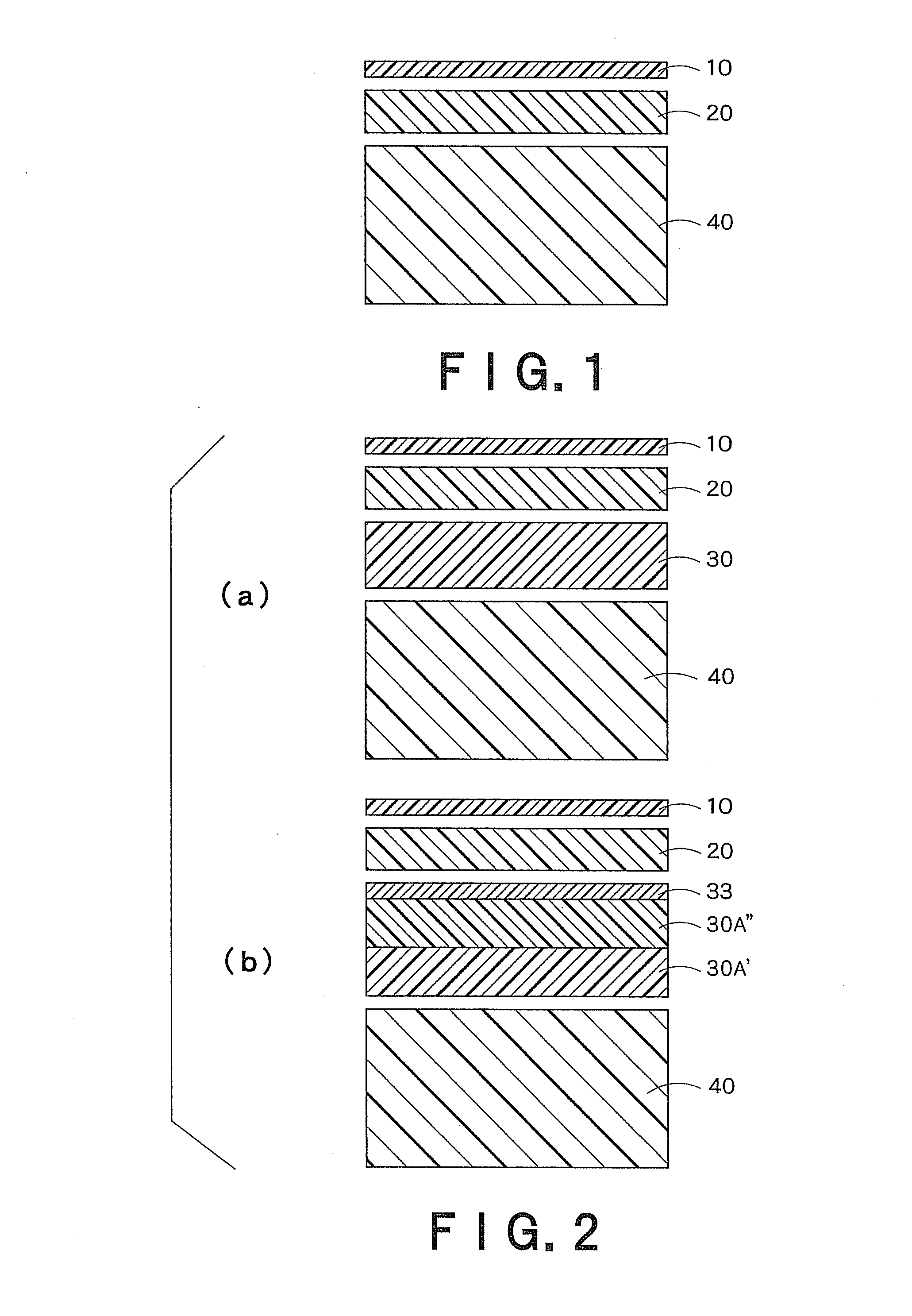

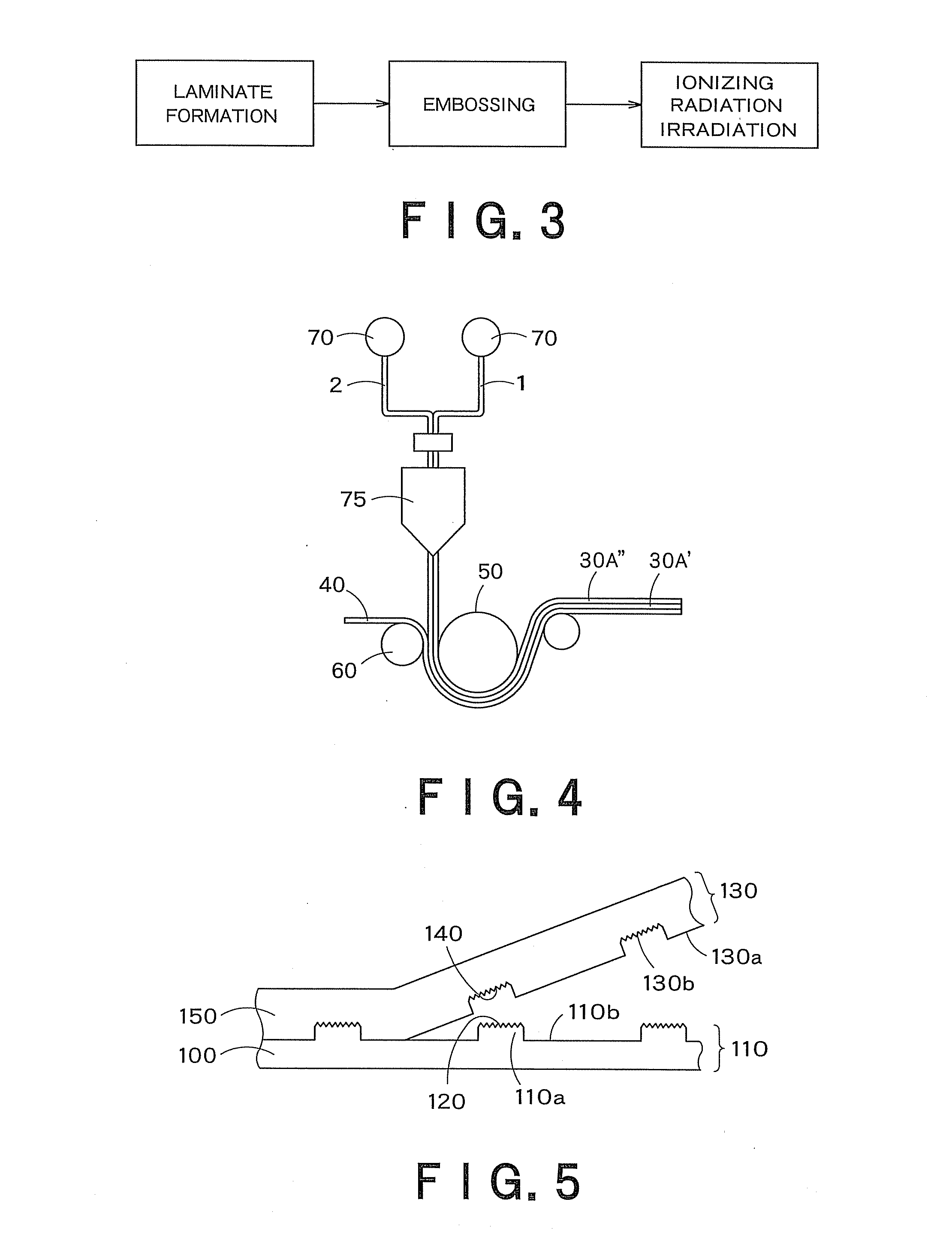

Embossed release paper for synthetic leather production and support therefor, and synthetic leather using the release paper and process for producing the synthetic leather

InactiveUS20070116929A1Excellent embossabilityExcellent releasabilityPaper coatingPaper/cardboardAdhesiveHeat resistance

This invention provides an embossed release paper for synthetic leather production, which has embossability, heat resistance and durability and, at the same time, has excellent separability from a two-pack curing type PU adhesive and can be used in all of synthetic leathers such as PU, PVC, and semisynthetic leathers, and a process for producing the same. The embossed release paper for synthetic leather production comprises at least paper as a support and an ionizing radiation cured film provided on the paper. The upper part of the cured film has been embossed. The ionizing radiation cured film has been formed by applying an ionizing radiation to a coating liquid having a specific composition to cure the coating liquid.

Owner:DAI NIPPON PRINTING CO LTD

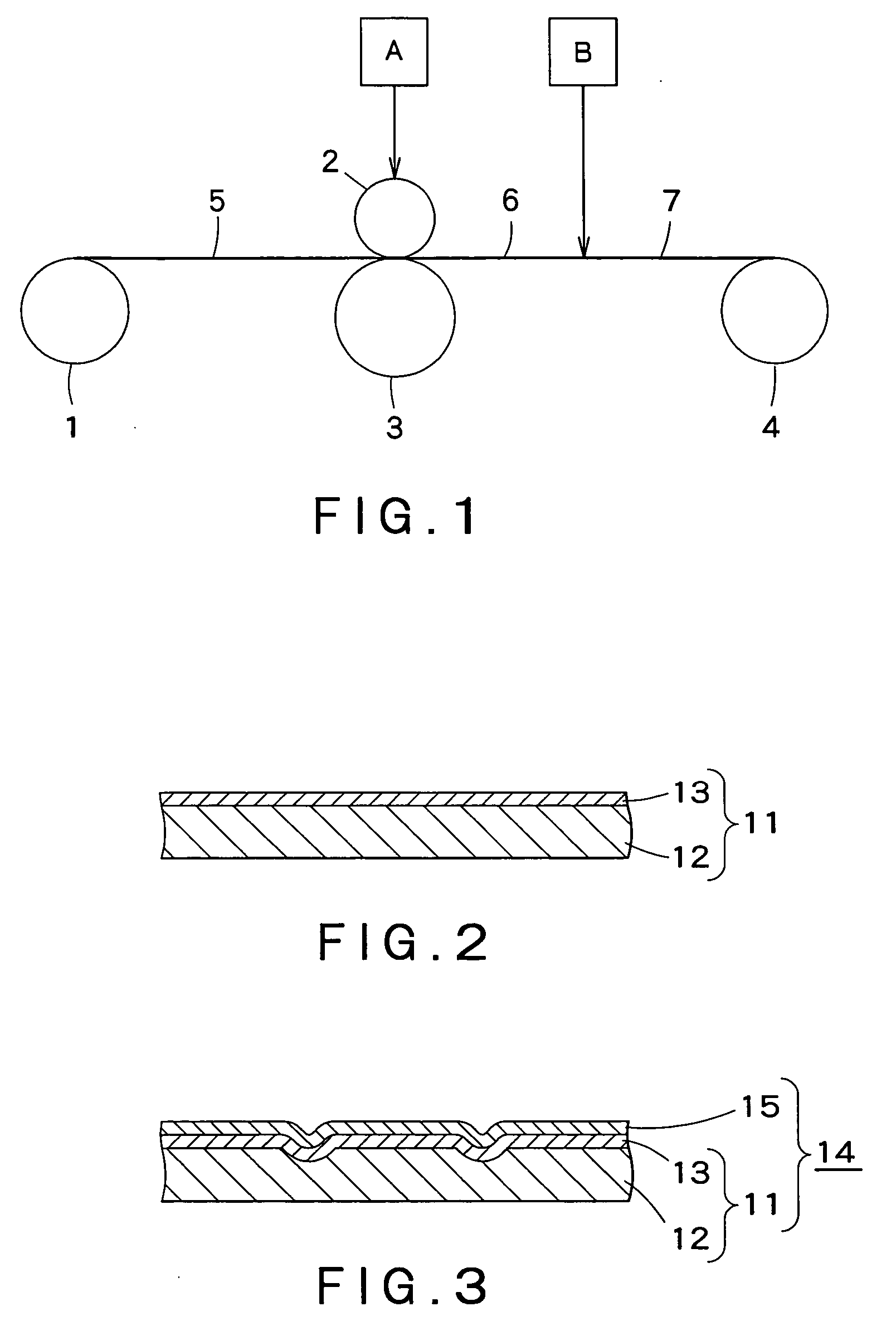

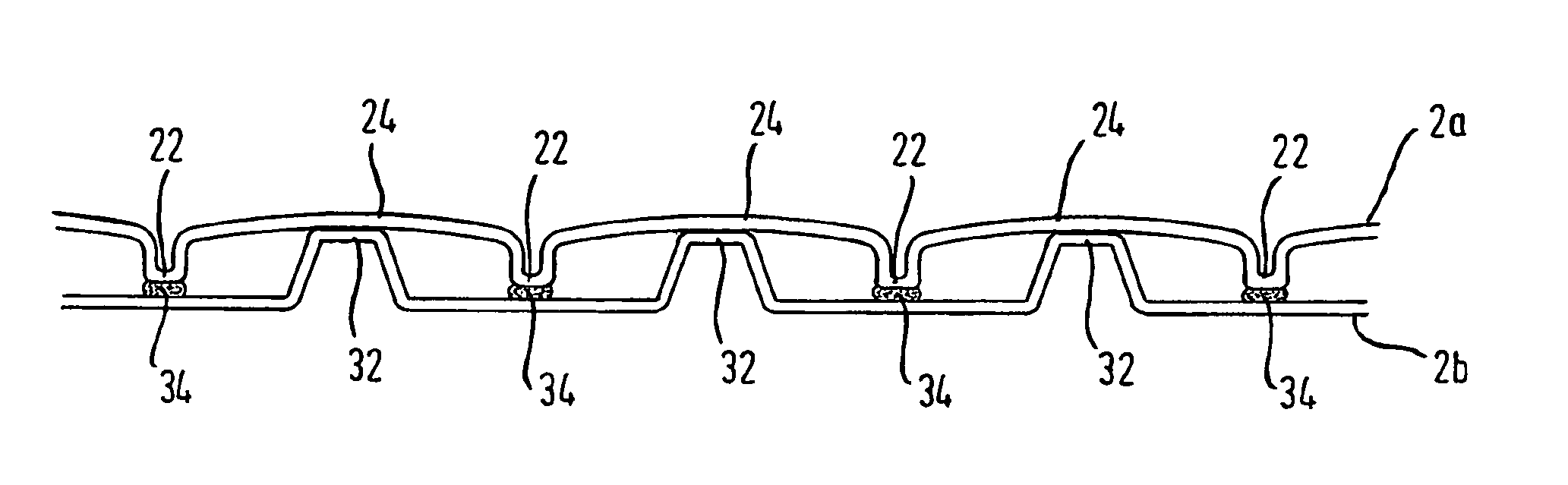

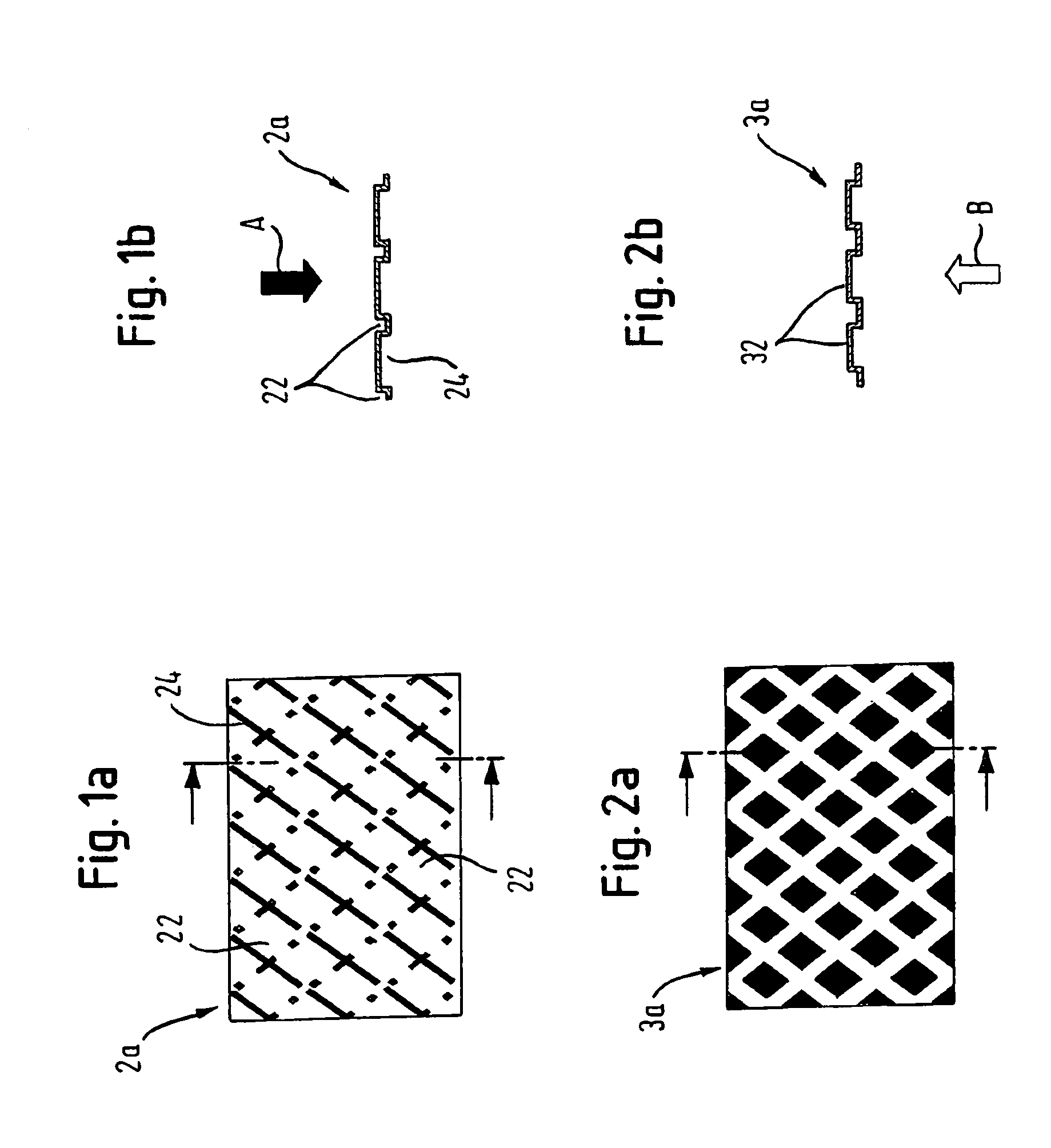

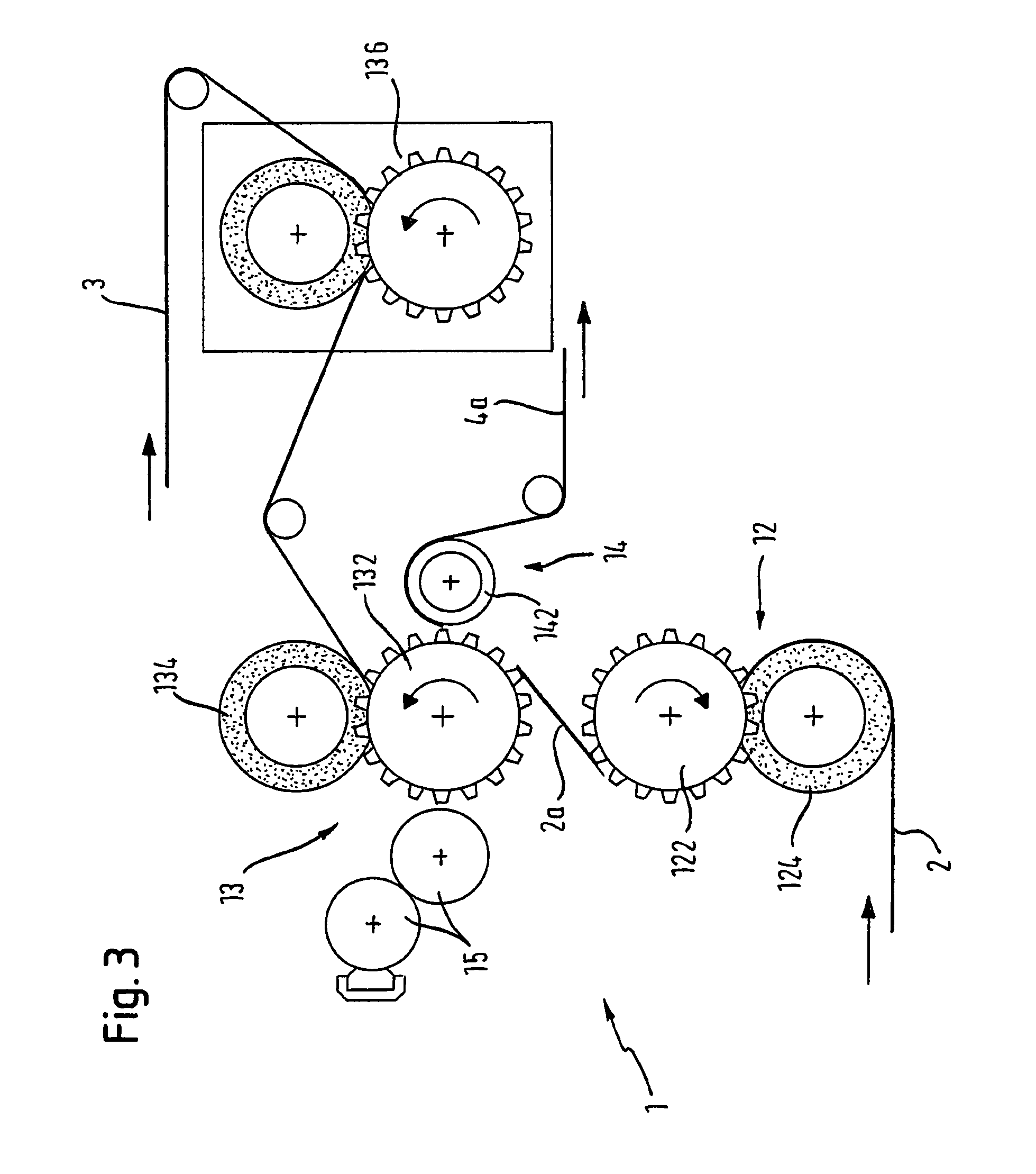

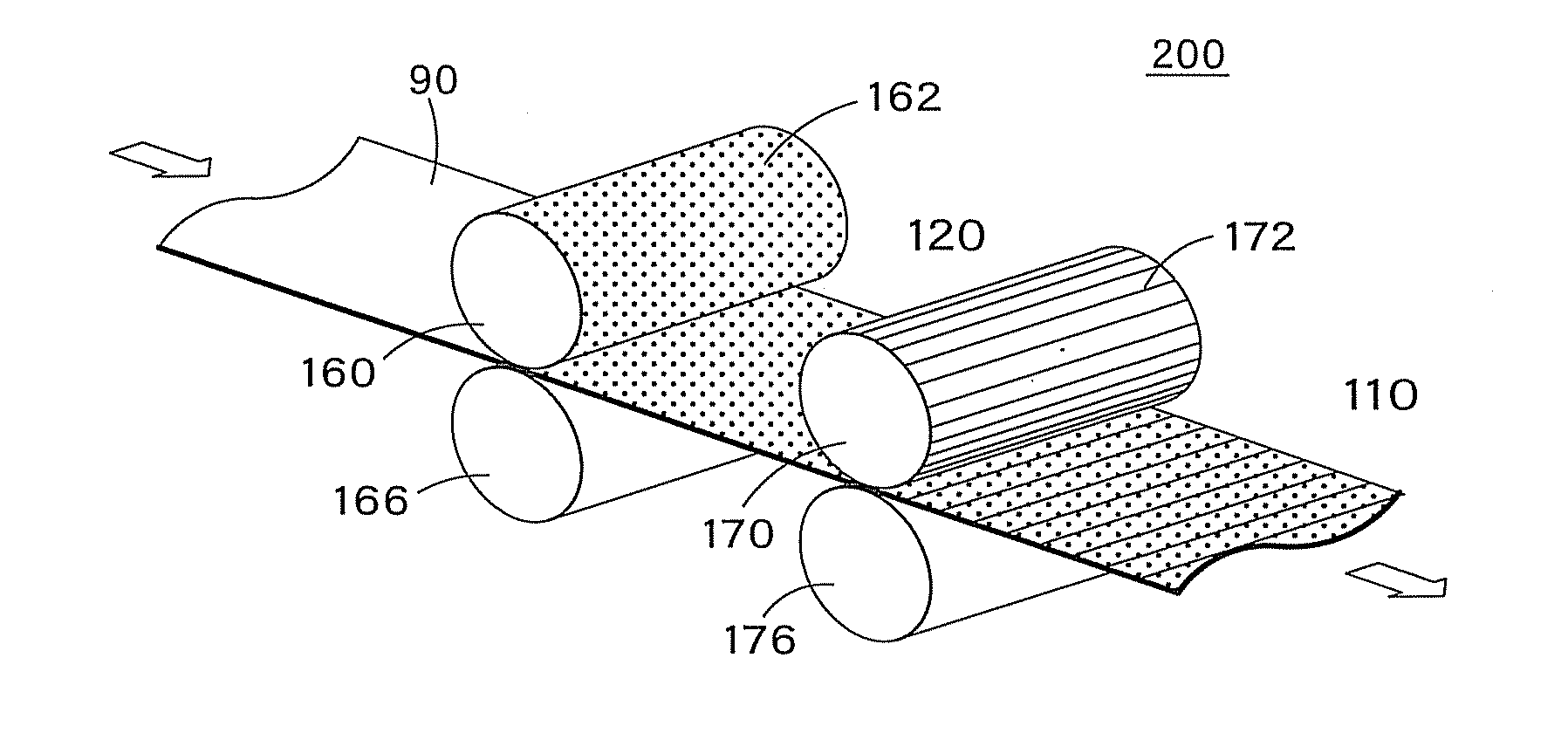

Multi-ply tissue paper, paper converting device and method for producing a multi-ply tissue paper

InactiveUS7871692B2Feel goodGood optical appearanceMechanical working/deformationPersonal careFiberBiomedical engineering

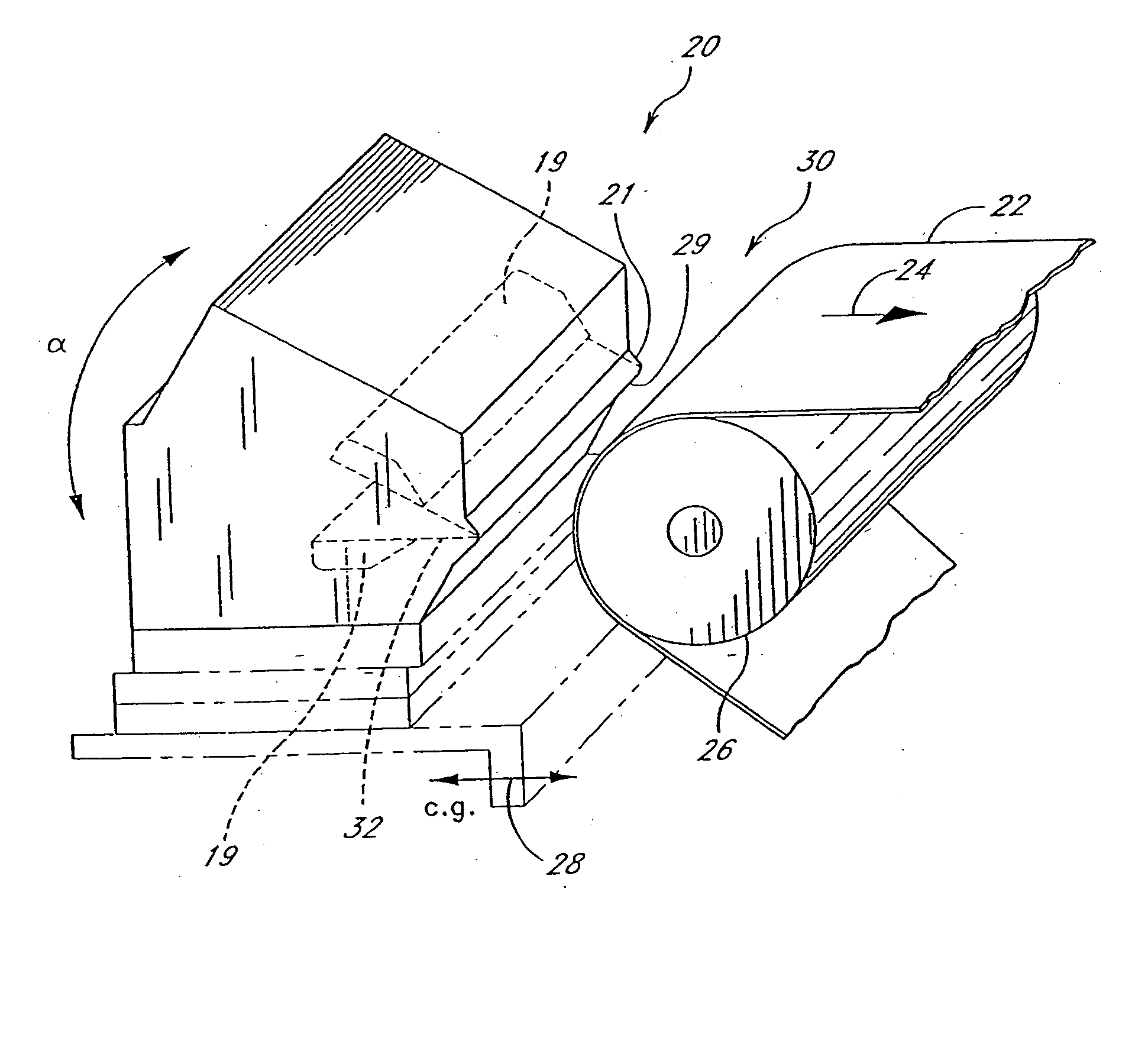

A multi-ply web of tissue paper having at least two plies comprising a first web (2a) consisting of at least one ply and being provided with a first embossing pattern forming cushions (24) limited by regions (22) of compressed material and a second web (3a) having at least one ply and being provided with a second pattern with protrusions (32) of compressed material. The first web and the second web are combined together such that the protrusions of compressed material (32) of the second web (3a) are positioned inside the cushions (24) limited by the regions (22) of compressed material (22). Further, the invention relates to a paper converting device and a method for producing such product.

Owner:ESSITY OPERATIONS MANNHEIM GMBH

Creped paper product and method for manufacturing

ActiveUS20060207735A1High tear strengthNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

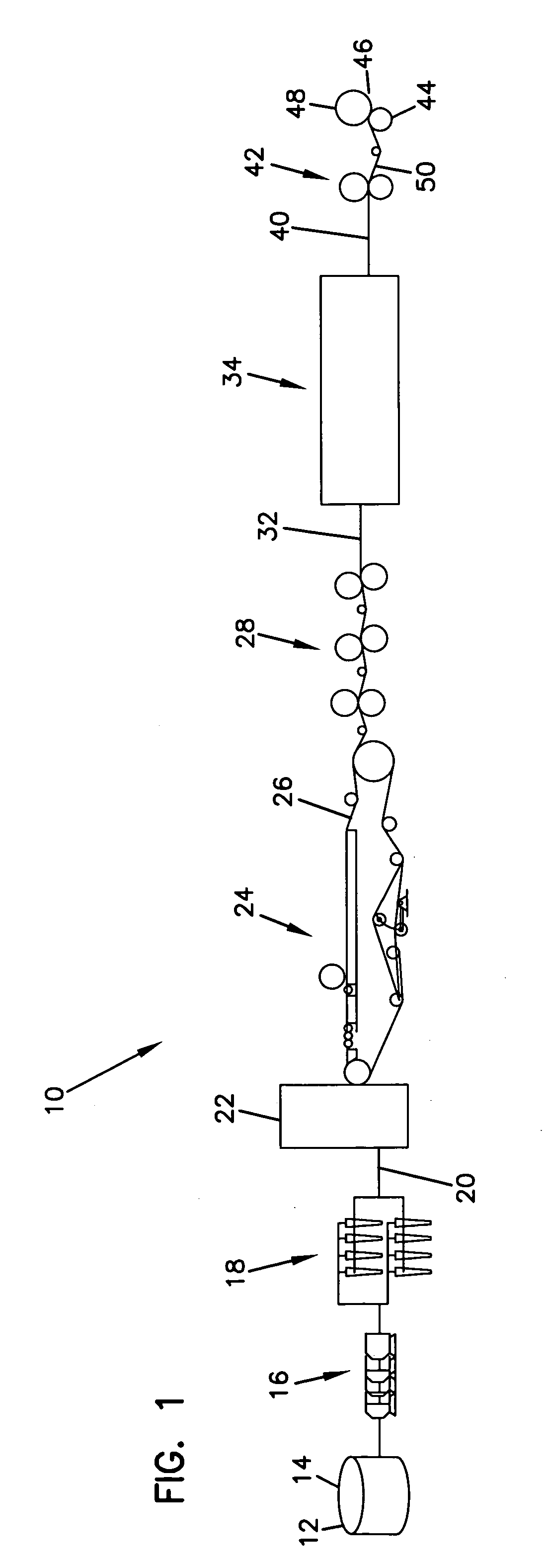

A creped paper product is provided according to the invention. The creped paper product comprises a result of creping a web of fibers comprising synthetic fibers to provide a creped paper product having a stretch of at least 3% in the machine direction according to TAPPI test T494. The web of fibers can include about 0.5 wt. % to 100 wt. % synthetic fibers based on the total weight of the fibers. In addition, the web of fibers can contain about 0.5 wt. % to about 10 wt. % of synthetic fibers and about 90 wt. % to about 99.5 wt. % of cellulosic fibers. When the web of fiber includes a mixture of synthetic fibers and cellulosic fibers, the creped paper product can be provided having a tear strength in the machine direction according to TAPPI test T494 at least 10% greater than an otherwise identical creped paper product that does not contain synthetic fibers. A method for forming a creped paper product is provided according to the invention.

Owner:AHLSTROM MUNKSJO NA SPECIALTY SOLUTIONS LLC

Heat, grease, and cracking resistant release paper and process for producing the same

InactiveUS20100059191A1Natural cellulose pulp/paperPaper after-treatmentOil and greaseCrack resistance

Owner:COPAMEX DE C V

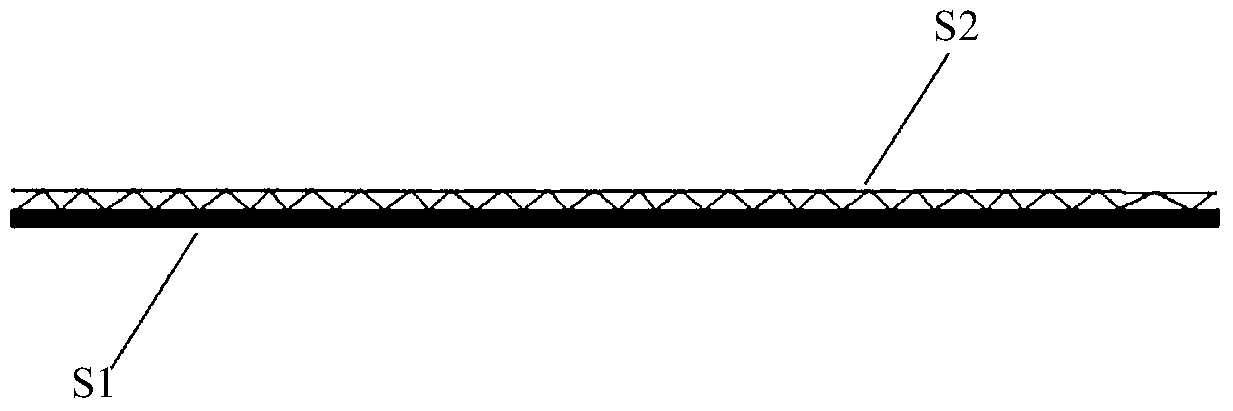

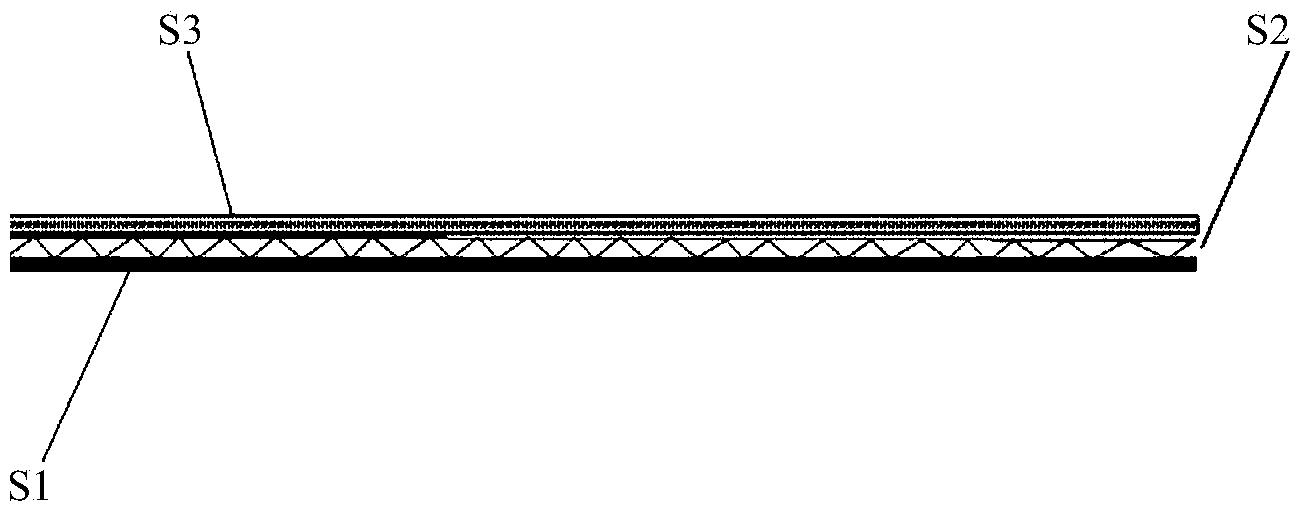

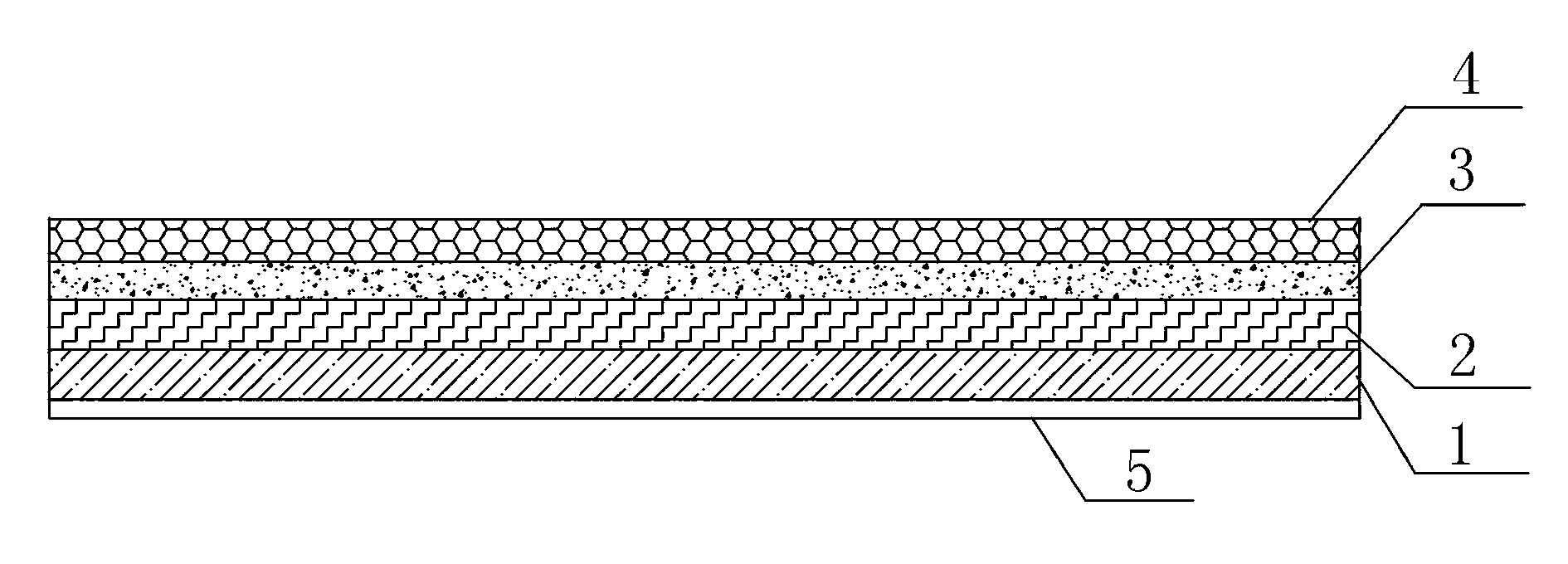

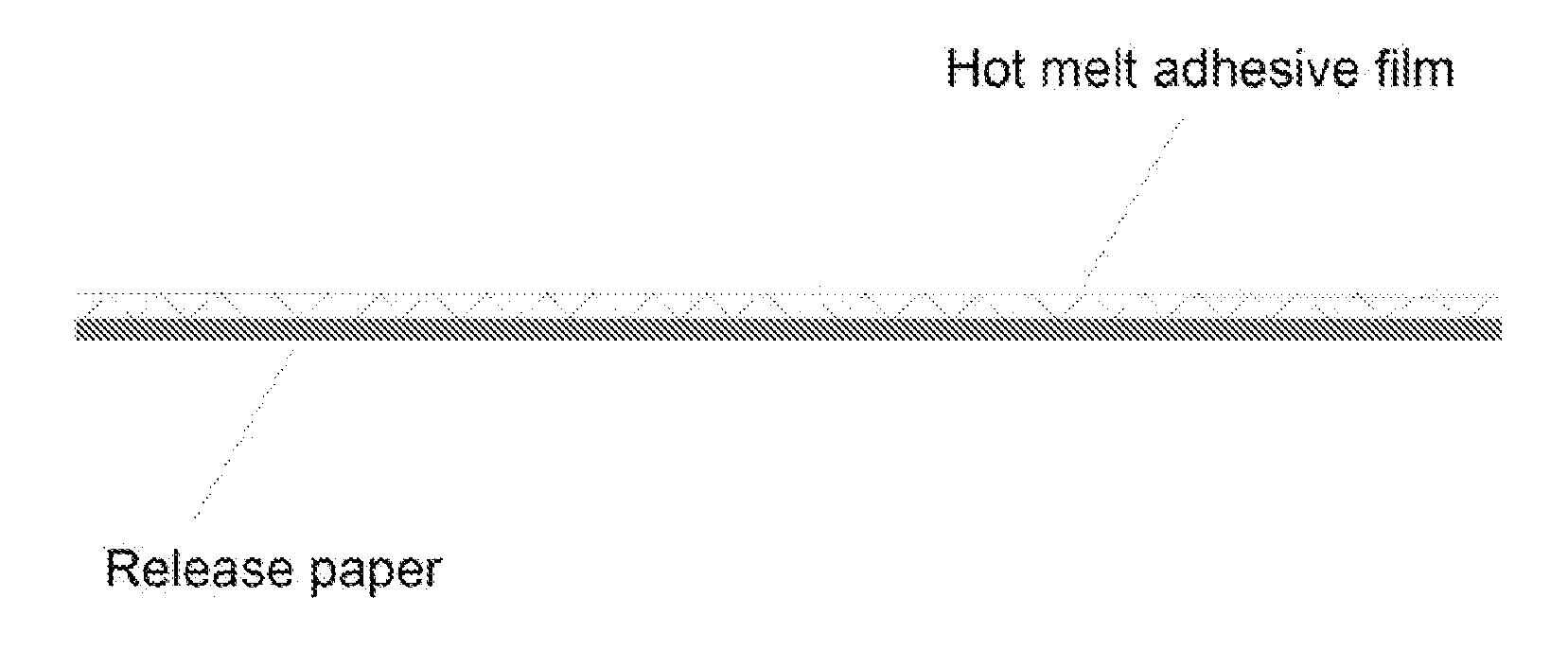

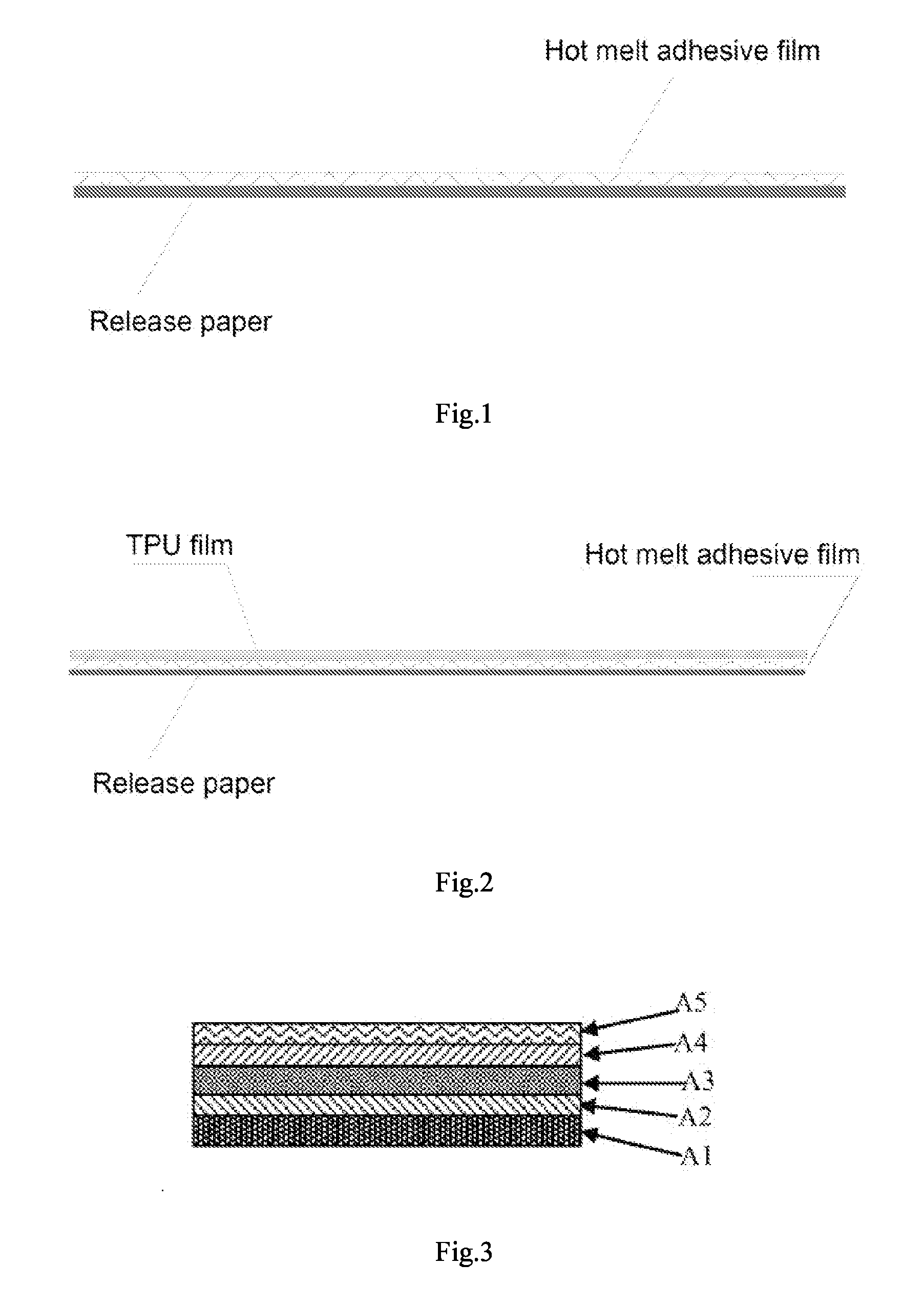

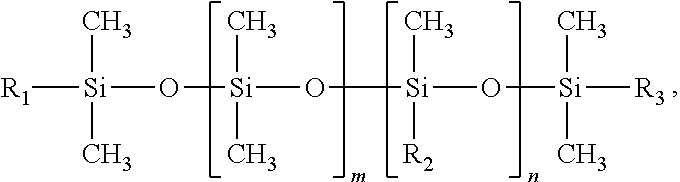

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

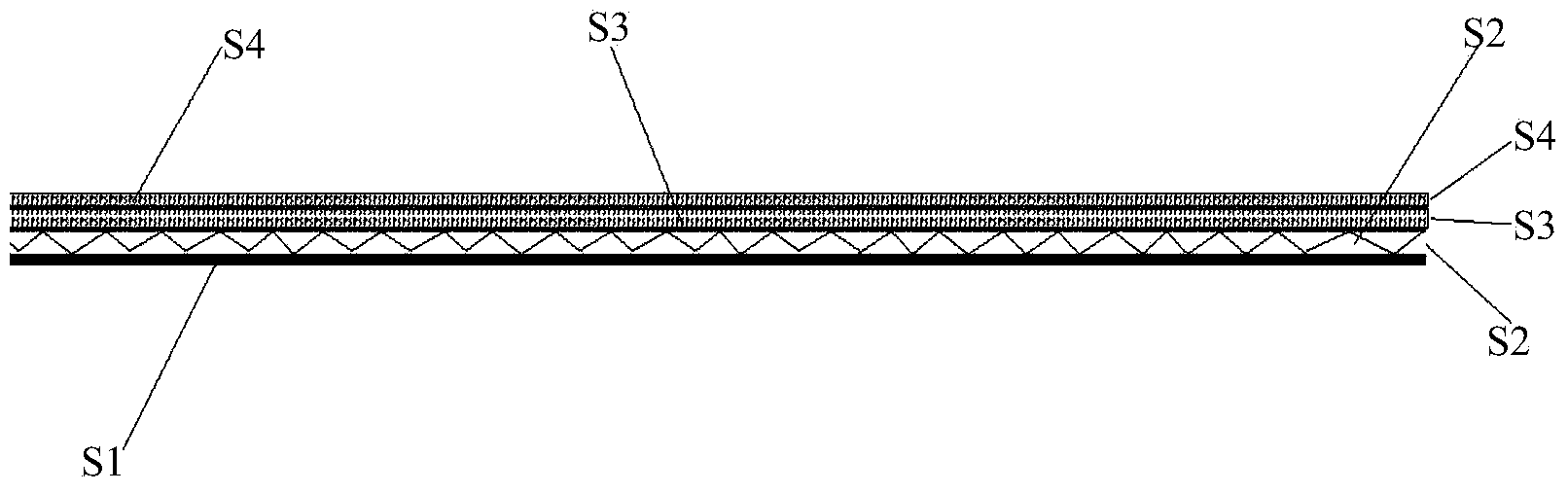

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Food-release packaging

InactiveUS20060122318A1Non-fibrous pulp additionNatural cellulose pulp/paperOil and greaseStarchy food

The invention is directed to hot moist food packaging, a method for packaging the same, and a method to impart oil and grease repellency to paper or paperboard. The compositions and methods are especially valuable when used for packaging foods such as hot moist breads, buns and oily starchy foods such as potatoes. The compositions and method ensure that the paper in contact with the food does not stick to the bread bun or starchy foods and cause breaking or fragmentation.

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

Additive compositions for treating various base sheets

ActiveUS7879189B2High strengthGood flexibilityCosmetic preparationsNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web and / or improve the perceived softness of the web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Release Paper and Method of Manufacture

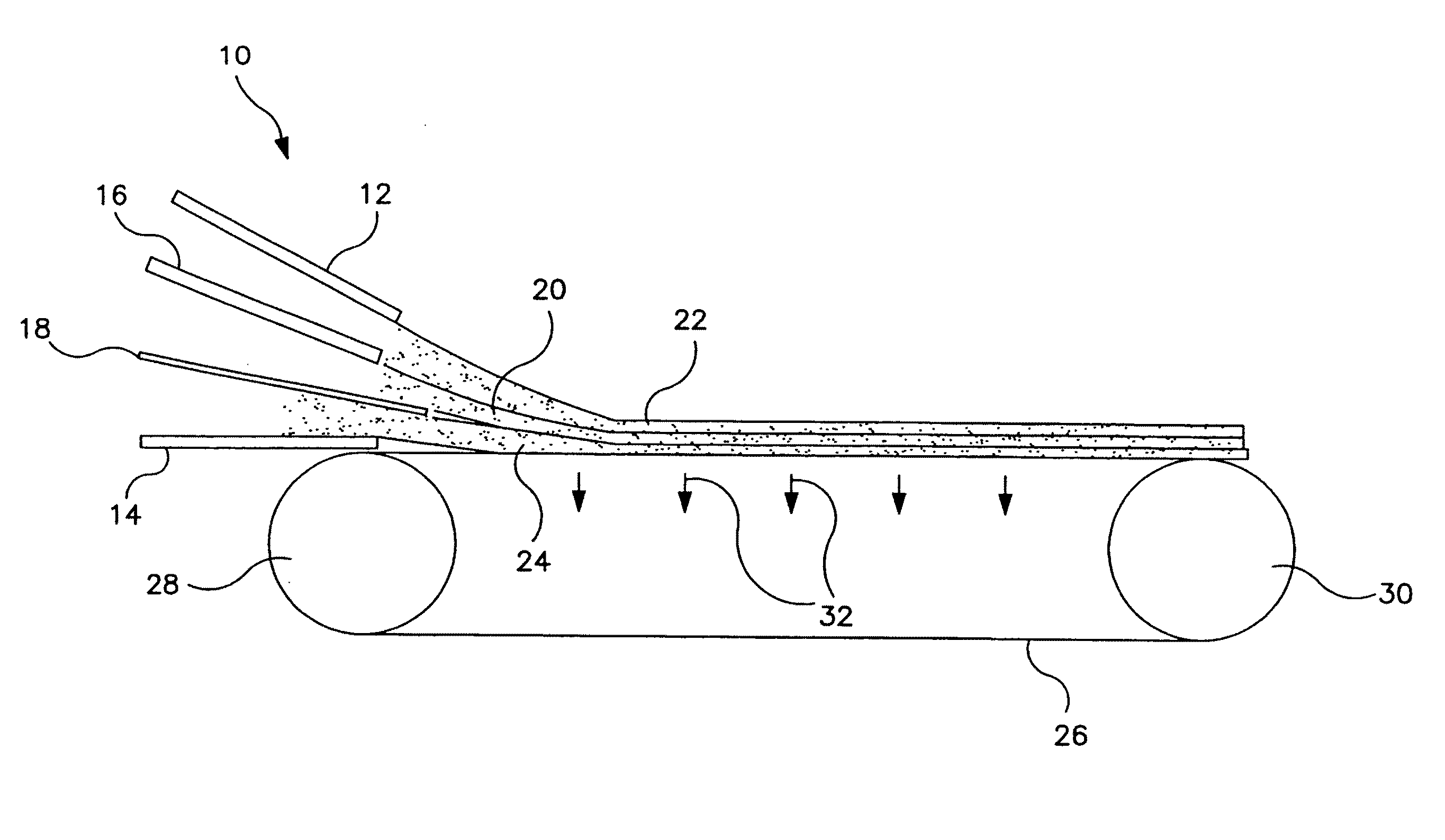

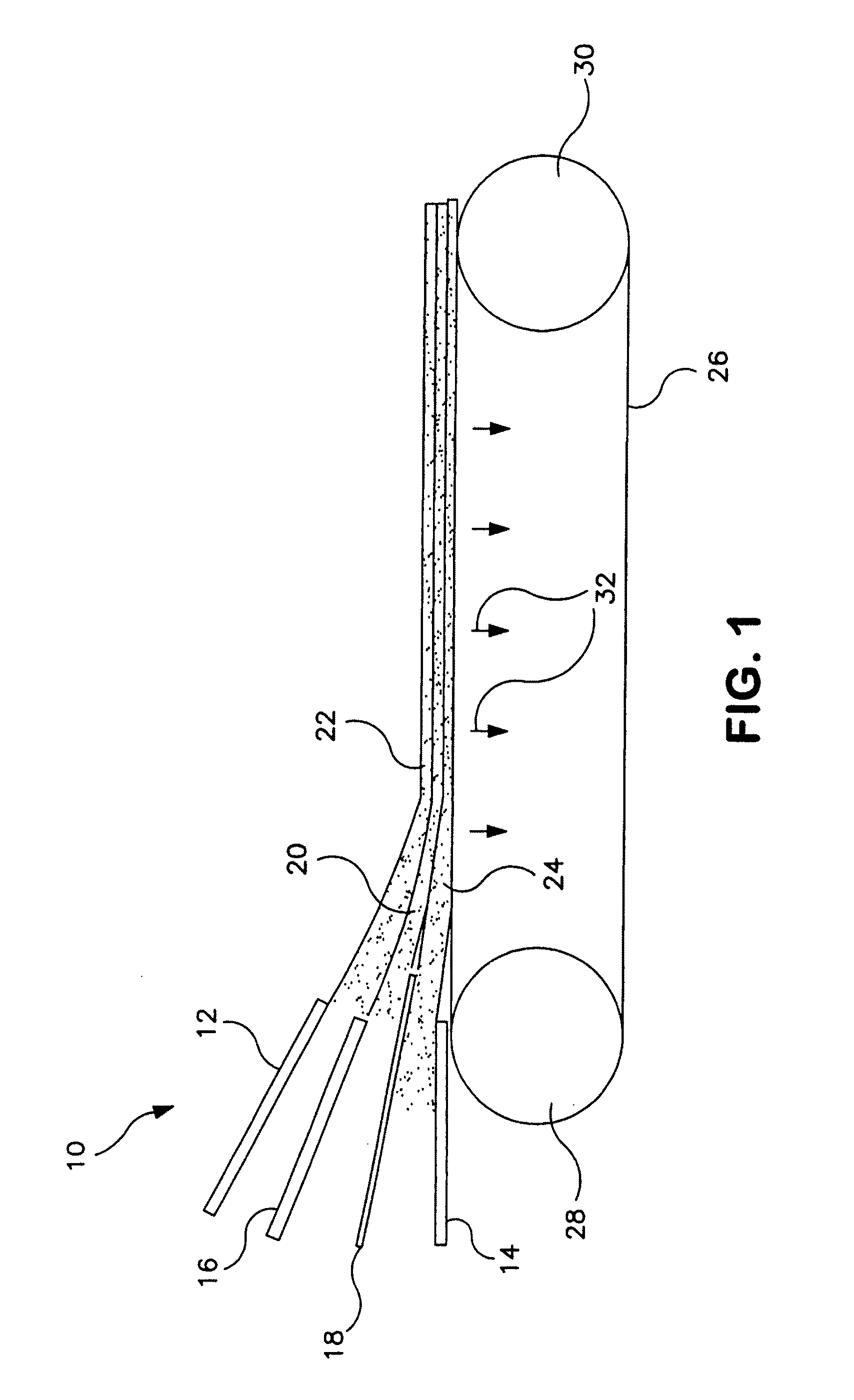

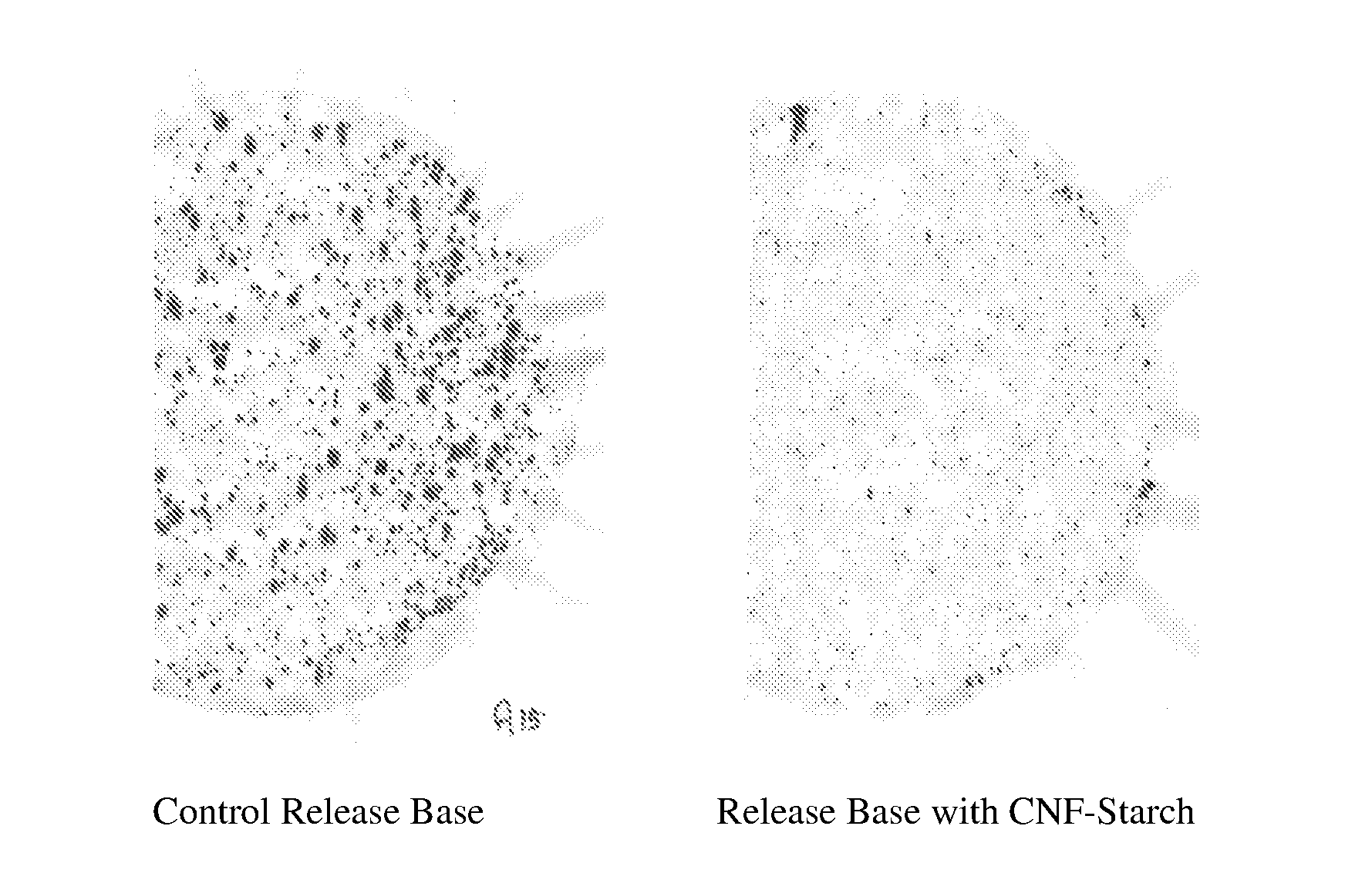

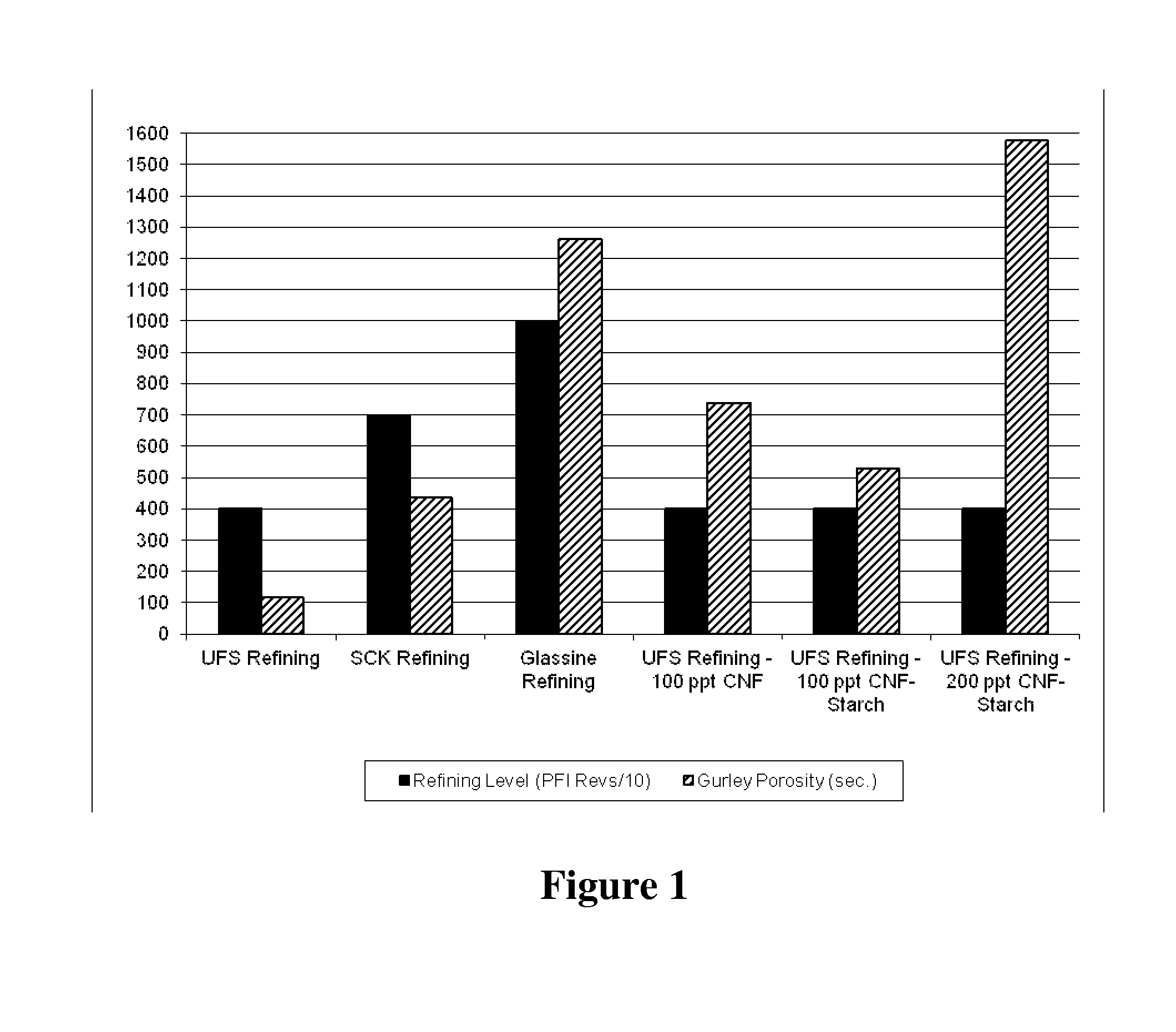

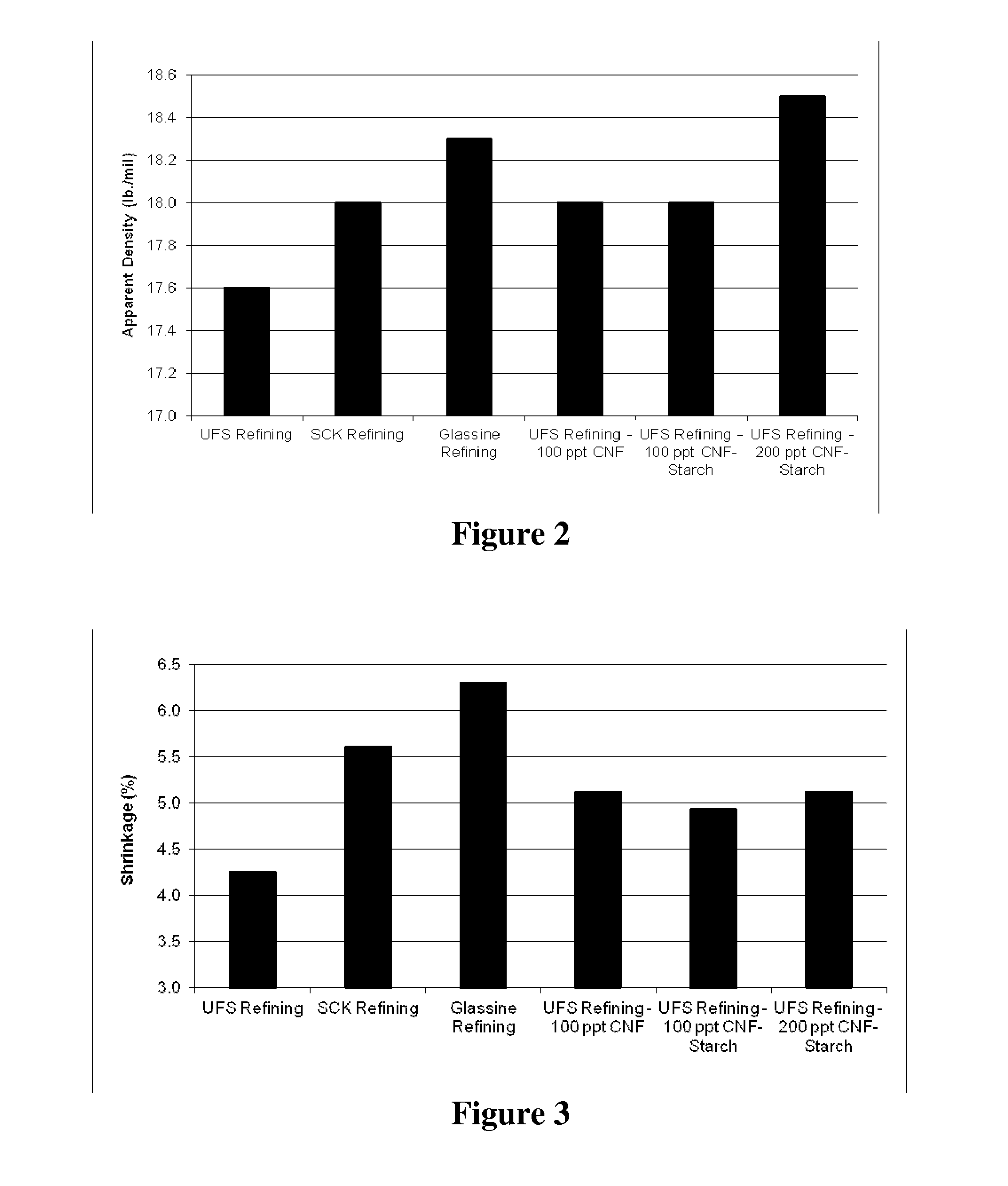

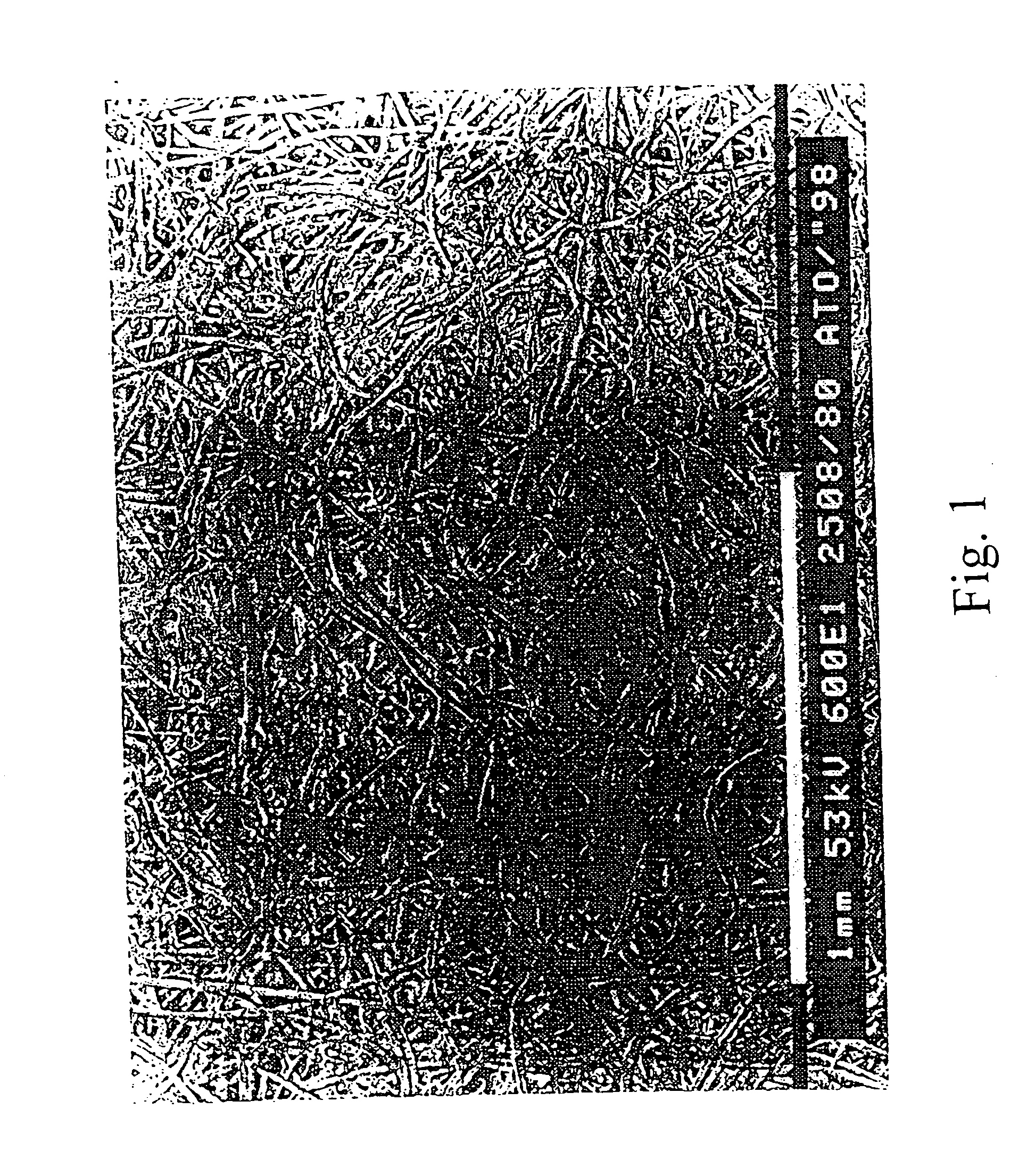

ActiveUS20150125658A1Increase speedLower requirementNon-fibrous pulp additionRecord information storageCellulosePolymer science

Release base papers with improved surface properties and more efficient manufacturing potential are made using cellulose nanofibrils (CNF) along with high freeness, less refined pulp. Release papers serve as the backing for common adhesive labels, for industrial film coatings, and also for certain food processing uses. The CNF may be added to the furnish and processed to paper, or the CNF may be added as a coating onto a partially dried web of paper. The CNF may optionally be combined with a starch and a starch crosslinker.

Owner:STIRLING CONSULTING +1

Transfer paper for printing with an inkjet printer

InactiveUS20050186363A1Reduce transfer efficiencyPaper is too highDecorative surface effectsTransfer printing processPorosityComputer printing

Transfer paper suitable for inkjet printing, provided, at least on the side to be printed, with a release or barrier layer, the layer having a porosity of at most 100 ml / min, and a method for manufacturing a transfer paper and a method for printing transfer paper with an inkjet printer with an aqueous dispersion of a sublimable ink.

Owner:BP IP LLC

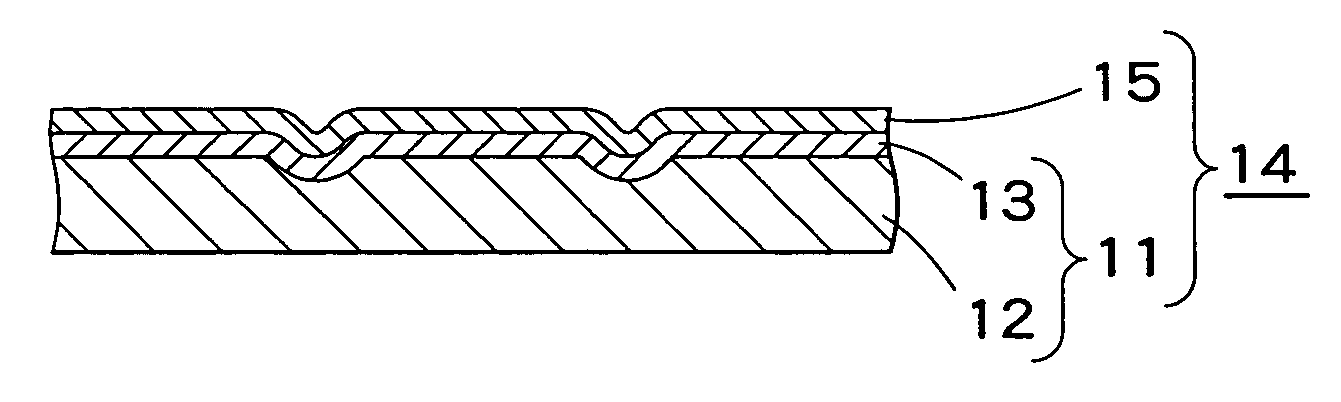

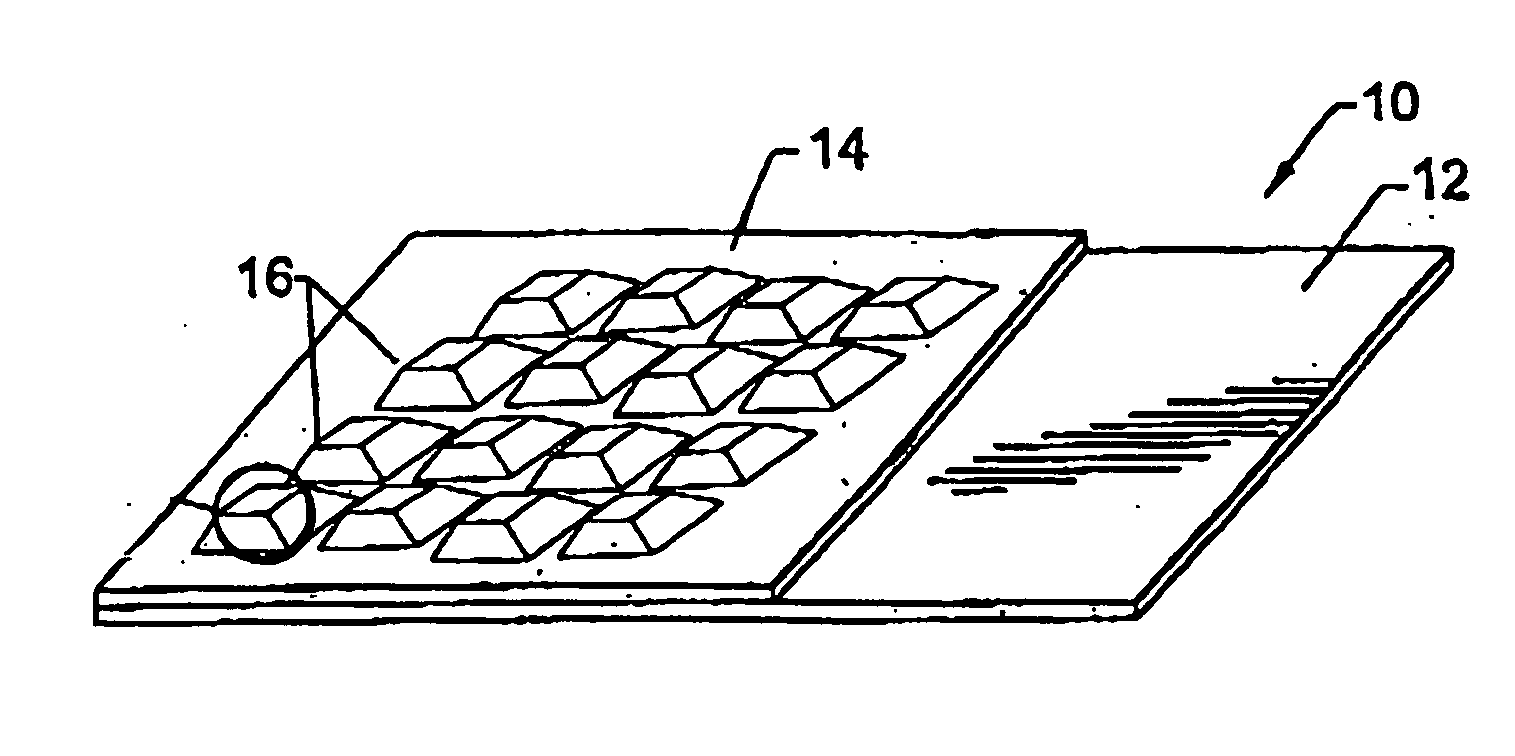

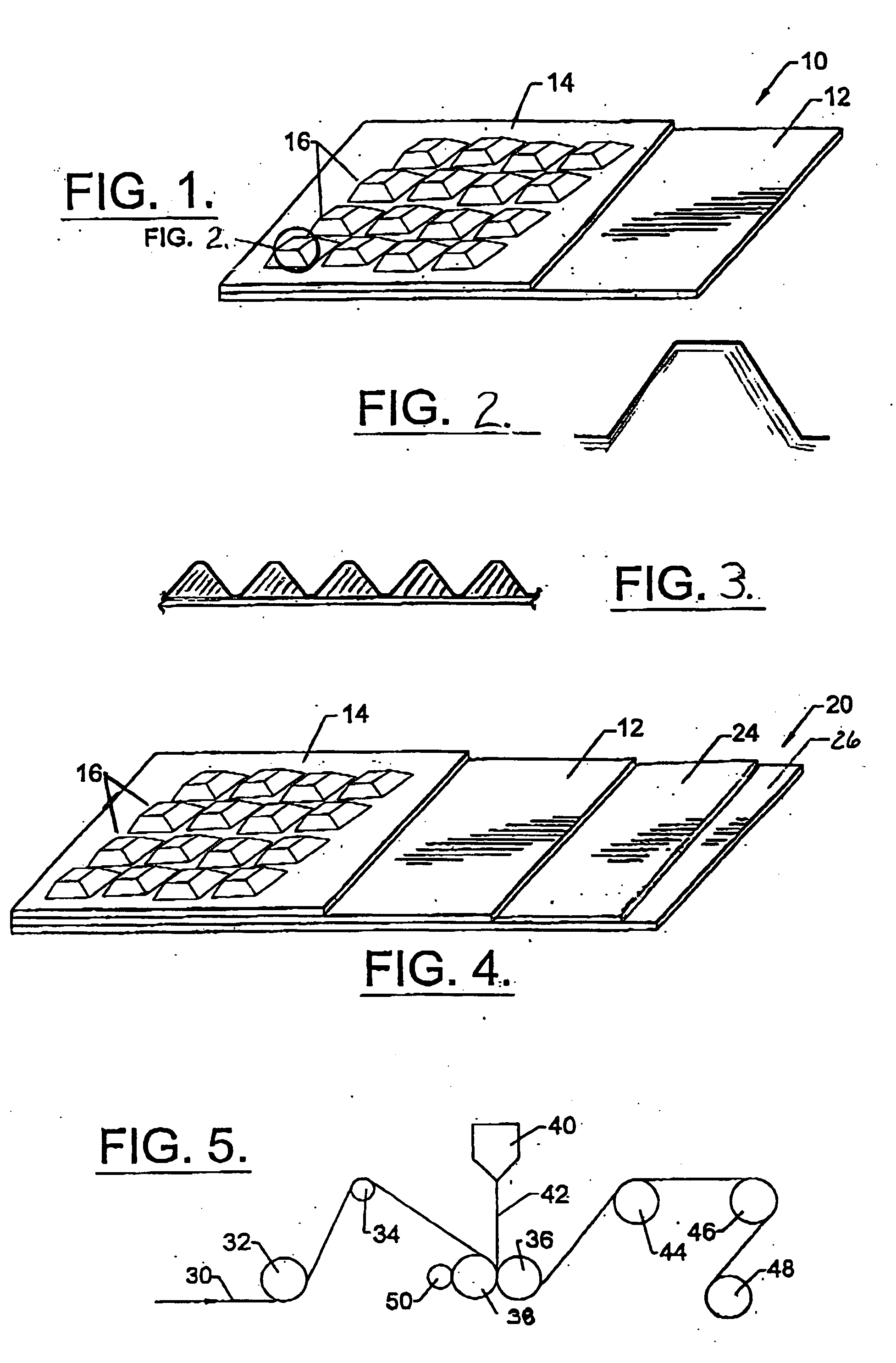

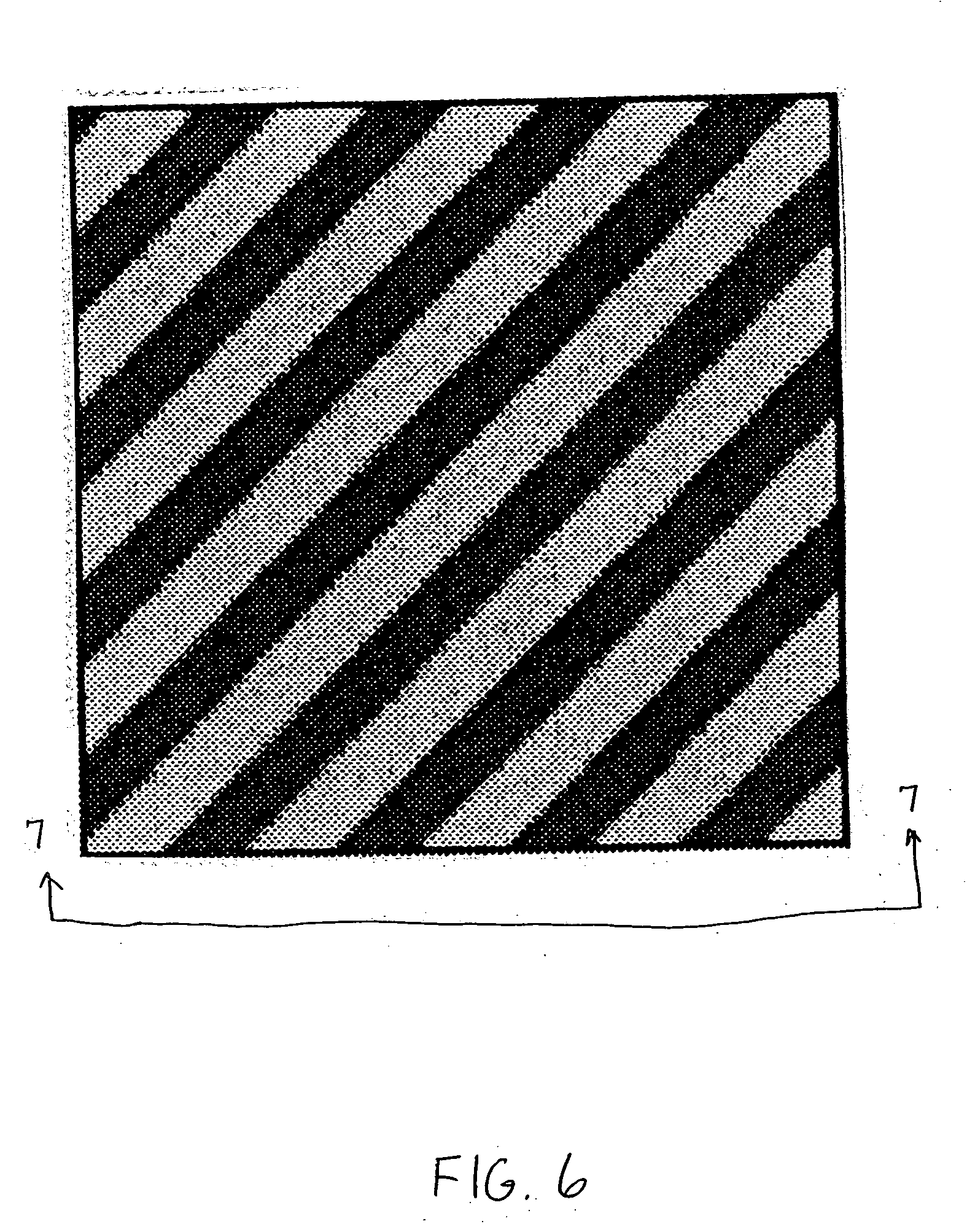

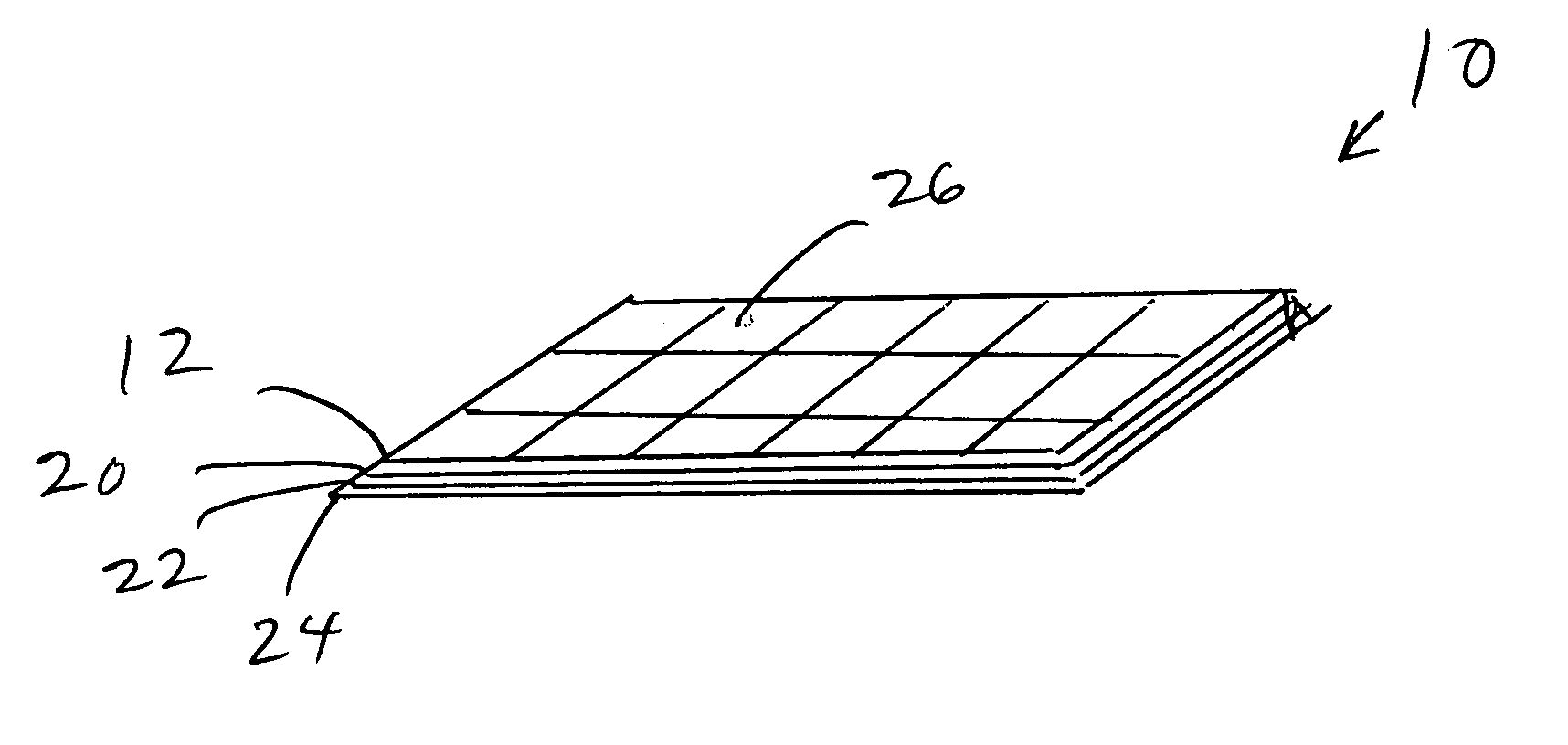

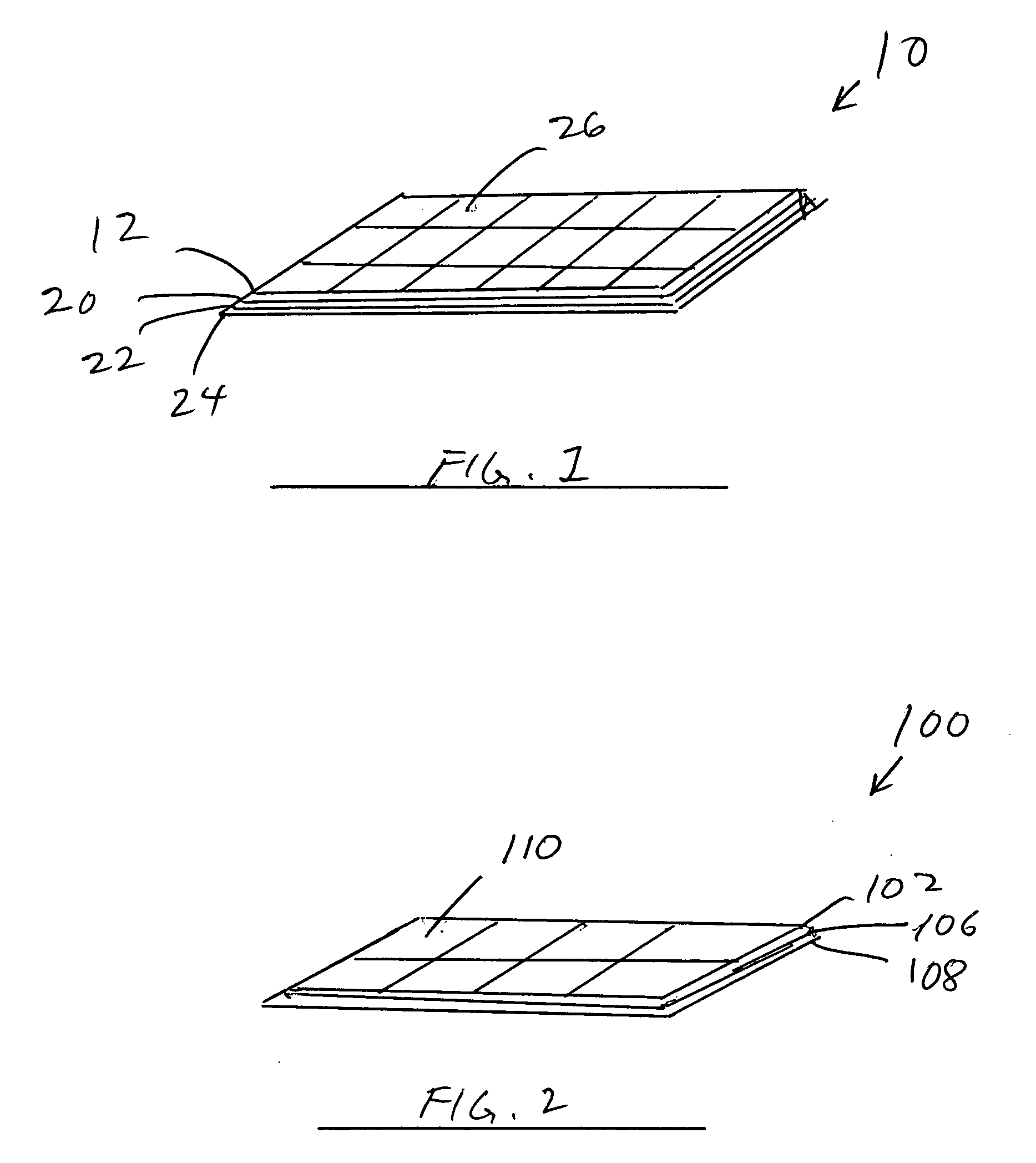

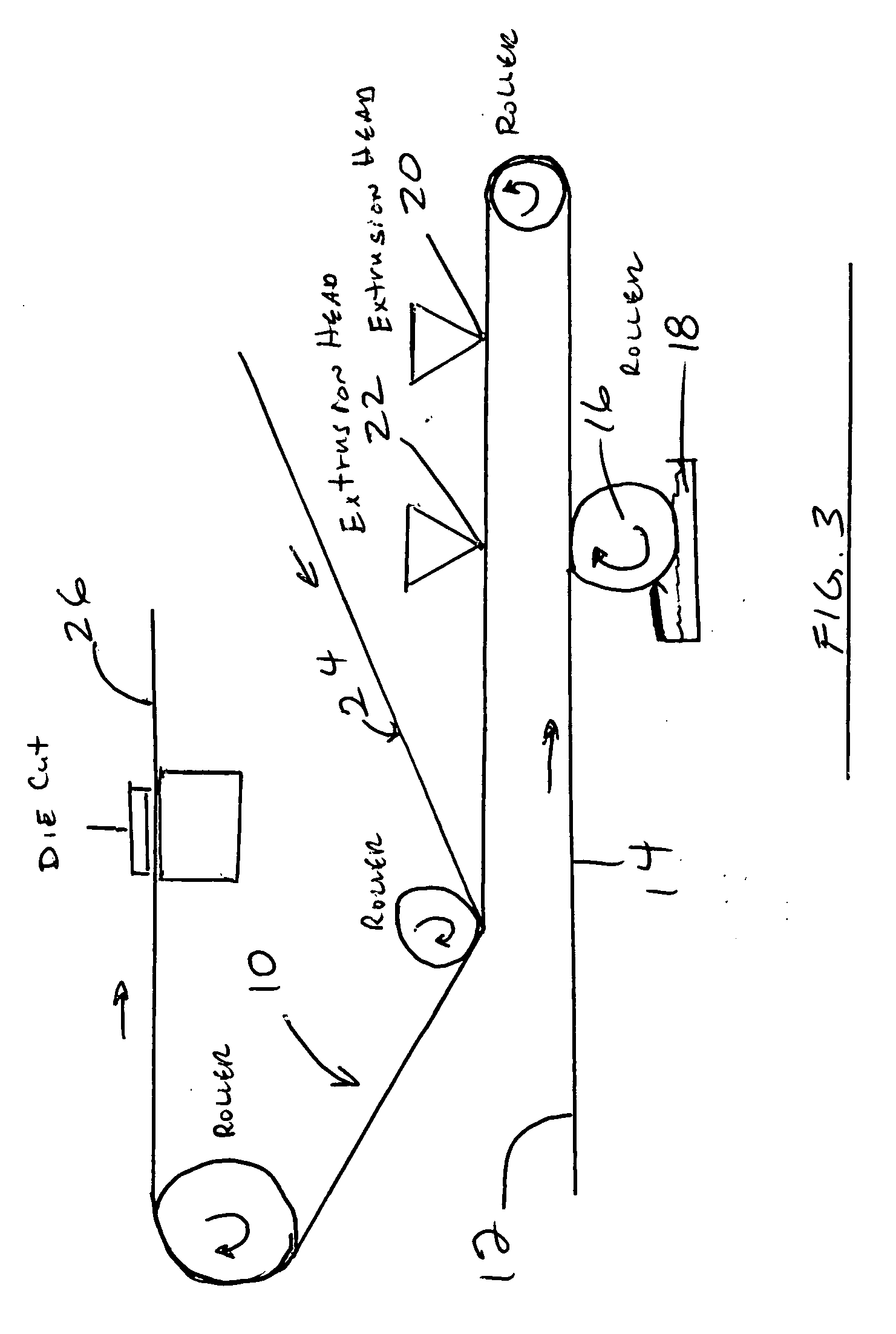

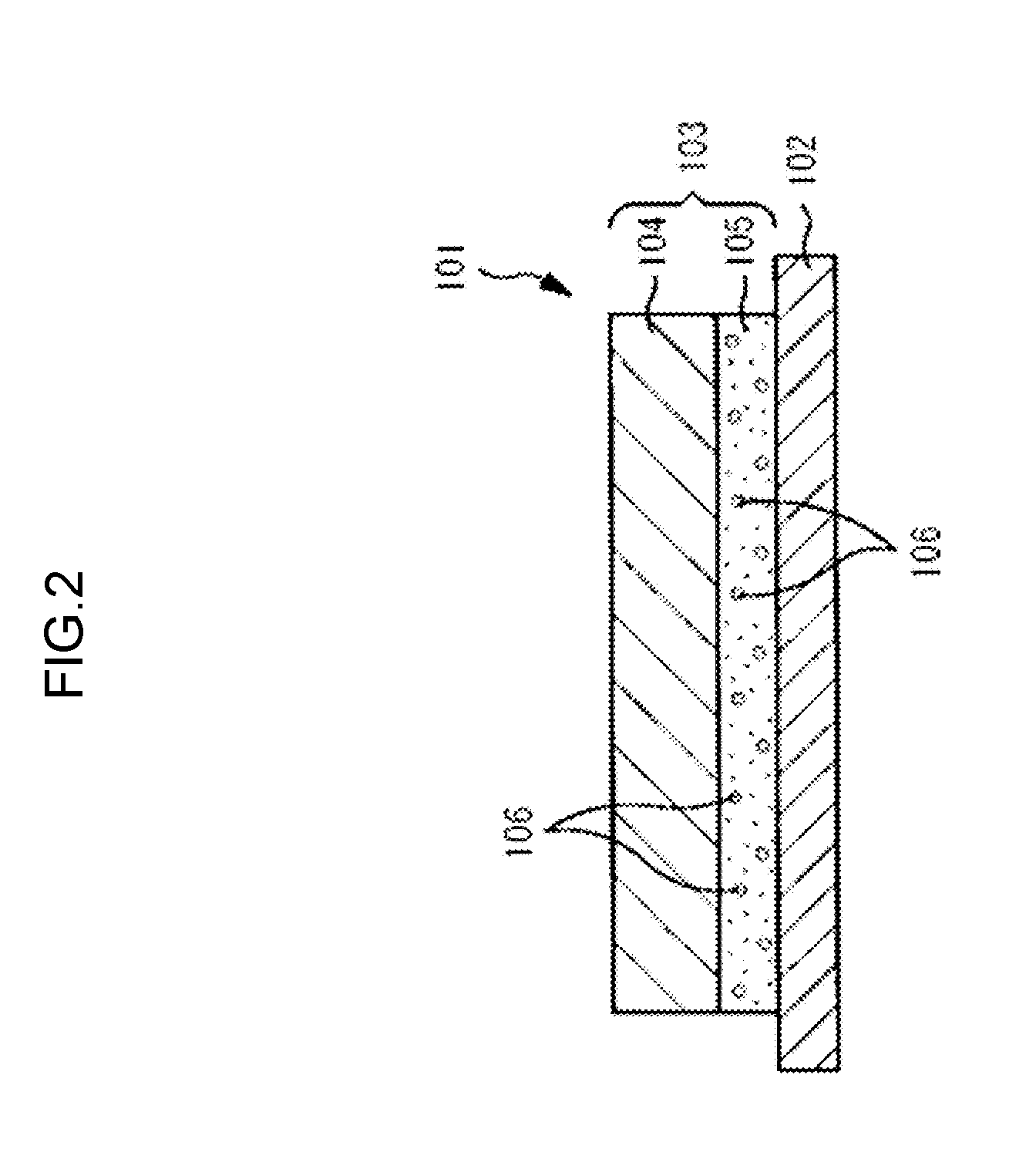

Structured paper release liner, adhesive-backed article assembly and method of making same

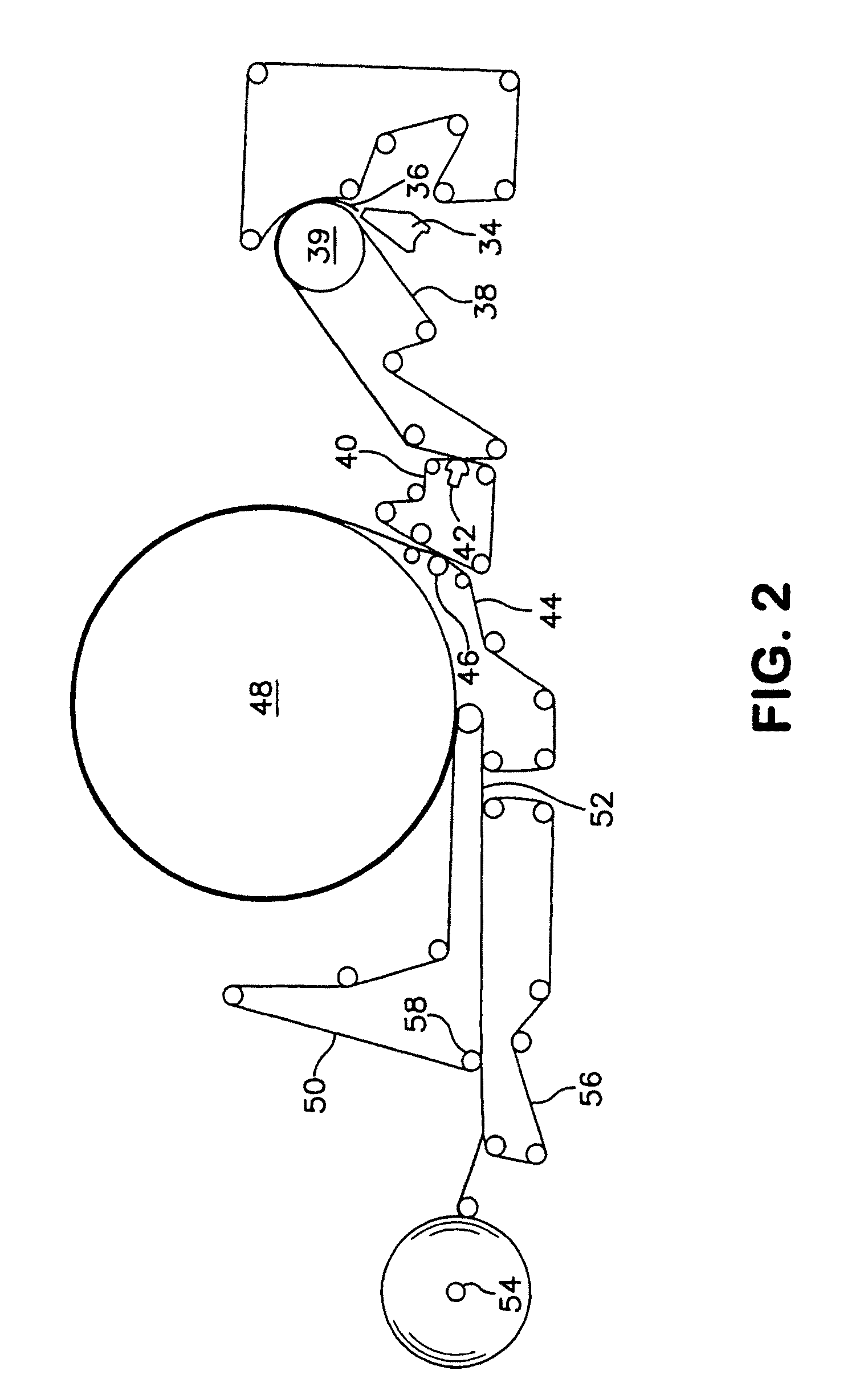

InactiveUS20070166501A1Low efficiencyFaster rateRecord information storagePaper/cardboardEngineeringPaper sheet

A structured paper release liner (10) for use with an article (44) backed with a pressure sensitive adhesive, an adhesive-backed article assembly (42) and methods of making each are disclosed. The liner (10) comprises a piece of paper (14) having a release side free of a structural support layer, a back side, and a structured release surface (48) having a pattern formed into the paper (14) on the release side. A release material is on the structured release surface of the paper. The pattern formed in the paper (14) is designed so as to form fluid egress channels in a bonding surface of the pressure sensitive adhesive (46). The fluid egress channels define a structured bonding surface (48) having exit pathways for fluid to bleed out from behind the article when the structured bonding surface (48) is adhered to or otherwise disposed on a substrate.

Owner:3M INNOVATIVE PROPERTIES CO

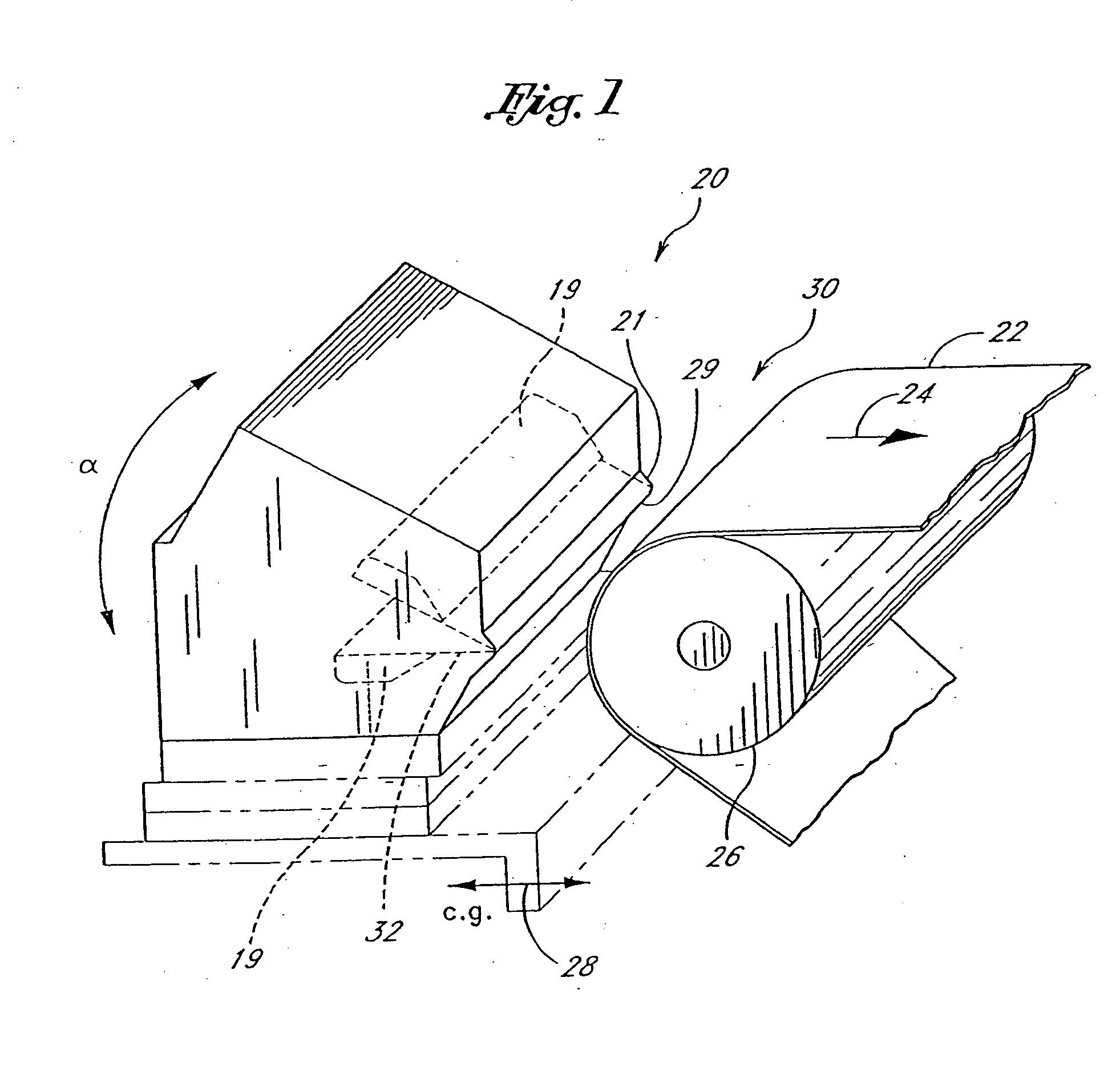

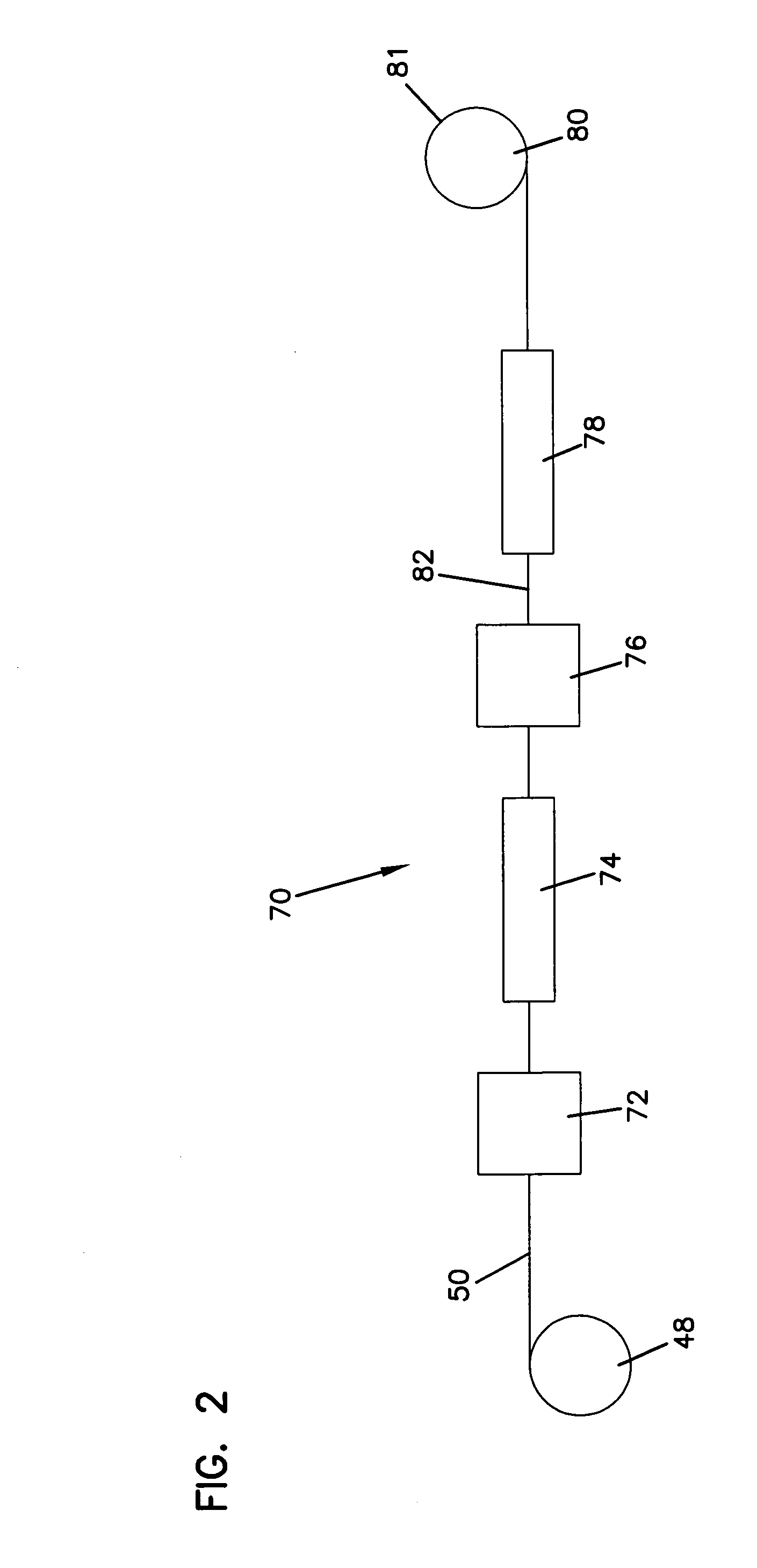

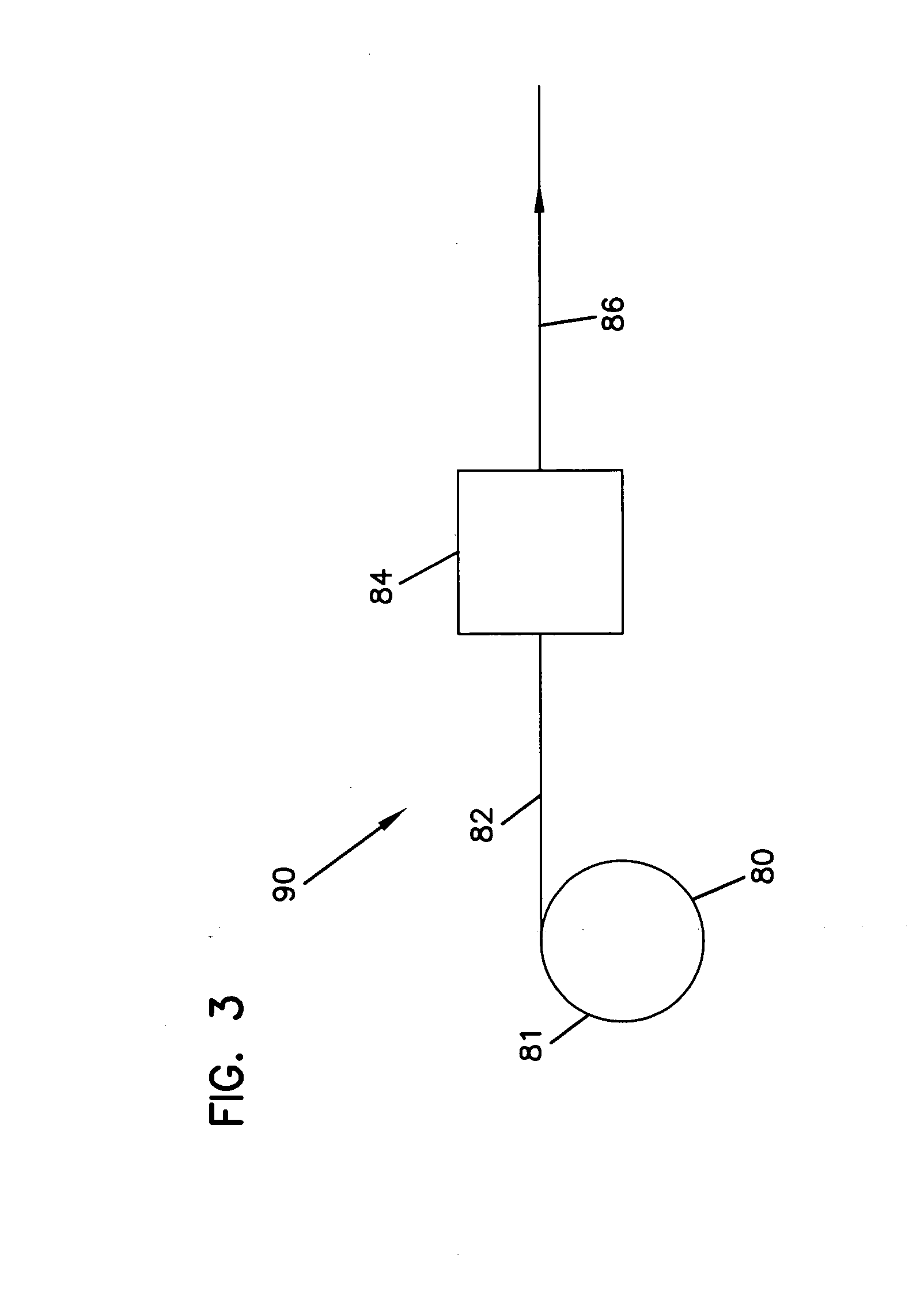

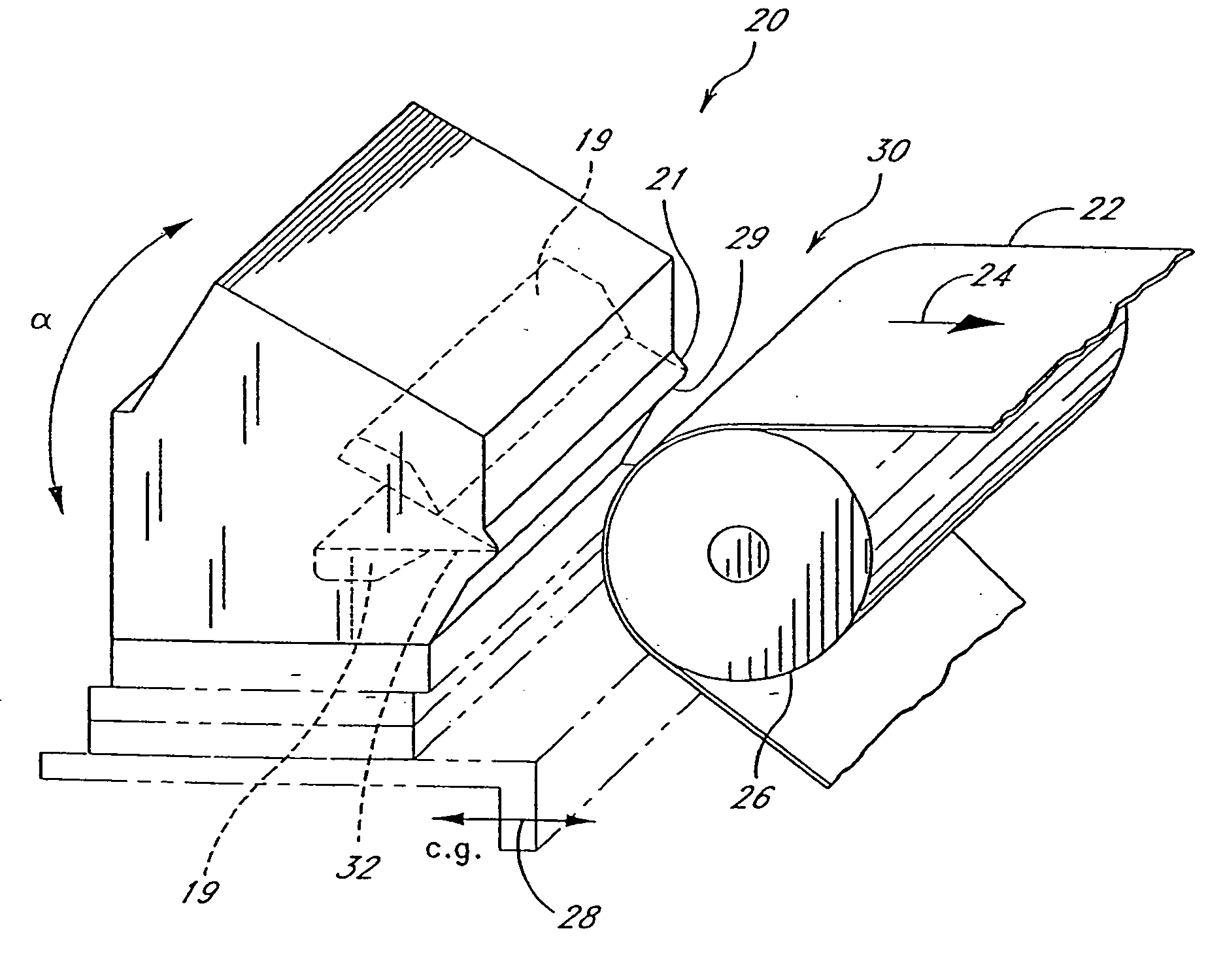

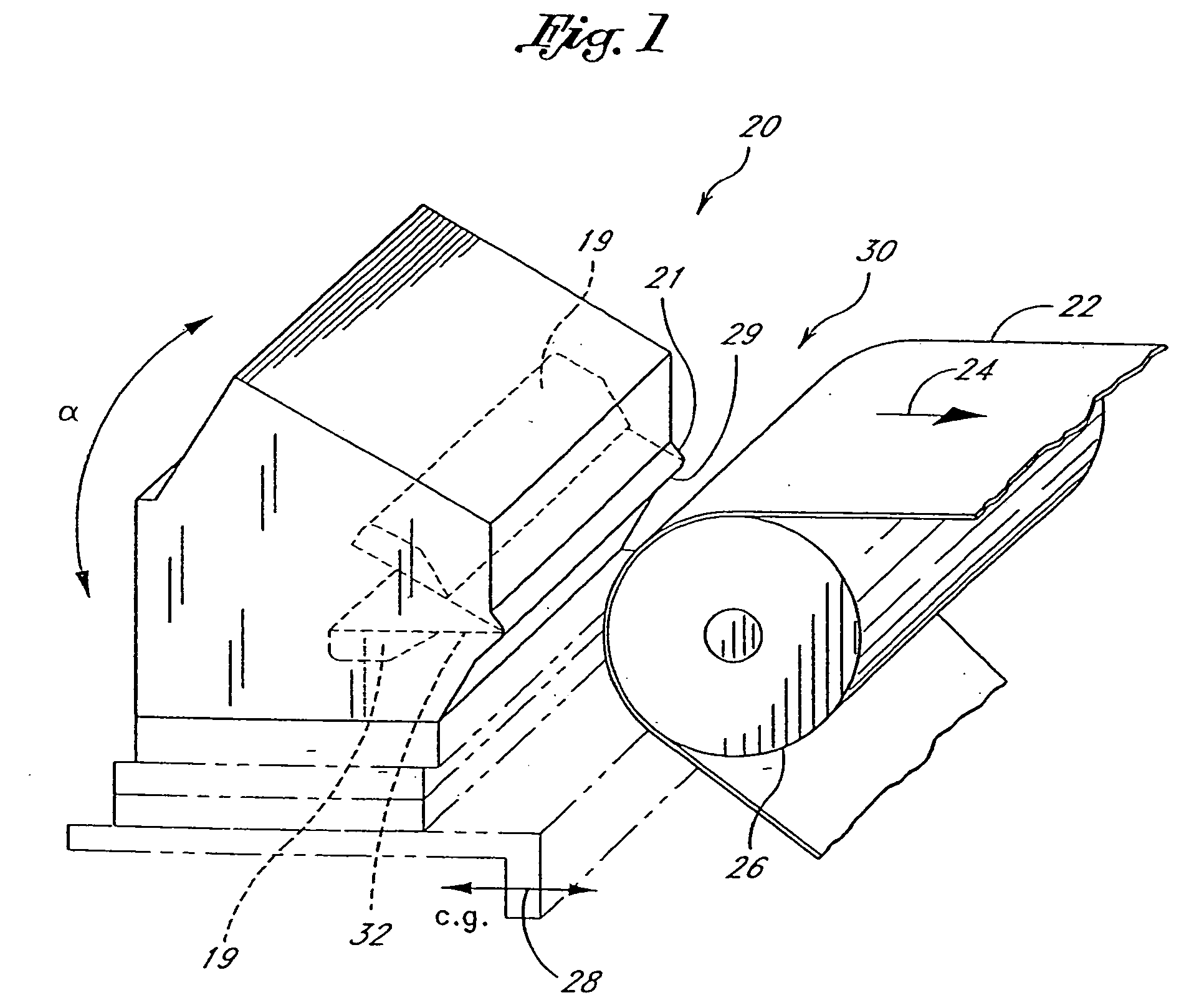

Engineered structured release liner and processes for making the same

InactiveUS20050074573A1Good at feeding propertySmooth and uniform appearanceDead plant preservationArtificial flowers and garlandsRegular patternPolyolefin

Highly roughened, precision engraved, patterned surface upon a substrate, preferably a polyolefin coated substrate, and processes for making the same. A chill roll is used to impart an engineered, highly structured surface upon the polyolefin coating of the substrate. The structured polyolefin coated substrates preferably have highly regular patterns, and those patterns may include either quadragravure, trihelical, or other regular, reproducible pattern.

Owner:LOPAREX

Granulation-free ecological plate high-pressure decorative surface material and manufacturing method thereof

InactiveCN103171211AIncreased transverse tensile strengthReduce pollutionLayered product treatmentSynthetic resin layered productsBoPETThin membrane

The invention belongs to the field of building decorative materials, and in particular relates to a granulation-free ecological plate high-pressure decorative surface material and a manufacturing method thereof. The granulation-free ecological plate high-pressure decorative surface material comprises a bottom paper layer, a core paper layer, a decorative paper layer and a surface paper layer which are sequentially arranged, wherein a demolding agent coating layer is coated on one surface (back on to the core paper layer) of the bottom paper layer. During subsequent processing, the back of a product does not need to be granulated after the process of edge sawing, so that the transverse tensile strength can be obviously improved, and the thickness can be obviously reduced; and the decorative surface material which is 0.25mm thick can be produced. The manufacturing method comprises the following steps of: preparing a special demolding agent, immersed core paper, immersed bottom paper, immersed decorative paper and immersed surface paper, assembling a blank and performing thermal pressing. During thermal pressing, the bottom paper demolding layers of two groups of plate blanks are in direct contact with each other, and an aluminum plate or a bidirectionally stretched PP thin film does not need to be used as an isolation material; and therefore, the cost is saved, pavement is facilitated and quick, and the production efficiency is high; waste cannot be produced; and the environment pollution and subsequent treatment energy consumption are reduced.

Owner:HENAN YONGWEI SECURITY

Release liners for pressure sensitive adhesive labels

InactiveUS6403190B1Easy transferReduce thicknessCoatings with pigmentsSynthetic resin layered productsEngineeringFacial tissue

A release liner for use with face stocks for pressure sensitive labels, tapes, decals and other products formed from sheet and roll stock. A filled polymer is laminated to one side of a paper web. An extrudate is laminated to the other side of the paper substrate to form a release liner. The filled polymer has paper-like properties and replaces paper tissue back liners.

Owner:FLEXCON

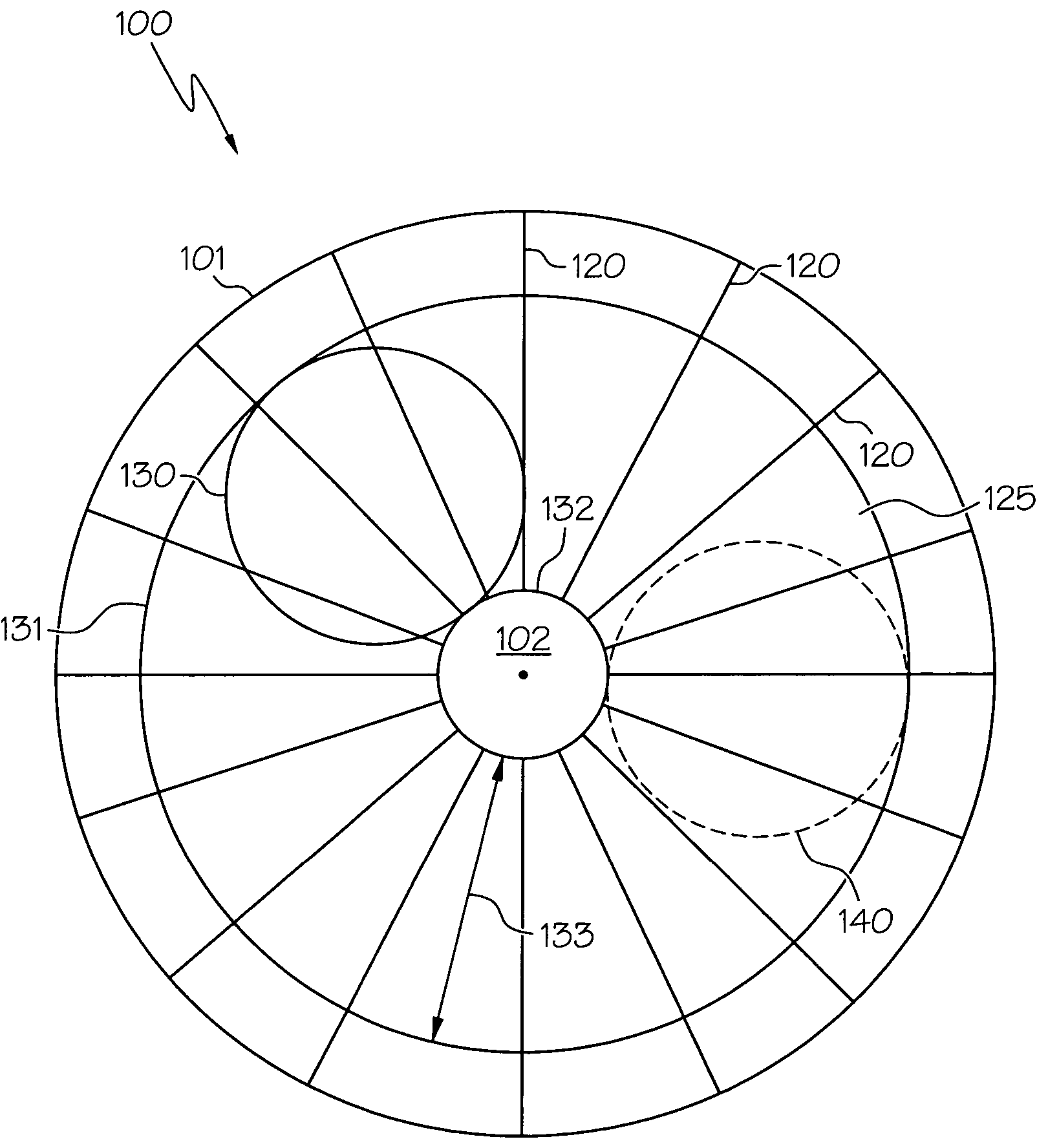

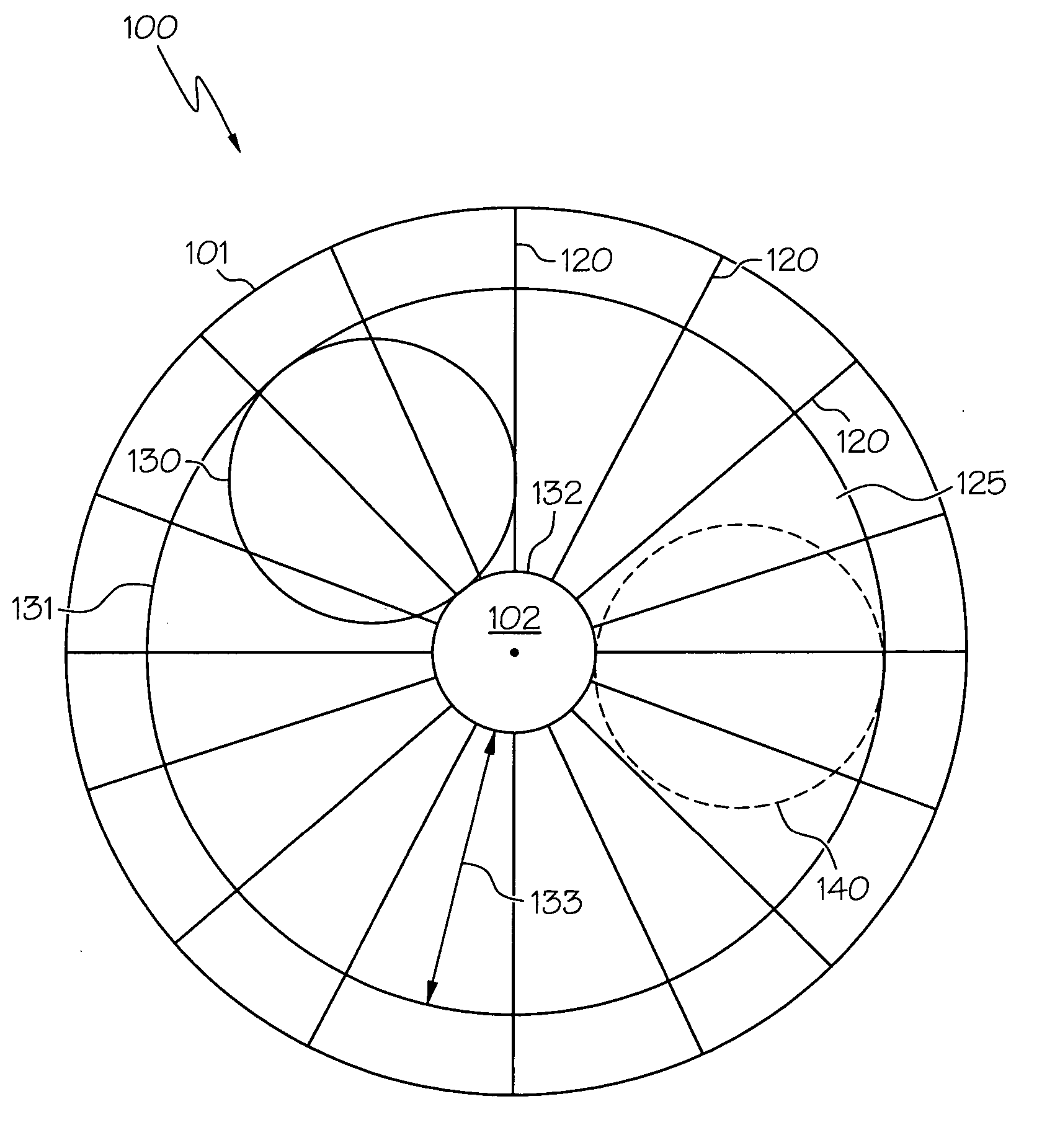

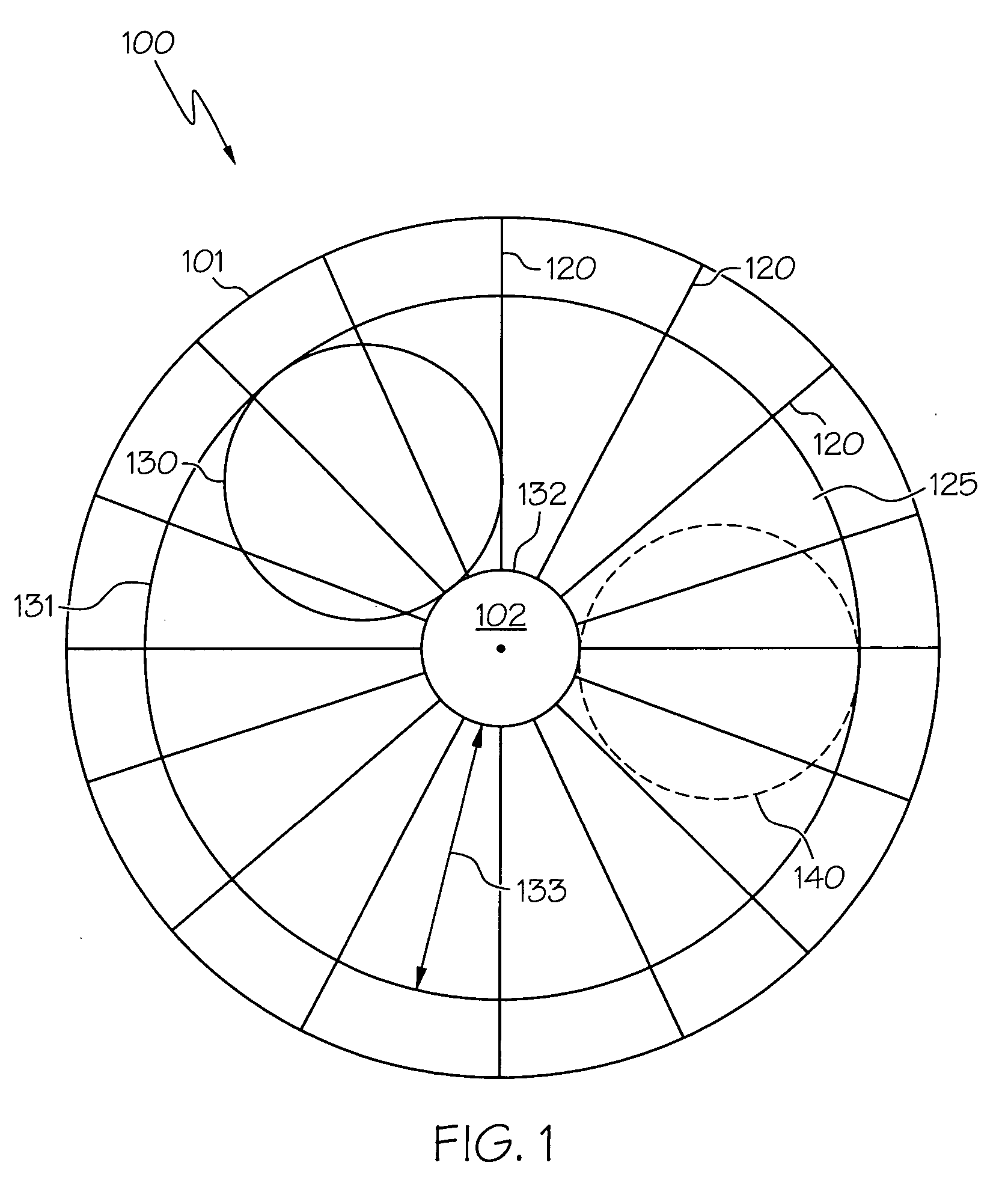

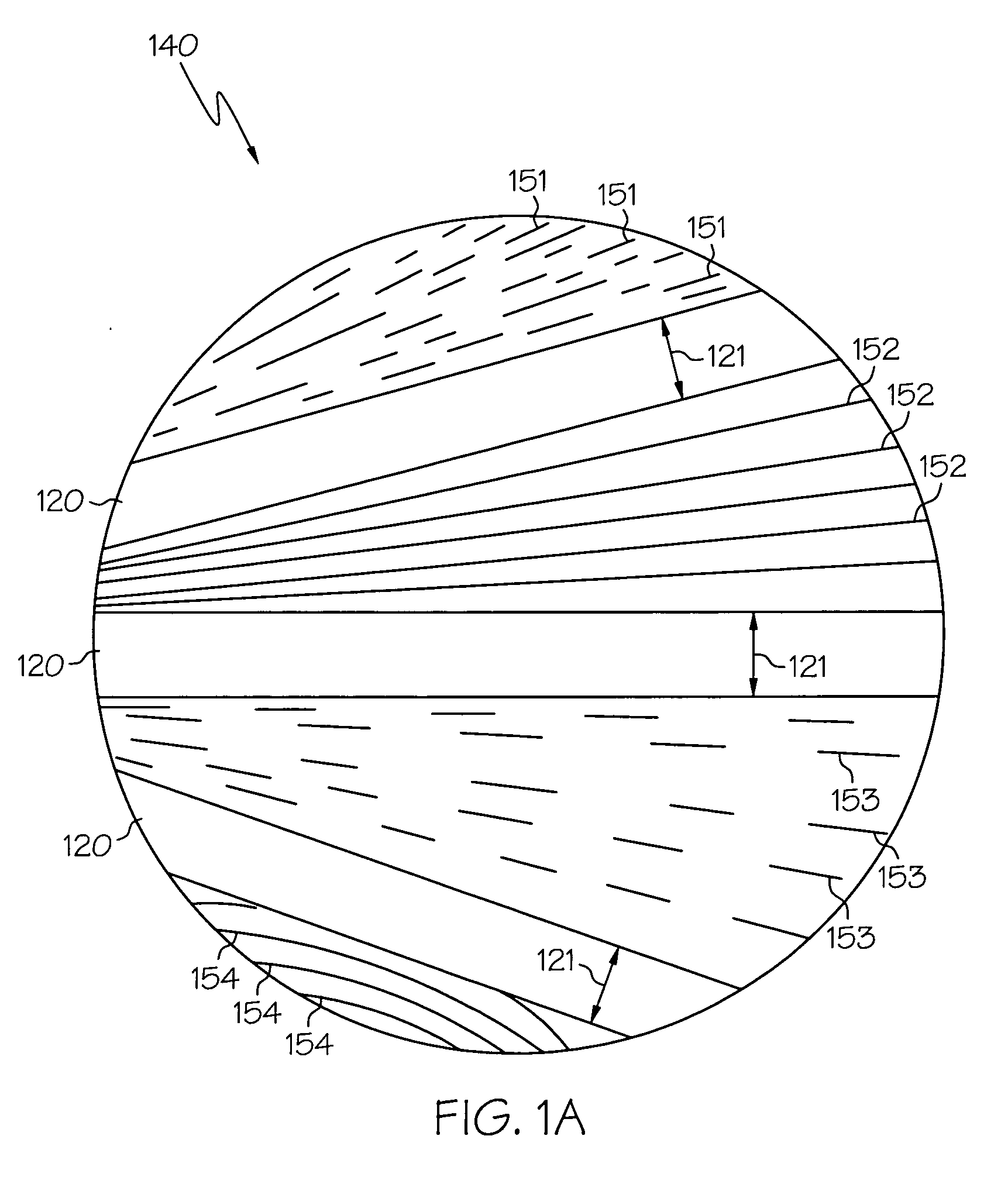

Radial-biased polishing pad

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

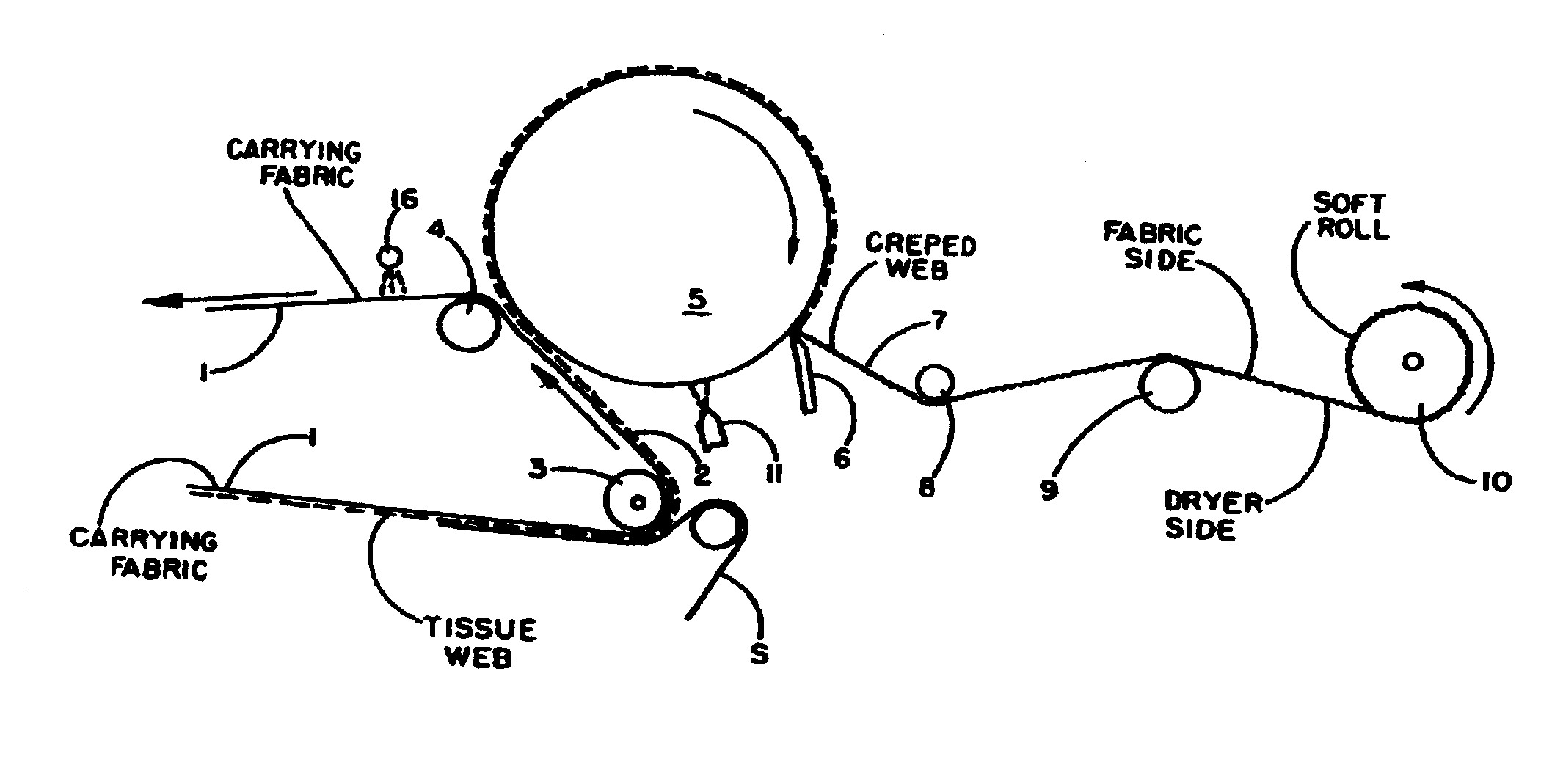

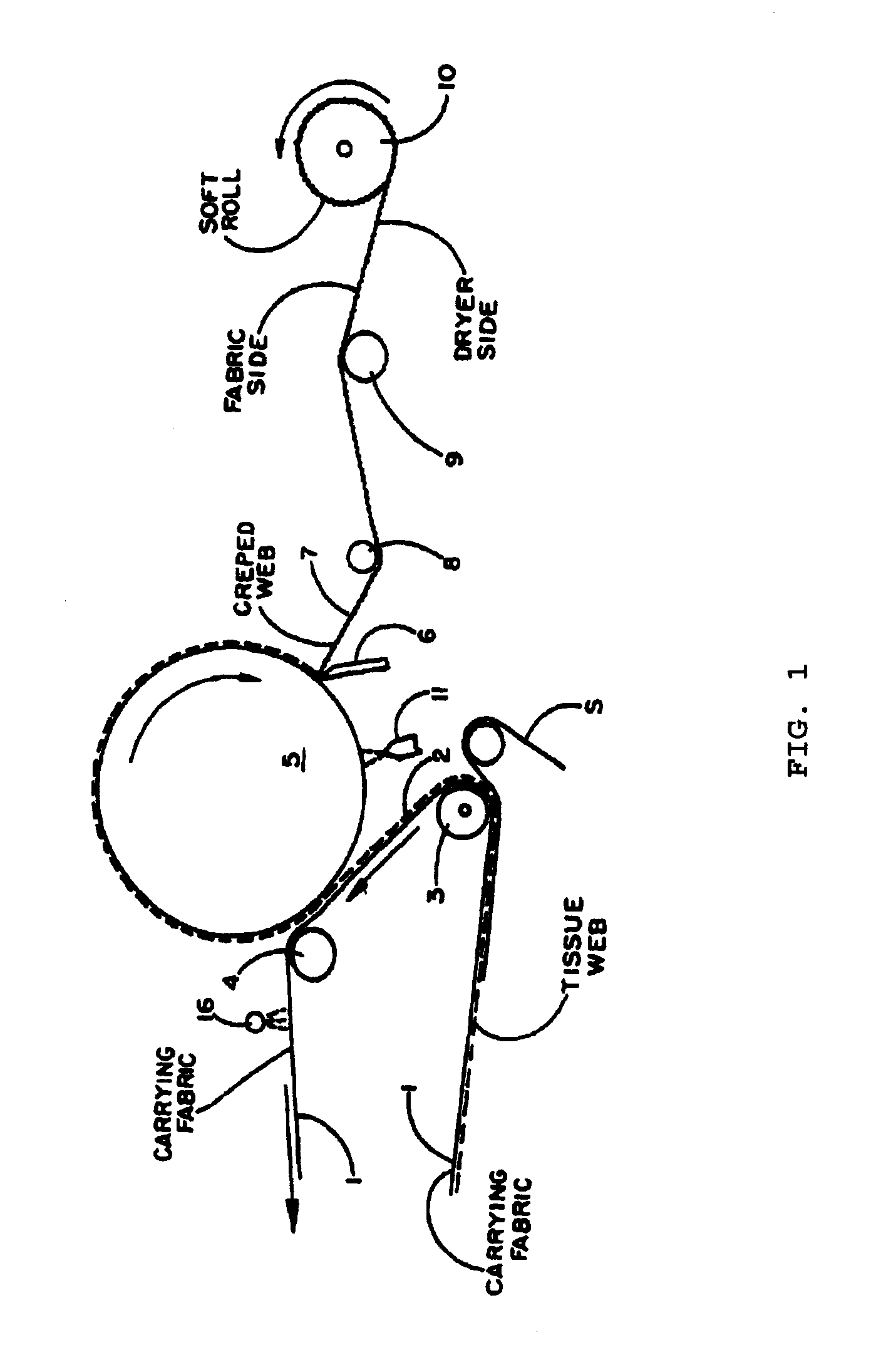

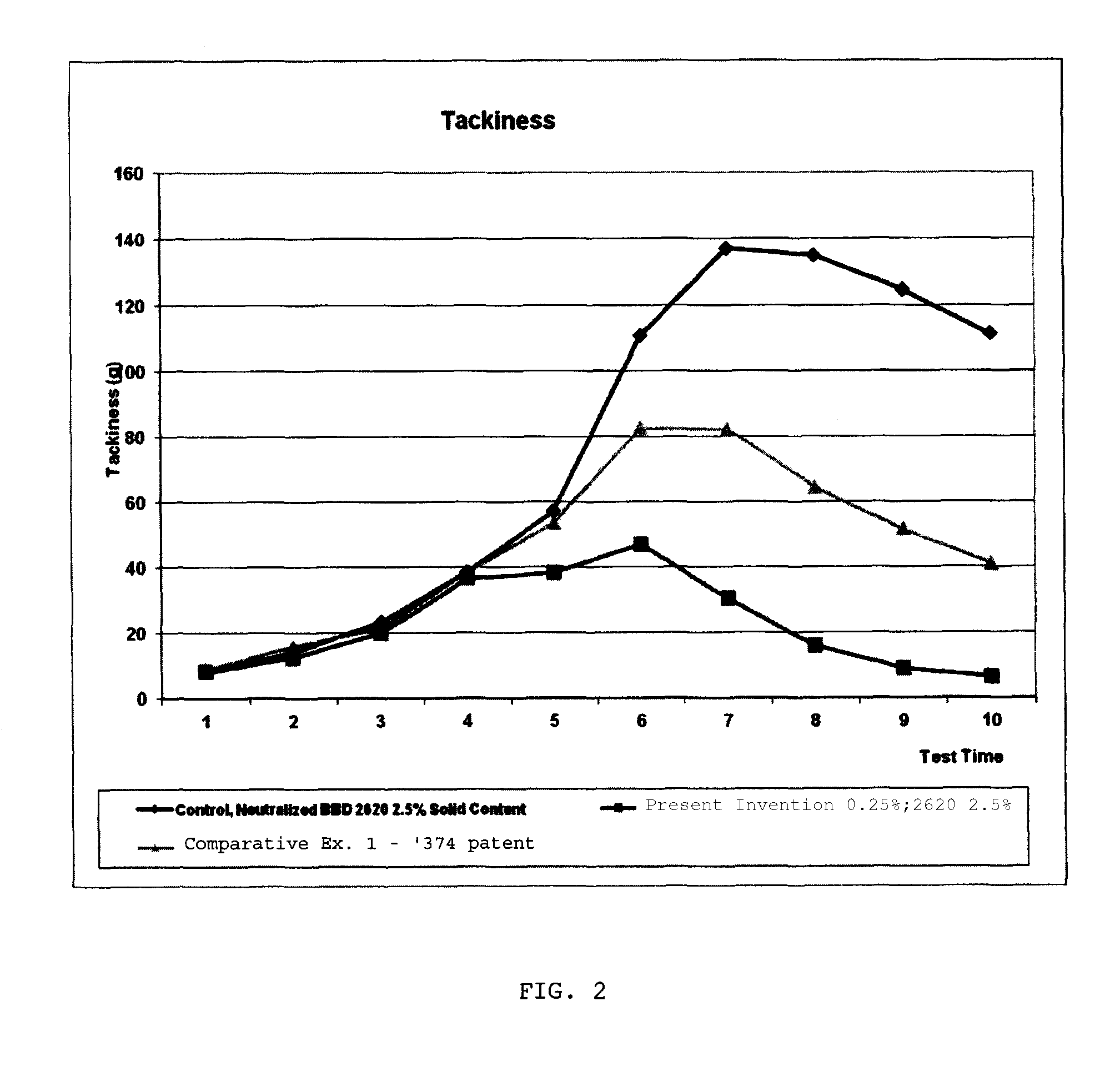

Oil-Based Creping Release Aid Formulation

InactiveUS20130048238A1Natural cellulose pulp/paperMechanical working/deformationPharmacologyCoating

An oil-based formulation useful as a creping release aid formulation or Yankee dryer coating composition is described. Methods of creping using the oil-based formulation are also described.

Owner:BUCKMAN LAB INT INC

Embossed release paper and process for producing the same

InactiveUS20100215911A1High solvent resistanceCost-effectiveMechanical working/deformationOrnamental structuresHeat resistancePaper based

This invention provides an embossed release paper that has high heat resistance and embossing properties. The embossed release paper comprises a paper base material, an ionizing radiation-cured resin layer, and a heat-cured silicone layer stacked in that order, the embossed release paper having embosses. The embossed release paper has high heat resistance and thus is suitable for use in synthetic leather production and melamine decorative sheet production that involve surface emboss pattern formation.

Owner:DAI NIPPON PRINTING CO LTD

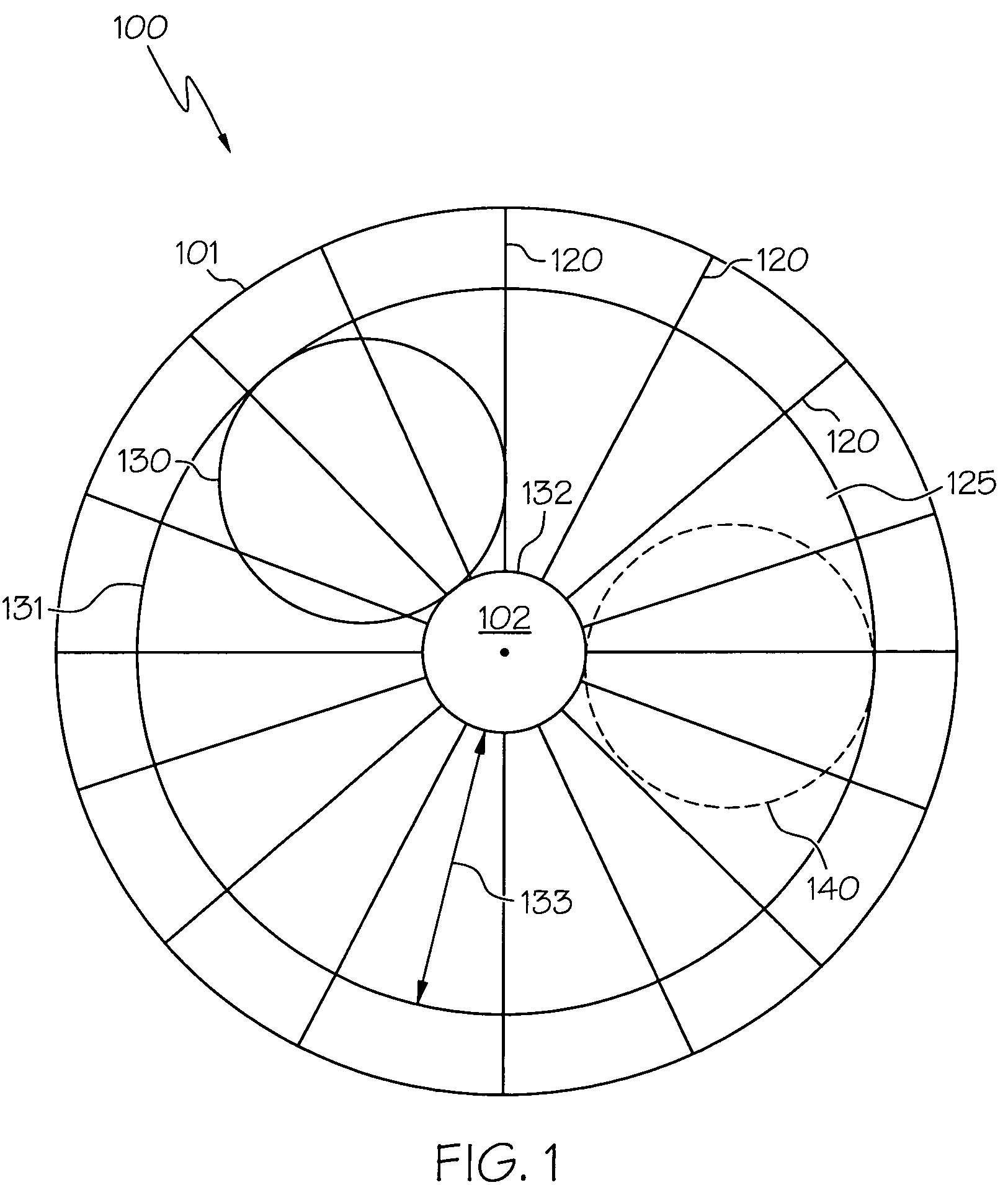

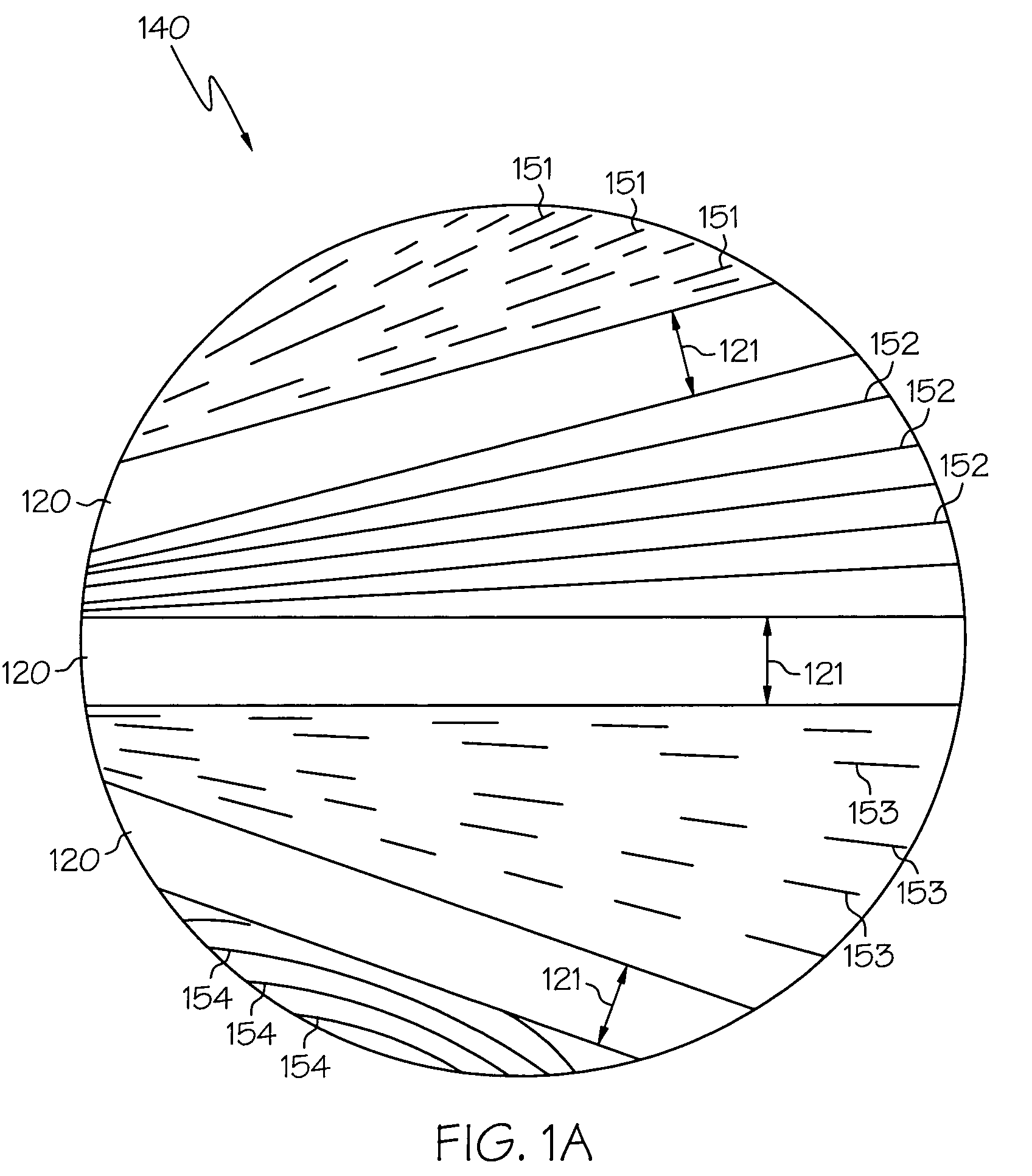

Radial-biased polishing pad

ActiveUS20060229002A1Great degree of planarityAbrasion apparatusRelease paperEngineeringSemiconductor

The polishing pad is useful for polishing magnetic, optical and semiconductor substrates. The pad includes a polishing layer having a rotational center and an annular polishing track concentric with the rotational center and has a width. The width of the annular polishing track is free of non-radial grooves. And the pad has a plurality of radial micro-channels in the polishing layer within the width of the annular polishing track with a majority of the radial micro-channels having primarily a radial orientation and an average width less than 50 μm.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

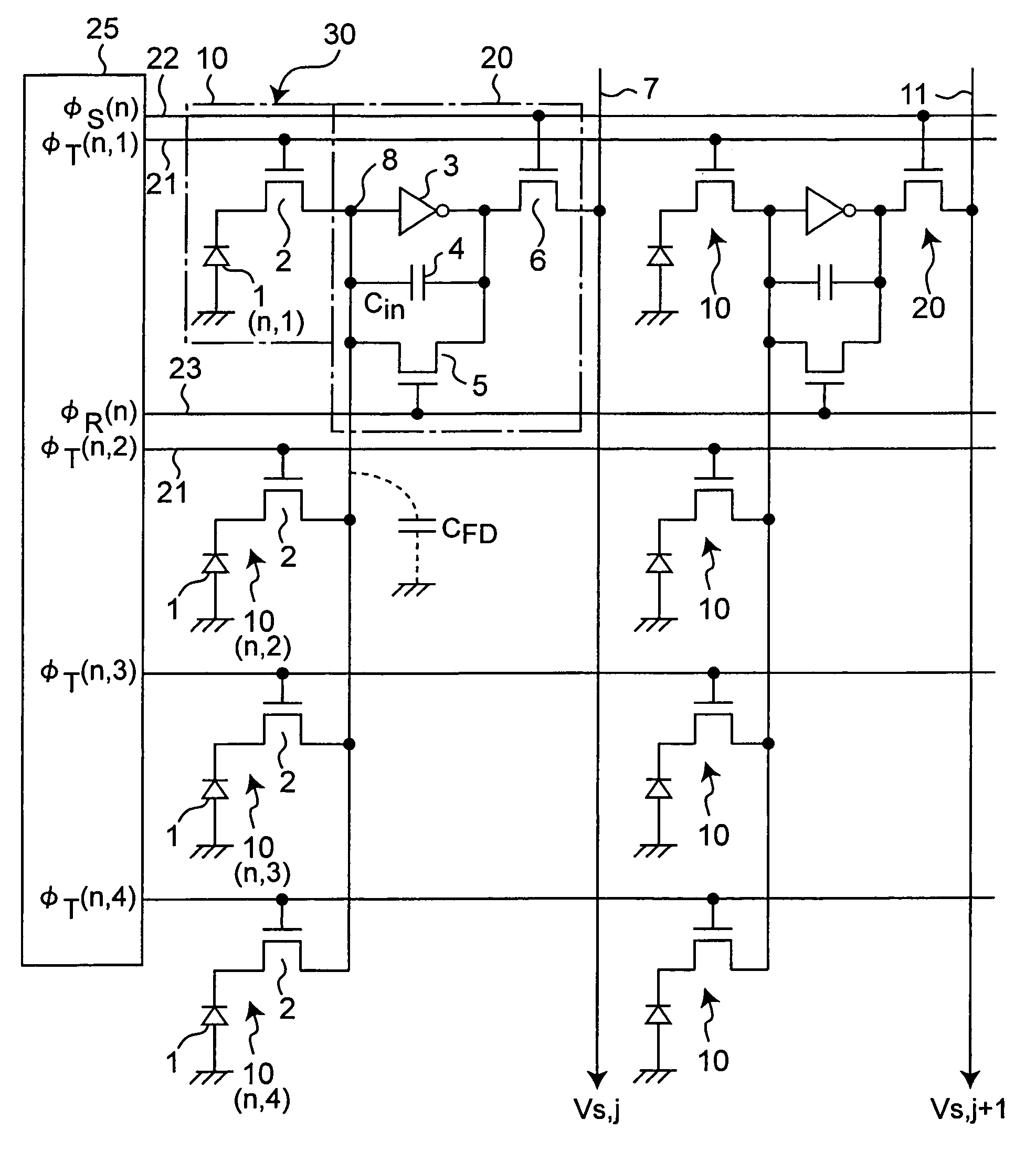

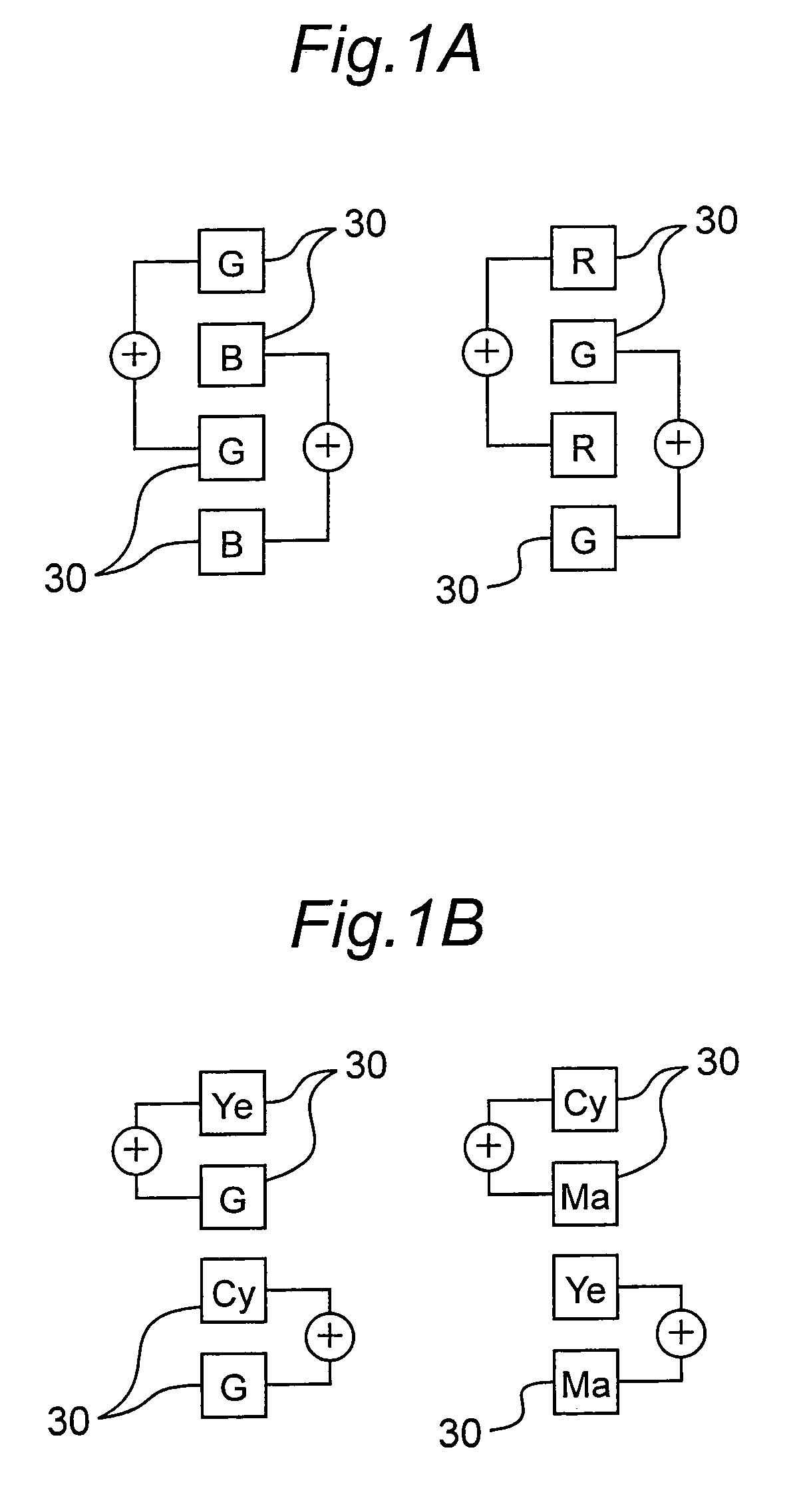

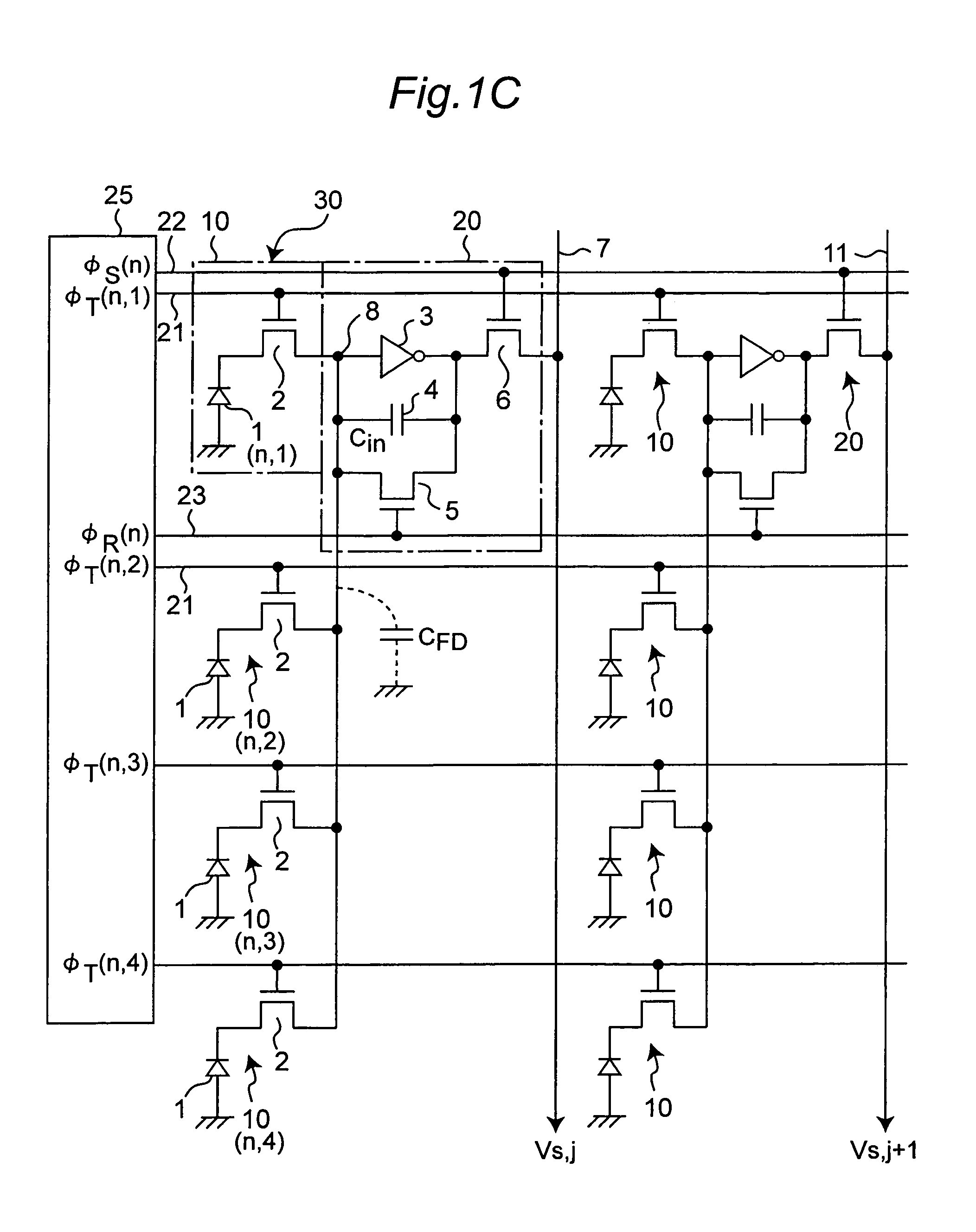

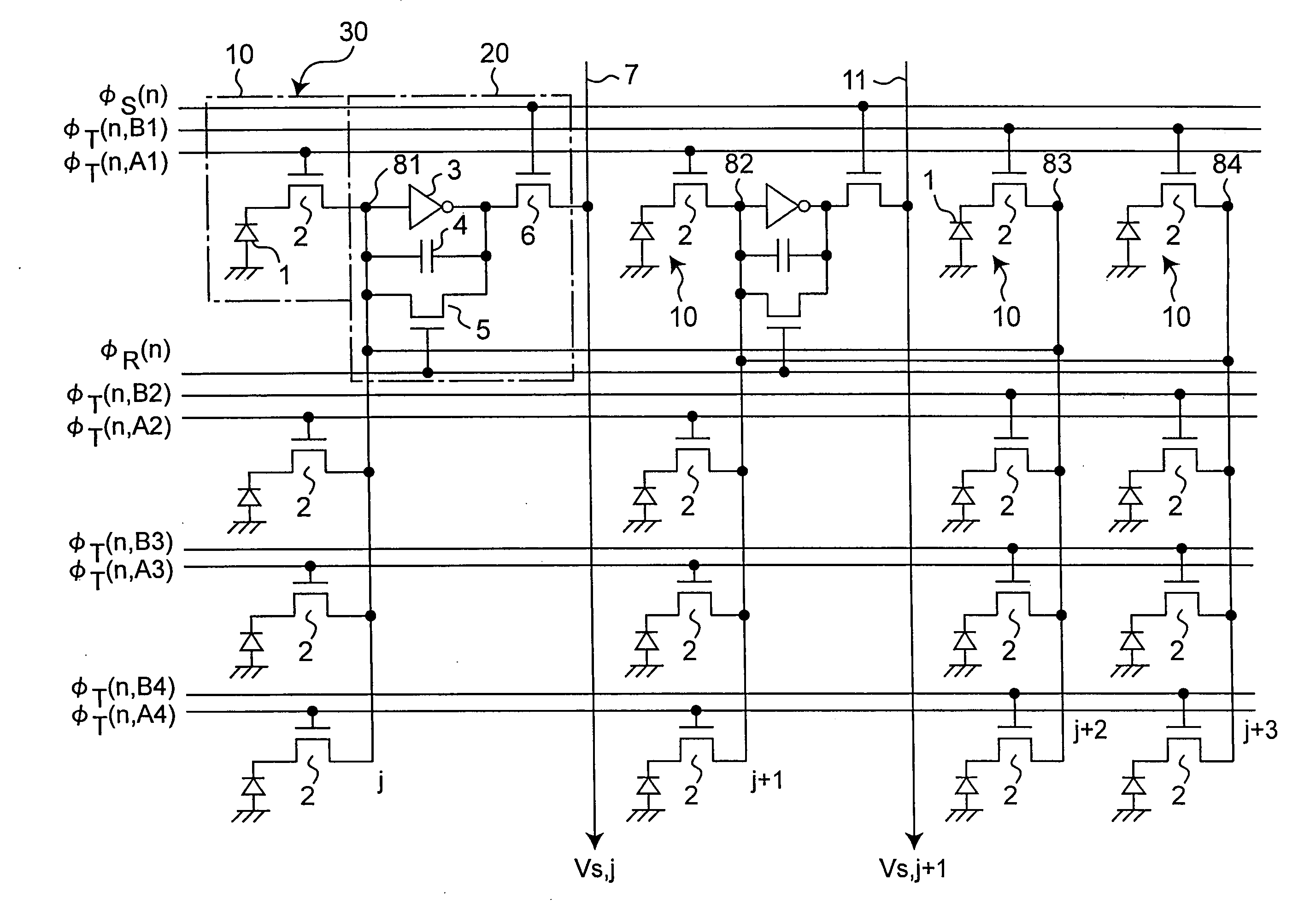

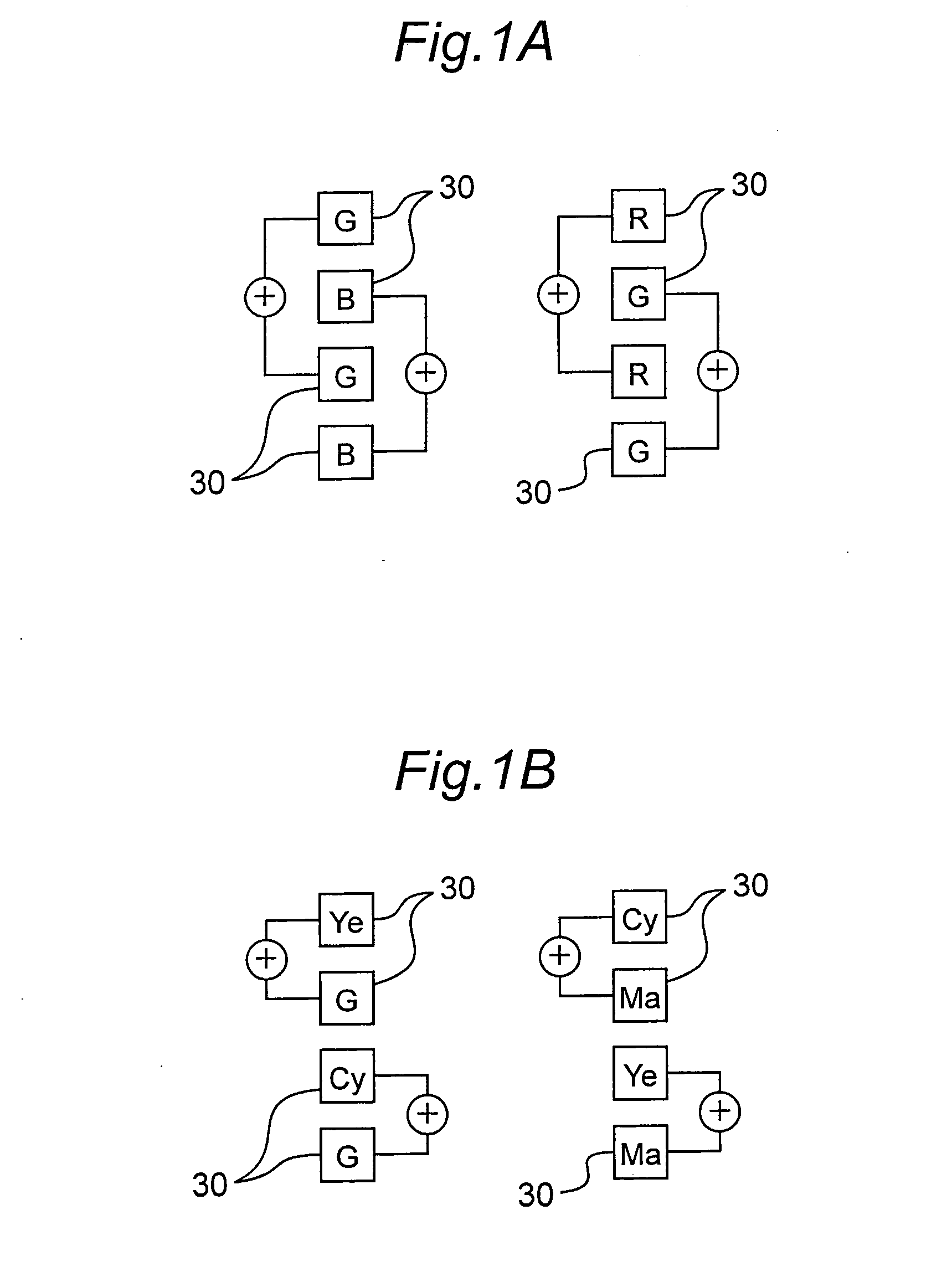

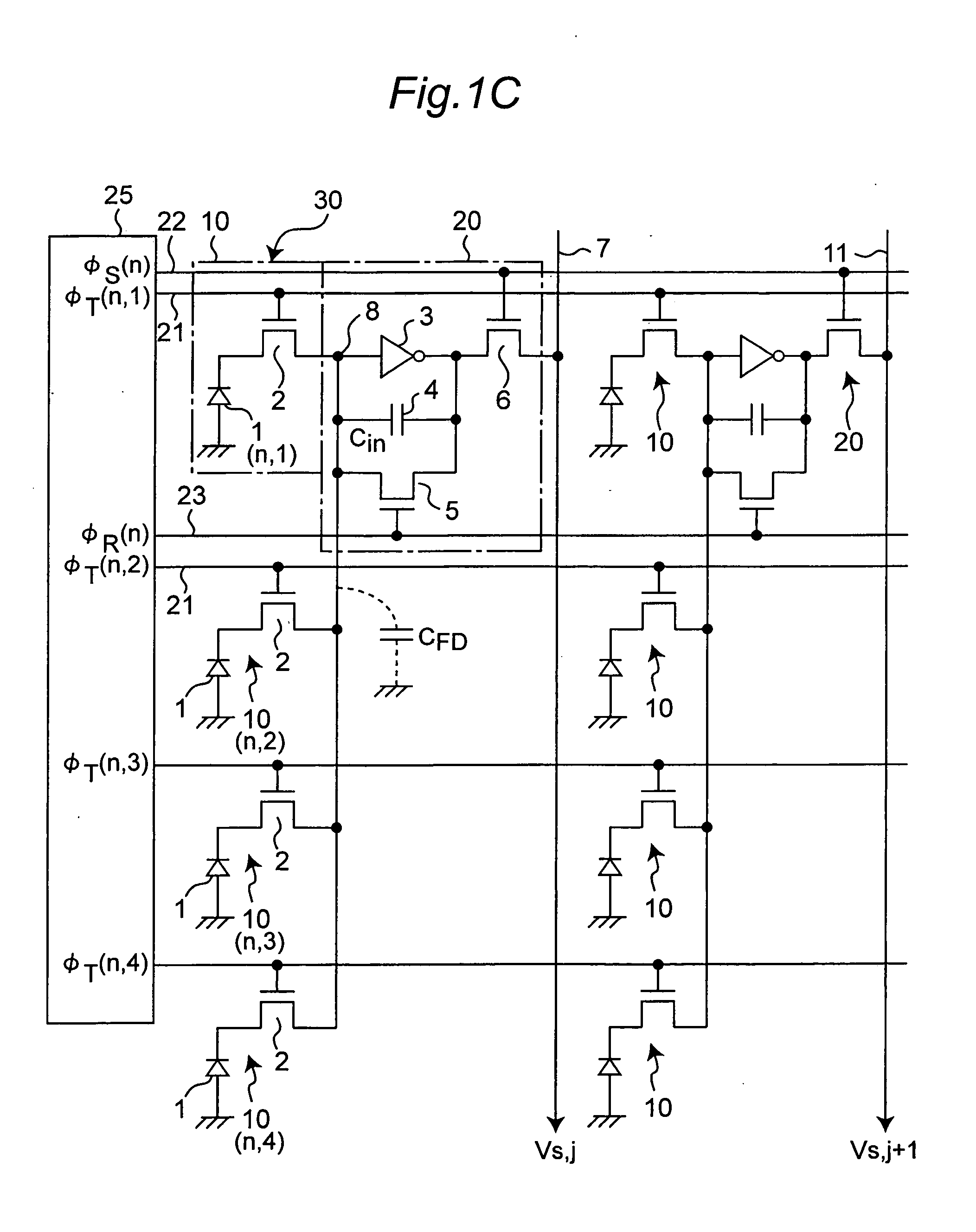

Amplifying solid-state image pickup device

InactiveUS6992341B2Improve convenienceEfficient conversionTelevision system detailsTelevision system scanning detailsPhotodiodeSwitched capacitor

There is provided an amplifying solid-state image pickup device capable of improving S / N and maintaining a charge-voltage conversion efficiency high. In the amplifying solid-state image pickup device, signal charges of a plurality of photodiodes 1 are added up on an input side of a switched capacitor amplification part 20 via the transfer transistors 2.

Owner:SHARP KK

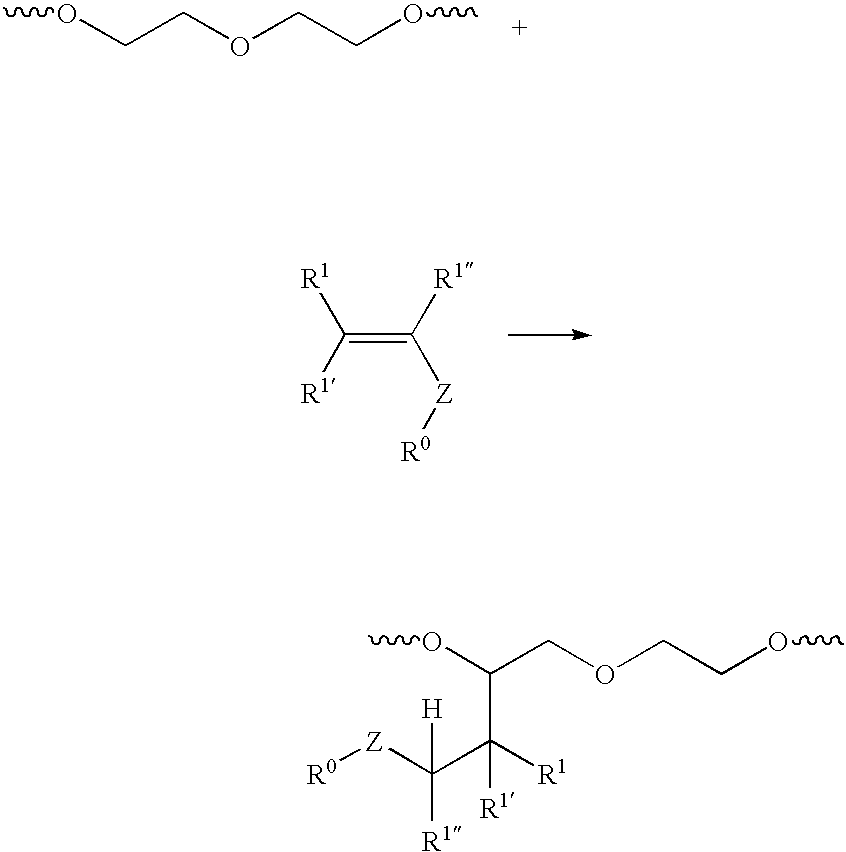

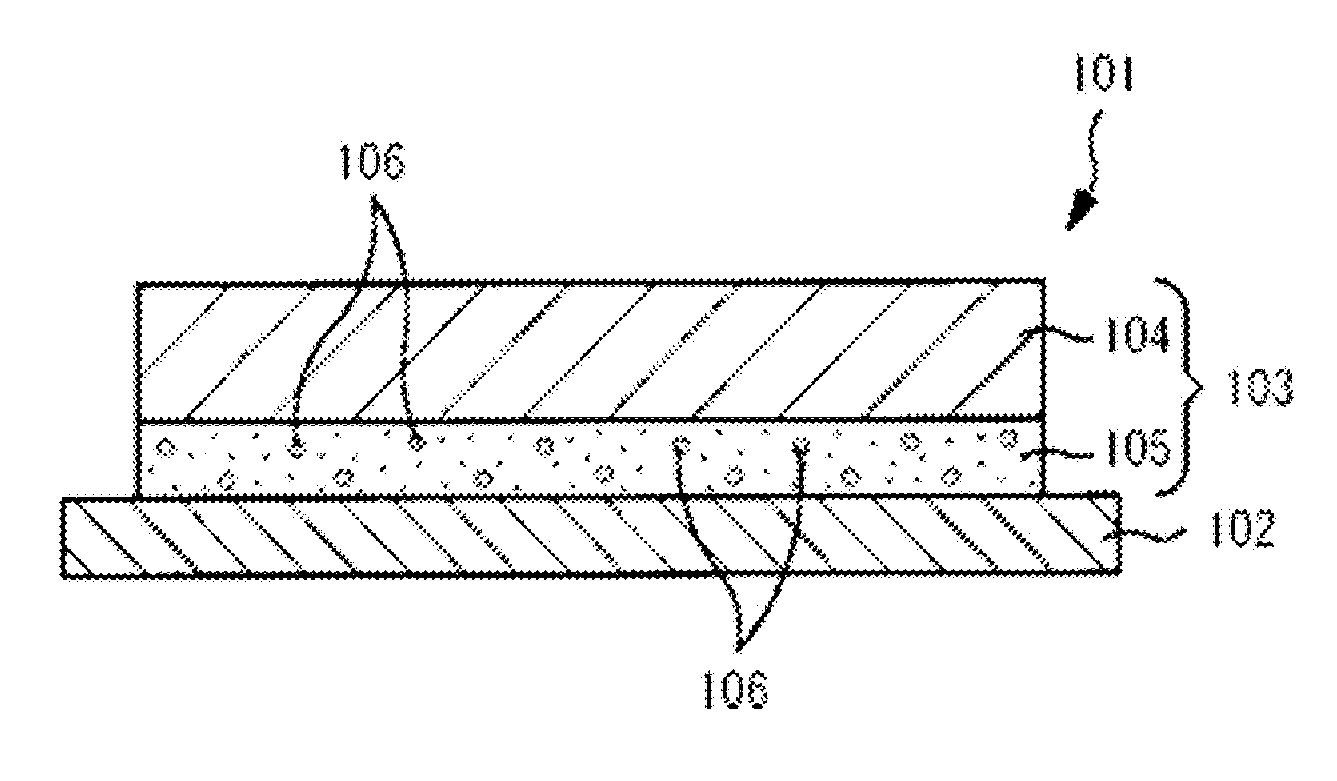

Paper release compositions having improved adhesion to paper and polymeric films

The present invention relates to curable alkenyl based silicone release coating compositions having improved adhesion to paper and polymeric substrates. Furthermore the present invention relates to the process for making a silicone release coating with improved adhesion to paper and polymeric substrates.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Wiping products having a low coefficient of friction in the wet state and process for producing same

InactiveUS7147751B2Feel goodNatural cellulose pulp/paperPaper after-treatmentPolyethylene oxideEthylene oxide

Base sheets are disclosed having a reduced coefficient of friction in the wet state. In accordance with the present invention, the base sheets can be treated with a high molecular weight polyethylene oxide, a derivatized polyethylene oxide or an acrylate copolymer containing polyethylene moieties. The base sheet can be single ply or multi-ply. The base sheet can be a tissue product, such as a facial tissue, a bath tissue, or a paper towel. Alternatively, the base sheet can be a pre-moistened wipe.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Peelable laminate and process of making the same

A peelable laminate includes a pulp paper-based substrate having a treated side to prevent undue adhesion to pulp fibers extending from the side and a polymer coating applied to the treated side in a manner such that the polymer coating is adhered to the treated side in a peelable manner.

Owner:EXACT PRODS

Sewing-free hot melt adhesive TPU leather and preparation method thereof

ActiveUS20160215174A1Excellent physicochemical performanceHigh bonding strengthFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The present invention provides a novel sewing-free hot melt adhesive TPU leather and a preparation method thereof. The hot melt adhesive TPU leather comprises a release paper, a hot melt adhesive film, and a TPU film. The release paper comprises a bottom paper layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material comprises polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; and a TPU raw material comprises polymer polyol, 1,4-cyclohexane-diisocyanate, a chain extender, and a plurality of functional additives. According to the present invention, innovations are conducted on raw material components of the release paper, the hot melt adhesive, and the TPU film, and extrusion shaping is conducted by utilizing the hot melt adhesive with strong plasticity and the TPU thin film; and the prepared sewing-free TPU leather has the technical advantages of firm adhesion, durability, environmentally-friendly materials, no invisible harm to human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Label, printing paper top layer formation material, information-bearing medium, wristband clip, and carbon dioxide reduction method using same

ActiveUS20130287986A1Reduction in carbon dioxideStampsCarbon compoundsCarbon dioxide absorberChemistry

Provided is one of labels 101, 120, 130 and 140, top layer materials formed on a printing medium 201, 246 and 266, information-bearing media 301, 330, 350 and 360, a solid fuel 401, and a wristband clip 510, having the function of absorbing carbon dioxide to which a new carbon dioxide absorbent is added. Provided are also carbon dioxide reduction methods of absorbing carbon dioxide by burning the same.

Owner:SATO HLDG CORP

Composite sheet, method of preparing same, and adhesive label sheet assembly having same

InactiveUS6846538B2Good light transmissionGood disintegrationNon-fibrous pulp additionFilm/foil adhesivesTransmittanceEngineering

A composite sheet including a paper layer made of a wood pulp having a Canadian standard freeness value of 350 to 500 ml, a transparency improving layer provided over one side of the paper layer, and a release liner provided over the transparency improving layer. The composite sheet has a transmittance of at least 10 to 20% for a light with a wavelength of 940 to 960 nm and a bulk density of 0.90 to 1.15 g / cm3. A thermosensitive recording adhesive label sheet has the above composite sheet and a thermosensitive recording sheet provided on the composite sheet through an adhesive layer.

Owner:RICOH KK

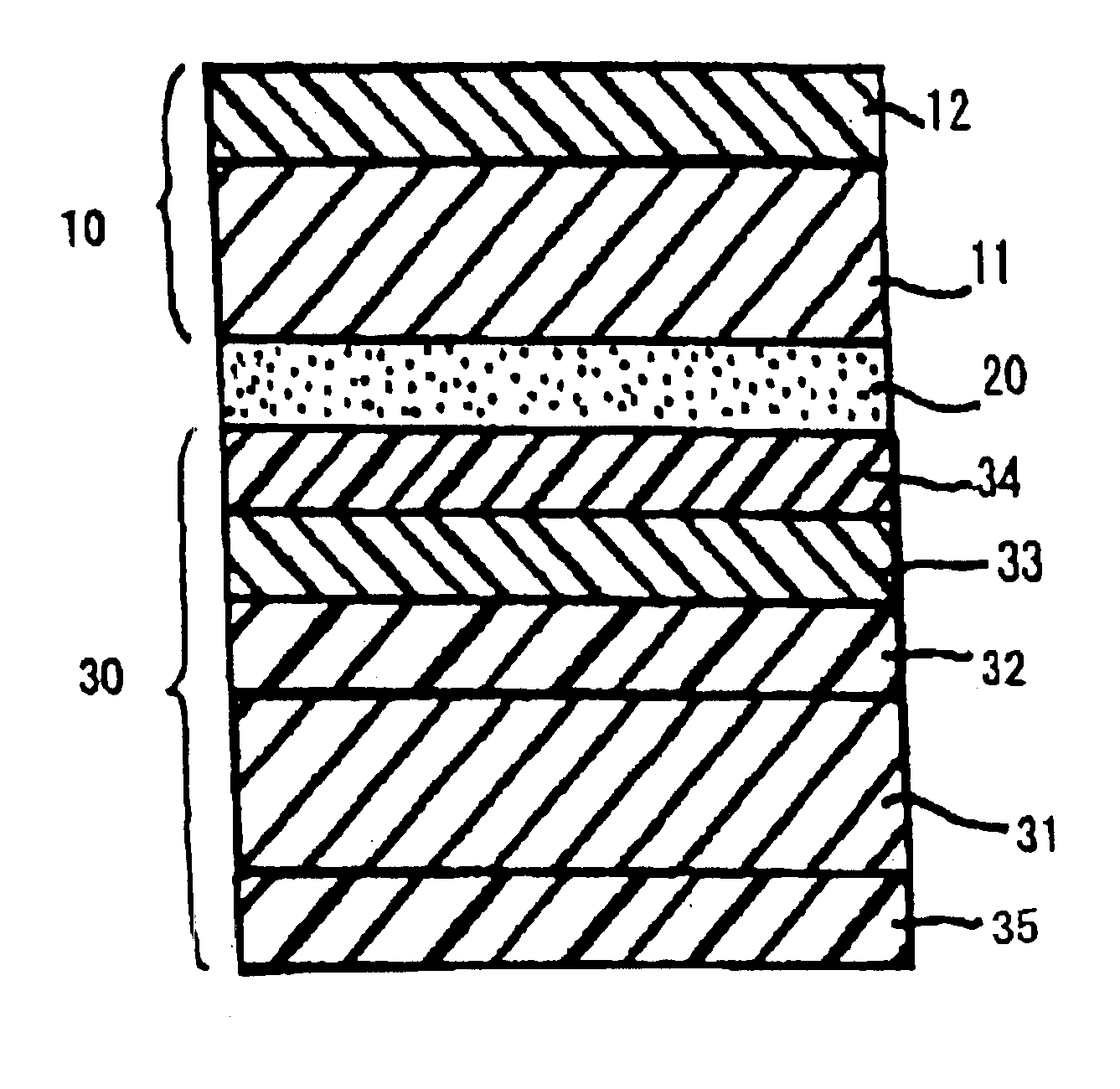

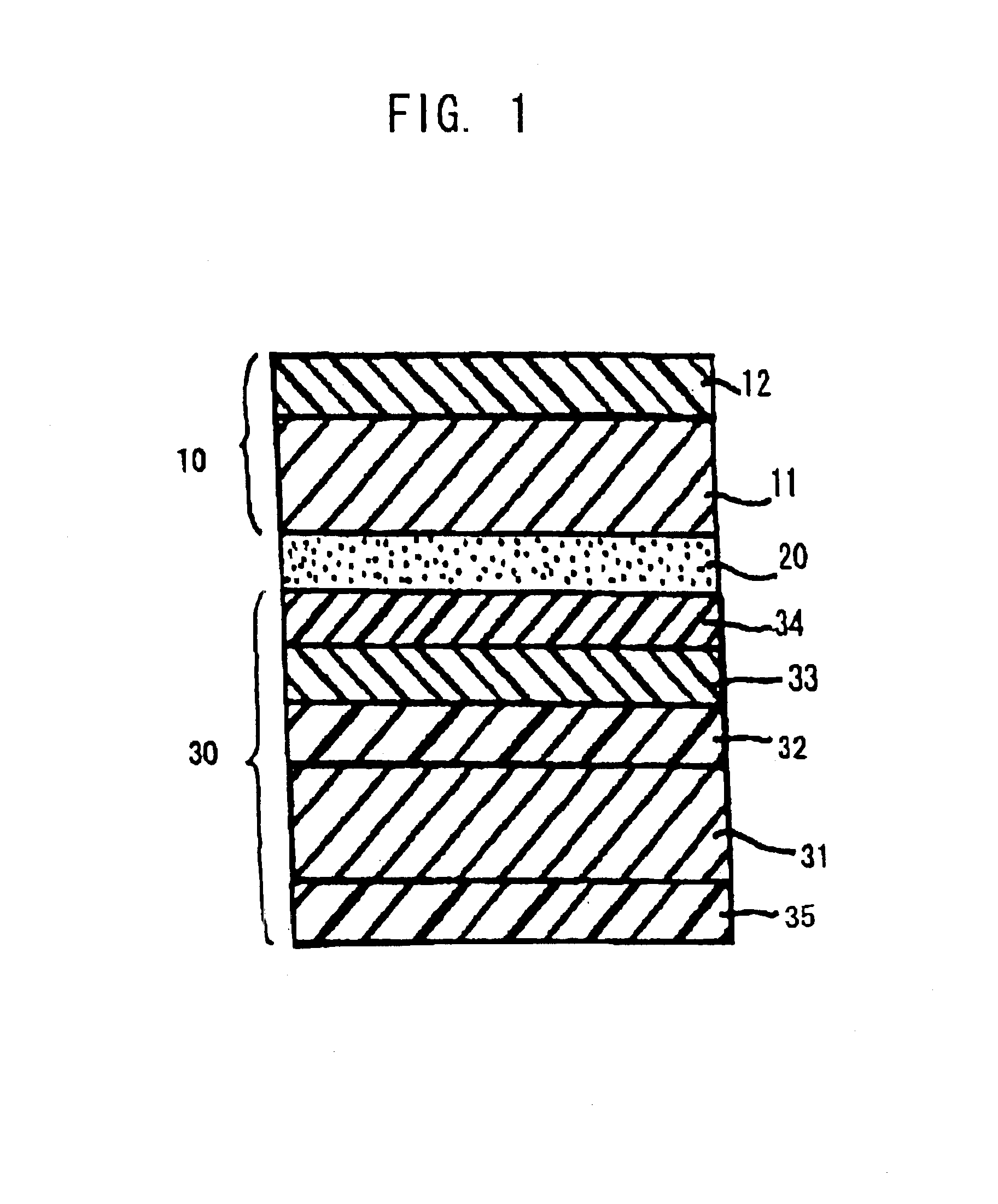

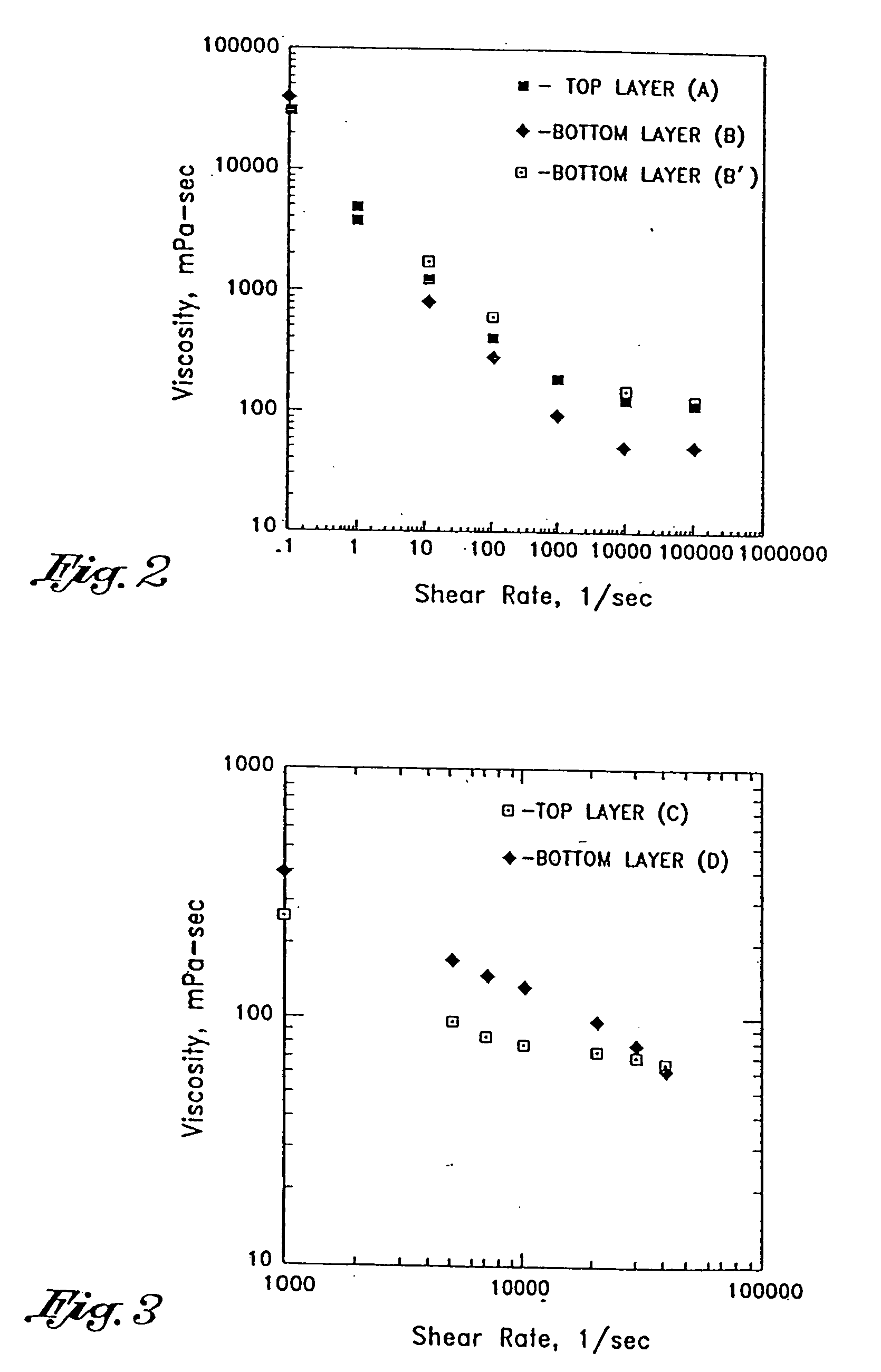

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050100677A1Low costShorten the timeLiquid surface applicatorsFilm/foil adhesivesBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

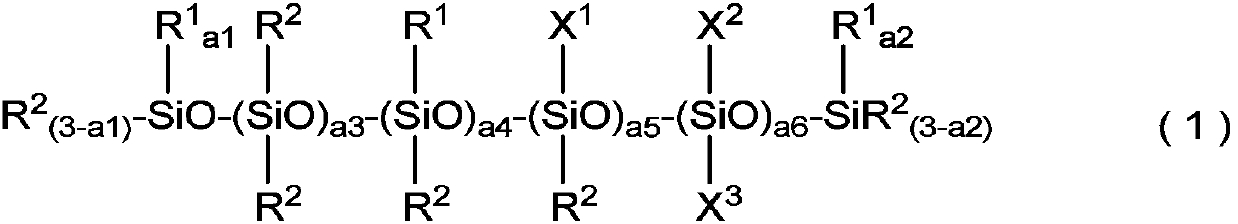

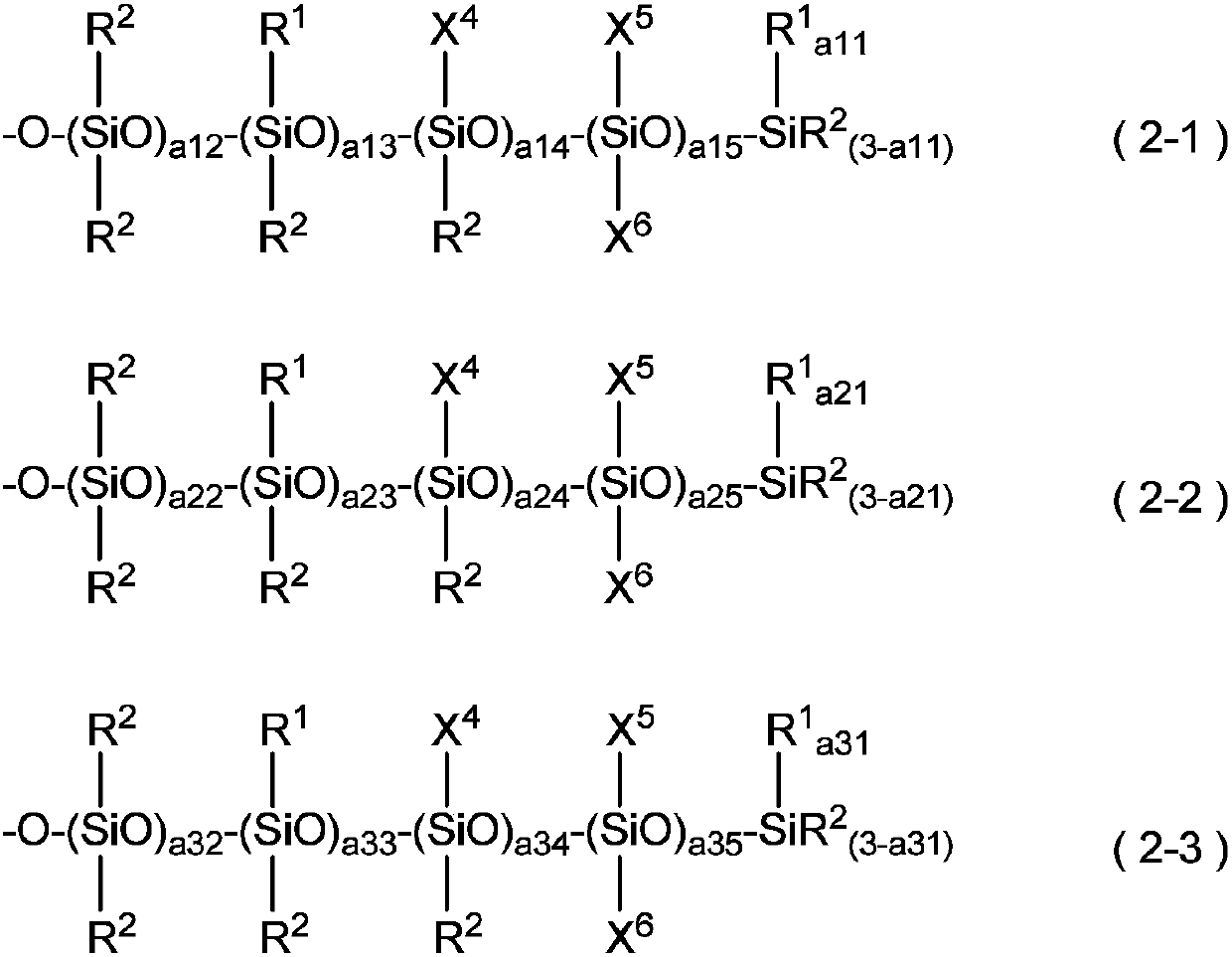

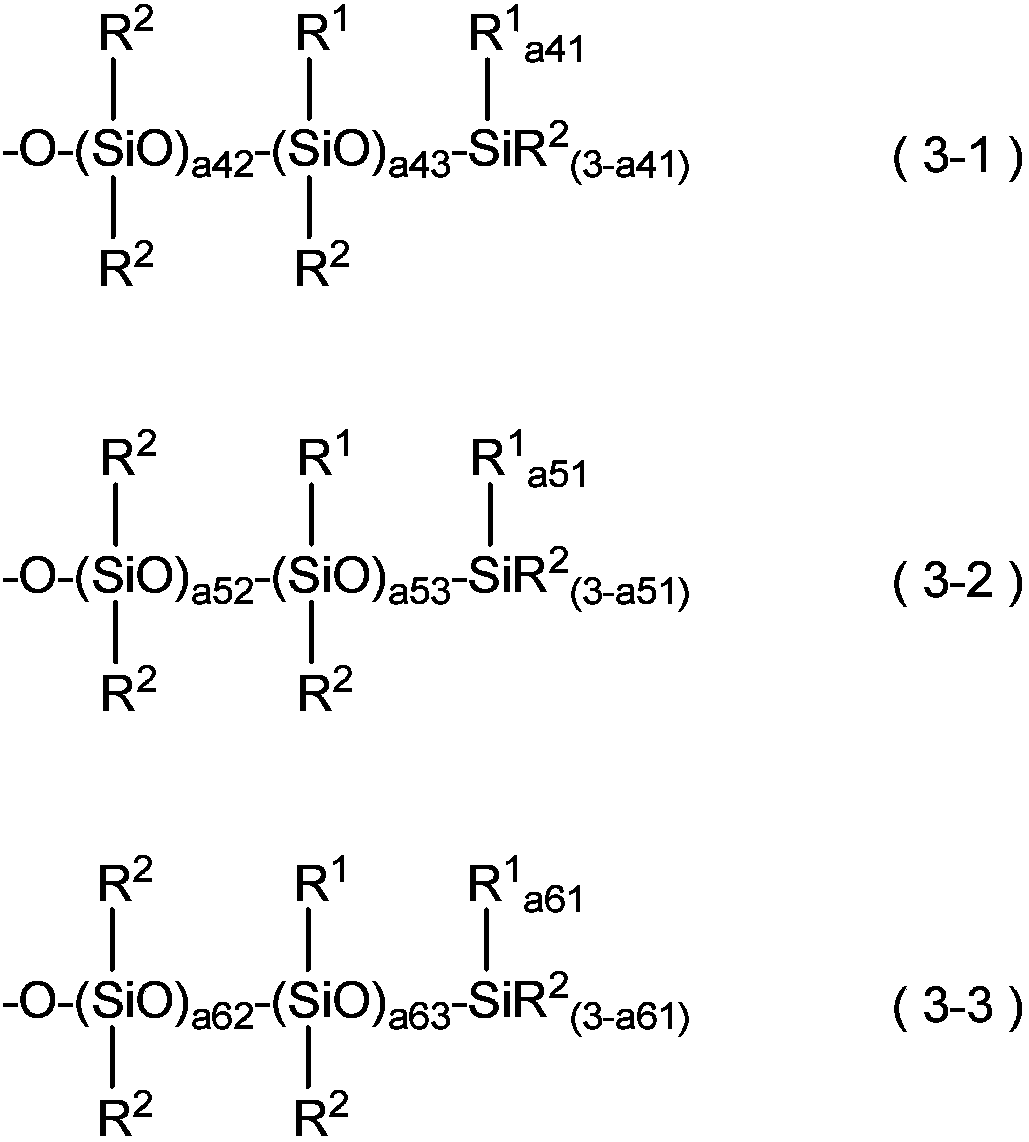

Silicone composition for release paper or release film, release paper, and release film

ActiveCN107636108AExcellent curabilityImprove curing effectOther chemical processesSynthetic resin layered productsPolymer scienceAdhesive

Provided are: an additive reaction-type silicone composition that is for release paper or for a release film, that is non-migratory, and that exhibits light releasability with respect to various adhesives, said silicone composition for release paper or for a release film making it possible to form a cured film that does not adversely affect residual adhesive strength or releasability; and a release paper or a release film obtained by applying the composition to a substrate and curing the result. In a silicone composition for release paper or a release film cured by additive reaction, an organopolysiloxane containing an alkenyl group having a terminal unsaturated bond is used as a base polymer, and a specific amount of an organopolysiloxane that has a lower molecular weight than the base polymer and that contains an alkenyl group having a terminal unsaturated bond is mixed with the base polymer.

Owner:SHIN ETSU CHEM CO LTD

Amplifying solid-state image pickup device

InactiveUS20050185073A1Enhancing S/N improvement effectKeeping charge-voltage conversion efficiencyTelevision system detailsTelevision system scanning detailsEngineeringPhotodiode

There is provided an amplifying solid-state image pickup device capable of improving S / N and maintaining a charge-voltage conversion efficiency high. In the amplifying solid-state image pickup device, signal charges of a plurality of photodiodes 1 are added up on an input side of a switched capacitor amplification part 20 via the transfer transistors 2.

Owner:SHARP KK

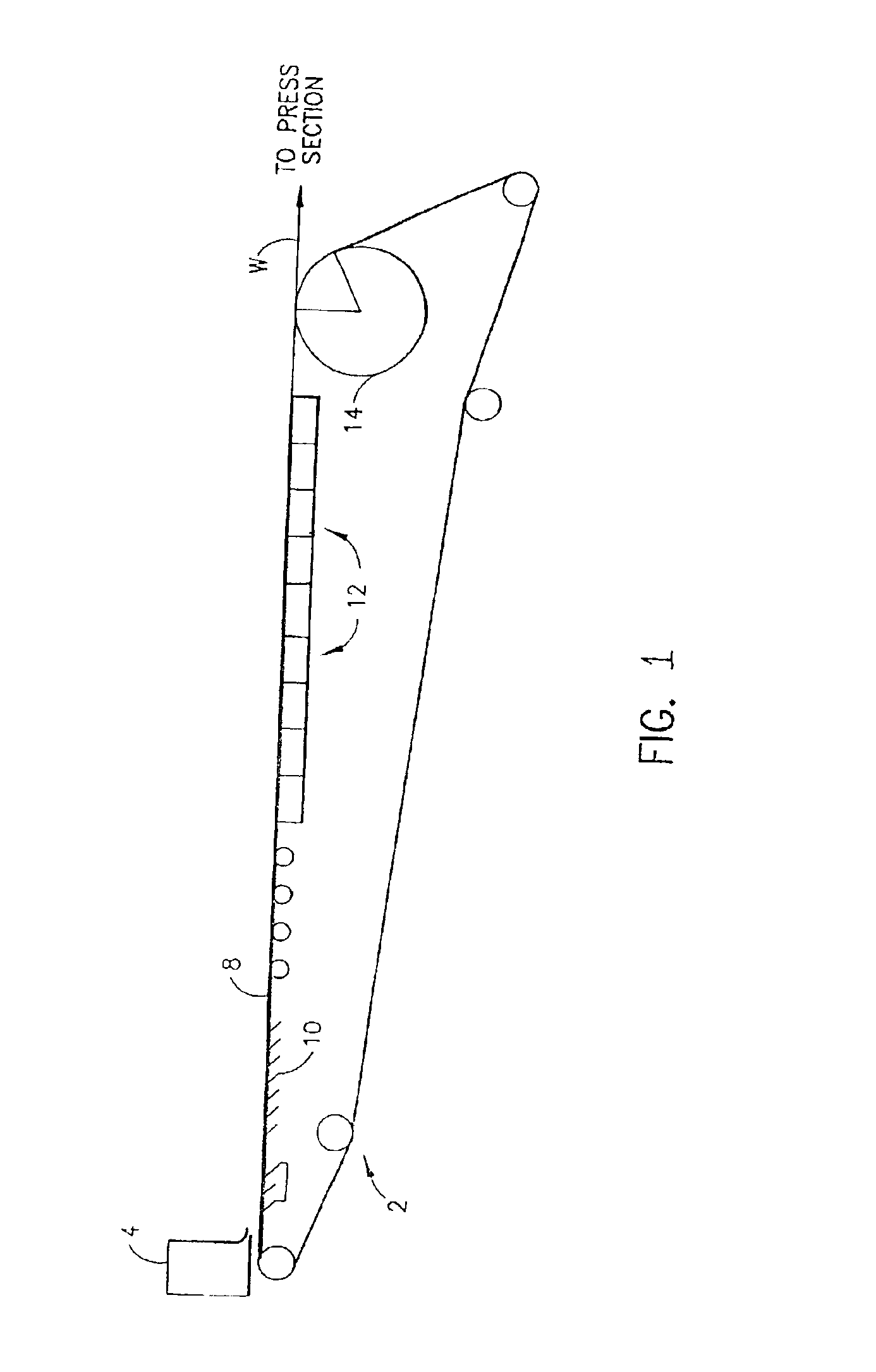

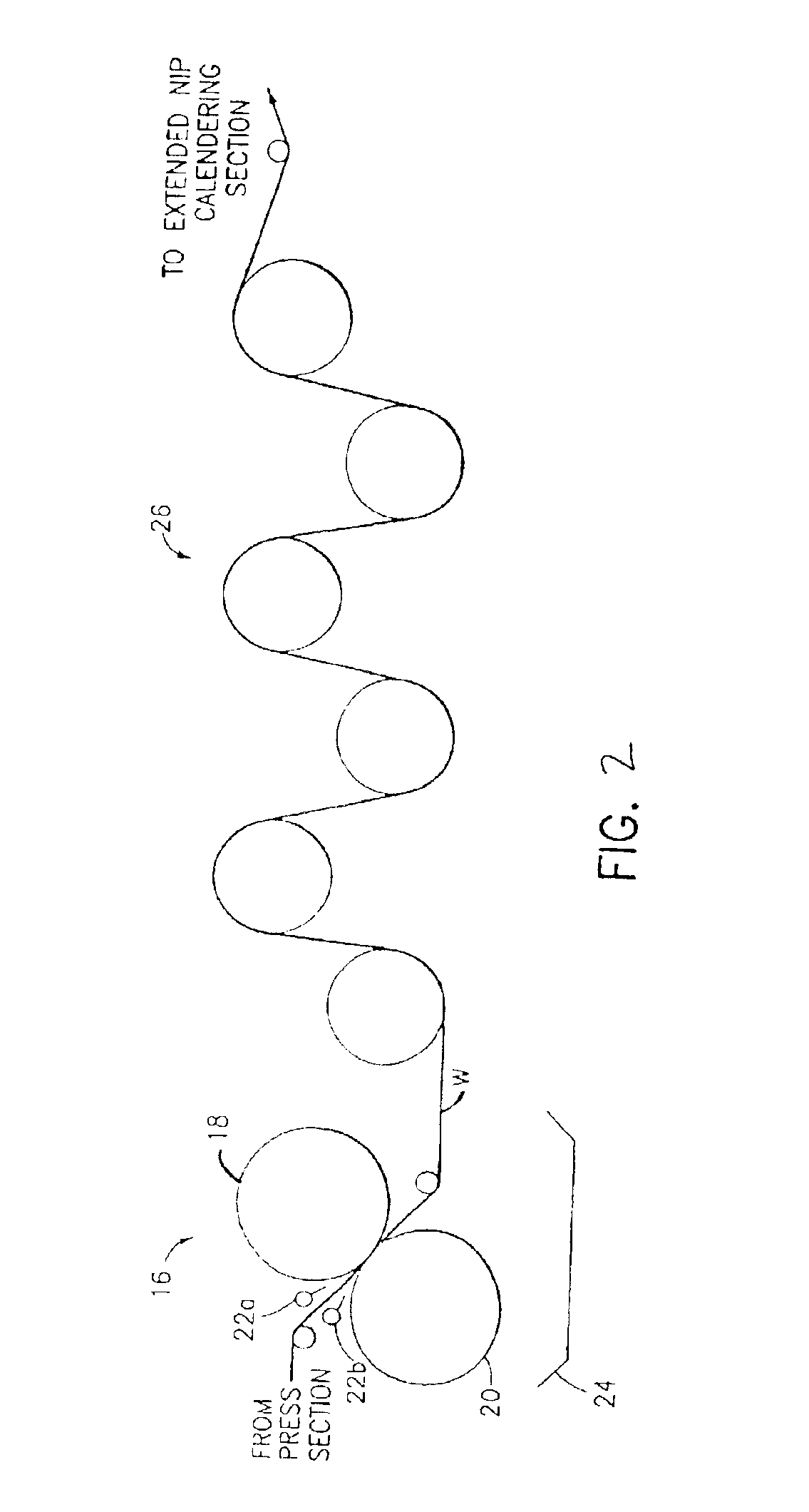

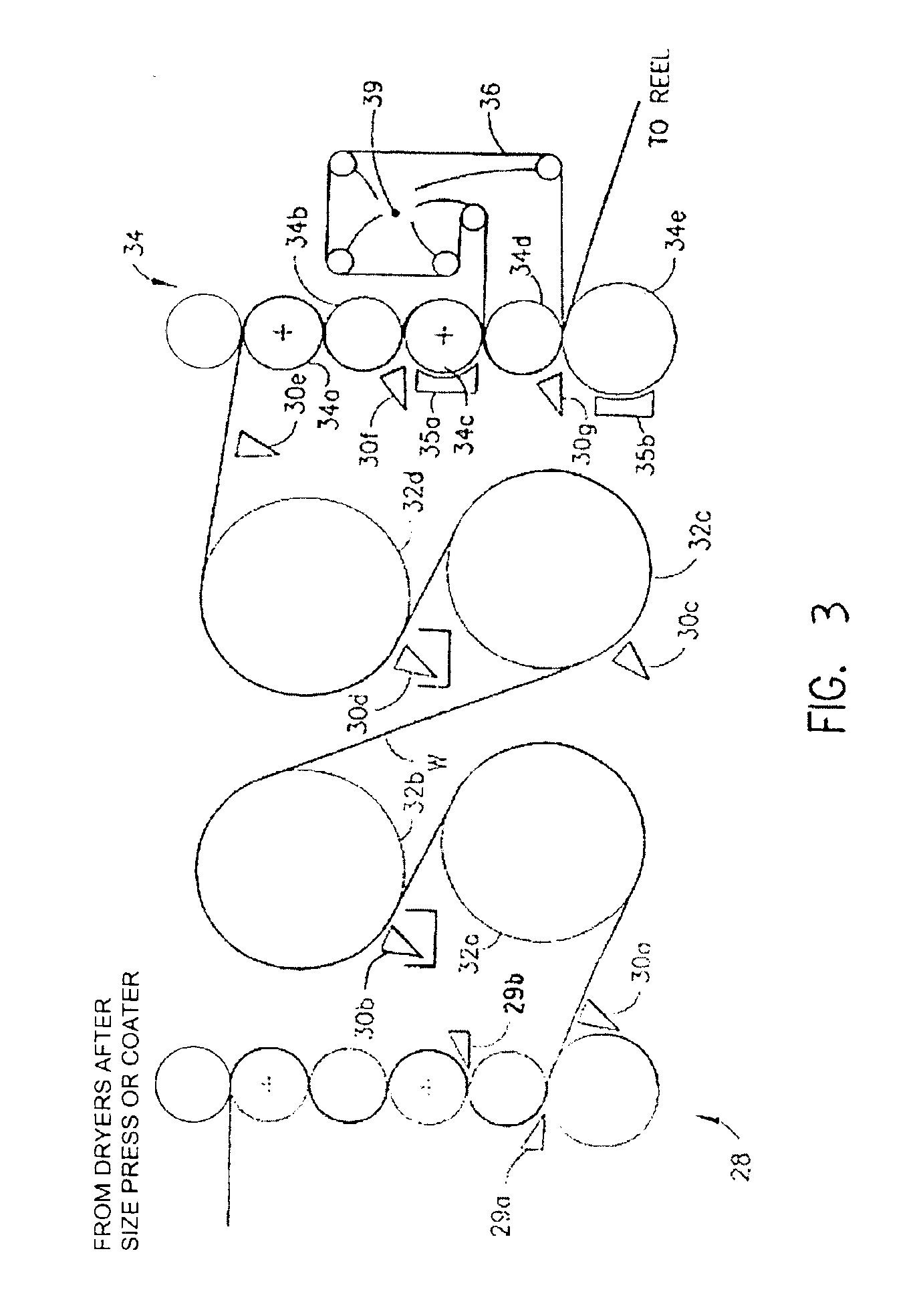

Uncoated facestock for adhesive-backed labels

InactiveUS6946186B2Improved flexographic print qualityGood holdoutNon-fibrous pulp additionNatural cellulose pulp/paperVolumetric Mass DensitySizing

Disclosed is an uncoated facestock product having enhanced printability, holdout, and edge wick properties, which are attained through a combination of manufacturing techniques including increased refining of the furnish, sizing, increased hard nip calendering, and the use of extended nip calendering. The resulting uncoated facestock product has the following properties: a density between about 0.7 and 1.0 g / cc and / or an ash content of less than about 15% as measured by the 525° C. standard test method; and a finished surface having a Sheffield smoothness between about 50 and 150 Sheffield units and a Parker Print Surf roughness (PPS-10) less than about 5.0 microns.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com