Method for forming multilayer release liners and liners formed thereby

a technology of release liners and release liners, which is applied in the field of multi-layer release liners and their methods, can solve the problems of stringent restrictions on solvent recovery, increase the cost of end product adhesive construction, so as to improve the optimization of the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

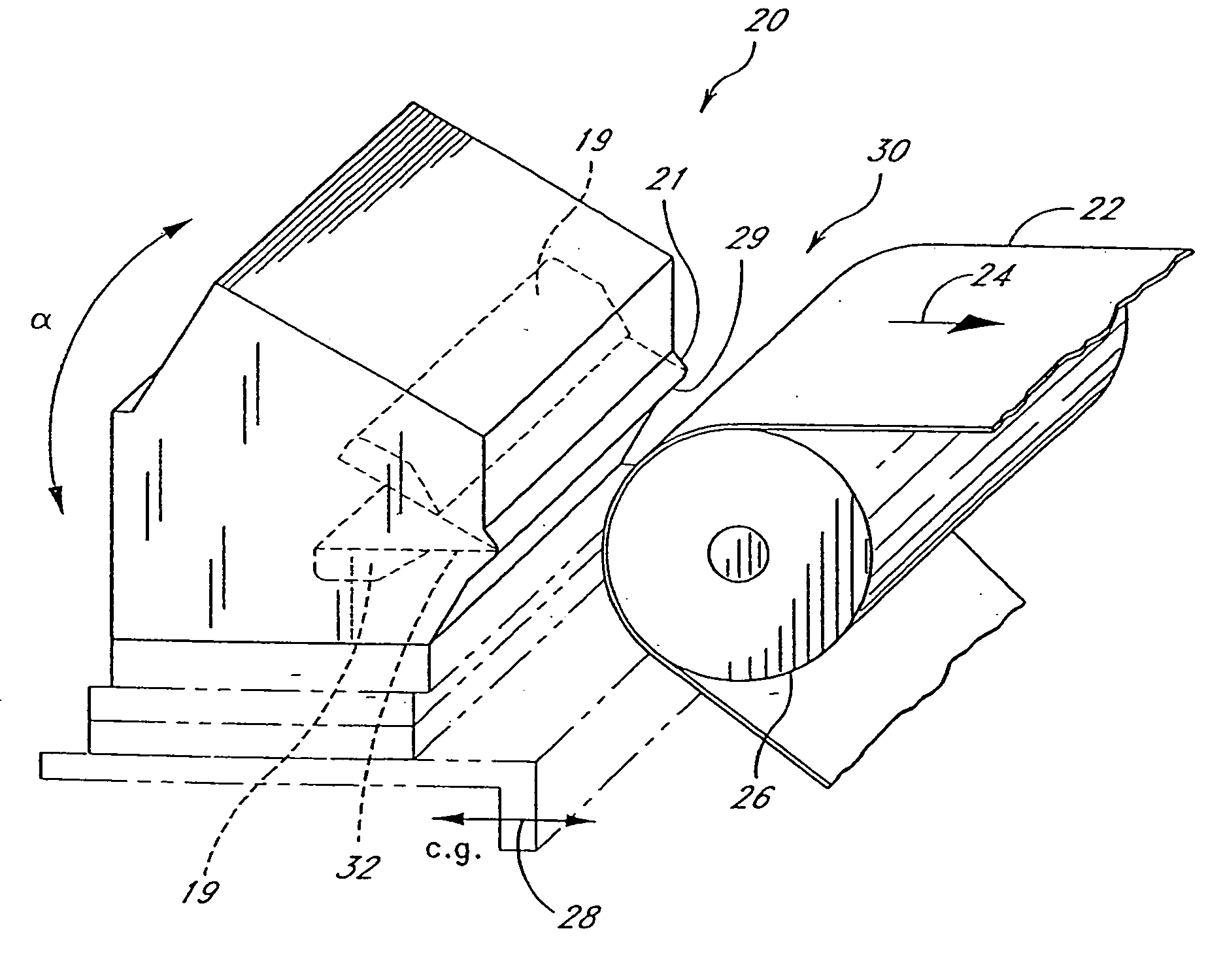

Method used

Image

Examples

examples

[0068] The release properties of the liners of Examples 1-22 were quantified using two methods, the 90° peel release force and the 180° peel release profile. The 90° peel release force was measured on a TLMI Lab Master instrument in the liner off mode, at a rate of 7.62 m / min, and results were measured in cN / 25 mm. The 180° release profile was generated by measuring the peel release force on an Instrumentors ZPE-1000 High Rate Peel Tester at rates of 10, 30, 100, 200, and 300 m / min. in the liner off mode, and results were measured in cN / 25 mm. Protocols for performing the tests are as follows:

90% Peel Release Force

[0069] This test method allows the end user to determine the force required to separate the release backing form the pressure sensitive adhesive coated face material. The release force is defined as the force required to separate a pressure sensitive adhesive coated material from its release surface (or vice versa) at an angle of 90° and a jaw separation rate of 7.62 m p...

examples 1 and 2

[0077] Examples 1 and 2 compare the relative release properties of release surface formed from a coating having 100% silicone solids to a release surface formed from a coating having 40% silicone solids. In each case, the silicone containing layer was coated on a release Support layer (RSL), where the RSL comprised a filler material coated on paper.

[0078] Example 1 consists of a General Electric silicone release layer coated on synthetic SBR as a RSL support layer, which in turn was coated on AT-70 paper. The top layer was prepared by mixing GE 1111-11-259 (62.7g), GE 1192-05-117 (3.3 g), and water (34.0 g). Because no solids other than silicone were coated to form the release layer, the release layer of Example 1 is formed from 100% silicone solids. The bottom RSL layer is 33% solid synthetic SBR filler. The coating was applied to AT-70 paper using a dual die at coating speed of 200 m / min, and cured at 160° C. for 4 seconds to produce the finished liner. The coat weight is 1.5 g / m...

examples 3-6

[0081] Examples 3-6 consist of Wacker silicone as a release layer coated on Air Products Airflex 465 as a RSL, which was coated on either Data-70 or Willamette paper. The top layer was prepared by mixing Wacker 38197 VP (66.0 g). Wacker crosslinker V20 (3.5 g), 10% solution of 3M Fluorad fluorochemical surfactant FC-129 (0.7 g), 1% aqueous Cellosize Hydroxyethyl Cellulose QP-100 MH (7.5 g), and water (22.3 g). The bottom RSL layer was prepared by mixing Air Products Airflex 465 (52.3 g) and water (47.7 g). The coating was applied to Data-70 or Willamette papers using a dual die at a coating speed of 400 nm / min, and cured at 170° C. for 3 seconds to produce the finished liners. The coat weight is 1.0 g / m2 silicone on 5.0 g / m2 RSL. These release liners were coated with S-2000 emulsion pressure-sensitive adhesive or S-2045 hot melt adhesives (Avery Dennison Corporation) to produce the PSA constructions of Examples 3-6.

[0082] The release properties of these liners were quantified using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| web speed | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com