Patents

Literature

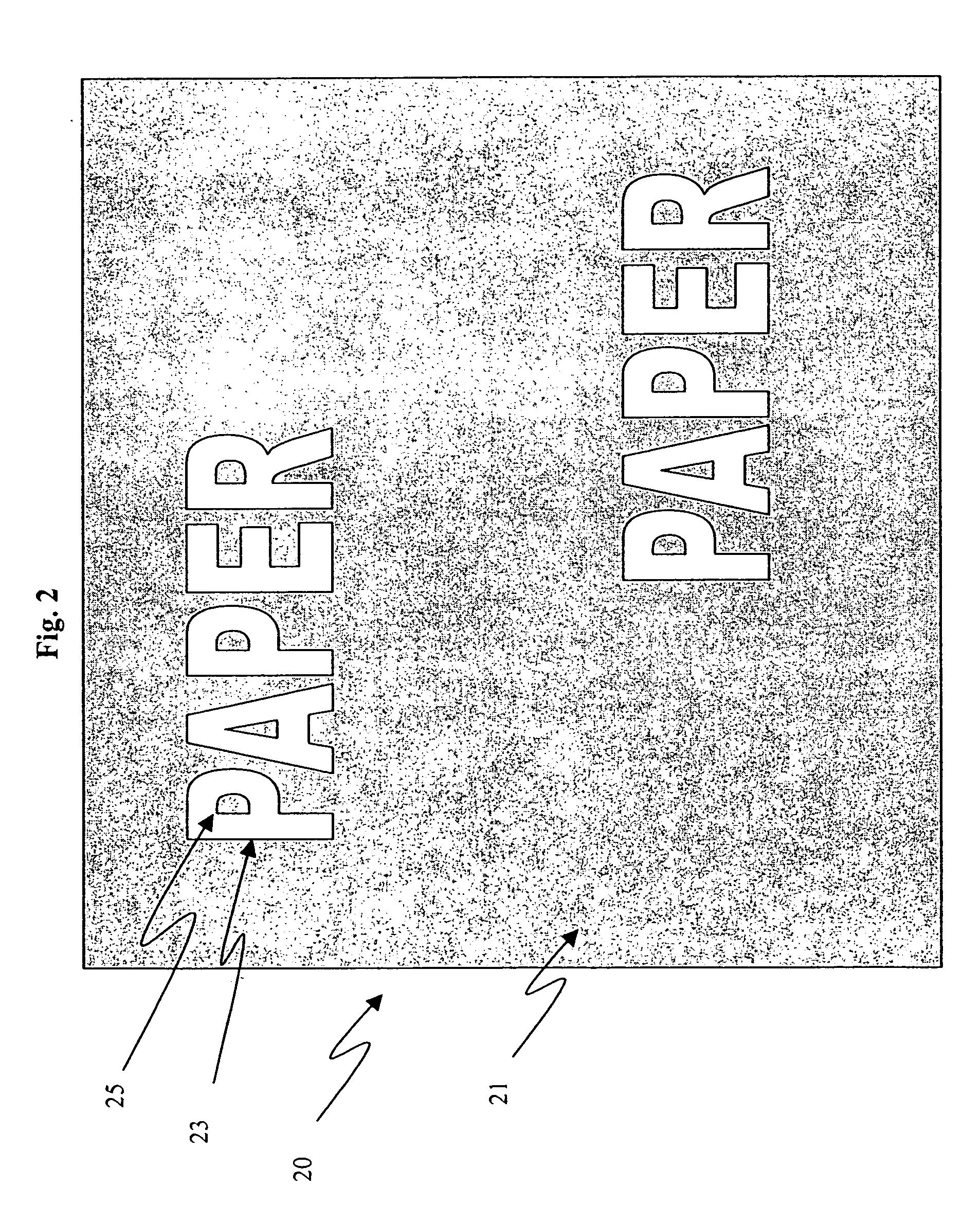

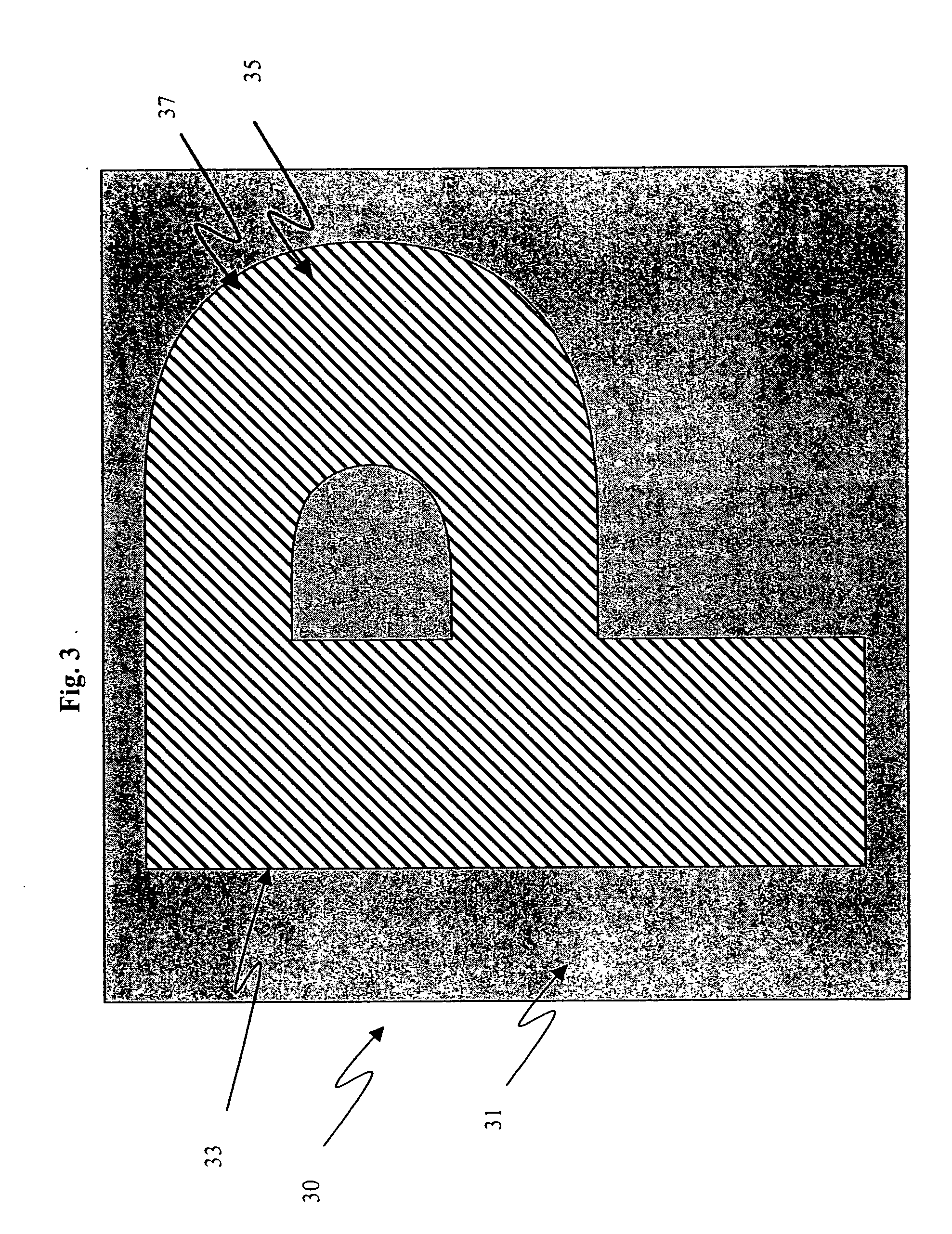

214results about "Photosensitive composition application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resist composition and patterning process

ActiveUS20080090172A1Improve barrier propertiesLow costElectric discharge tubesRadiation applicationsResistPolymer chemistry

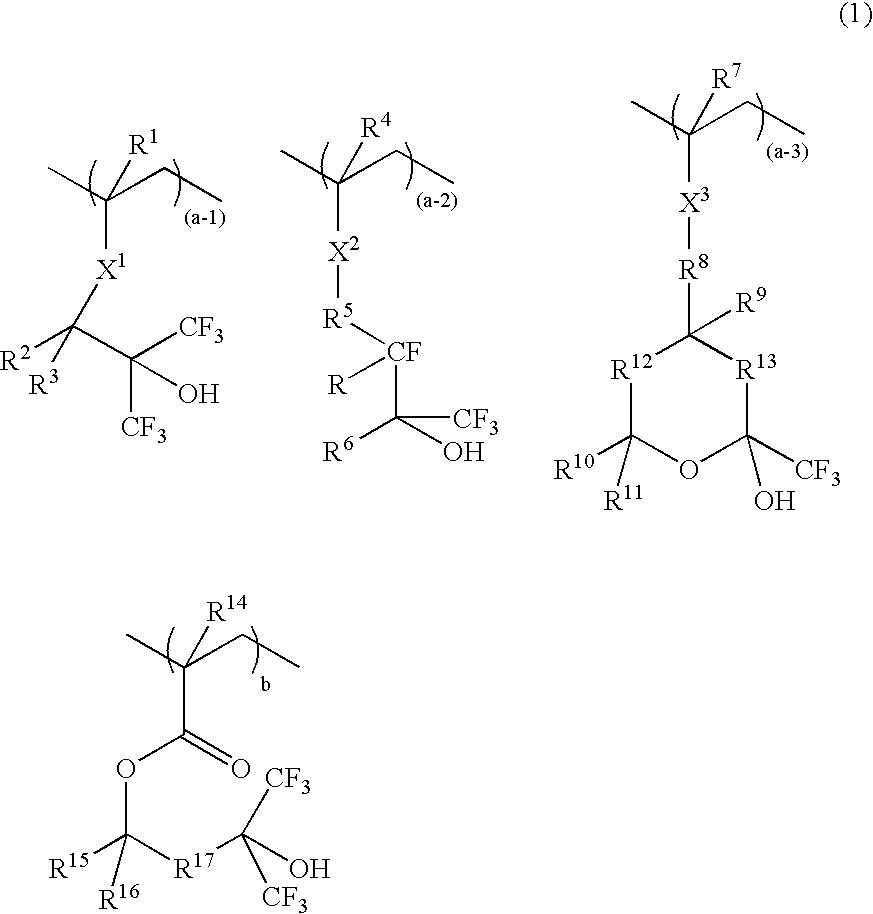

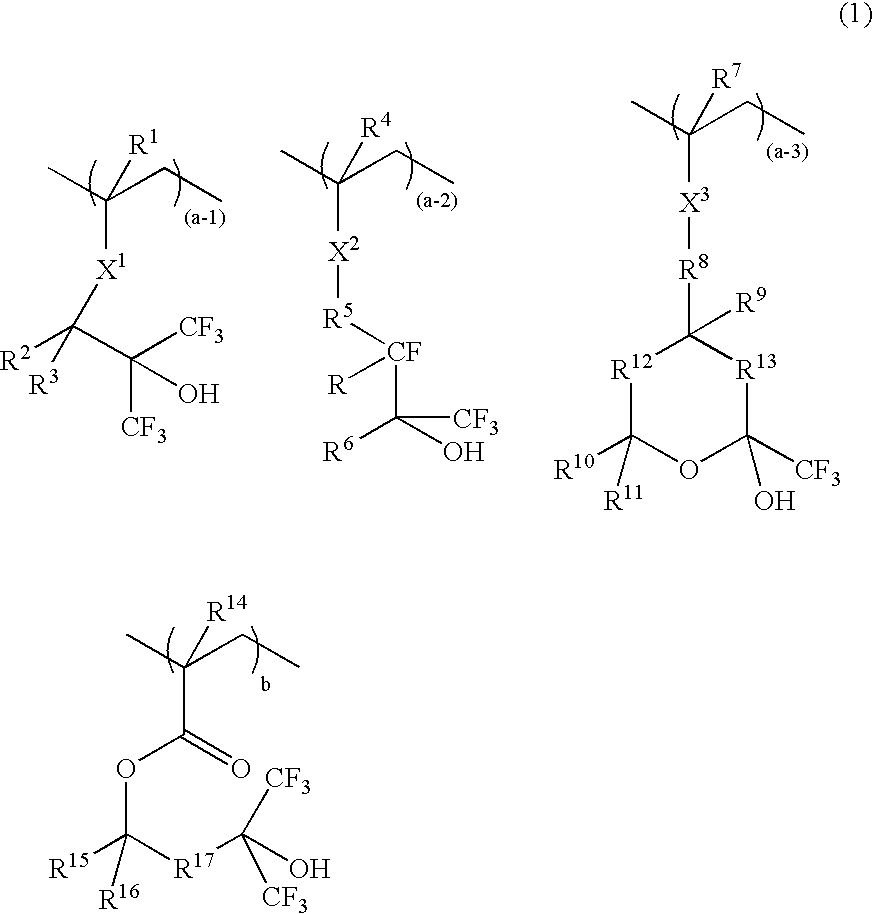

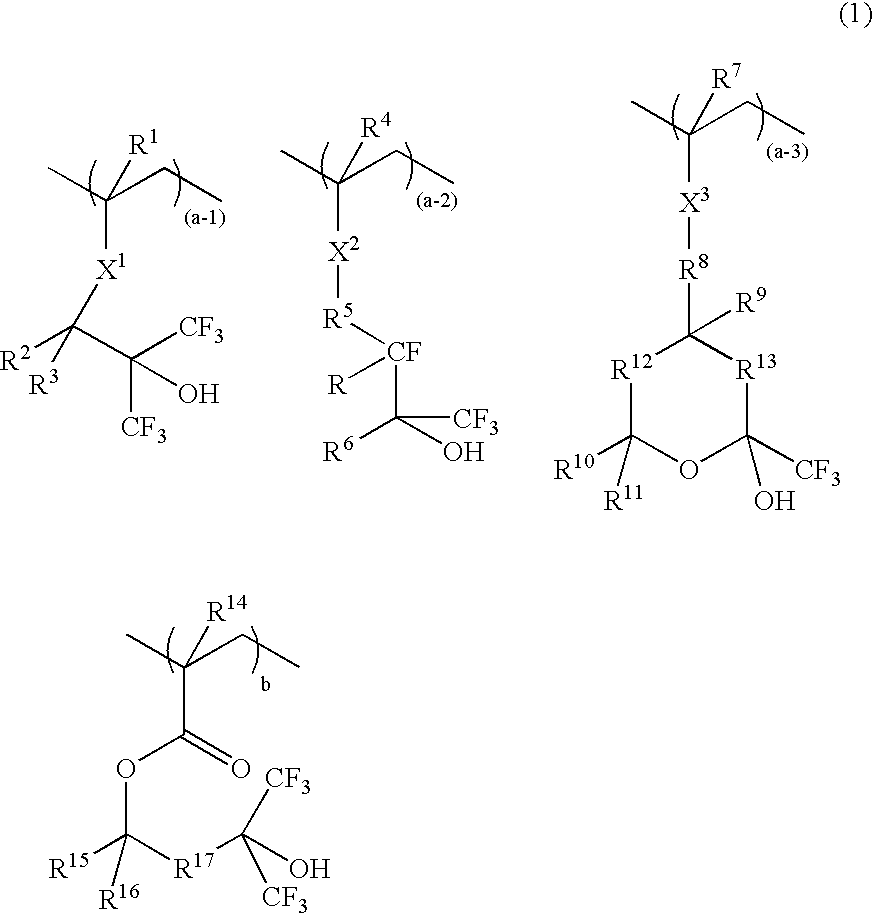

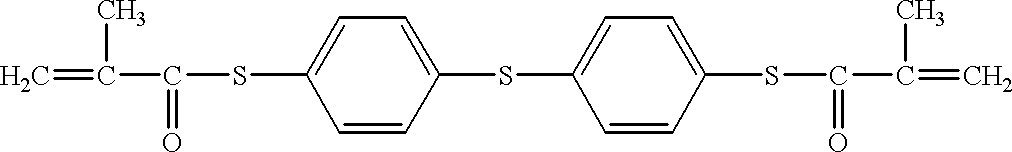

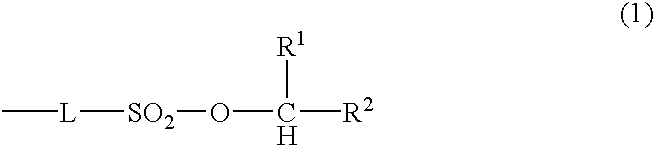

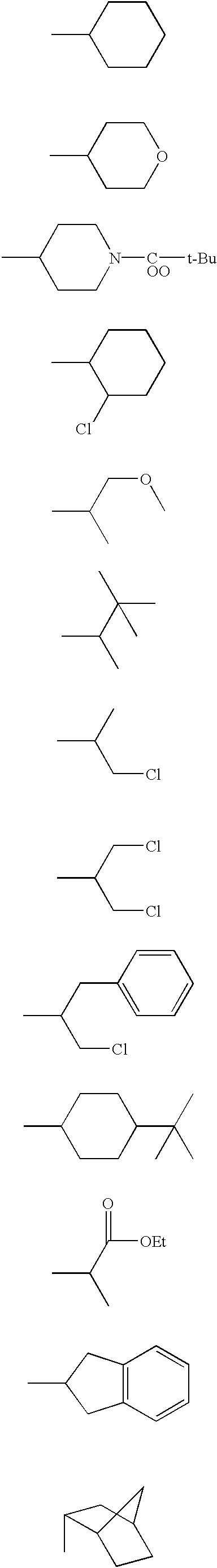

A resist composition comprises a polymer comprising recurring units having formula (1) wherein R1, R4, R7, and R14 are H or methyl, R2, R3, R15, and R16 are H, alkyl or fluoroalkyl, R is F or H, R5 is alkylene, R6 is fluorinated alkyl, R8 is a single bond or alkylene, R10 and R11 are H, F, methyl or trifluoromethyl, R12 and R13 are a single bond, —O— or —CR18R19—, R9, R18, and R19 are H, F, methyl or trifluoromethyl, R17 is alkylene, X1, X2 and X3 are —C(═O)—O—, —O—, or —C(═O)—R20—C(═O)—O— wherein R20 is alkylene, 0≦(a-1)<1, 0≦(a-2)<1, 0≦(a-3)<1, 0<(a-1)+(a-2)+(a-3)<1, 0<b<1, and 0<(a-1)+(a-2)+(a-3)+b≦1.

Owner:SHIN ETSU CHEM IND CO LTD

Structure including a photoresist underlayer and method of forming same

PendingUS20210013037A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusPhotoresistAtomic layer deposition

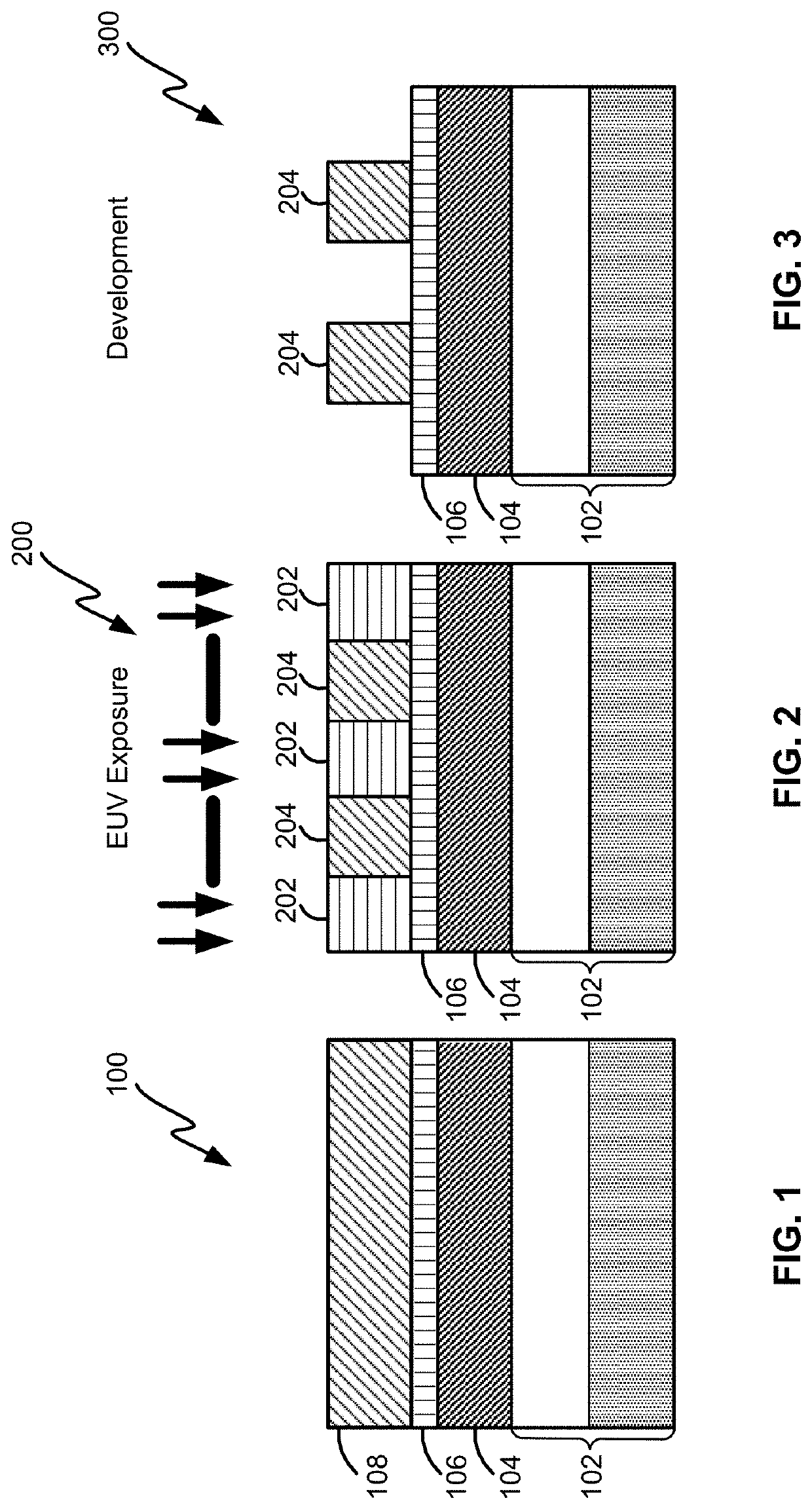

Methods of forming structures including a photoresist underlayer and structures including the photoresist underlayer are disclosed. Exemplary methods include forming the photoresist underlayer using one or more of plasma-enhanced cyclic (e.g., atomic layer) deposition and plasma-enhanced chemical vapor deposition. Surface properties of the photoresist underlayer can be manipulated using a treatment process.

Owner:ASM IP HLDG BV

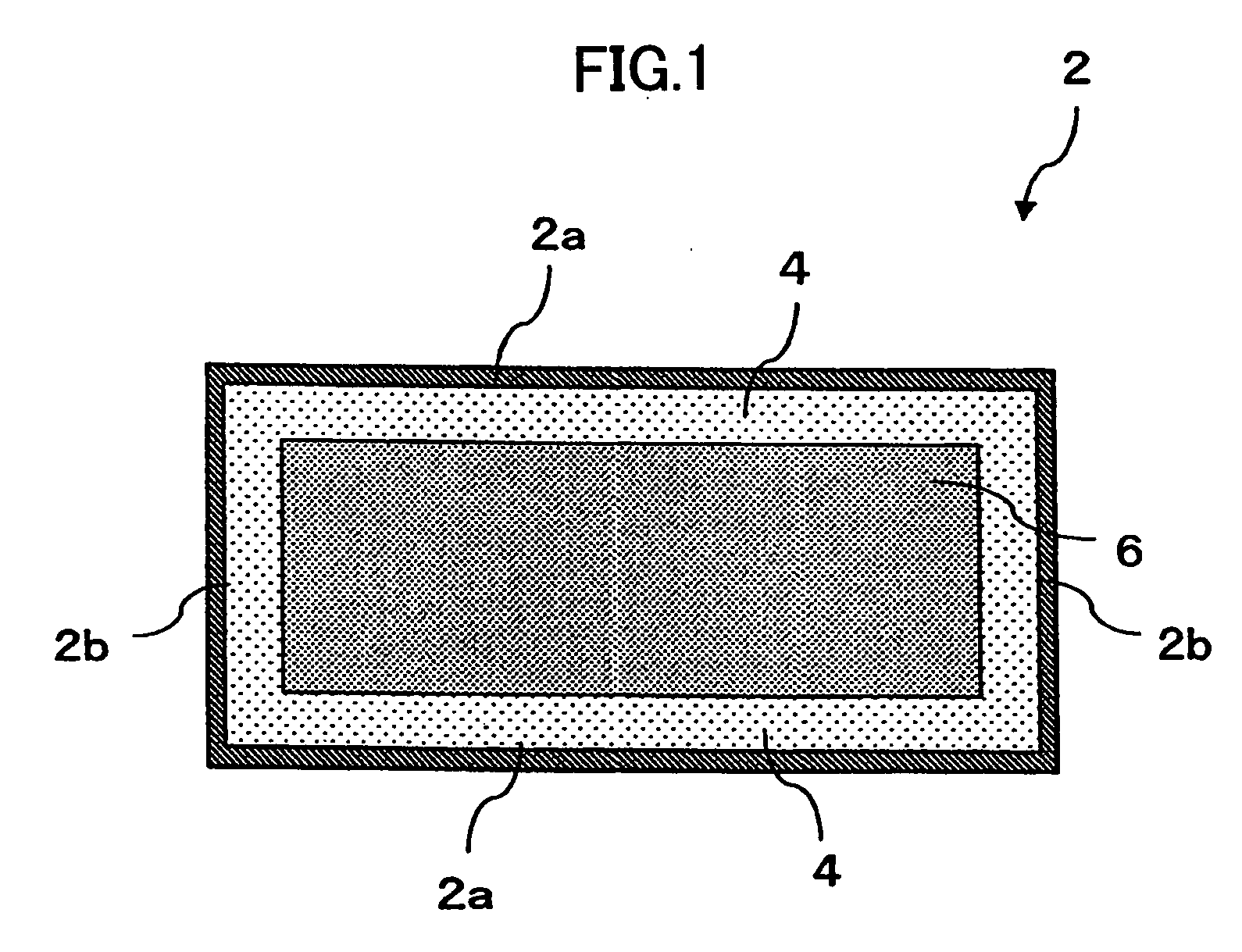

Photosensitive paste, a plasma display, and a method for the production thereof

InactiveUS6197480B1Reduce processDeformation MinimizationPhotography auxillary processesCoatingsInorganic particleDisplay device

To provide a photosensitive paste that permits pattern formation with a high aspect ratio and a high accuracy and to provide a plasma display including the photosensitive paste, by using a photosensitive paste that includes, as essential components, an inorganic particles and an organic component that contains a photosensitive compound with the difference between the average refractive index of the organic component and the average refractive index of the inorganic particles being 0.1 or less.

Owner:TORAY IND INC

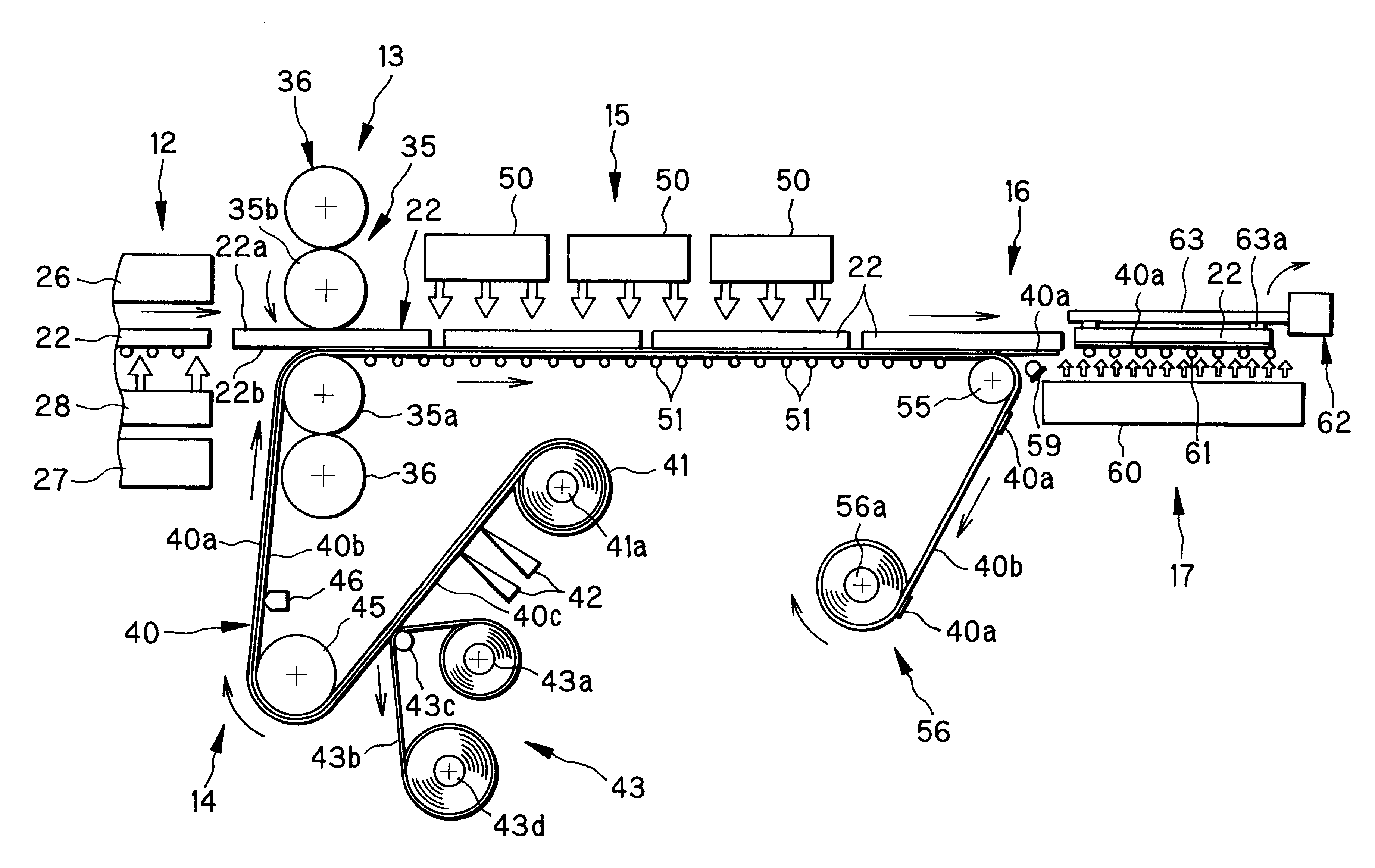

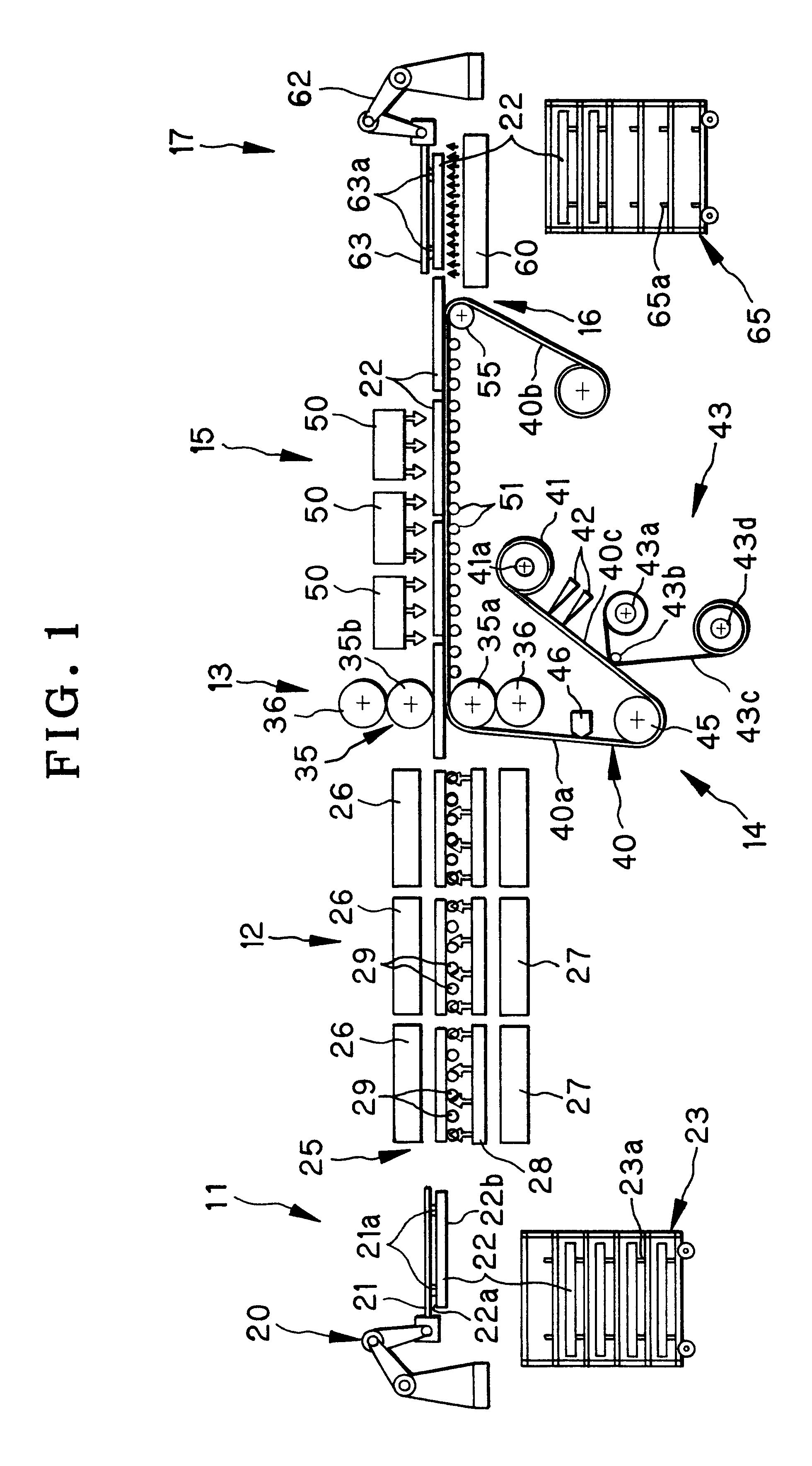

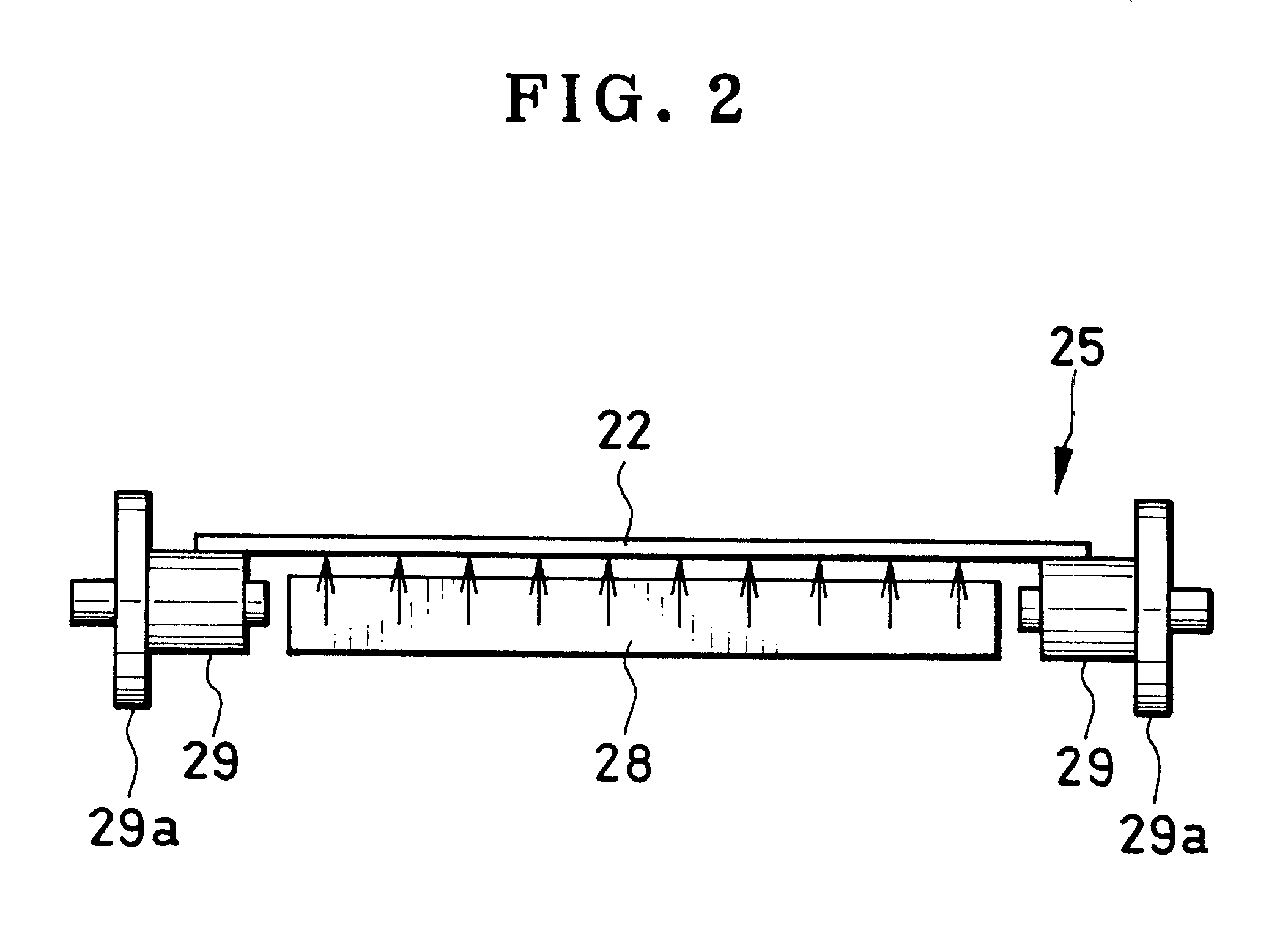

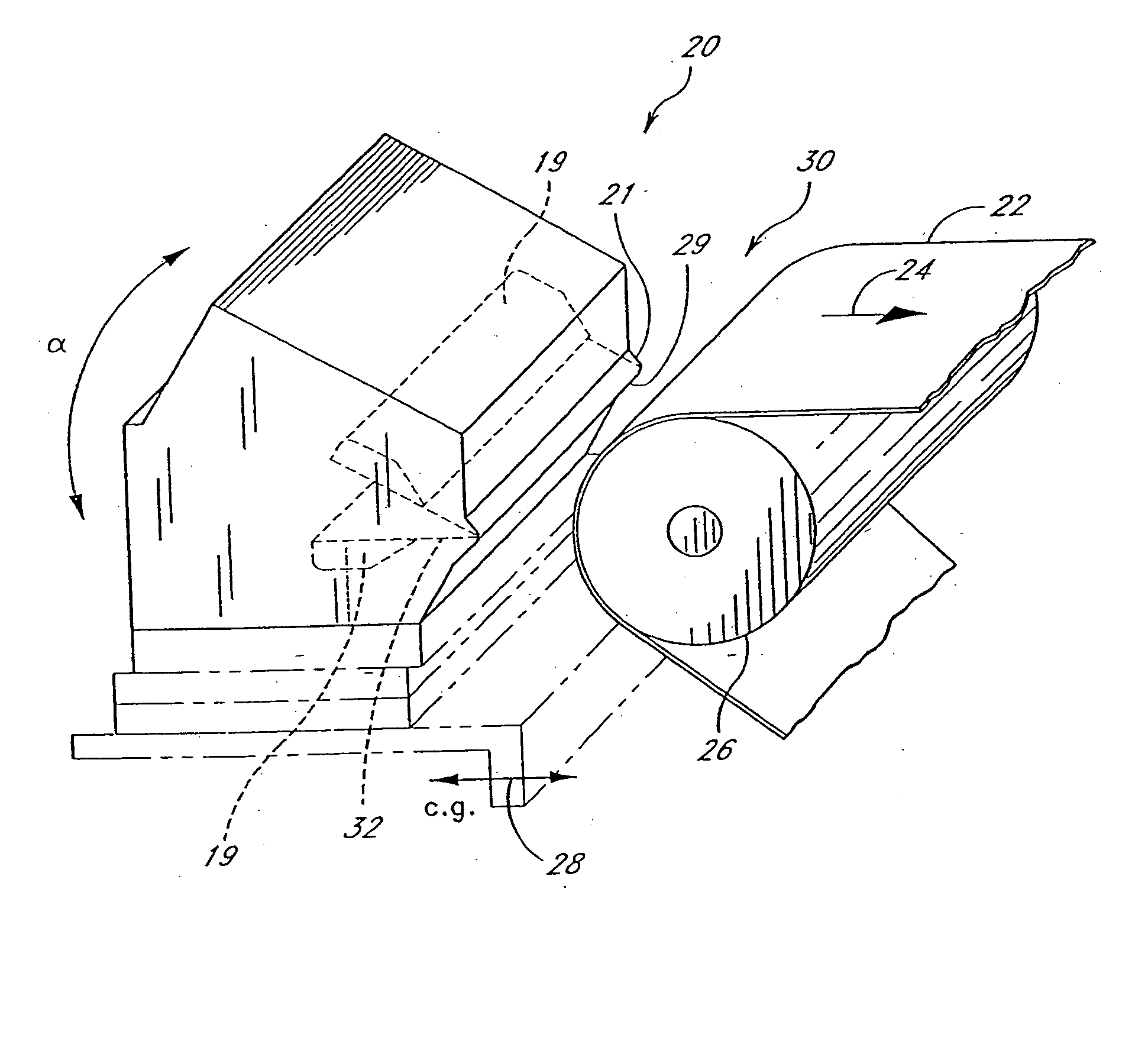

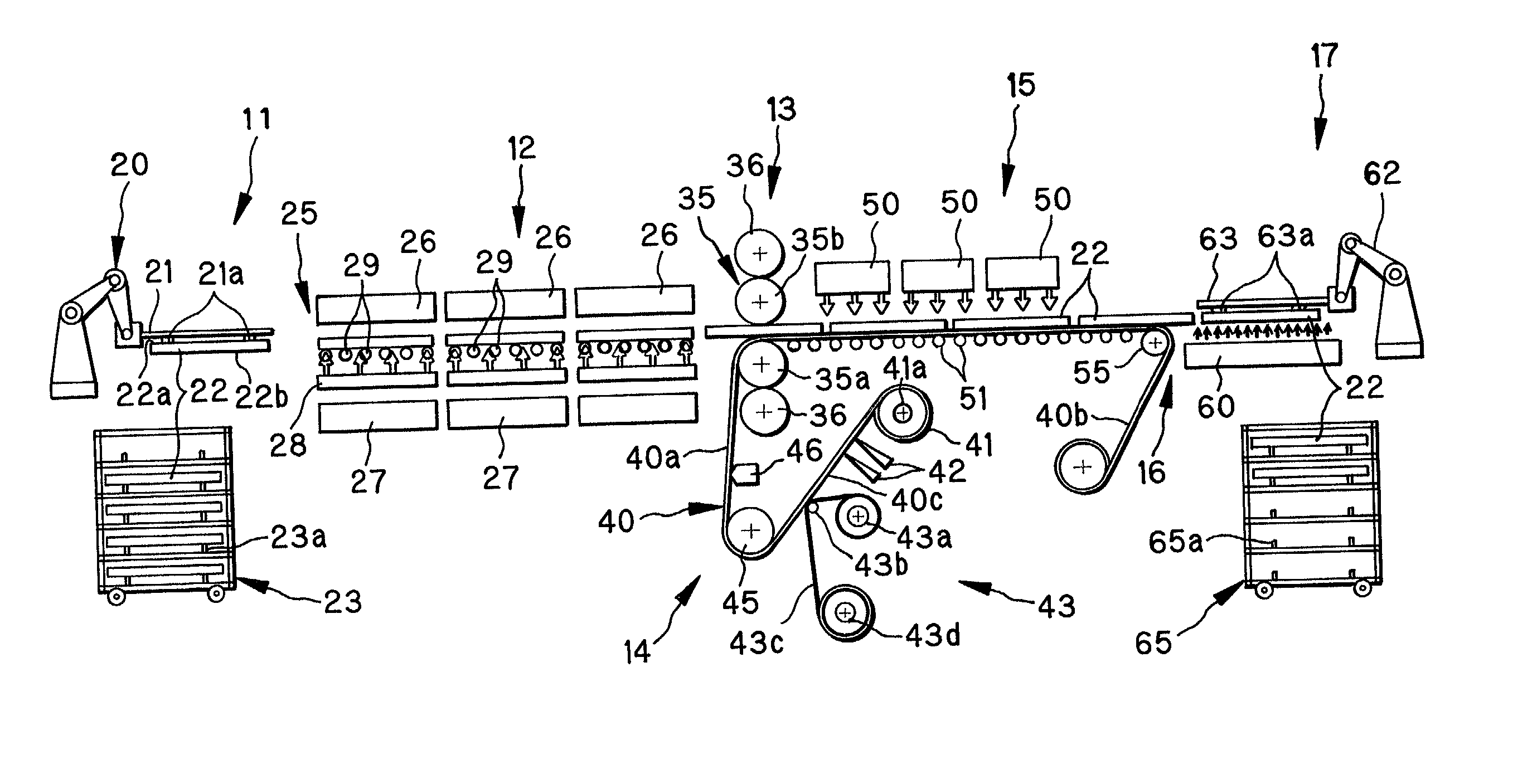

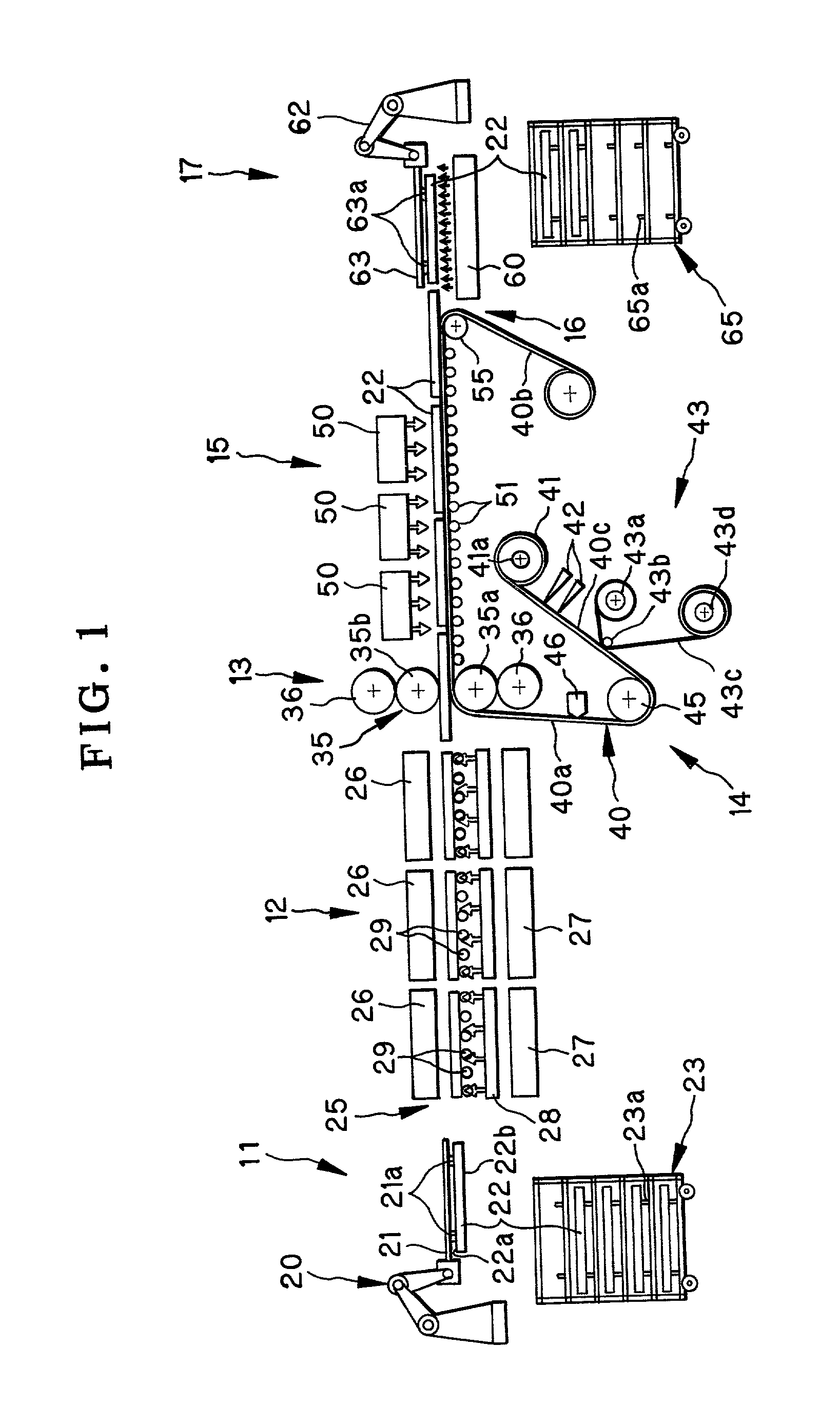

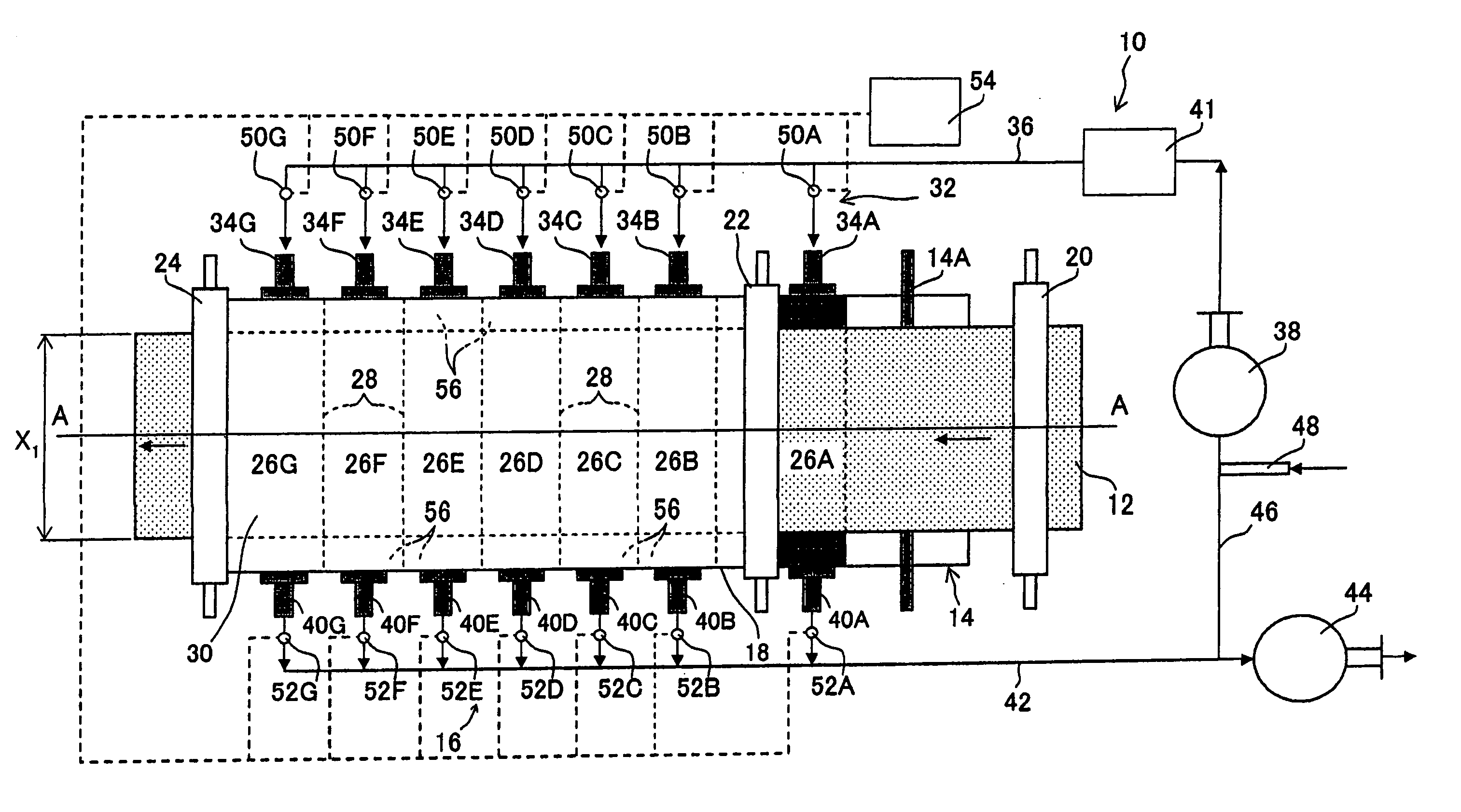

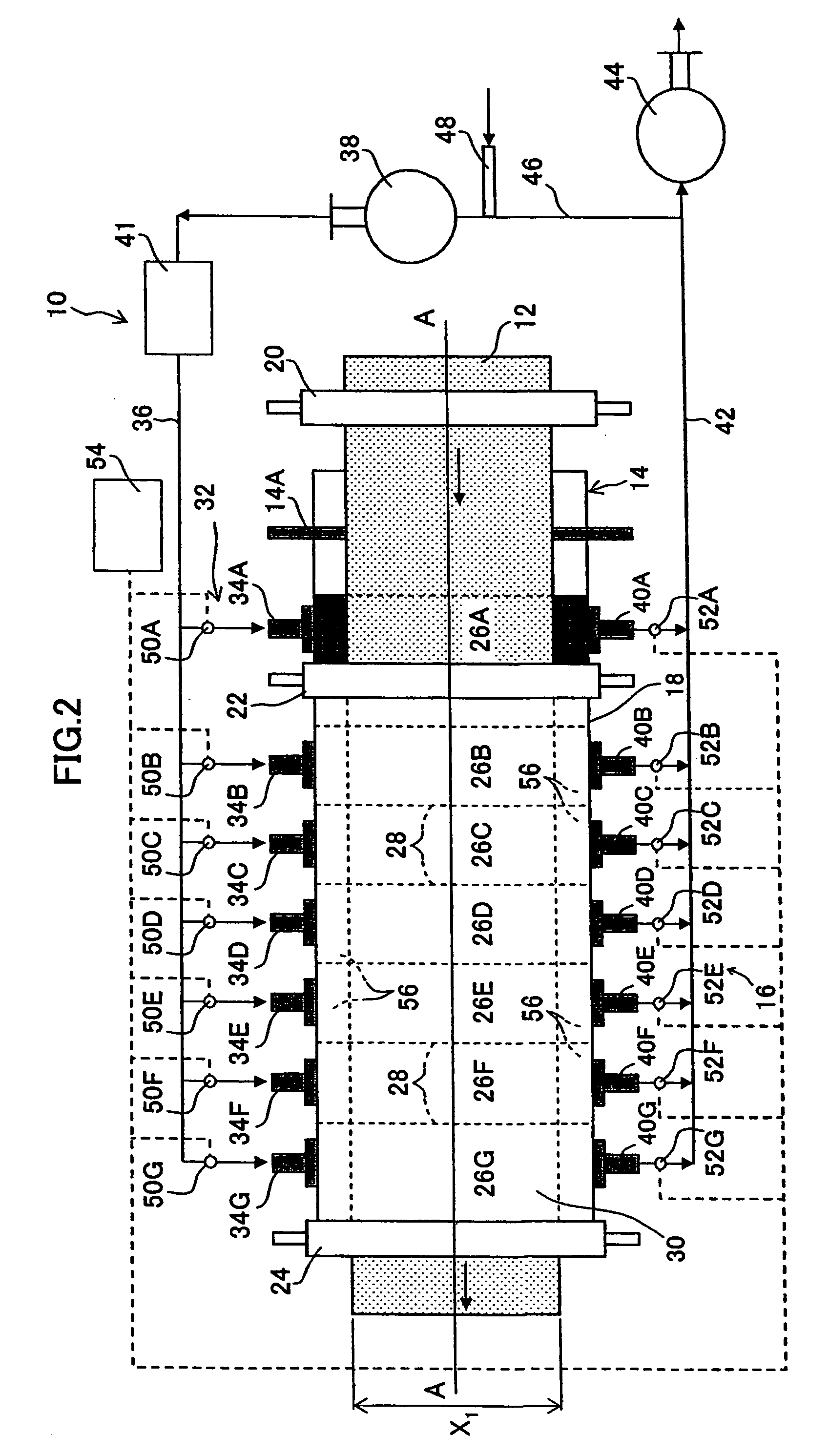

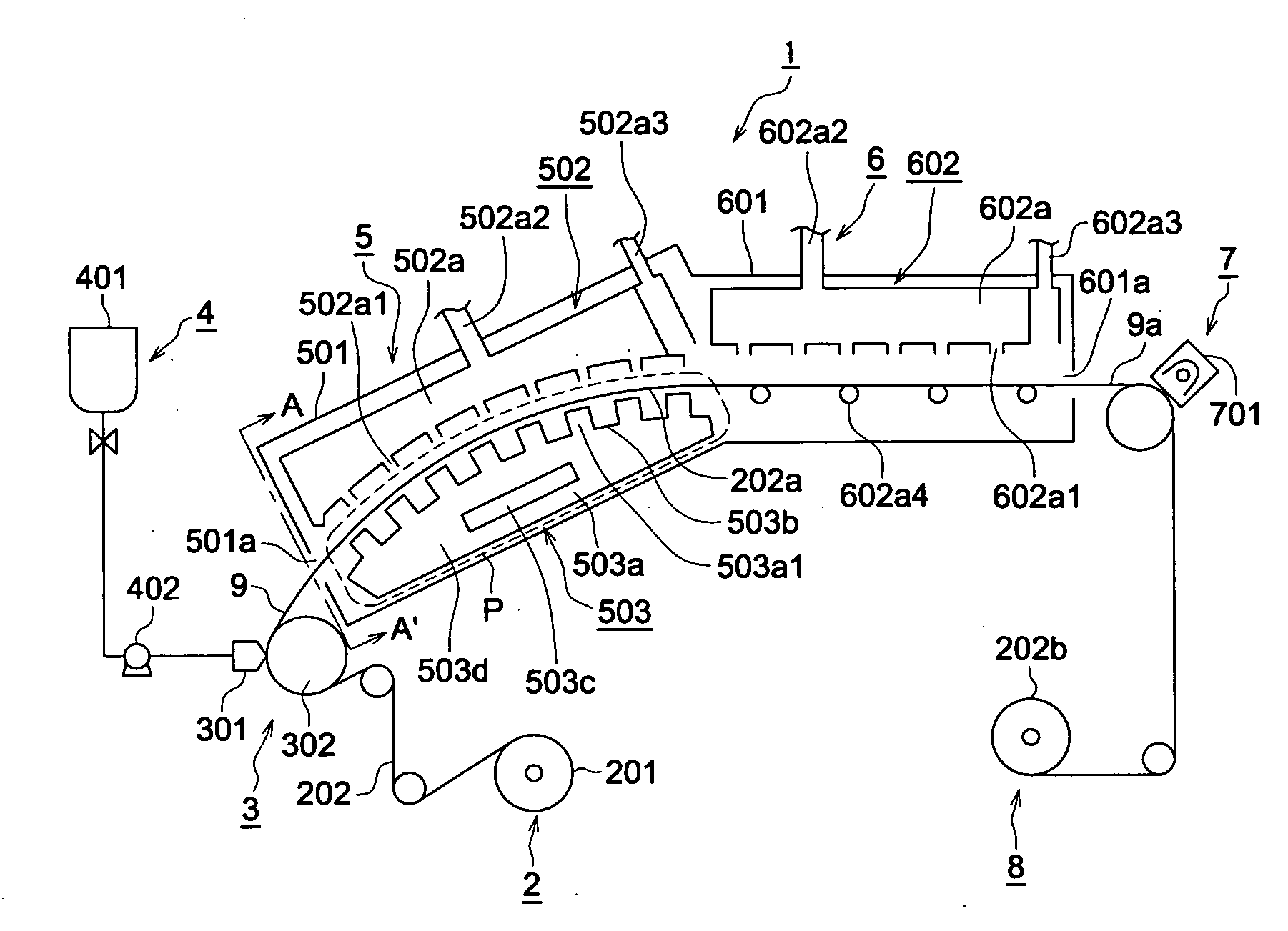

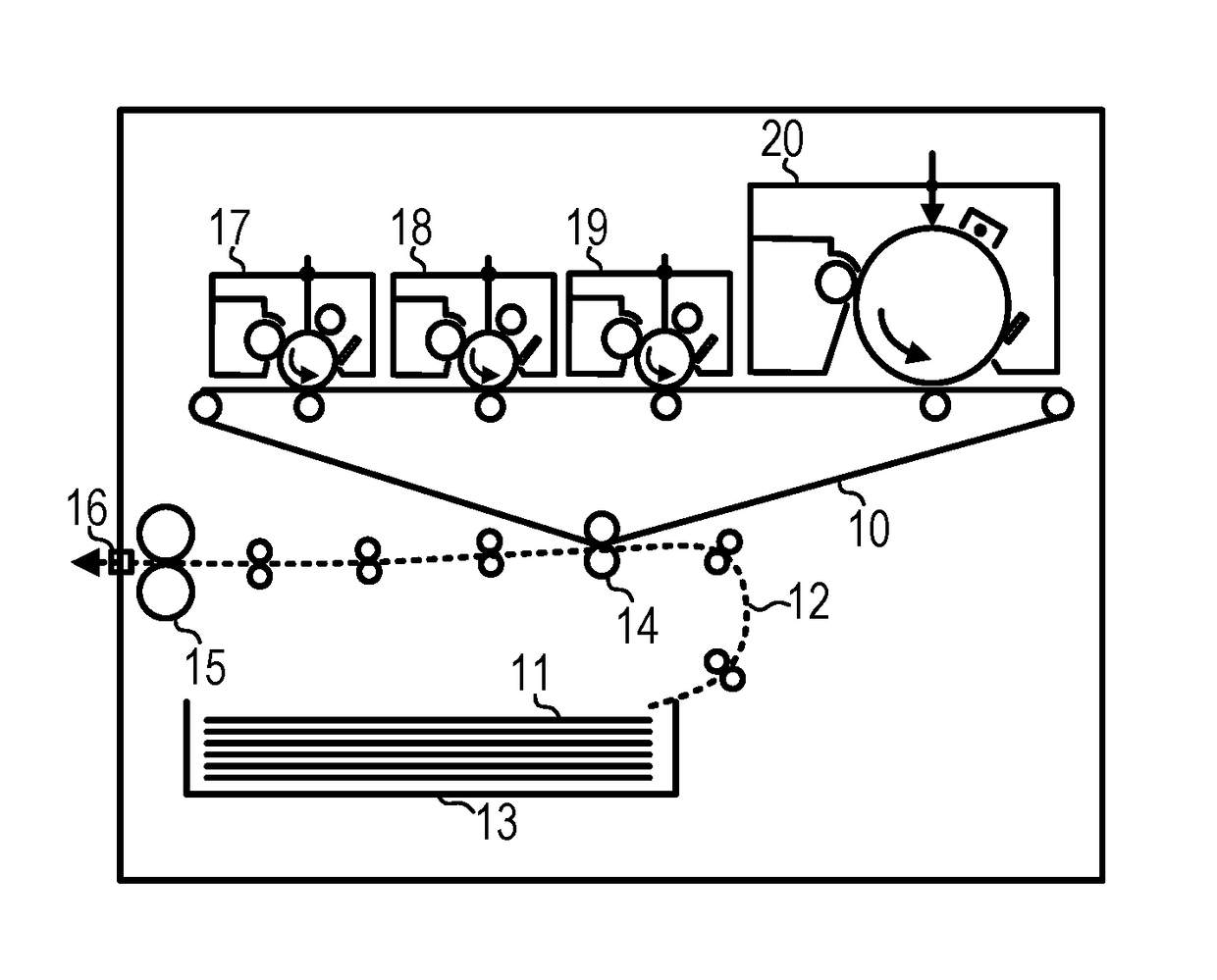

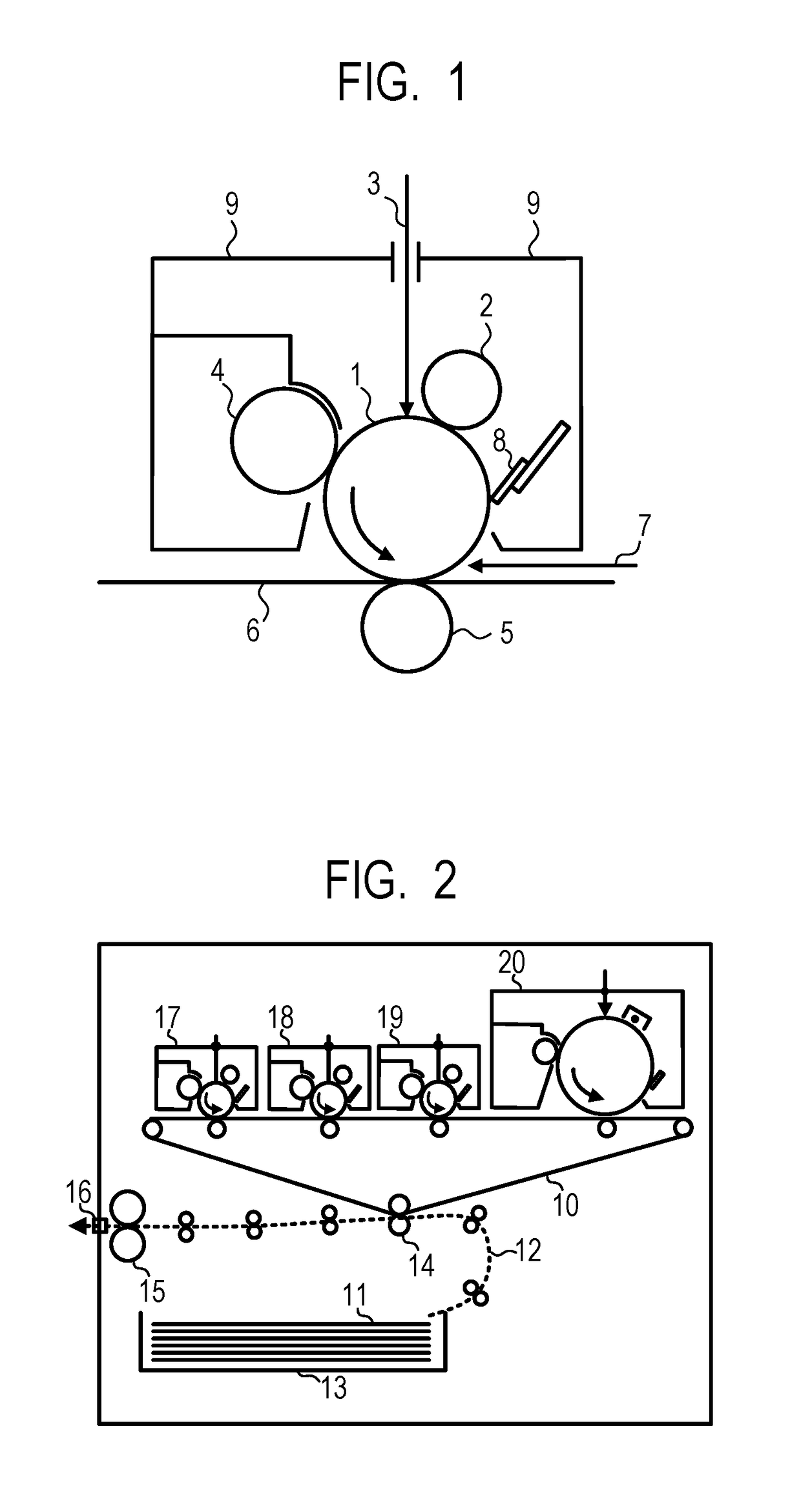

Laminator and laminating method for lamination to substrate

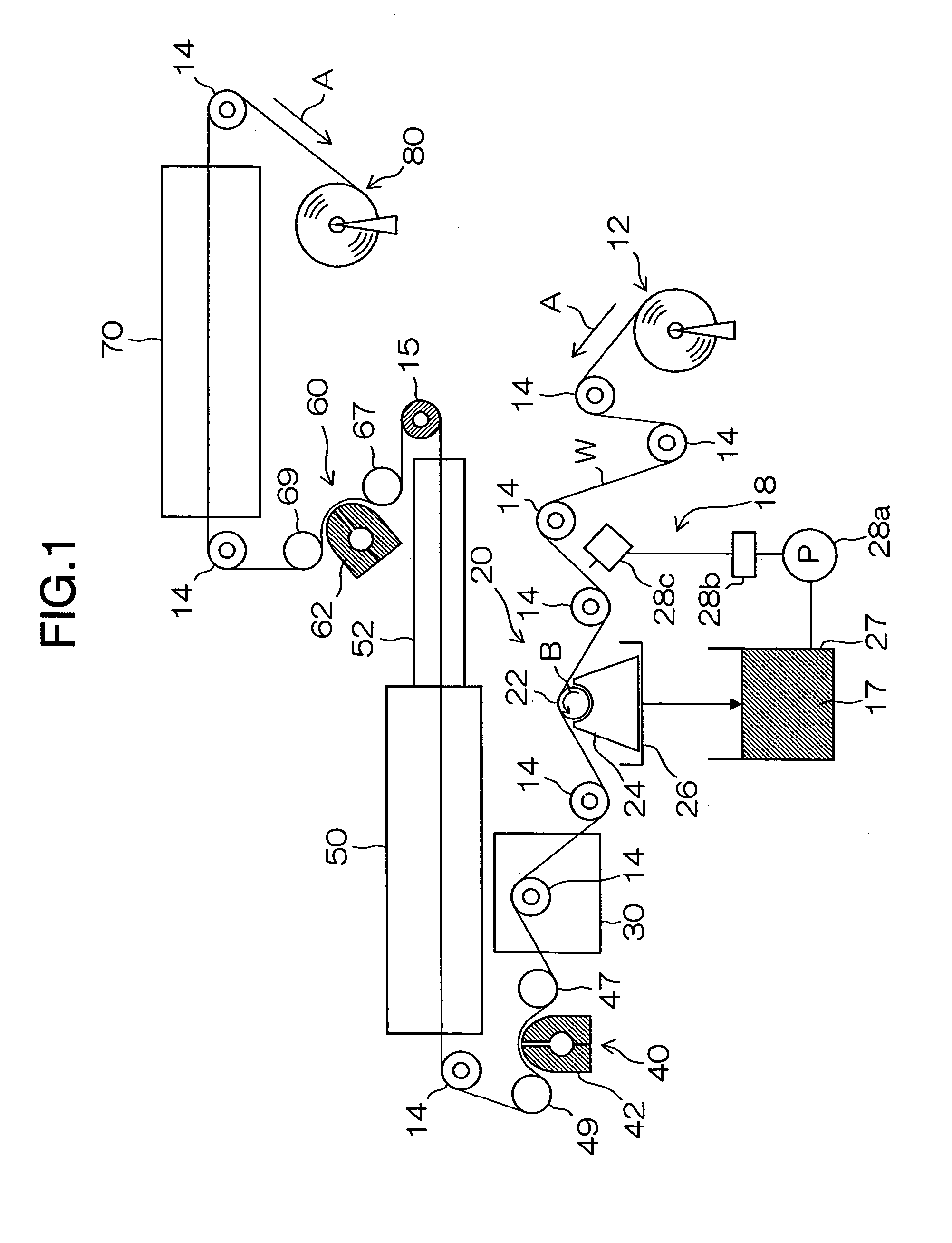

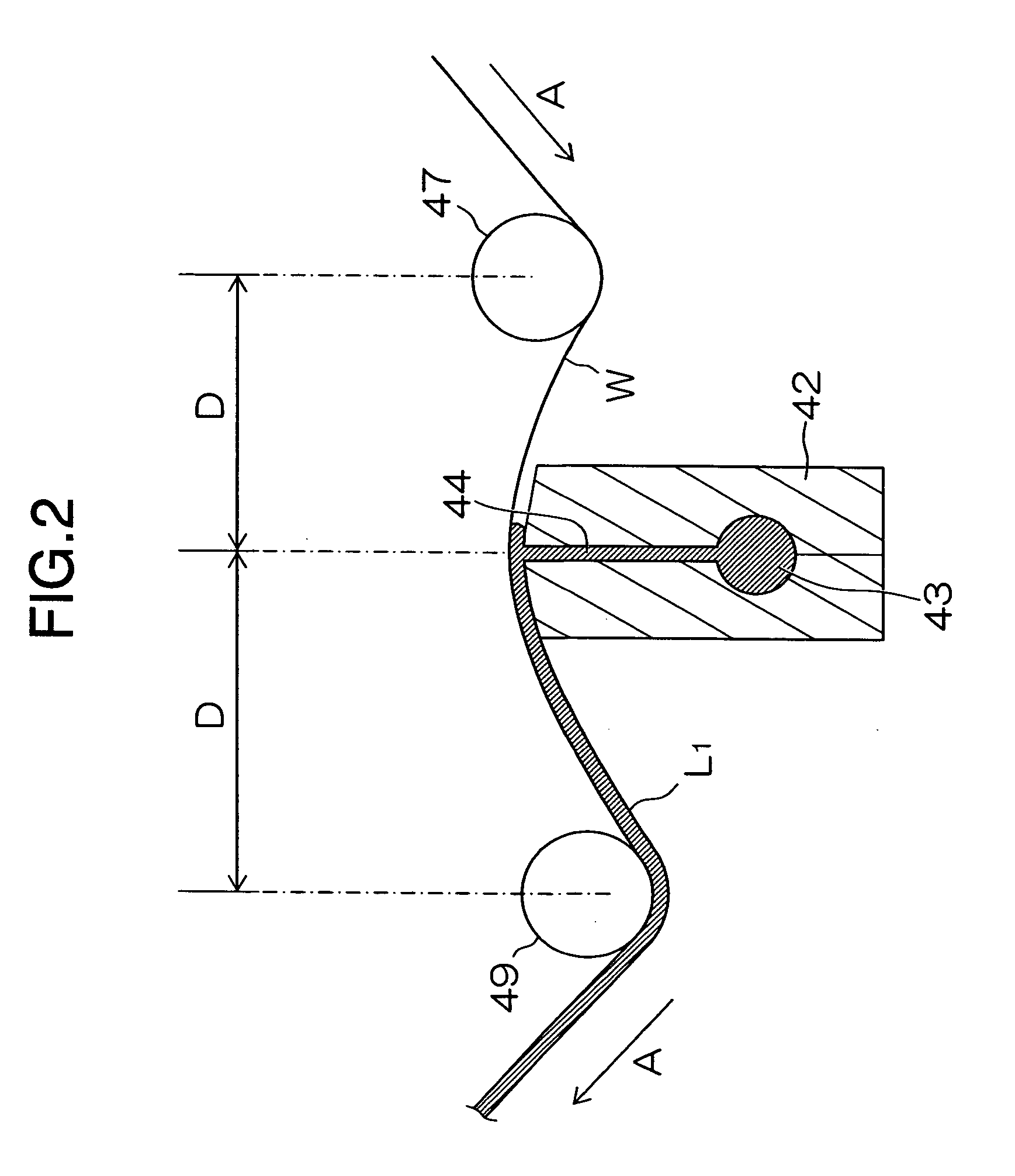

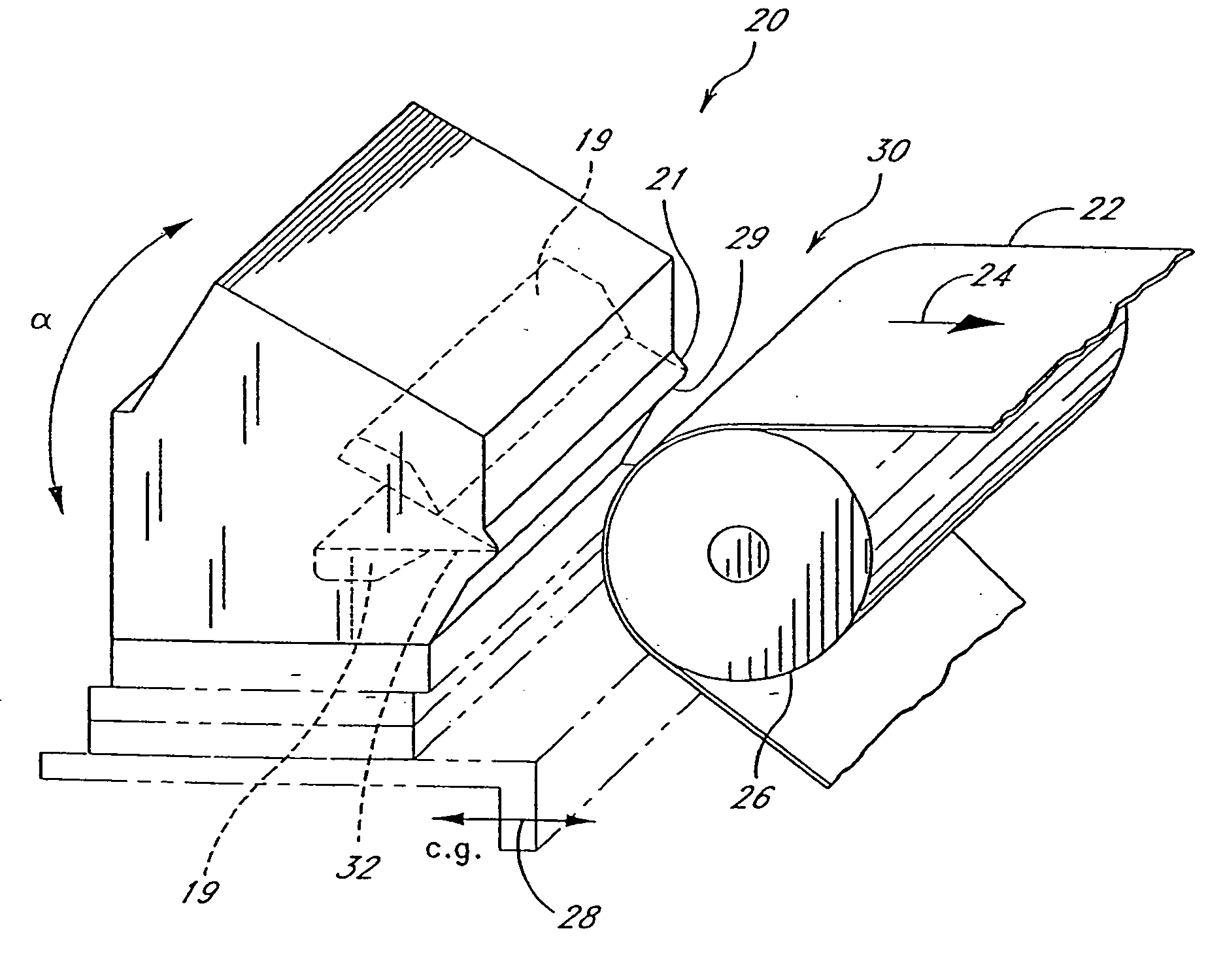

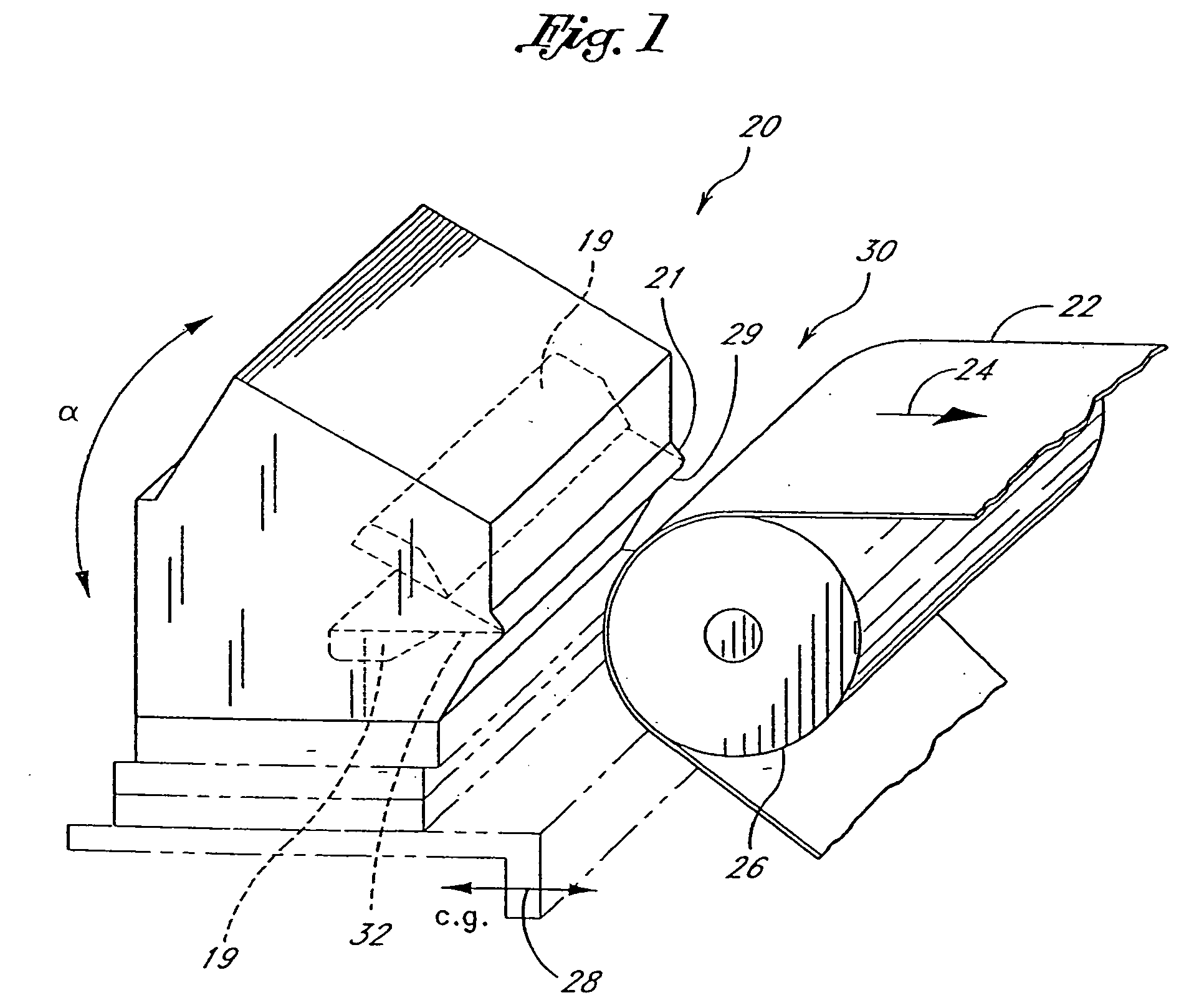

InactiveUS6684925B2Efficiently obtainedDiffusion transfer processesMechanical working/deformationEngineeringElectrical and Electronics engineering

Owner:FUJIFILM HLDG CORP +1

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050074549A1Easy to optimizeLow costFilm/foil adhesivesLayered productsBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

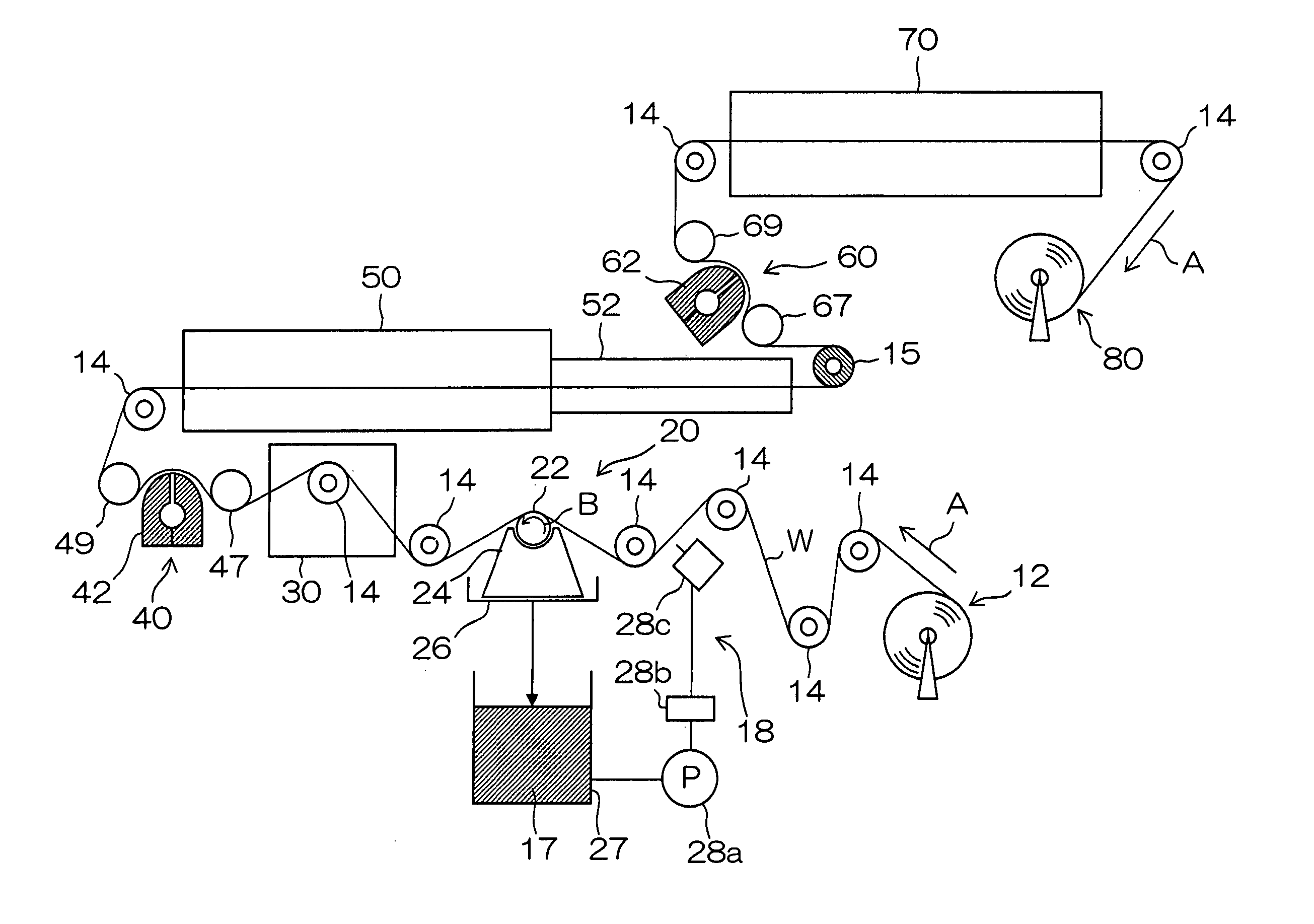

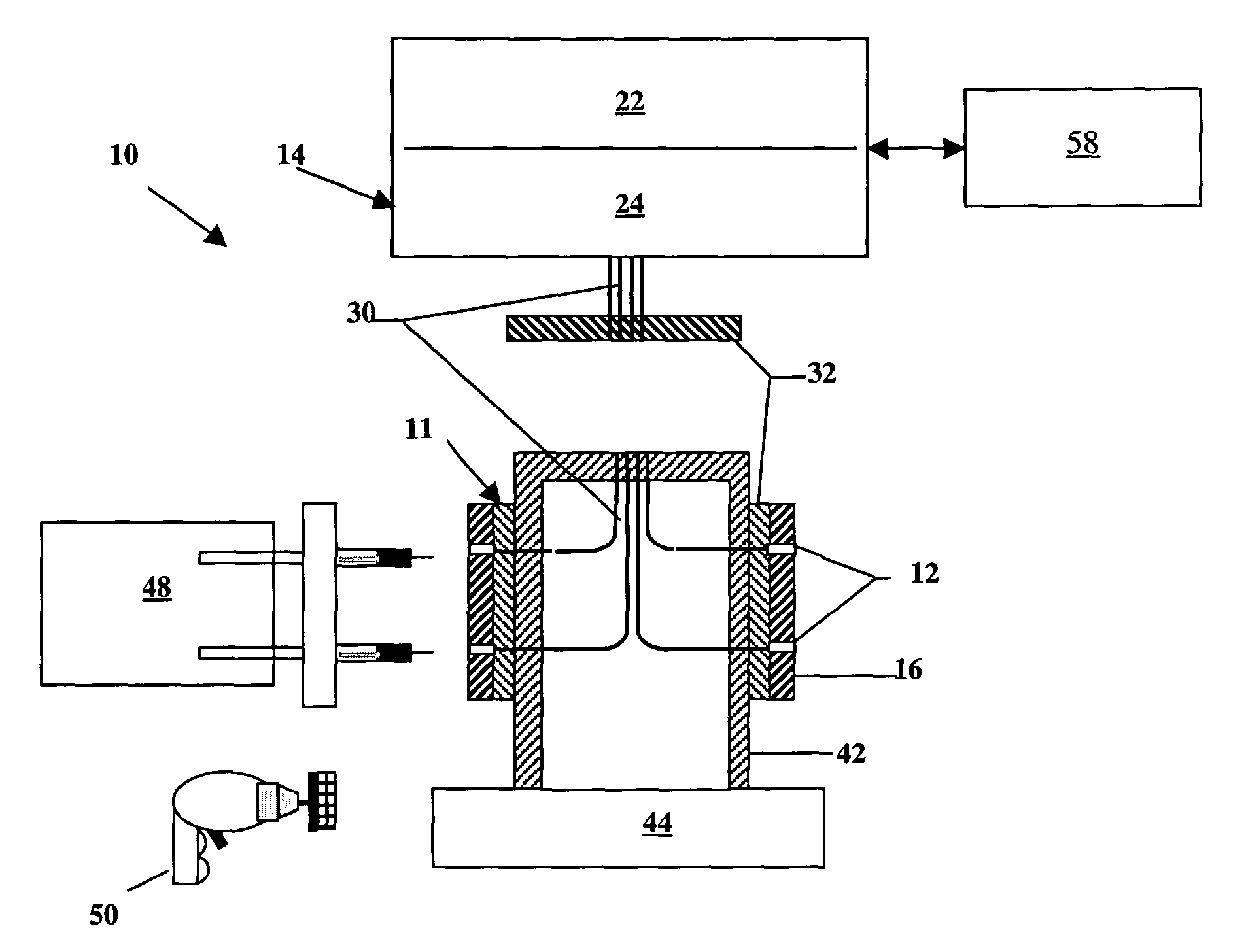

Coating process and apparatus

InactiveUS7032324B2Drying using combination processesDrying solid materials with heatEngineeringWeb handling

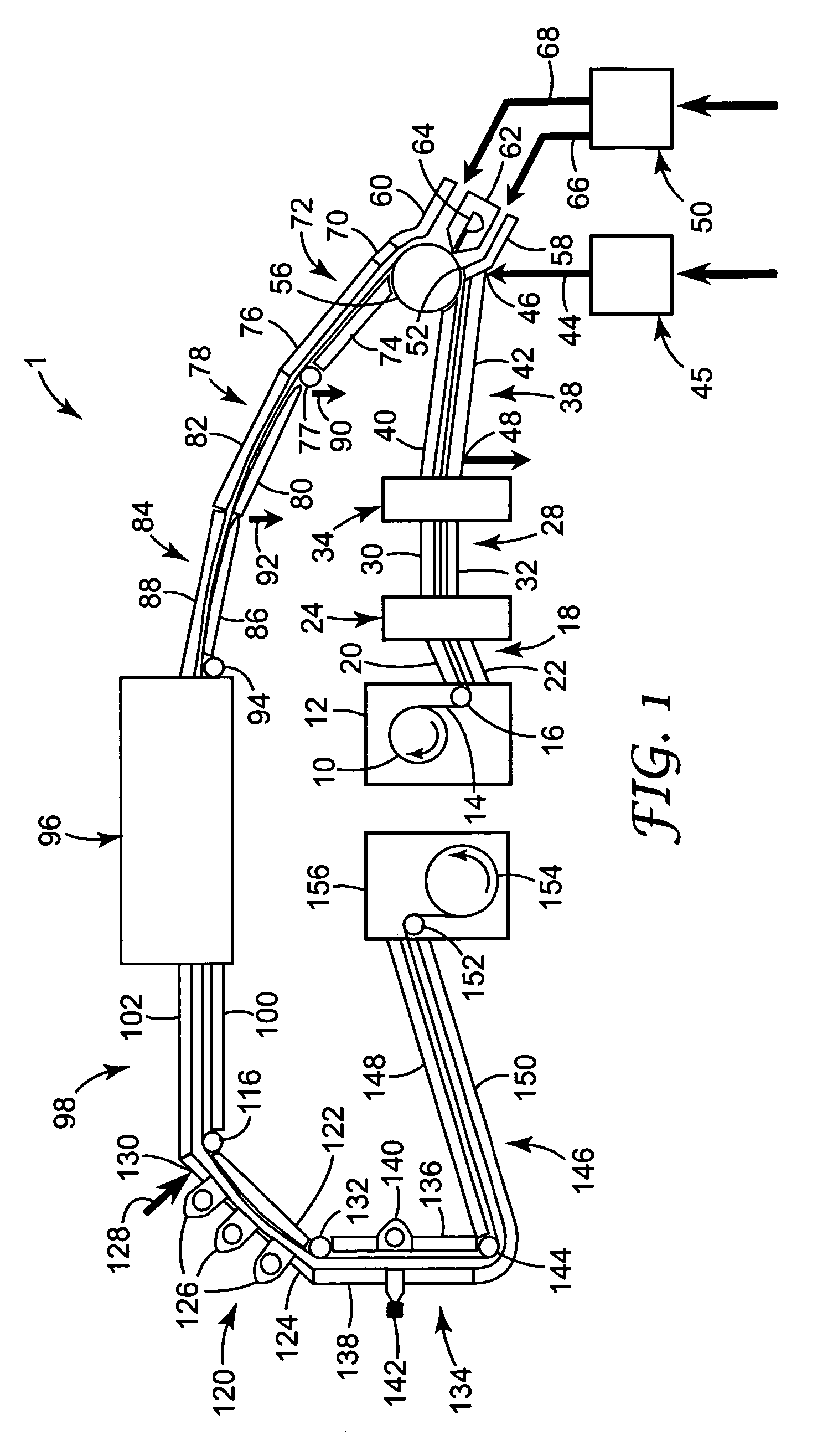

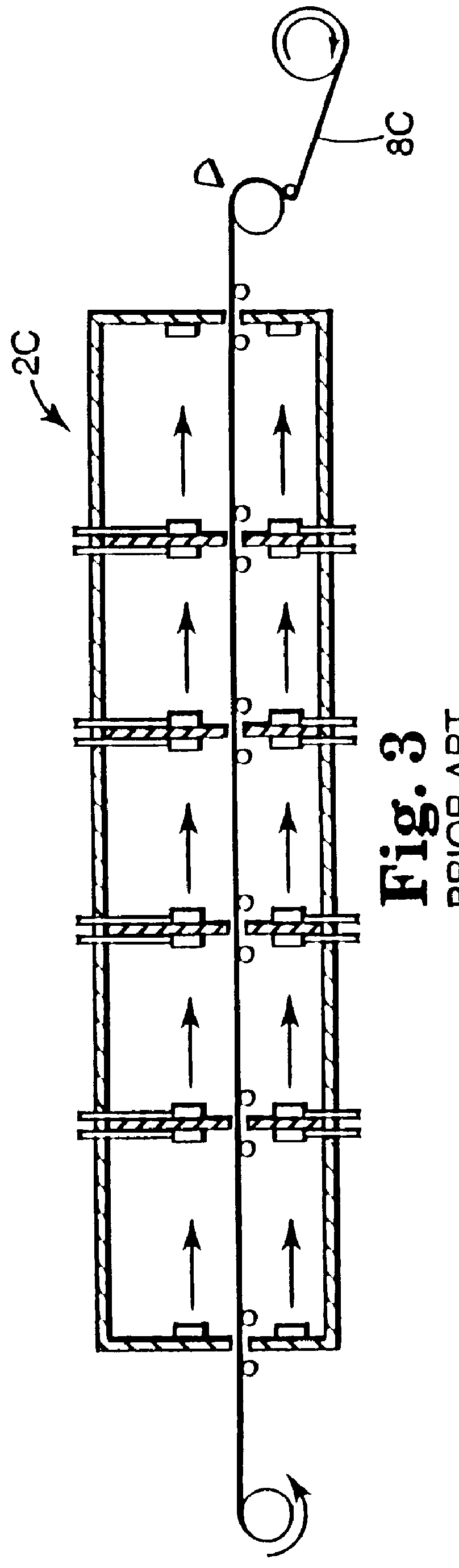

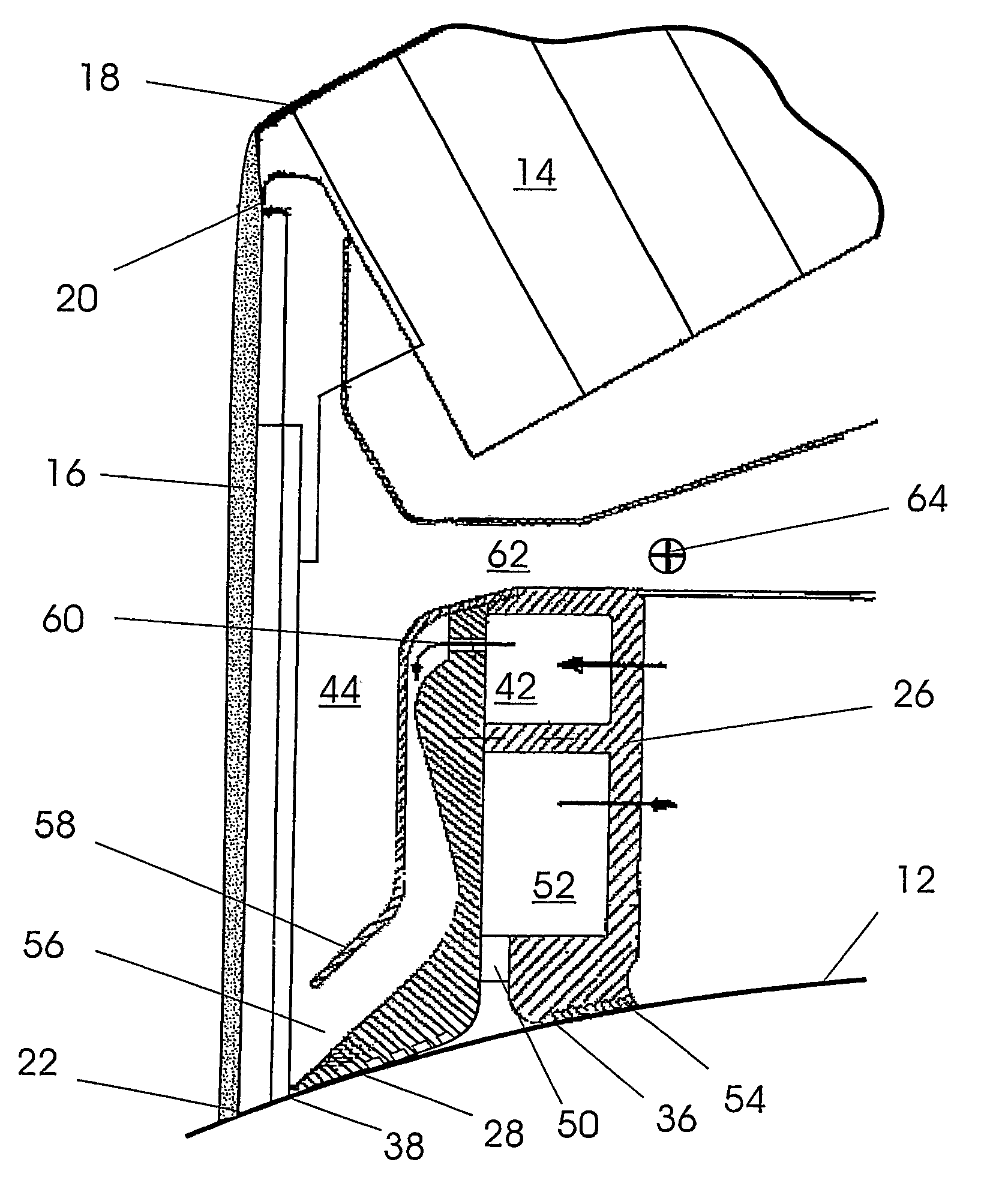

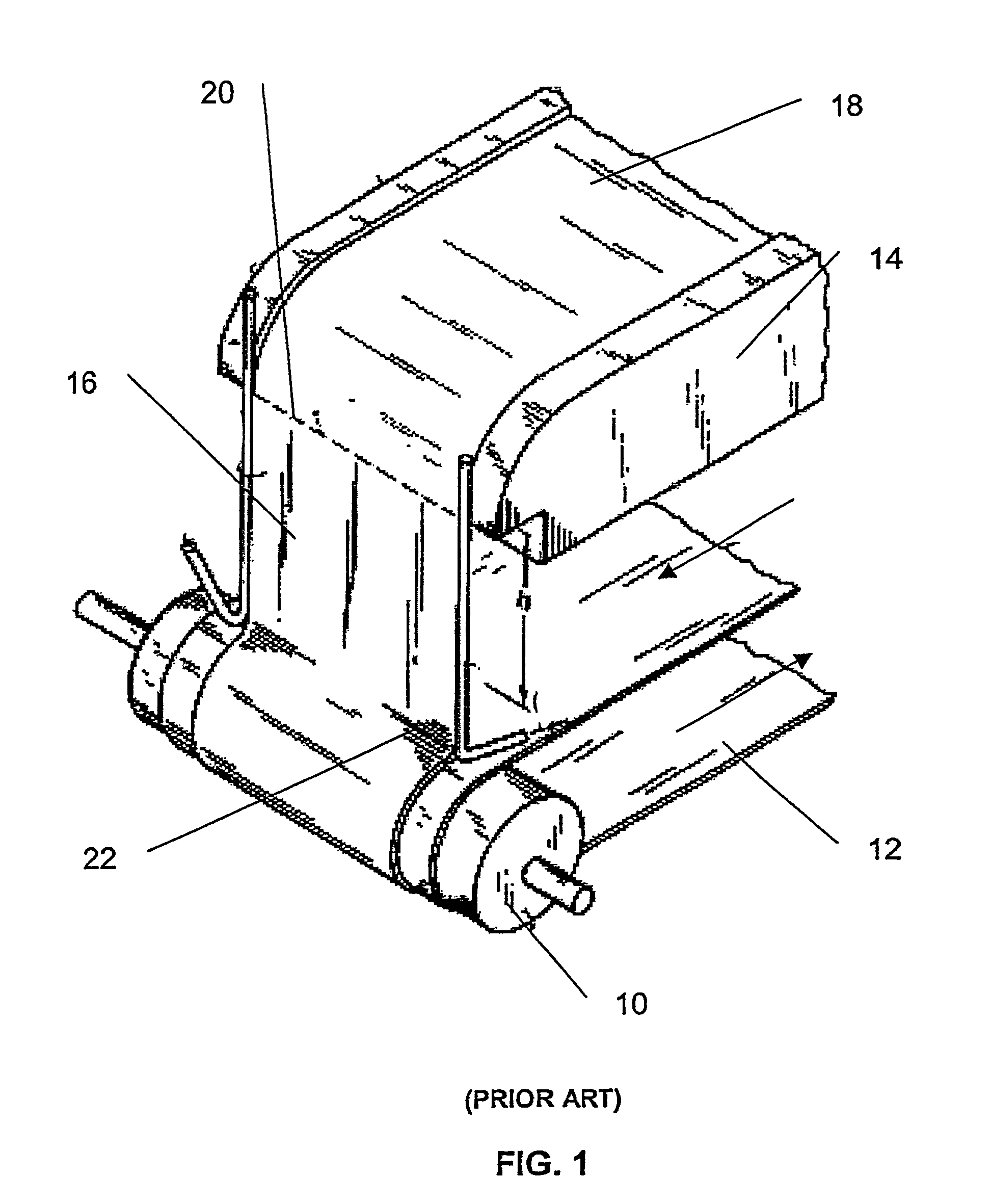

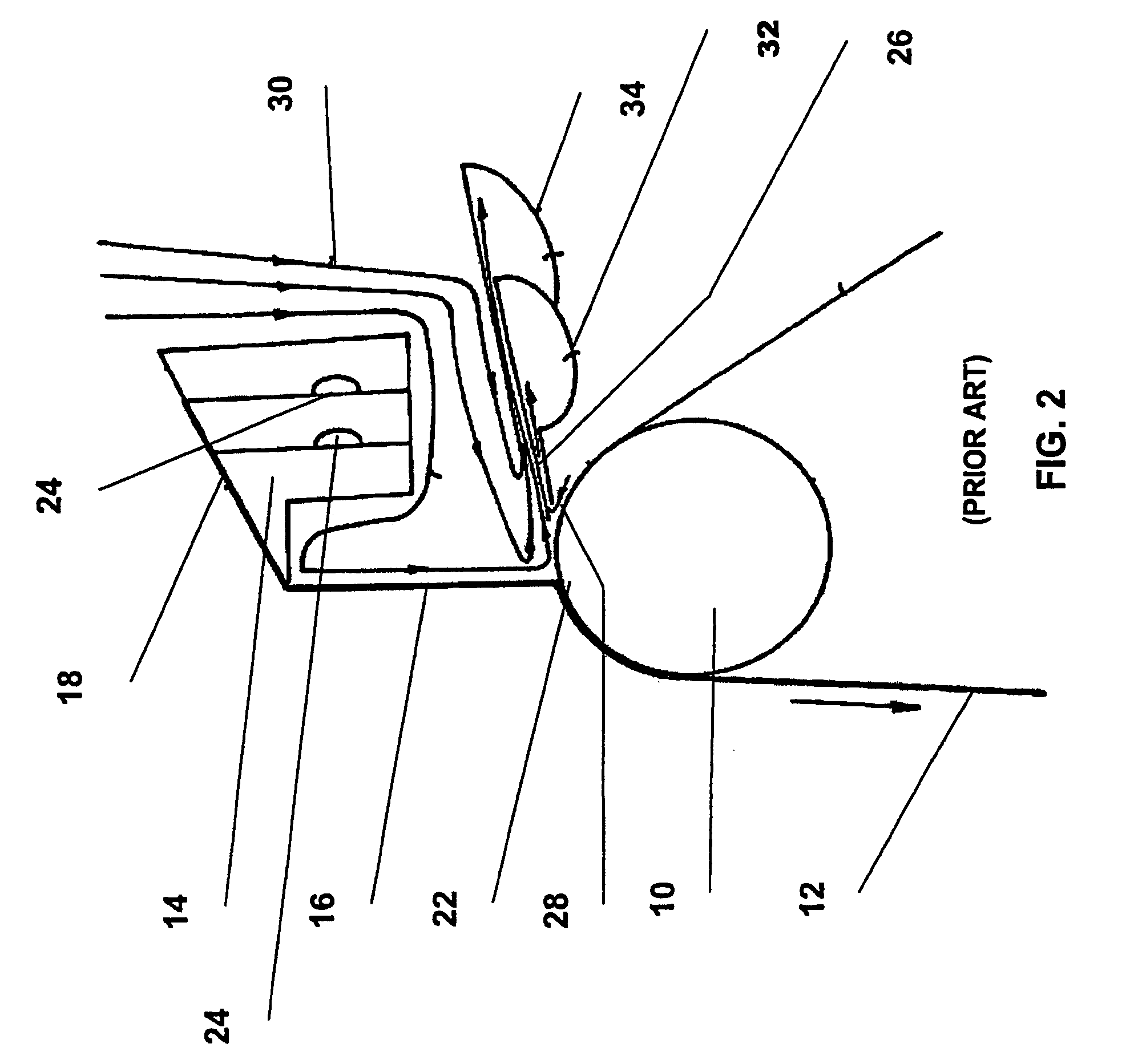

A web coating process and apparatus employing a coating applicator, dryer or curing station and web-handling equipment for conveying the web past the coating applicator and through the dryer. The web is enclosed from at least the coating applicator to the dryer or curing station in a close-coupled enclosure or series of close-coupled enclosures supplied with one or more streams of conditioned gas flowing at a rate sufficient to reduce materially the particle count or change materially a physical property of interest in a close-coupled enclosure.

Owner:3M INNOVATIVE PROPERTIES CO

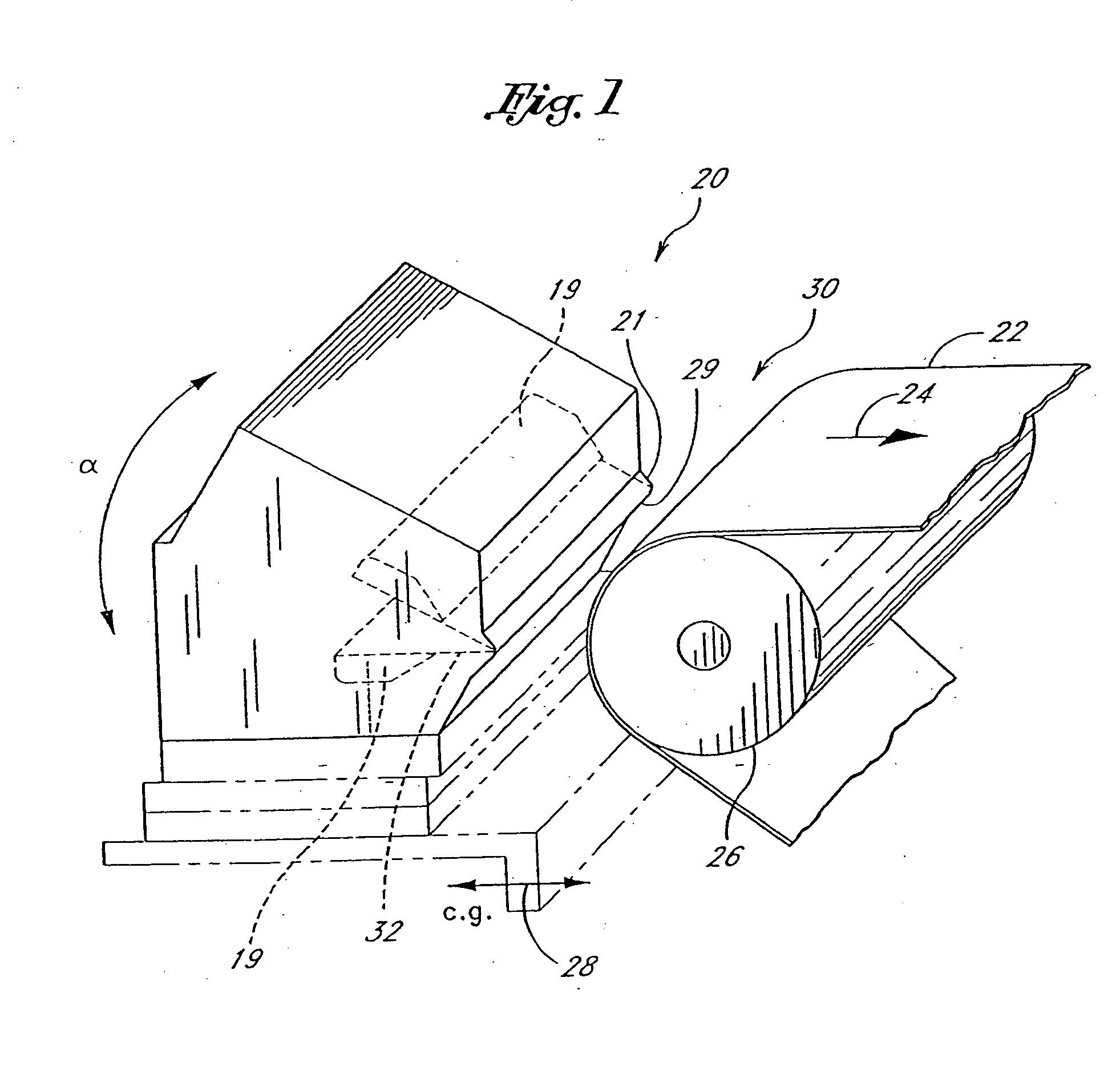

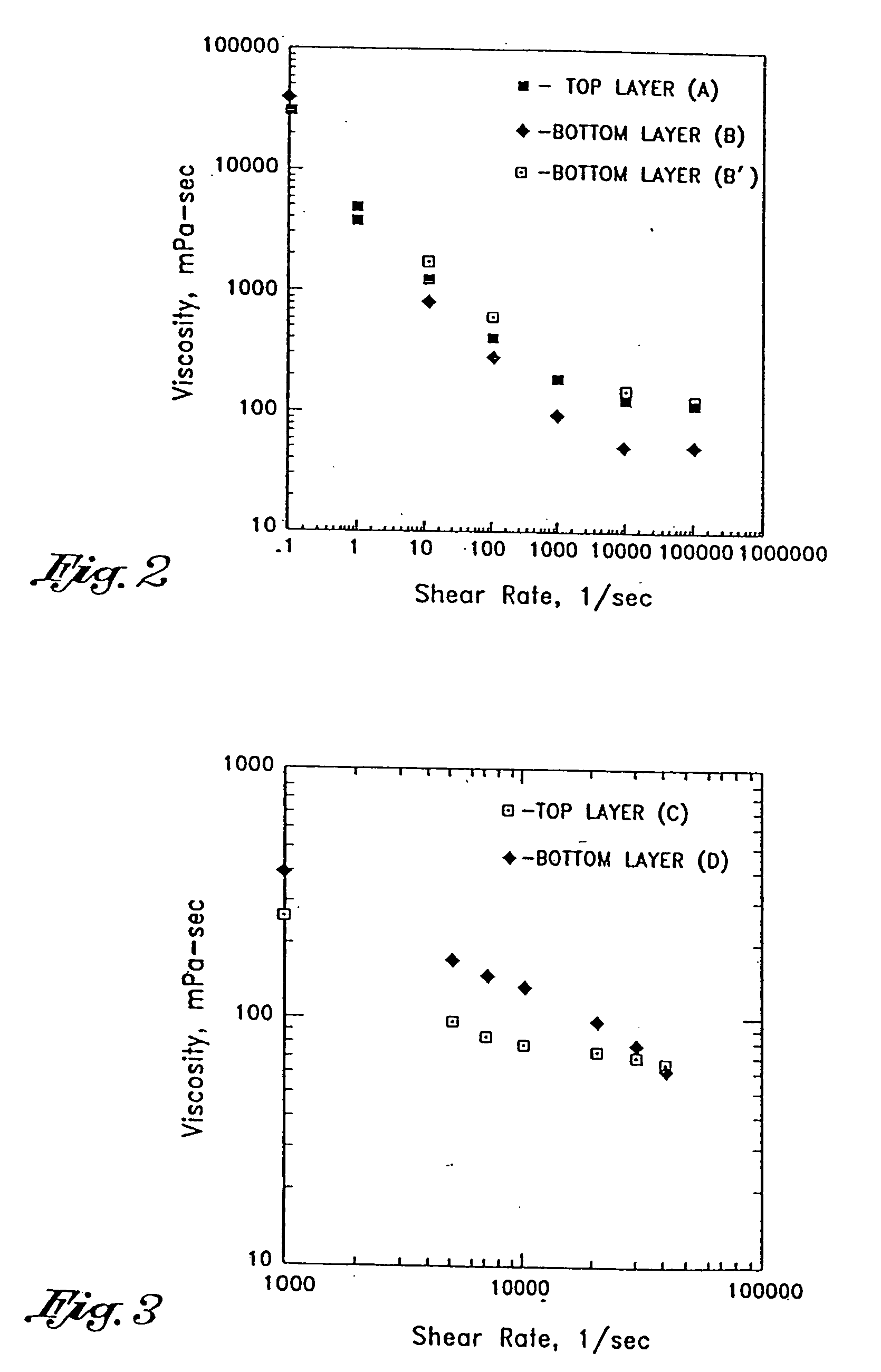

Method for drying a coating on a substrate and reducing mottle

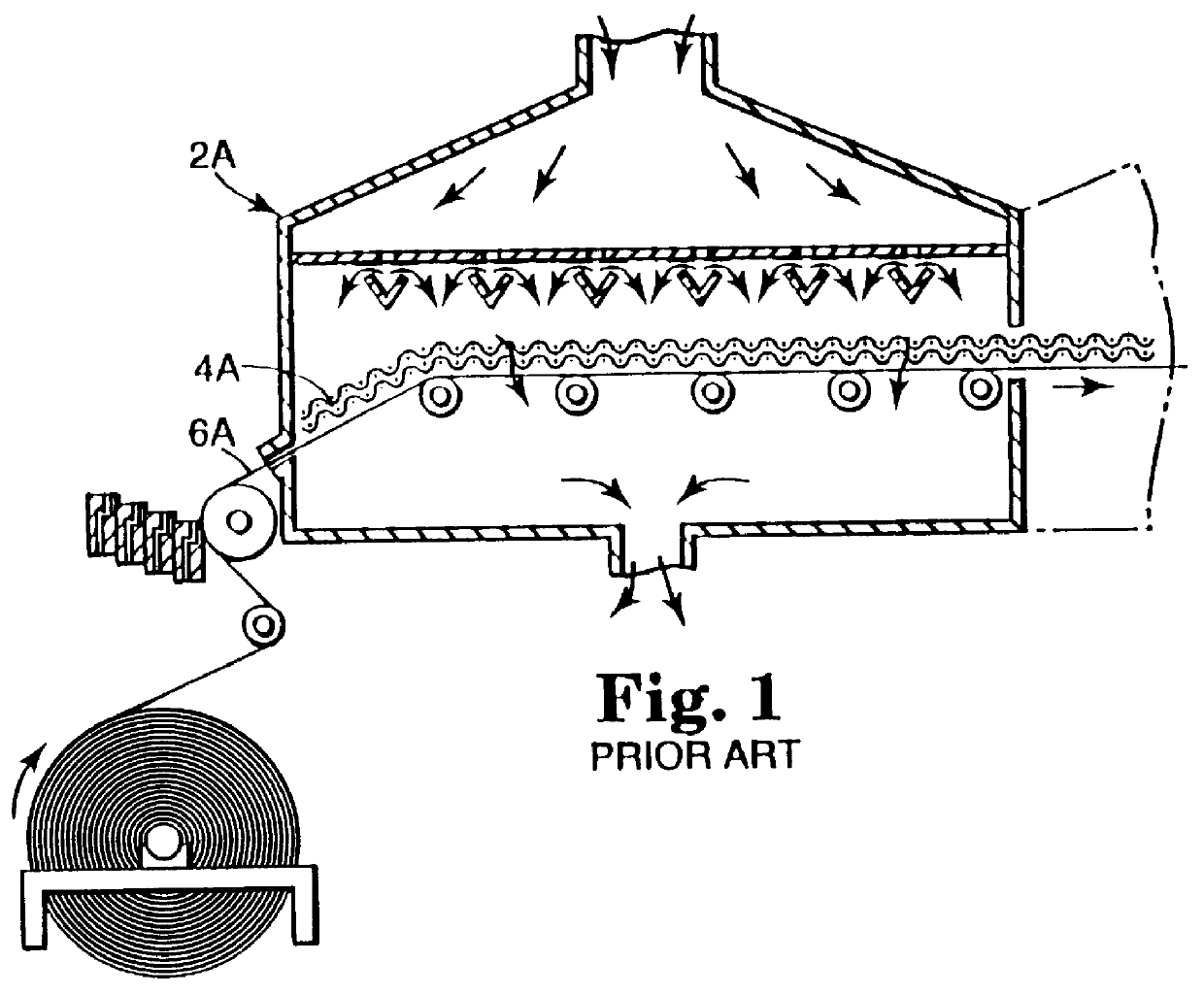

InactiveUS6015593AHigh web speedIncrease speedDuplicating/marking methodsPretreated surfacesEvaporationTemperature difference

An apparatus and method for evaporating a coating solvent from a coating on a substrate and for minimizing the formation of mottle. The coating is heated with a first drying gas at no higher than a first heat transfer rate. The first heat transfer rate is created by a first heat transfer coefficient and a first temperature difference between the first coating temperature and the first drying gas temperature. The first heat transfer rate causes maximum evaporation of the coating solvent yet insignificant formation of mottle when the coating is at the first coating thickness and the first coating viscosity.

Owner:3M CO

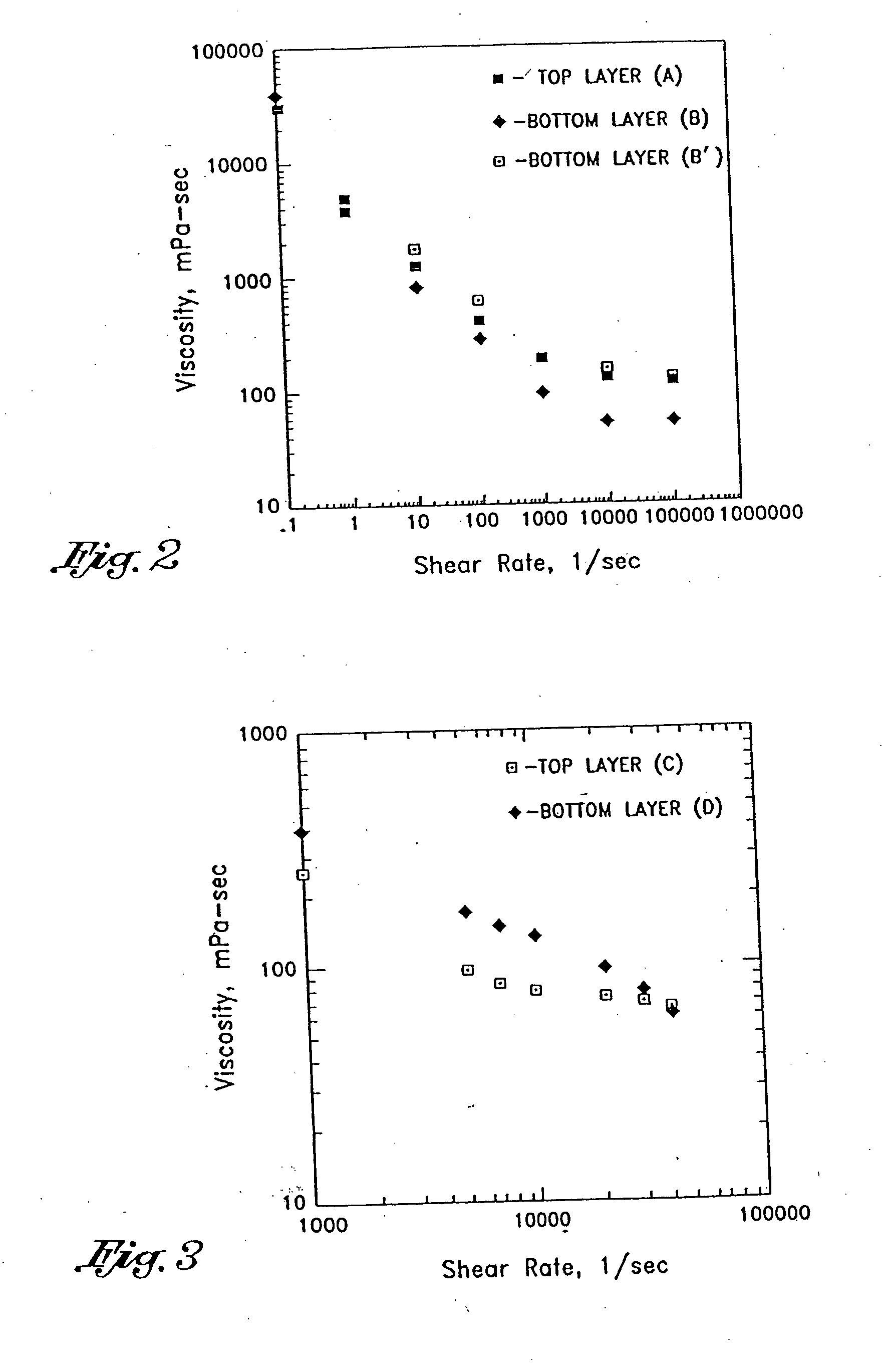

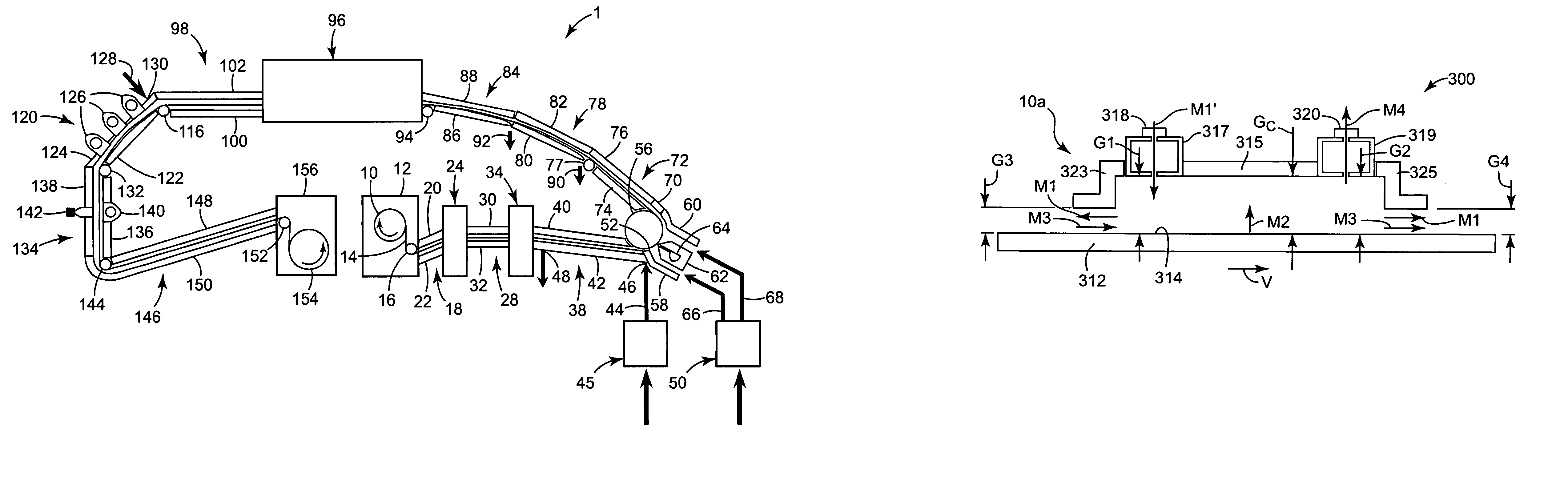

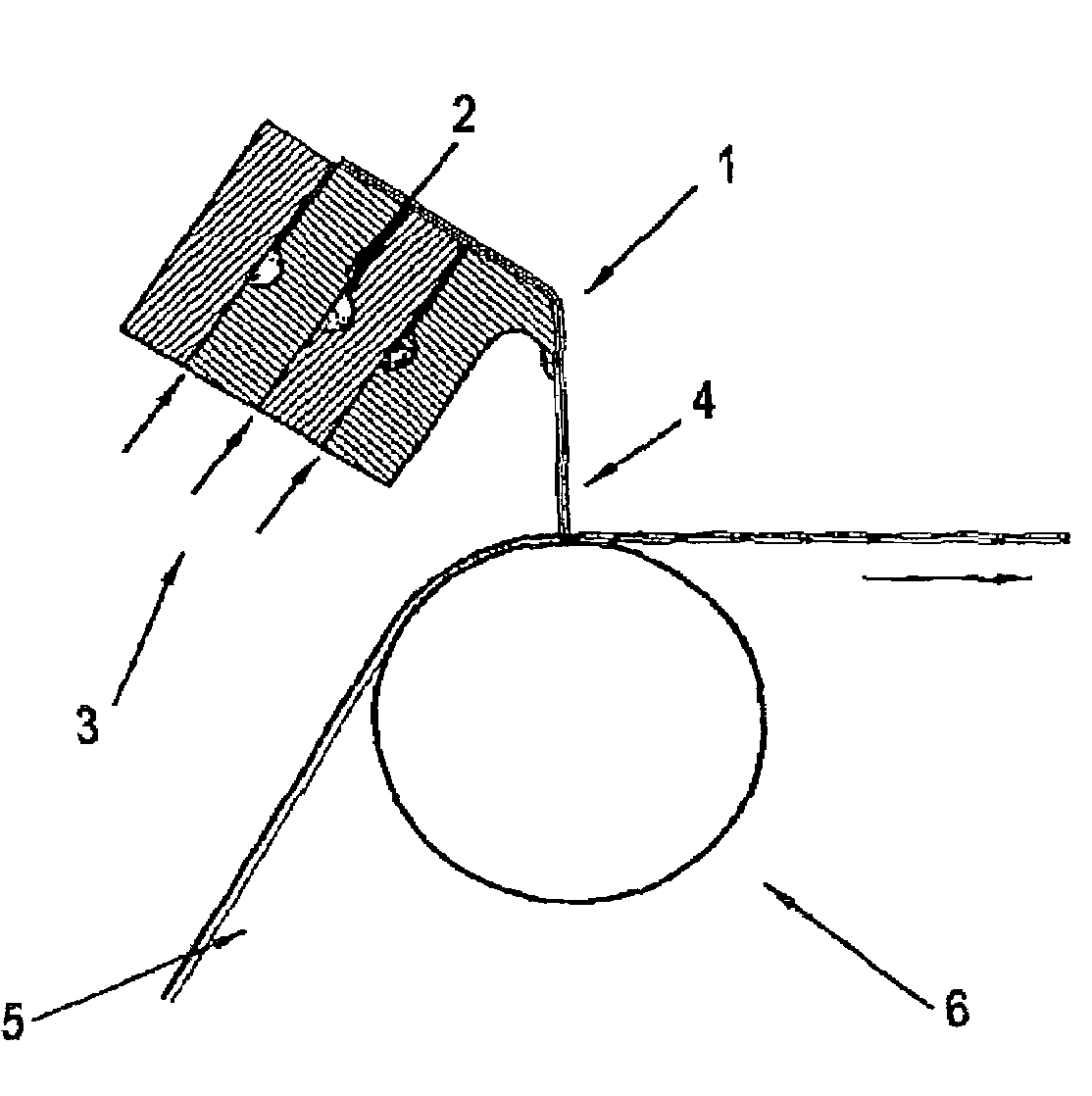

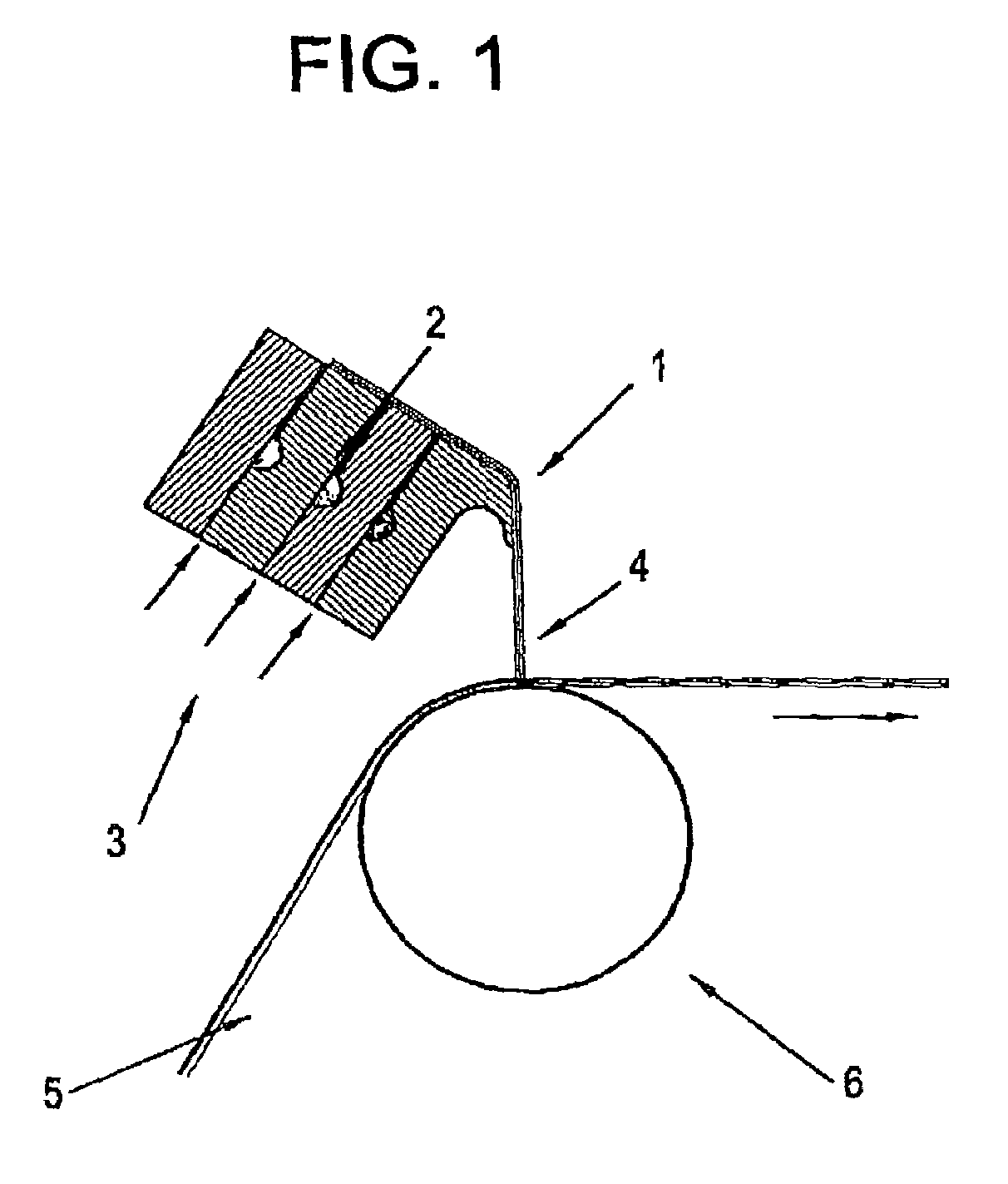

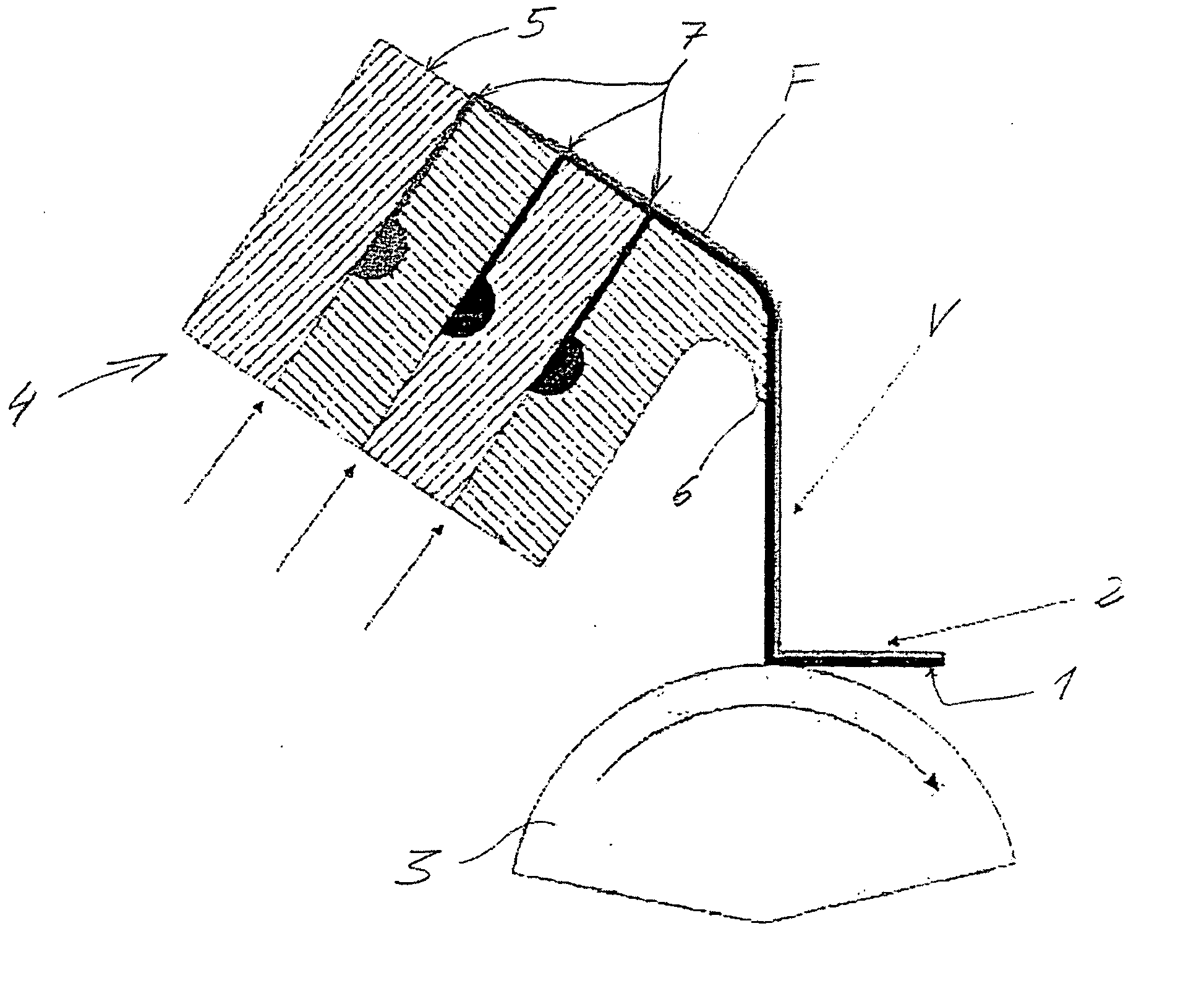

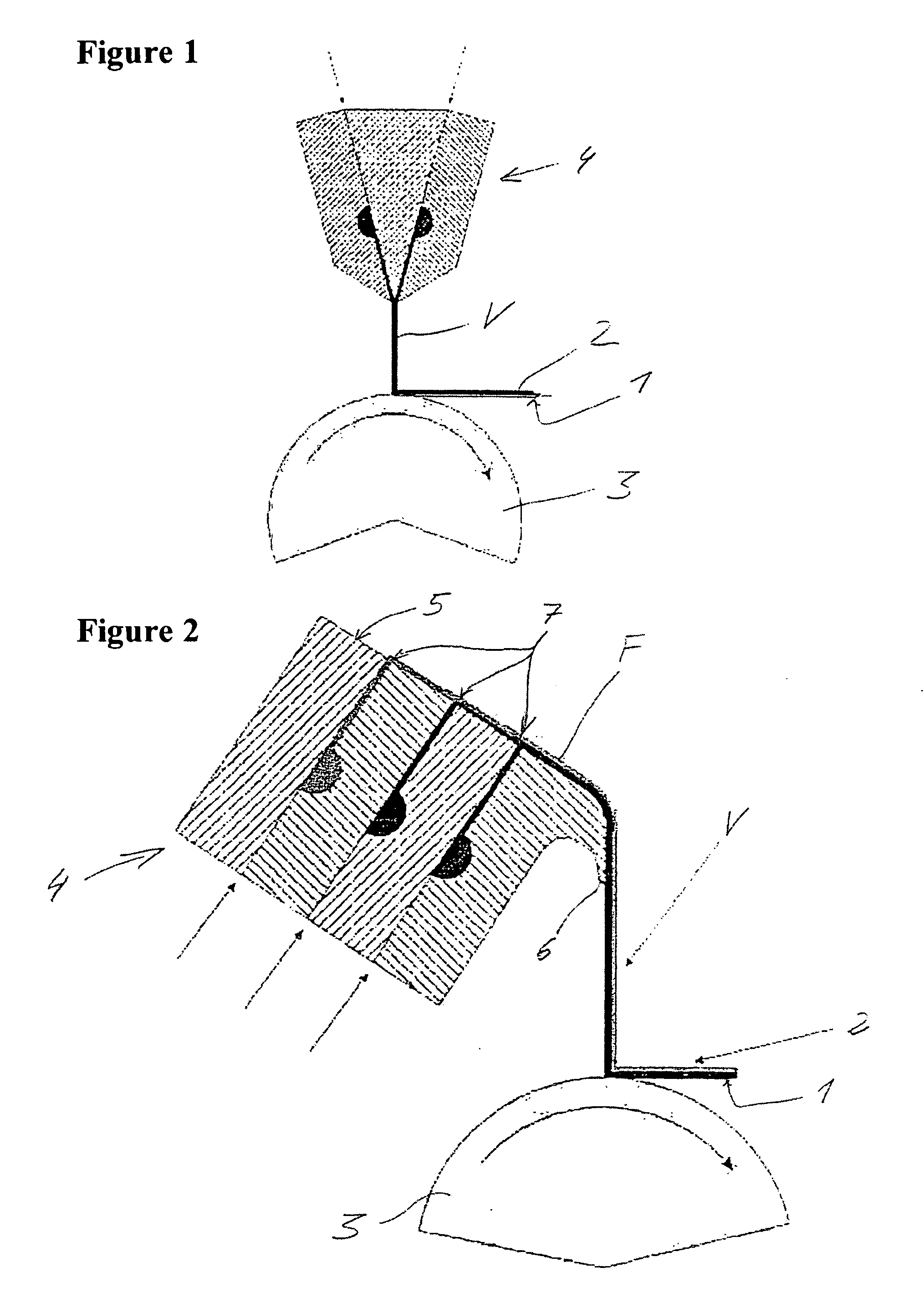

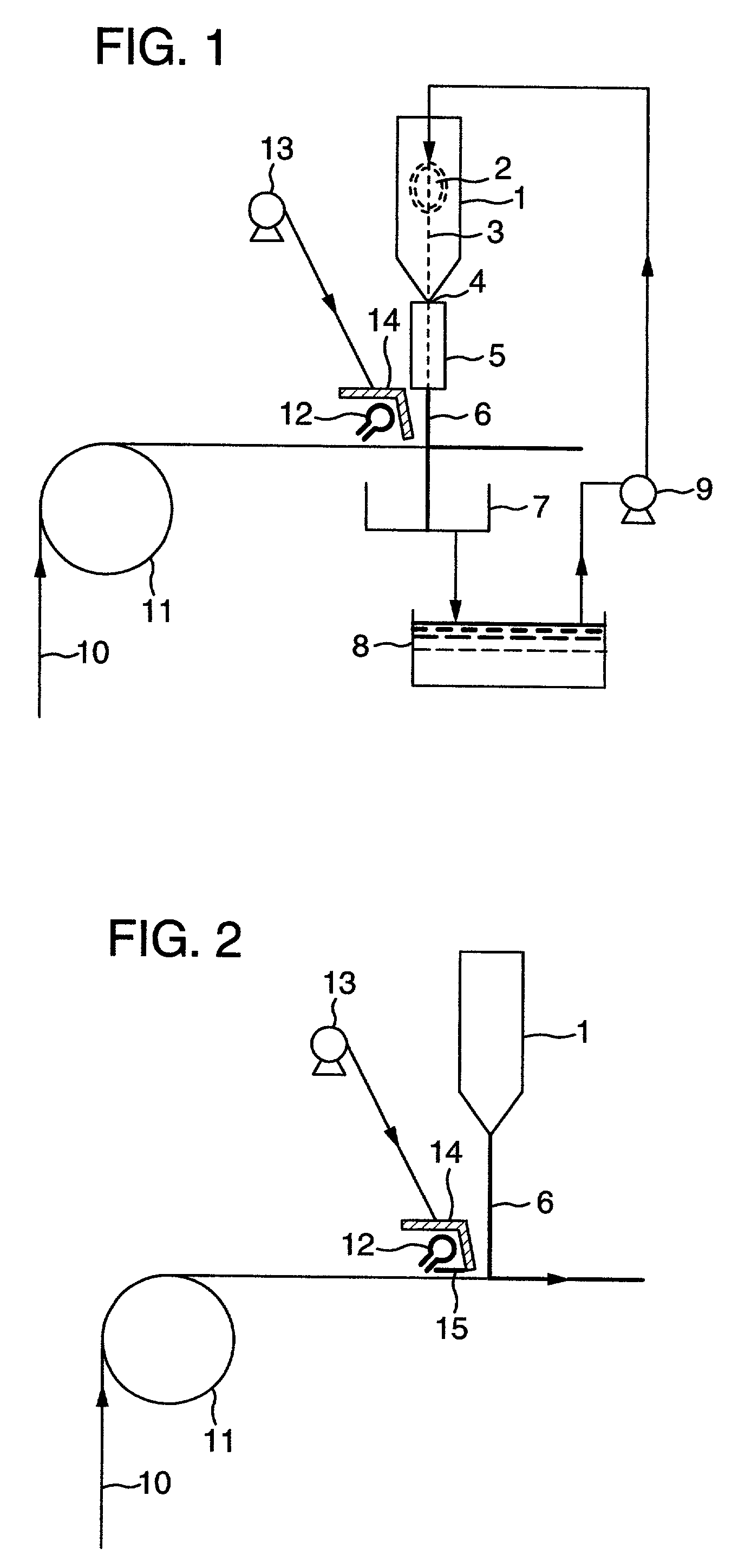

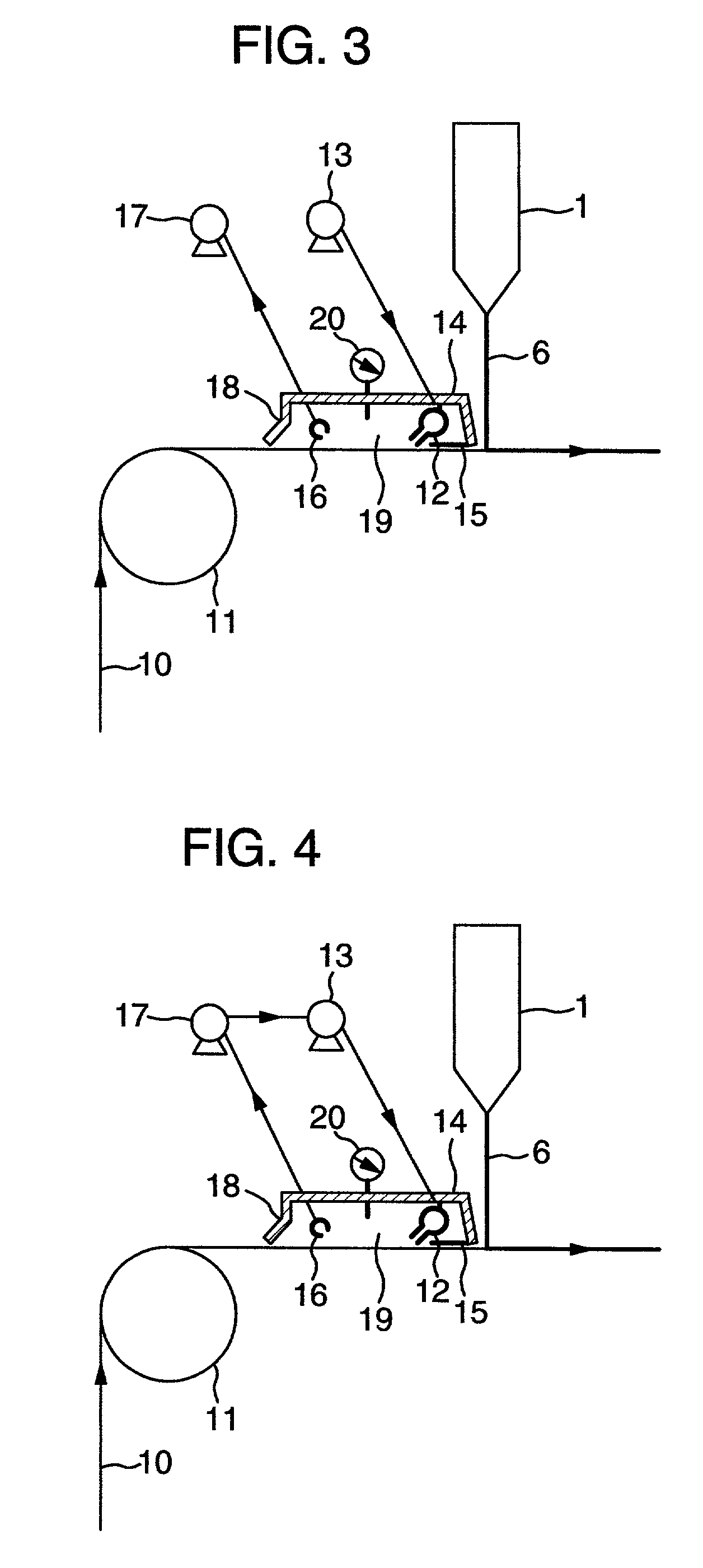

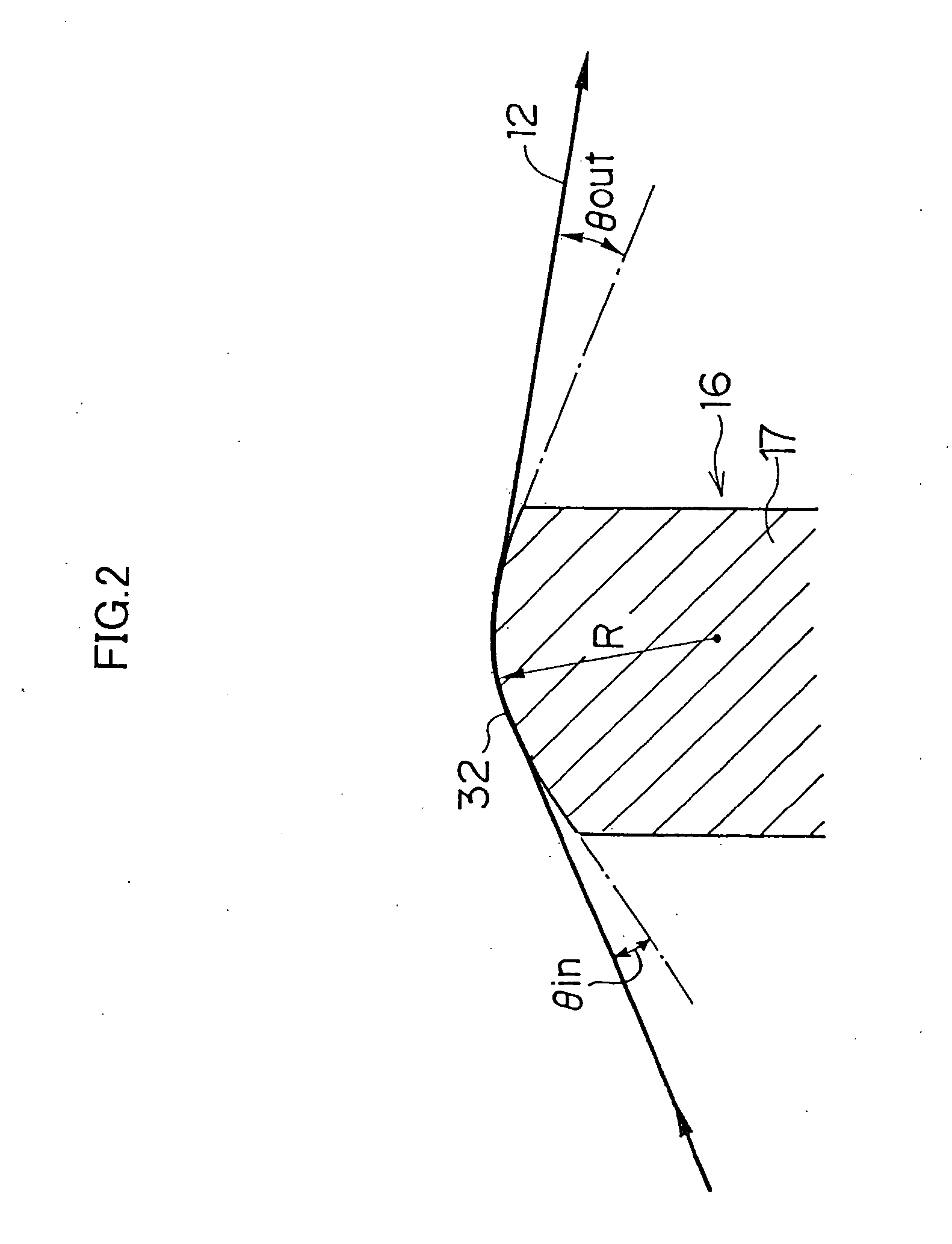

Method and apparatus for curtain coating

In a method and an apparatus for curtain coating of a moved substrate like a paper web substrate is moved below a liquid supply means providing a single or multilayer liquid coating in the form of a free-falling curtain impinging the substrate at a dynamic wetting line and a blade or air shield located upstream of the dynamic wetting line with respect to the moving direction of the substrate. The dynamic wetting line of the coating curtain on the substrate or web is oriented generally perpendicular to the moving direction of the substrate or web, providing substantially the same air pressure over an essential part of the coating curtain on its front and back side with respect to the moving direction of the substrate and providing a first supply air flow upstream to the wetting line. The supply air flows over a substantial length along the free-falling curtain and evacuates air from a location upstream of the supply air flow so that the air near the dynamic wetting line is moved against the moving direction of the substrate web and the boundary air layer entrained to the substrate. A second supply air is provided in proximity to the wetting line.

Owner:TRINSEO EURO GMBH

Process for making multilayer coated paper or paperboard

InactiveUS7425246B2Reduce weightImprove efficiencyNon-fibrous pulp additionNatural cellulose pulp/paperFree fallingEmulsion

Owner:DOW GLOBAL TECH LLC

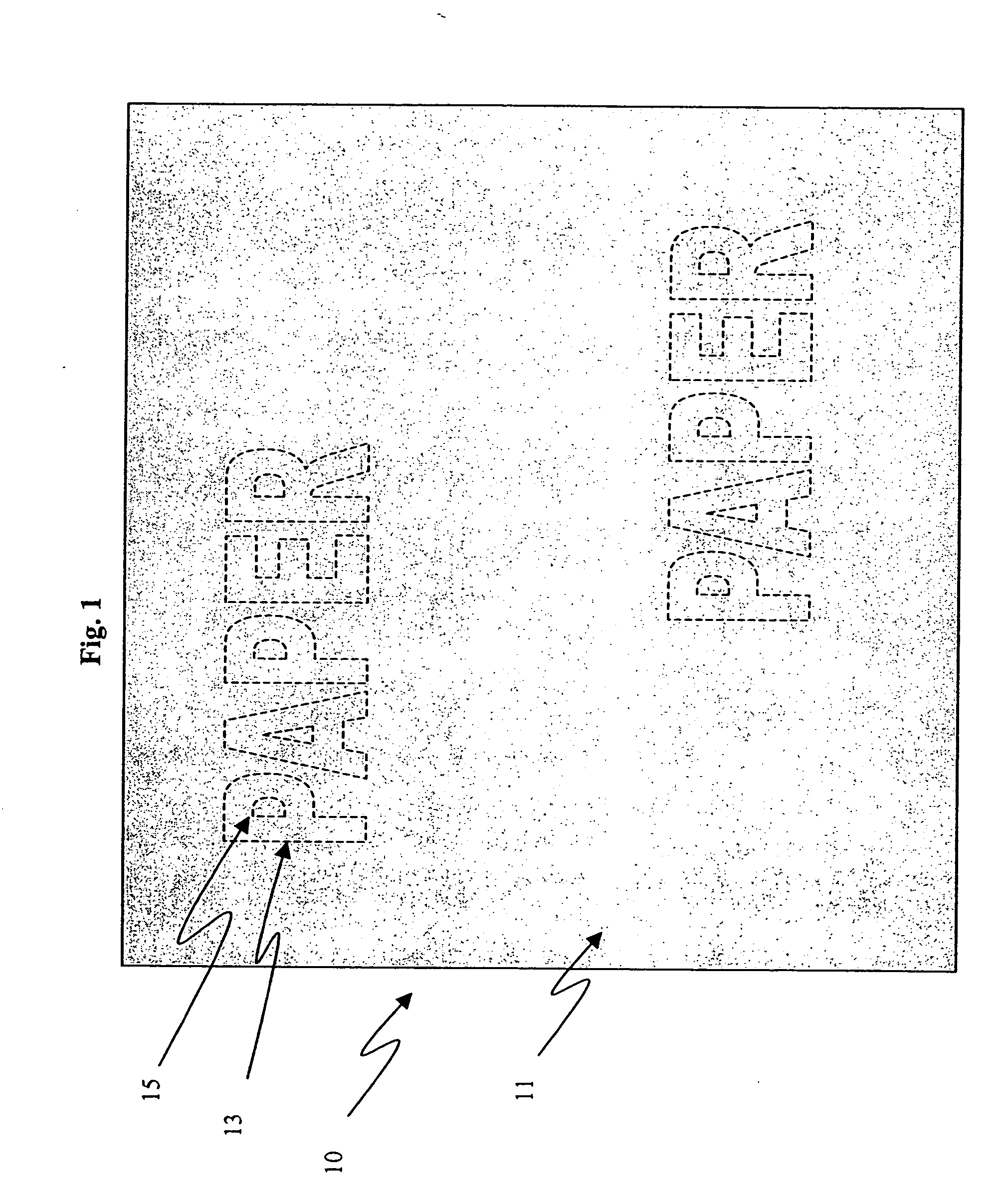

Antistatic conductive grid pattern with integral logo

InactiveUS20050069683A1Reduce coverageConserve material costDecorative surface effectsSynthetic resin layered productsGrid patternEngineering

The present invention relates to an article comprising a substrate having thereon at least one antistatic layer, wherein said antistatic layer comprises at least one conductive material, and wherein said antistatic layer comprises areas of patterned coverage, and wherein said patterned coverage comprises a graphic design.

Owner:EASTMAN KODAK CO

Method of coating a multilayered element

InactiveUS20050084788A1High speed manufacturingImprove coating uniformityRadiation applicationsPretreated surfacesPolymer chemistryMultiple layer

This invention relates to a method of coating multiple layers on a support comprising a) taking a support; b) simultaneously coating on said support a chill settable layer and a non-chill settable layer; c) lowering the temperature of the layers to immobilize said layers; and d) drying said layers. It further relates to imaging elements made by this process.

Owner:EASTMAN KODAK CO

Laminator and laminating method for lamination to substrate

InactiveUS20020056512A1Efficiently obtainedDiffusion transfer processesMechanical working/deformationEngineeringElectrical and Electronics engineering

Owner:FUJIFILM HLDG CORP +1

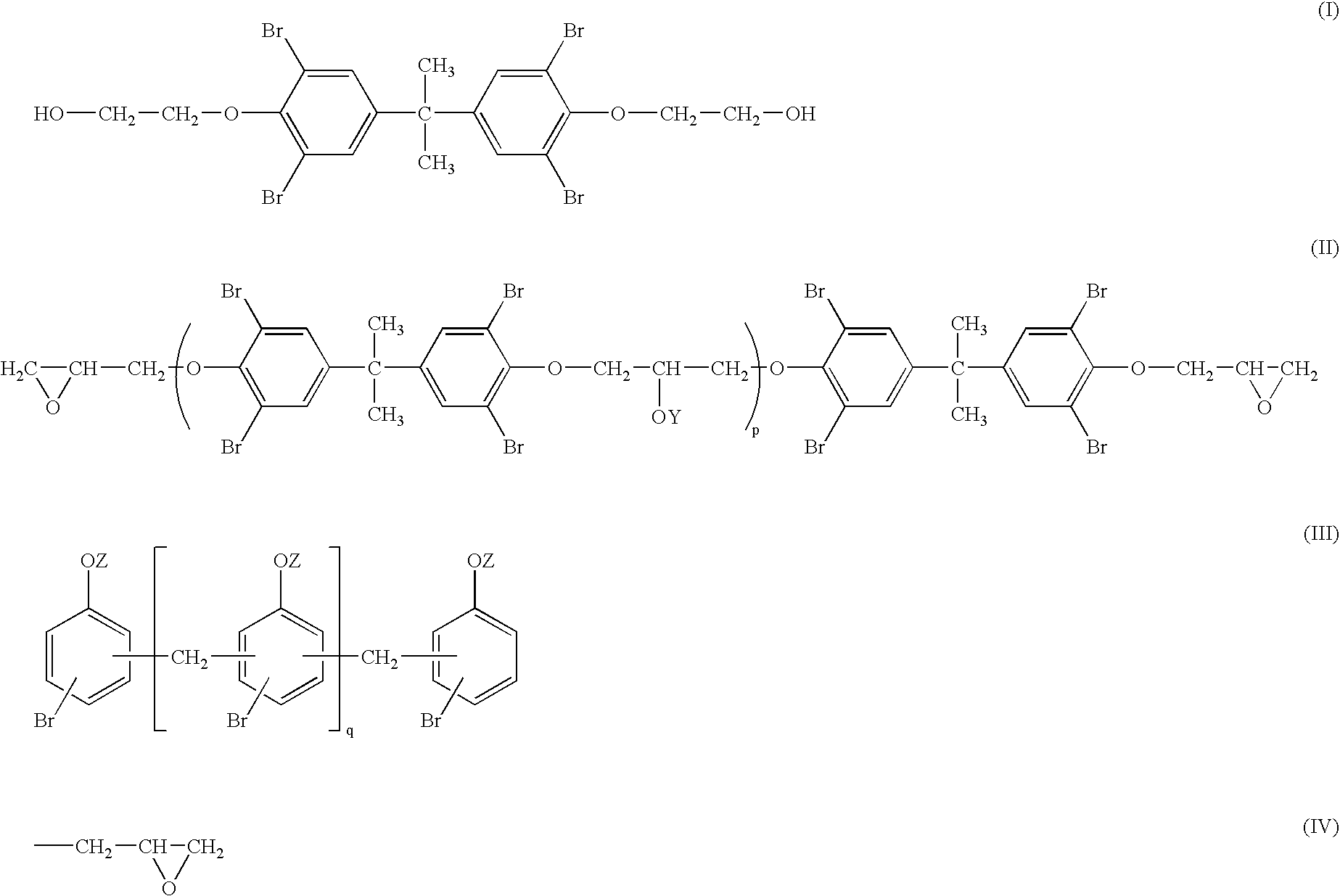

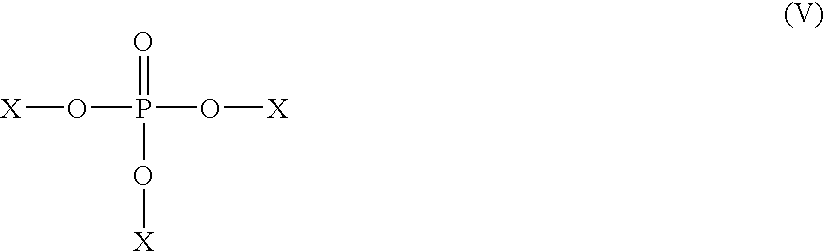

Resist curable resin composition and cured article thereof

InactiveUS7195857B2High-level pliabilityHigh-level resistanceSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistEpoxy

A resist curable resin material composed mainly of a curable prepolymer (for example, a photocurable resin material comprising a photosensitive prepolymer having an ethylenically unsaturated terminal group originating in an acrylic monomer (A), a compound having an ethylenically unsaturated group excluding the photosensitive prepolymer (B), and a photopolymerization initiator (C)) and a flame-retarding agent containing a hydrated metal compound and a brominated epoxy compound are mixed to produce a resist curable resin composition. Alternatively, the resist curable resin material described above and a hydrated metal compound surface-treated with a surface treating agent having an amphipathic property and a polarity are mixed to produce a resist curable resin composition.

Owner:SHOWA DENKO KK

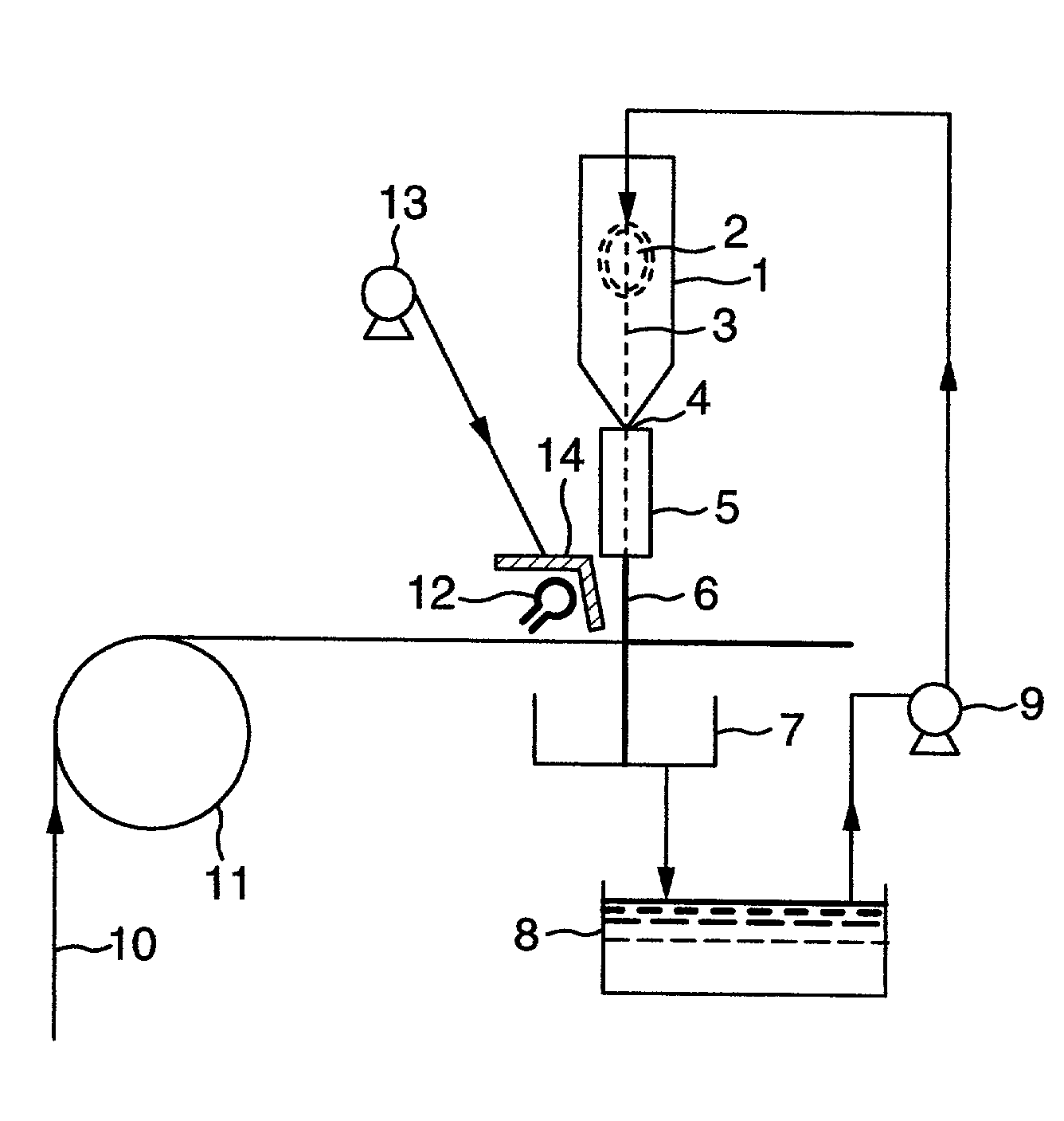

Method for drying coating film, apparatus therefor, and optical film using the same

InactiveUS20080104861A1Avoid unevennessImprove accuracyDrying solid materials with heatLayered productsSpray nozzleCentral layer

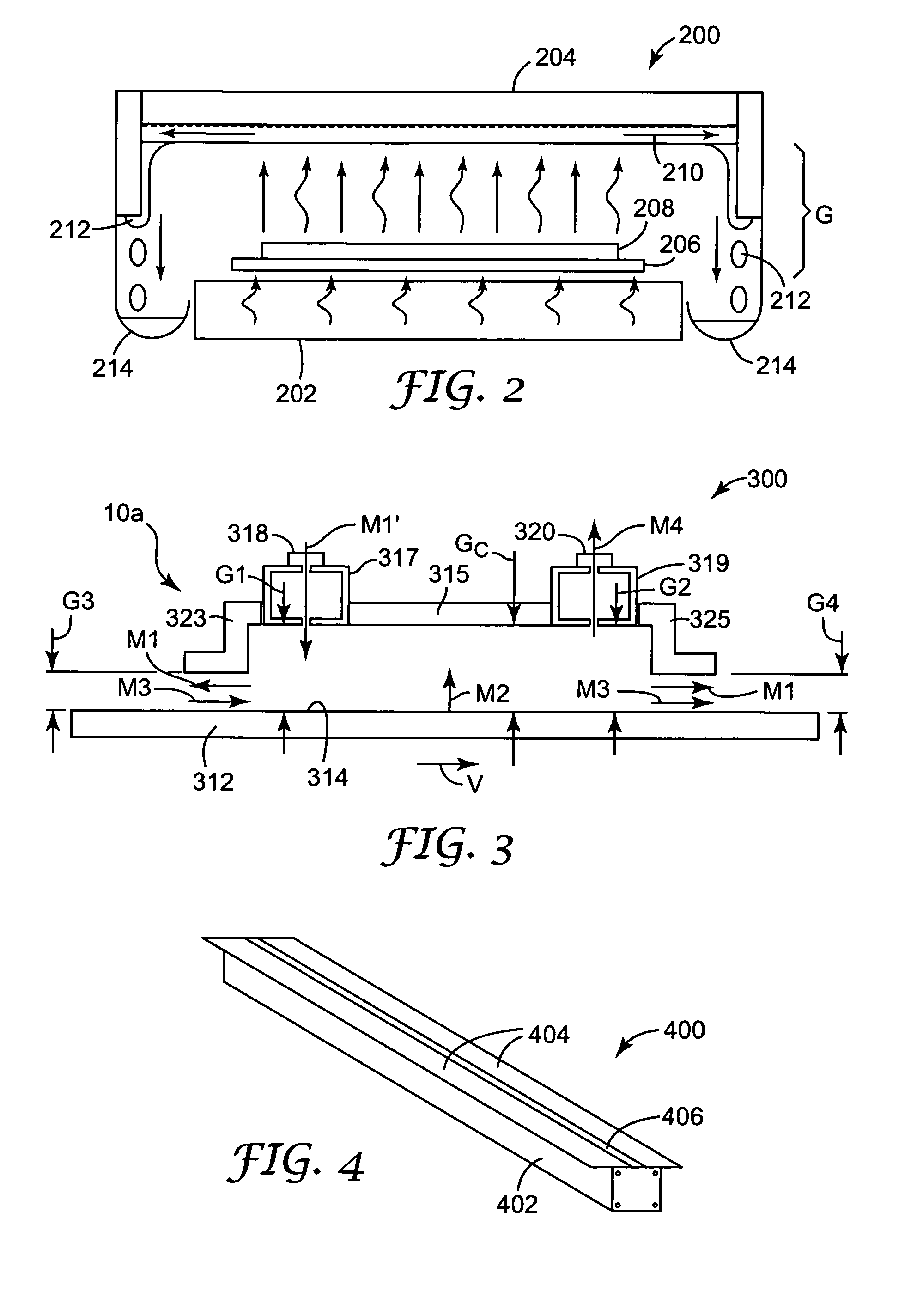

An aspect of the present invention provides a method for drying a coating film that has been formed by applying a coating liquid to a traveling long support, by forming a tunnel-shaped drying zone so as to surround the support, and supplying drying air into the drying zone from a rectangular air-supplying nozzle which faces to the drying zone, wherein the air-supplying nozzle is designed so that among layer components of the drying air which is supplied from the air-supplying nozzle, a boundary layer component which has flowed in the vicinity of the inner wall surface of the air-supplying nozzle and is supplied from the nozzle cannot hit the surface of the coating film, while there are the boundary layer component and a central layer component which has flowed in a central part of the air-supplying nozzle and is supplied from the nozzle, in the layer components.

Owner:FUJIFILM CORP

Curtain coater and curtain coating method

InactiveUS20070137563A1Reduce peripheral effectReduce impactLiquid surface applicatorsCoatingsFree fallingBiomedical engineering

A curtain coating device for the coating of a moving substrate, comprising a nozzle device, for the generation of a curtain dropping onto the substrate, made up of at least one coating fluid and a curtain guide structure with a guide surface, which laterally guides the curtain, whereby the guide surface is convex to the curtain along a width exceeding the depth of the curtain when measured transversely. Additionally, a curtain coating method, whereby a curtain made up of at least one coating fluid is deposited on a moving substrate in free fall and guided on both sides by means of a convex guide surface transverse to the curtain.

Owner:POLYTYPE CONVERTING

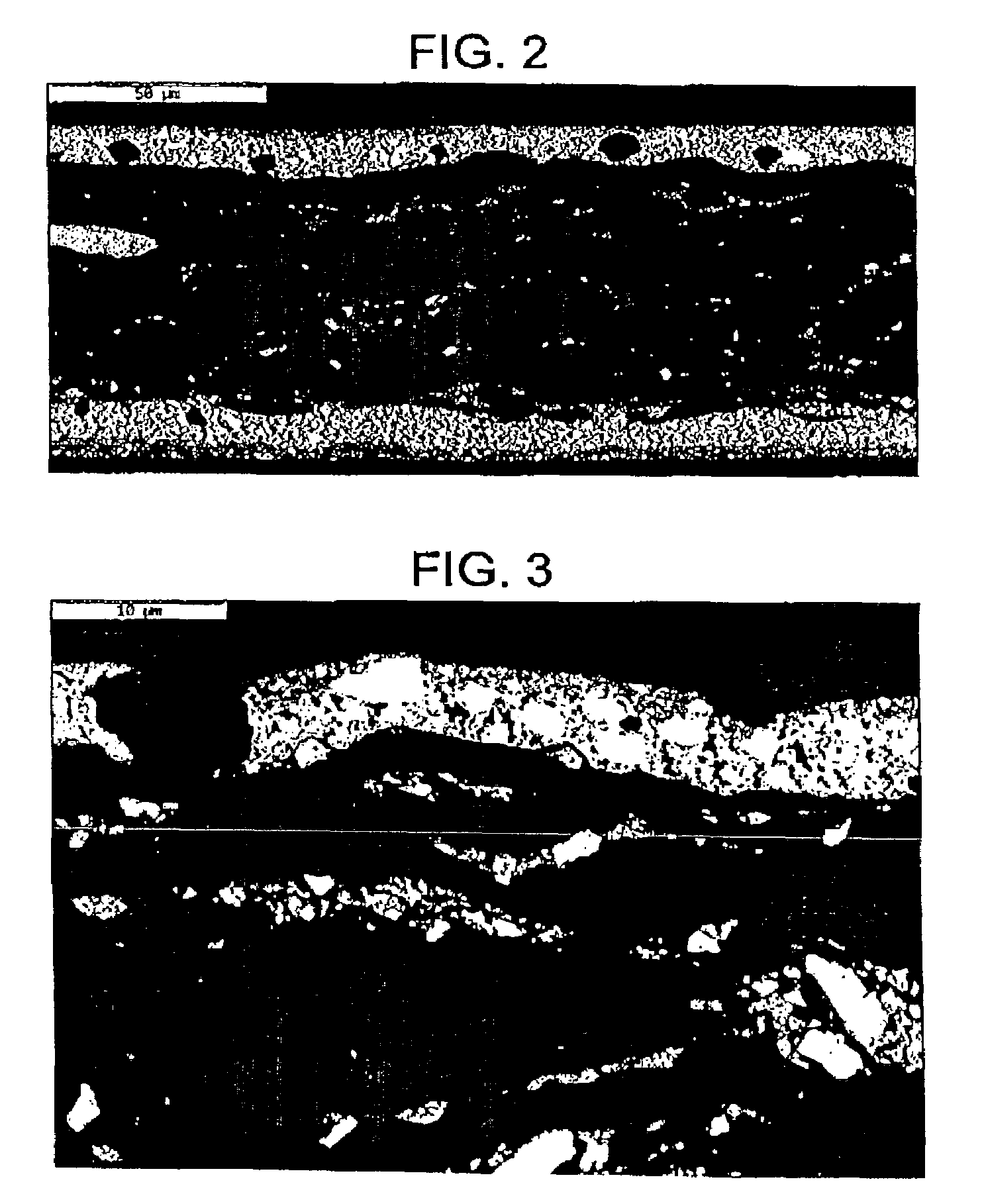

Photosensitive material for forming conductive film, and conductive material

ActiveUS20110070404A1High transparencyImprove conductivityFinal product manufactureLayered productsFiberEmulsion

A photosensitive material for forming a conductive film including a silver salt-containing emulsion layer, and a conductive layer containing conductive fibers, wherein the amount of the conductive fibers in the conductive layer is 0.005 g / m2 to 0.2 g / m2.

Owner:FUJIFILM CORP

Lithographic printing plate precursor

InactiveUS6461792B1Efficient use ofSemiconductor/solid-state device manufacturingPlate printingPolymer scienceBackbone chain

Disclosed is a positive or negative lithographic printing plate precursor which can form an image at high sensitivity by heating or heat developed by light-heat conversion, requires no development processing after image writing, has good sensitivity and excellent printing durability, is significantly improved in scumming resistance, and can directly make a plate by operating an infrared laser based on a digital signal, the precursor comprising a polymer compound having a functional group changeable in hydrophilicity by heat, acid or radiation and an under layer with which the polymer compound combined, wherein the polymer compound is a straight-chain polymer compound directly combined at an end of a polymer chain thereof with a surface of the under layer by chemical bonding, or comprises (i) a polymer backbone chemically combined with a surface of the under layer and (ii) a straight-chain polymer compound combined at an and of a polymer chain thereof with the polymer backbone and having a functional group changeable in hydrophilicity.

Owner:FUJIFILM CORP

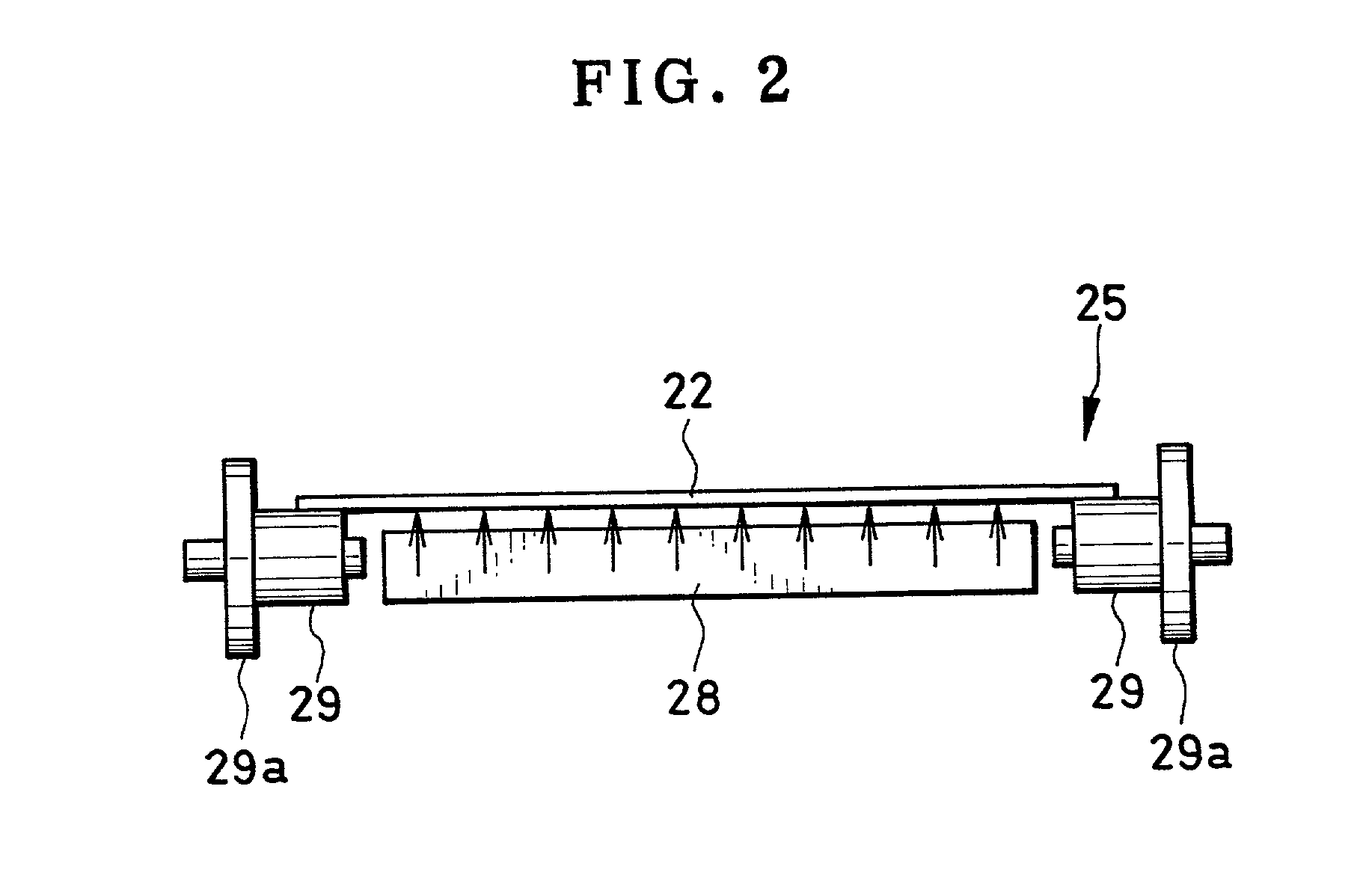

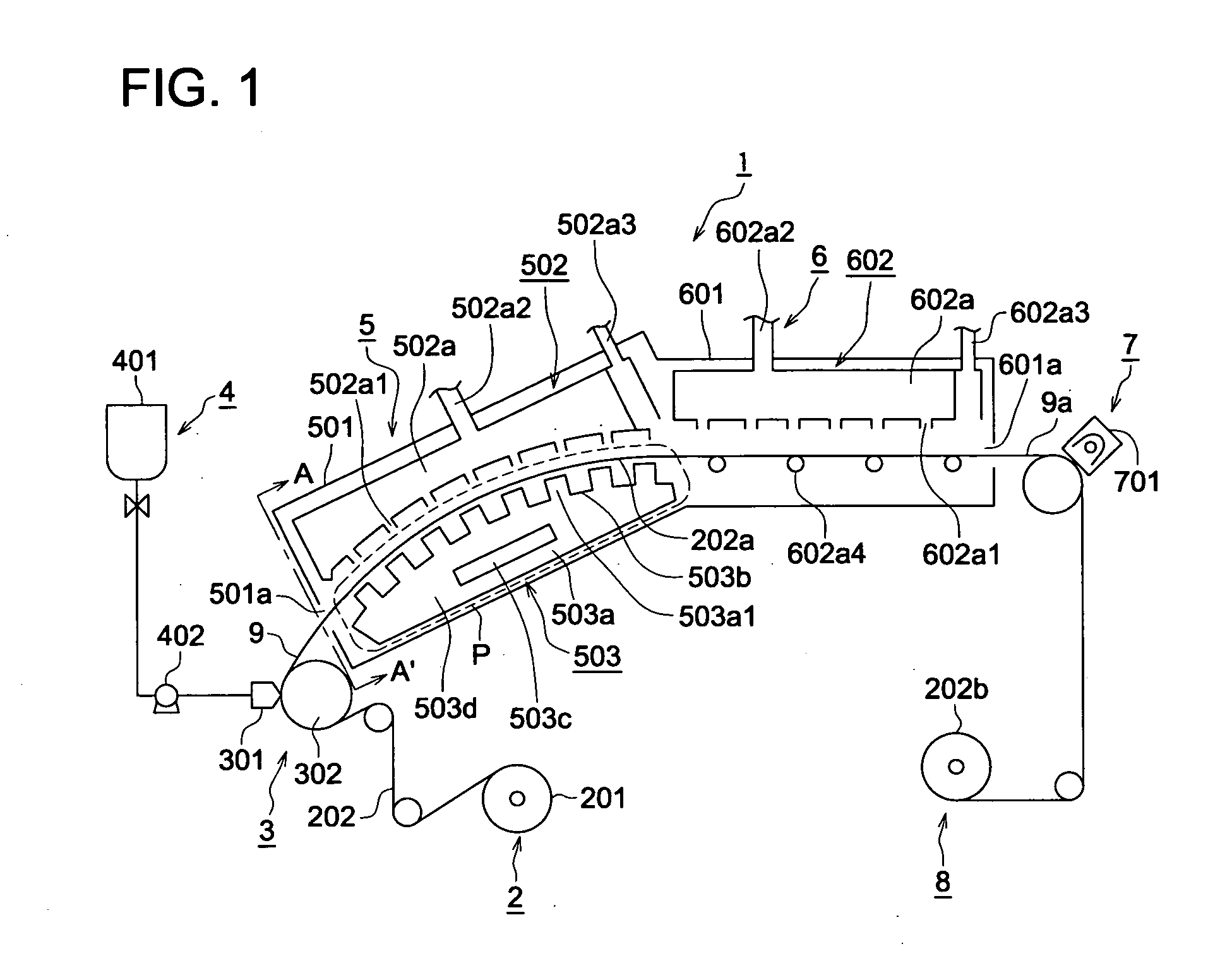

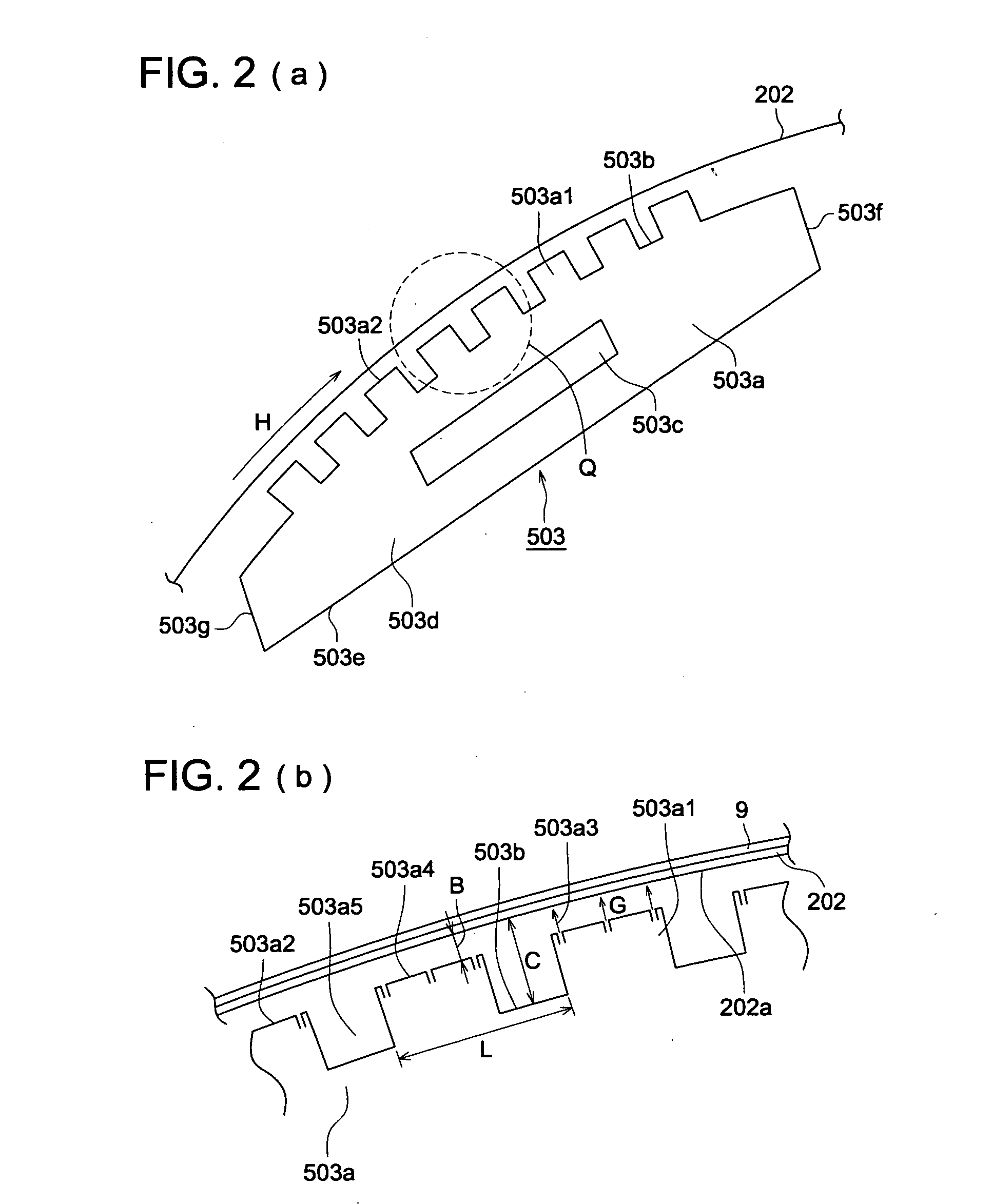

Method for production of functional film, substrate conveyance apparatus, and functional film produced with the method

InactiveUS20070128368A1Quality improvementImprove productivityPaper coatingPretreated surfacesThin membraneEngineering

A method for producing a functional film having the steps of: (a) forming a coated layer with a coating solution onto a substrate, and (b) drying the coated layer while the substrate is conveyed in a floating state by blowing a gas to an uncoated surface of the substrate from a plurality of blowing outlets arranged along the direction of the conveyance of the substrate, wherein the conveyance apparatus features alternately squared notches and raised portions having the blowing outlets, and in a plurality of the adjacent raised portion and the squared notch, the gas is blown from the blowing outlets to make a difference of back pressure between the raised portion and the uncoated surface of the substrate and the back pressure between the squared notch adjacent to the raised portion and the uncoated surface of the substrate to be between 10-1,000 Pa.

Owner:KONICA MINOLTA OPTO

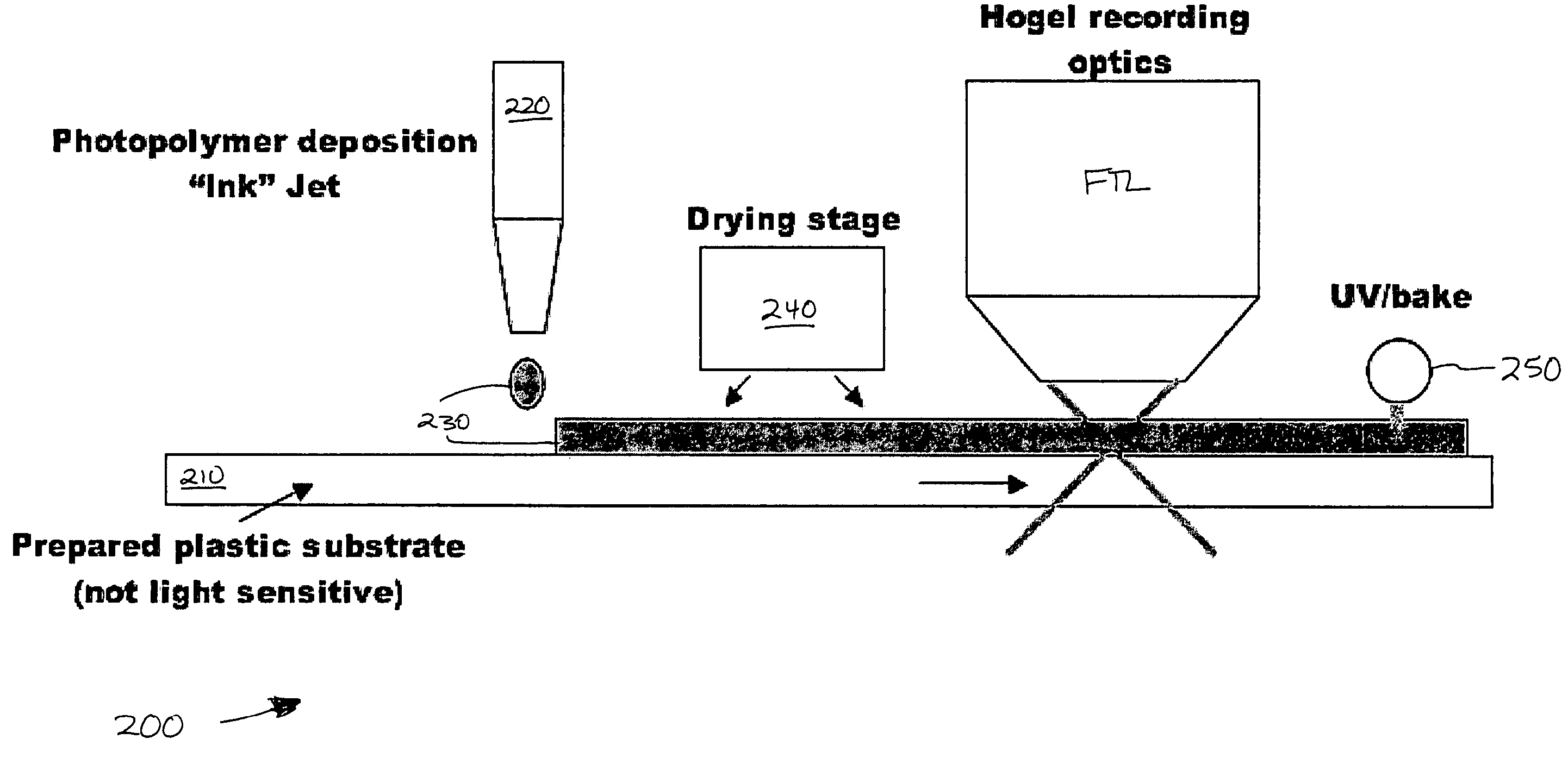

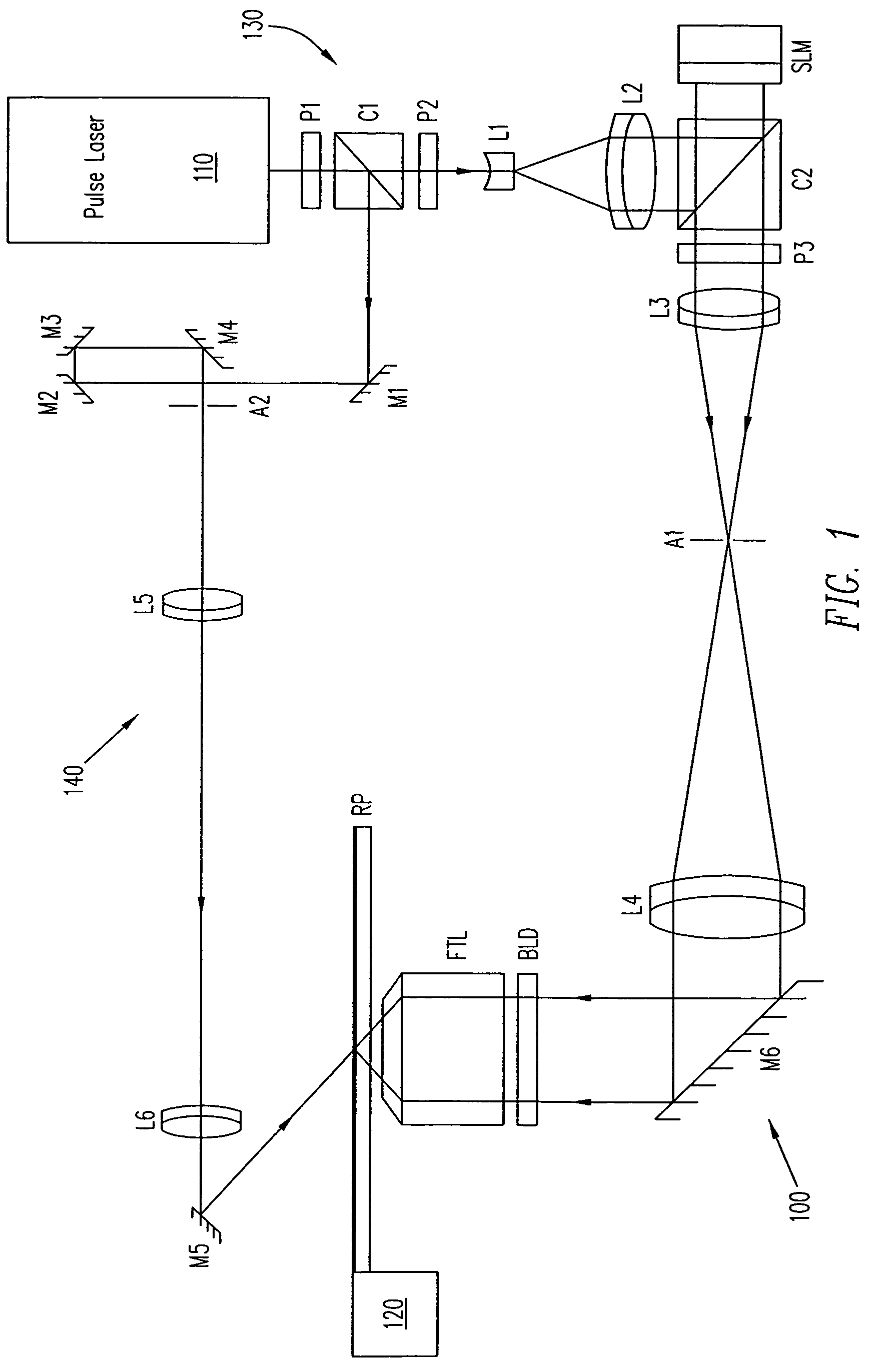

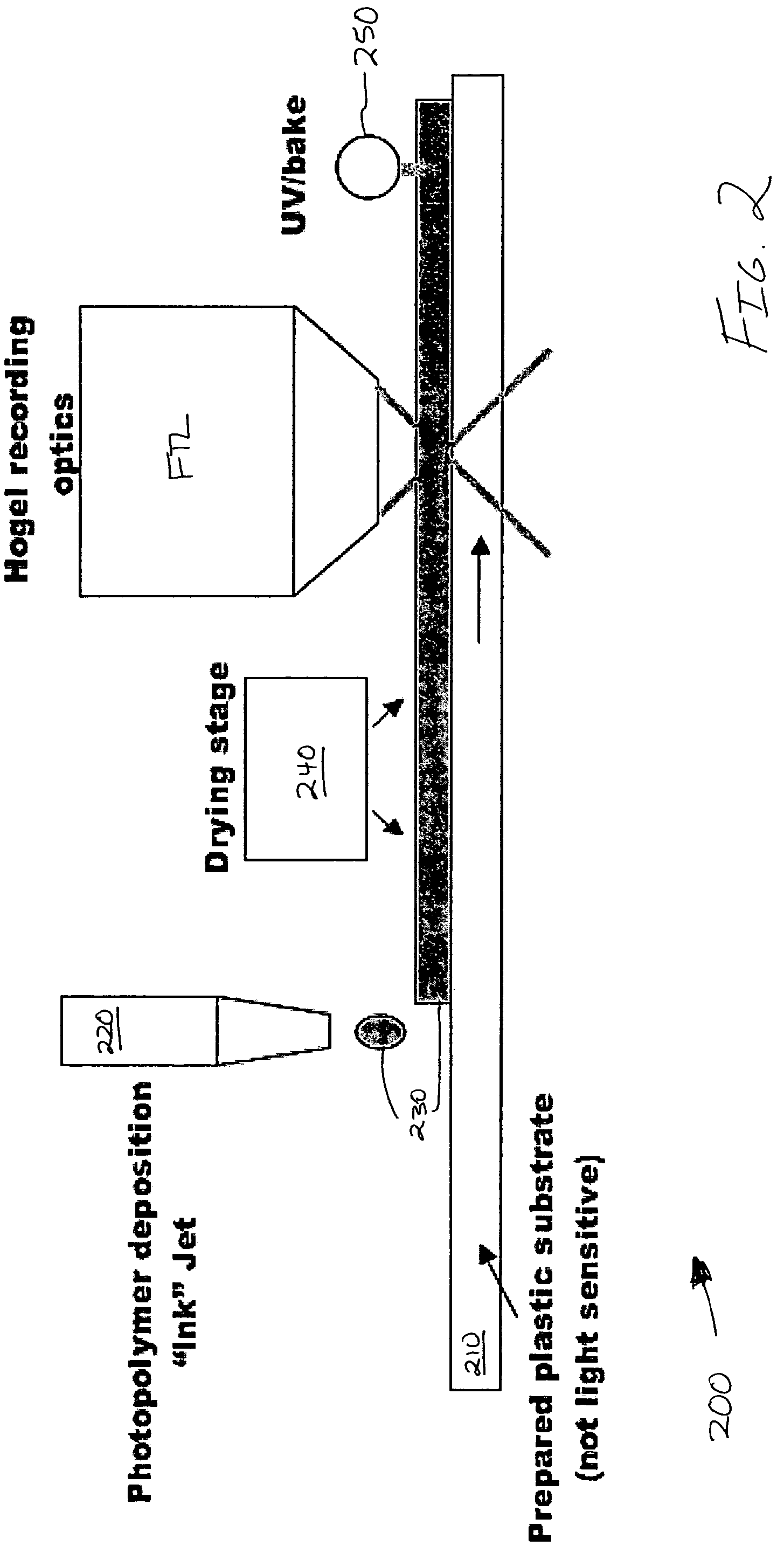

Deposition of photosensitive media for digital hologram recording

InactiveUS7271940B2Liquid surface applicatorsRecord information storageProviding materialMaterials science

Hologram production devices can include holographic recording material deposition systems to deposit holographic recording material as needed by the hologram production device. Various nozzles, ink jets, and similar devices can be used to deposit one or more components of the holographic recording material on to an appropriate substrate. If needed, the material is pre-processed to, for example, provide material stability for the holographic recording material. Once holograms are recorded in the holographic recording material, the material can be post-processed as desired.

Owner:ZEBRA IMAGING

Electrophotographic photosensitive member, process for producing electrophotographic photosensitive member, and electrophotographic apparatus and process cartridge including electrophotographic photosensitive member

ActiveUS10120331B2Increased durabilitySacrificing wear resistancePhotothermographic systemsPhotosensitive material auxillary/base layersSurface layerEngineering

The present invention provides a satisfactory electrophotographic photosensitive member which satisfies wear resistance and electrical properties and further, with which image defects do not occur, a process for producing an electrophotographic photosensitive member, and an electrophotographic apparatus and a process cartridge each including the electrophotographic photosensitive member. The electrophotographic photosensitive member the surface layer of which contains a copolymer of a polymerizable functional group-containing charge transporting substance and a particular polymerizable compound.

Owner:CANON KK

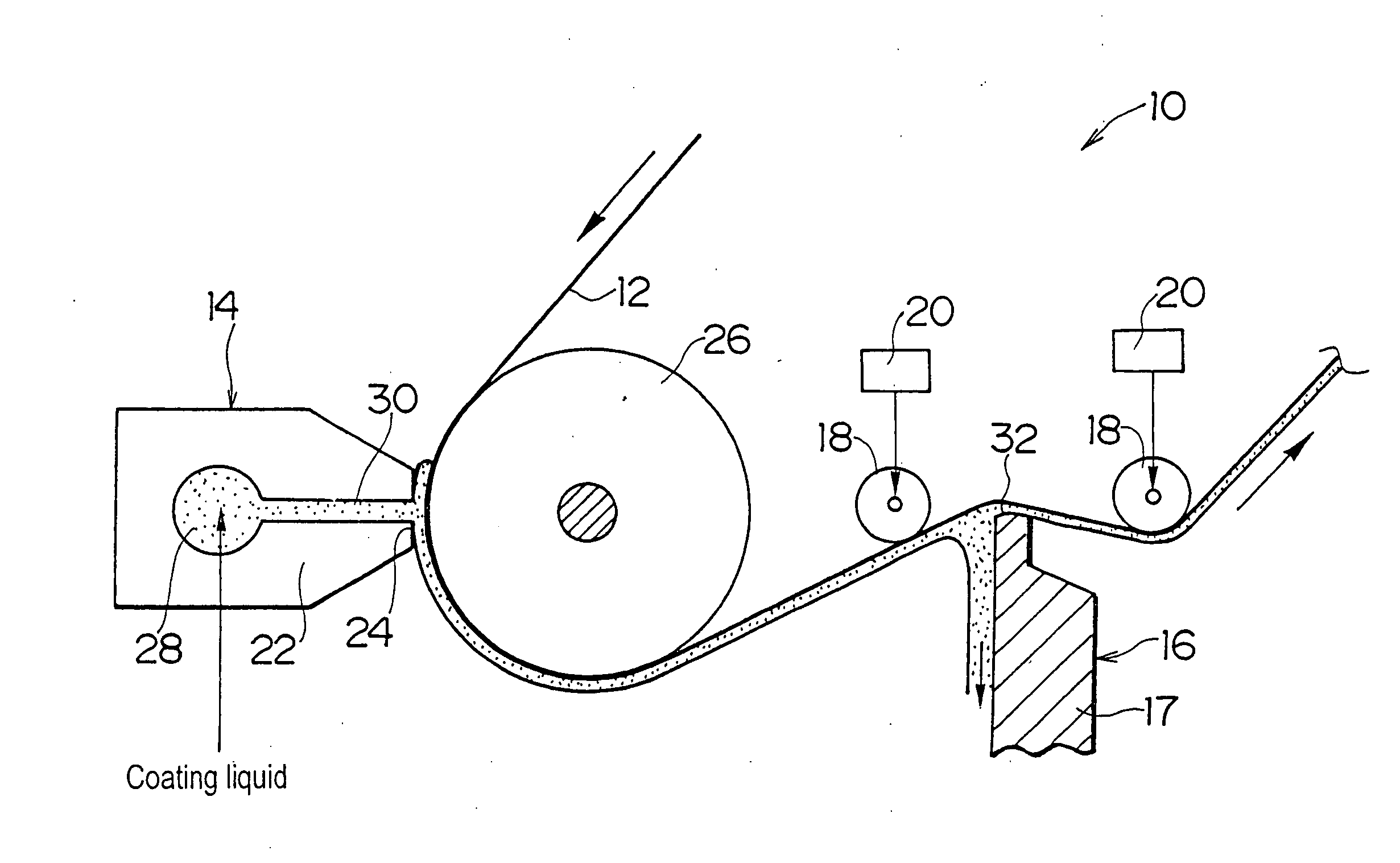

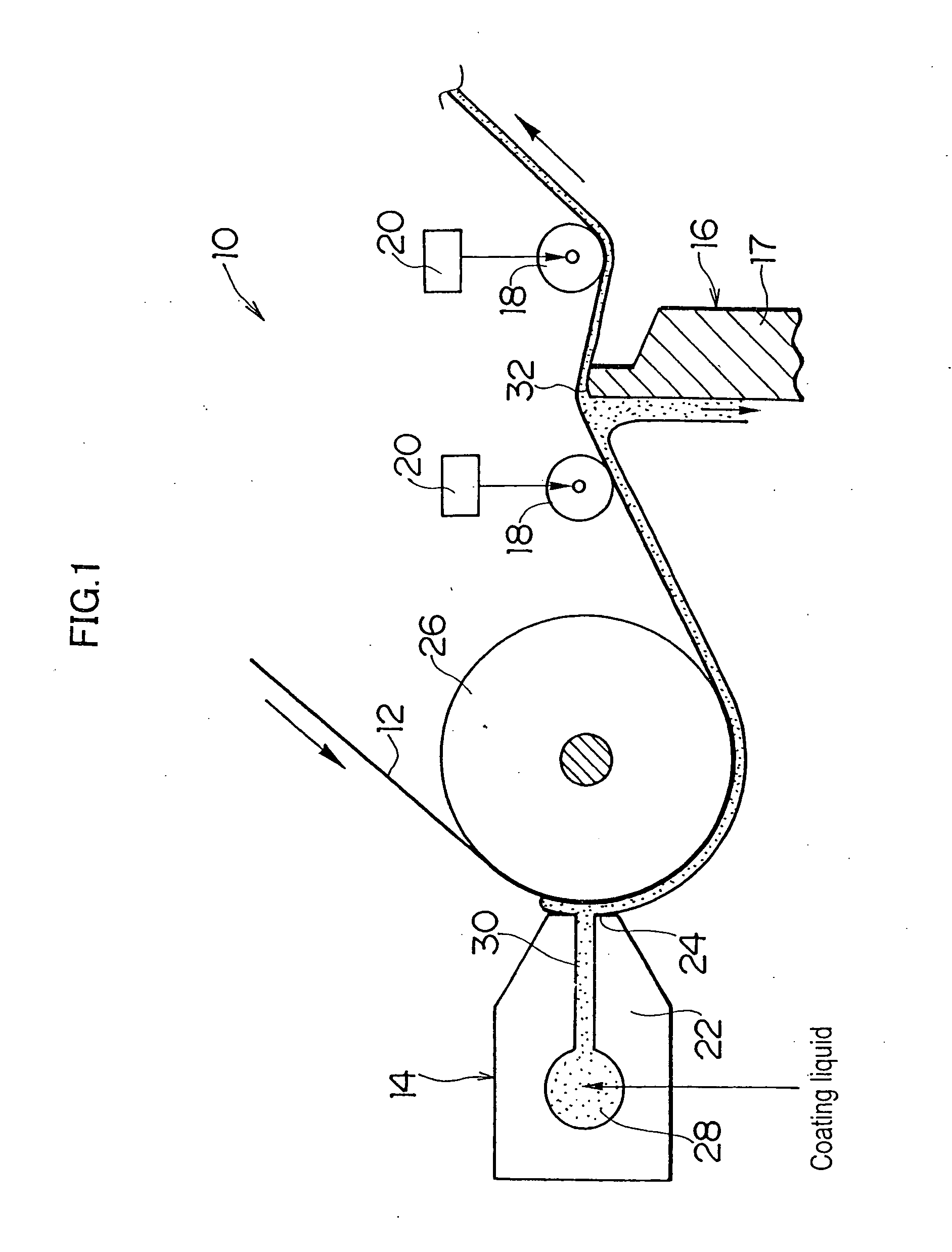

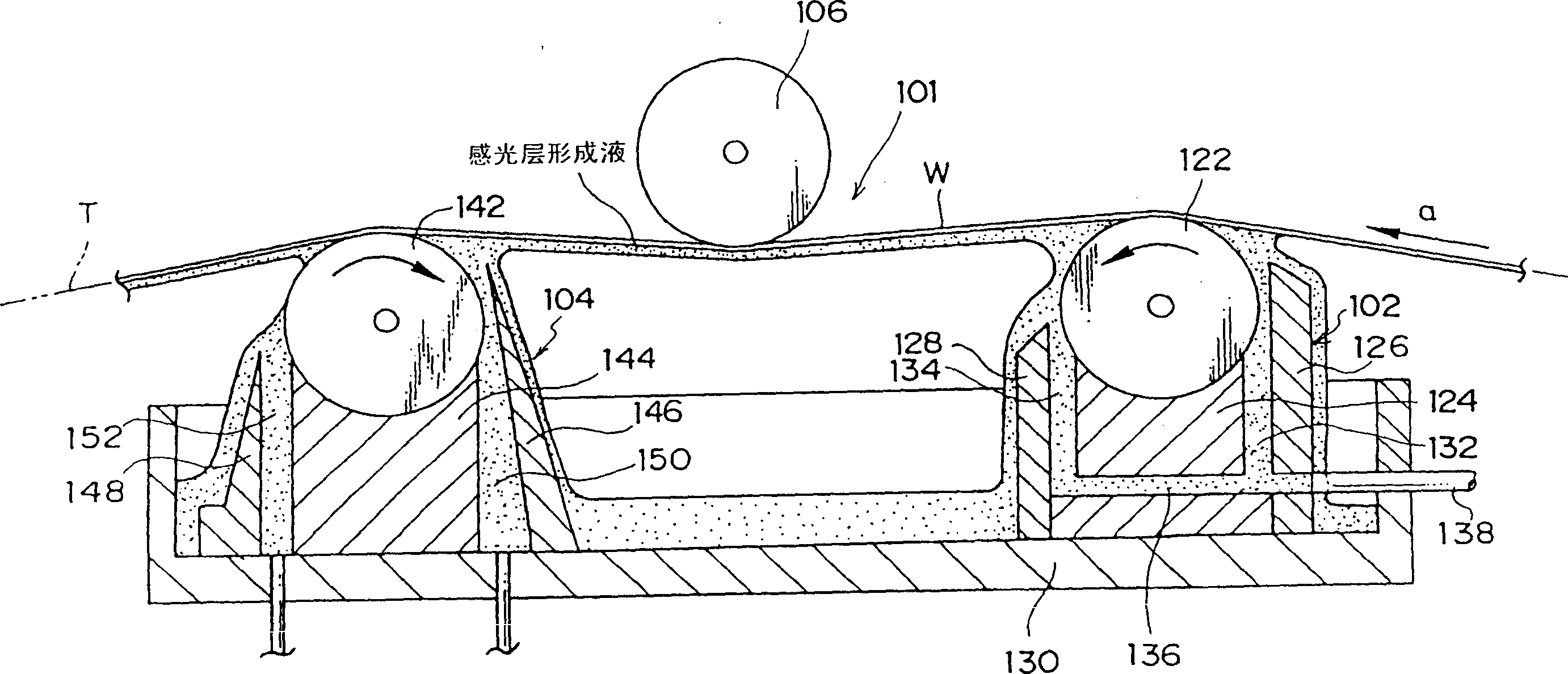

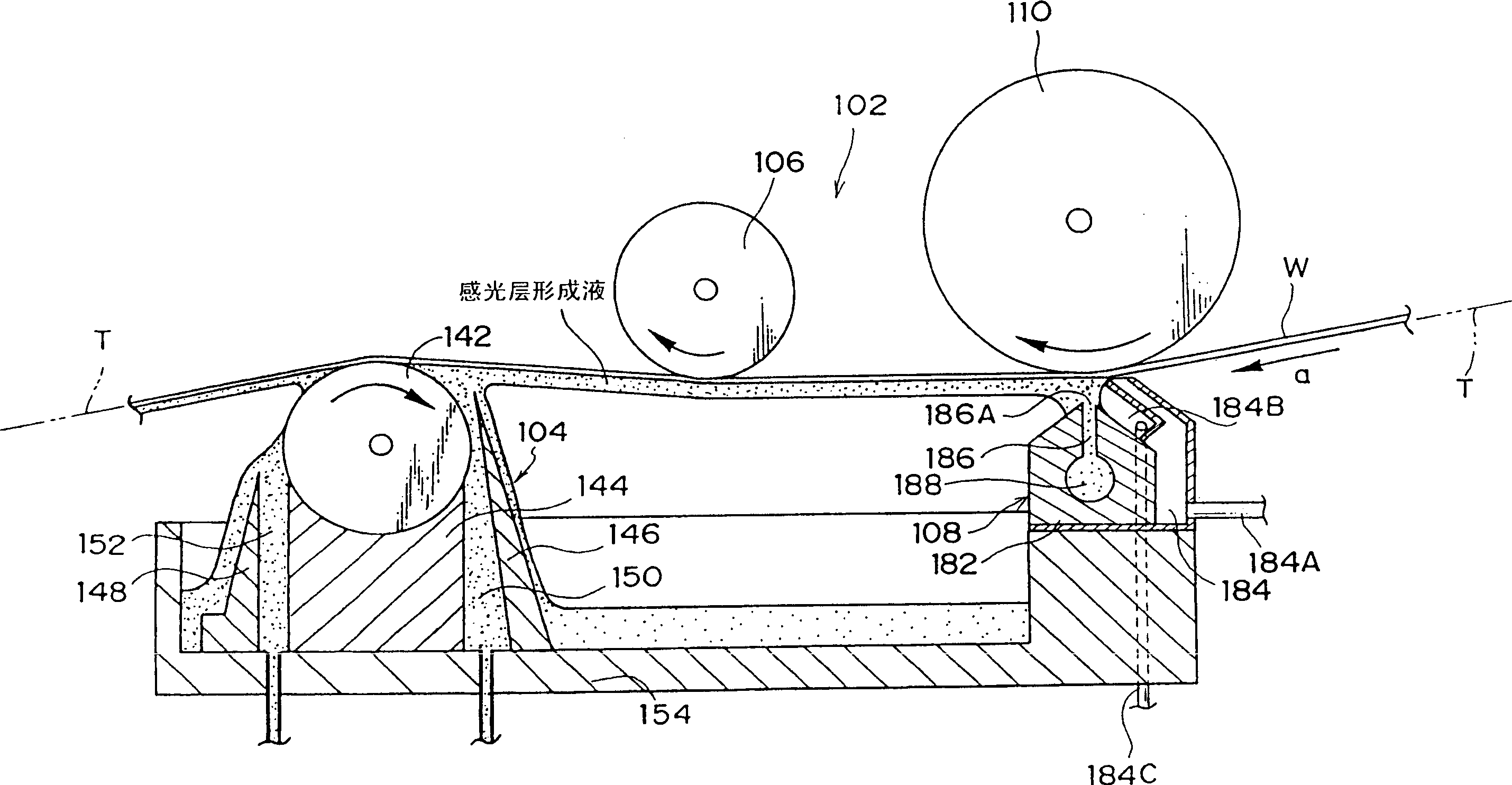

Curtain coating apparatus and curtain coating process

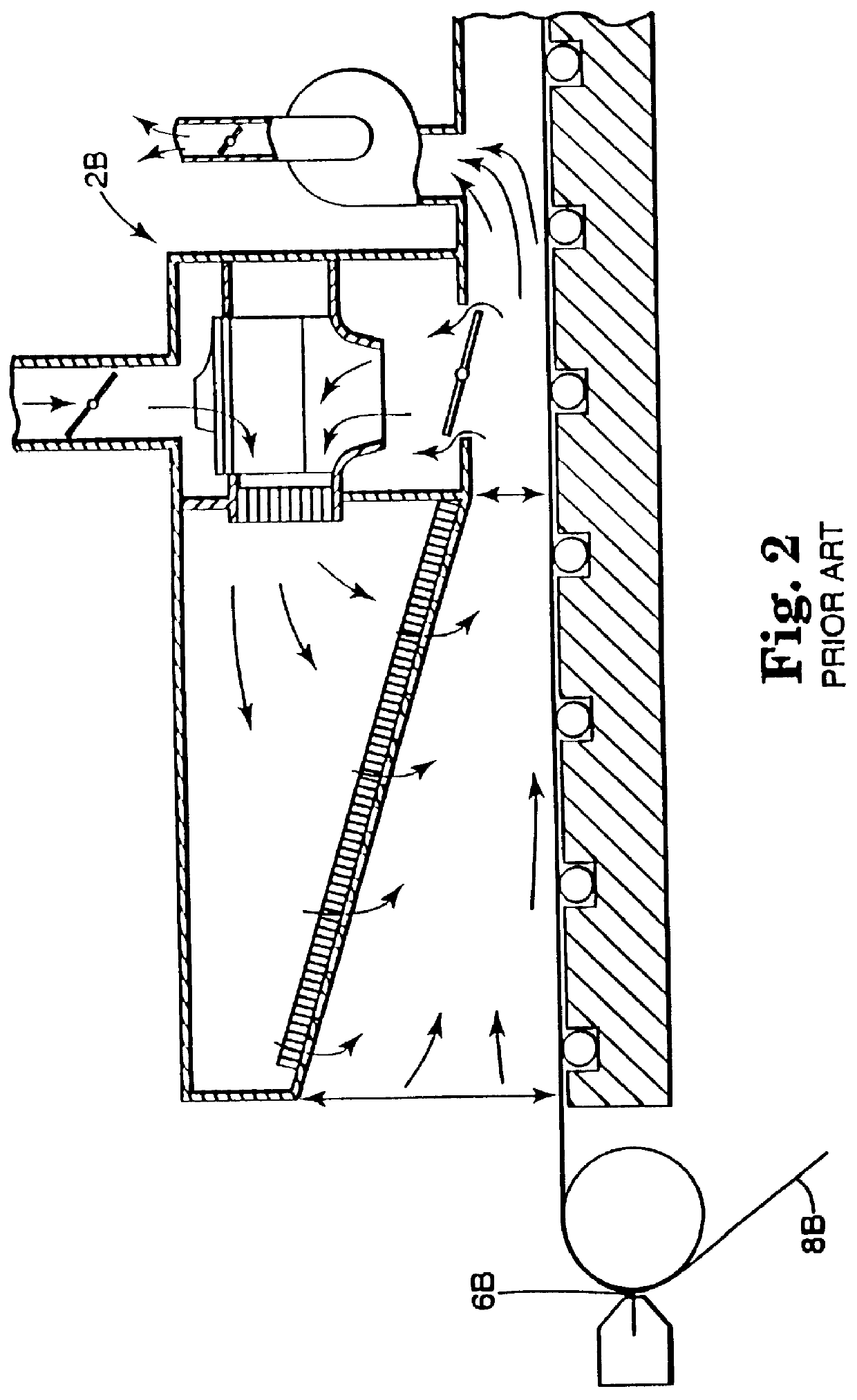

A curtain coating apparatus for applying a coating solution to a continuously moving web, which comprises an air jet injector for injecting air in the upstream direction of a web, provided at a position upstream of a contact point of a curtain film with the web and a shielding member shutting off entrained air generated by movement of the web, provided between the contact point and the air jet injector, thereby diminating an influence of turbulent air flow and preventing the curtain film from suction toward the air jet injector, or which further comprises a control member connected to the shielding member, the control member being provided at a position near and in parallel to the web, or which further comprises a control member and a partition wall member, both being integrated with the shielding member to form a closed space, the air jet injector and an air suction means being provided in the closed space, thereby making the closed space a subatmospheric pressure zone, can produce coated products of good quality by eliminating entrained air around a web at a high speed coating to stabilize the curtain film.

Owner:MITSUBISHI PAPER MILLS LTD

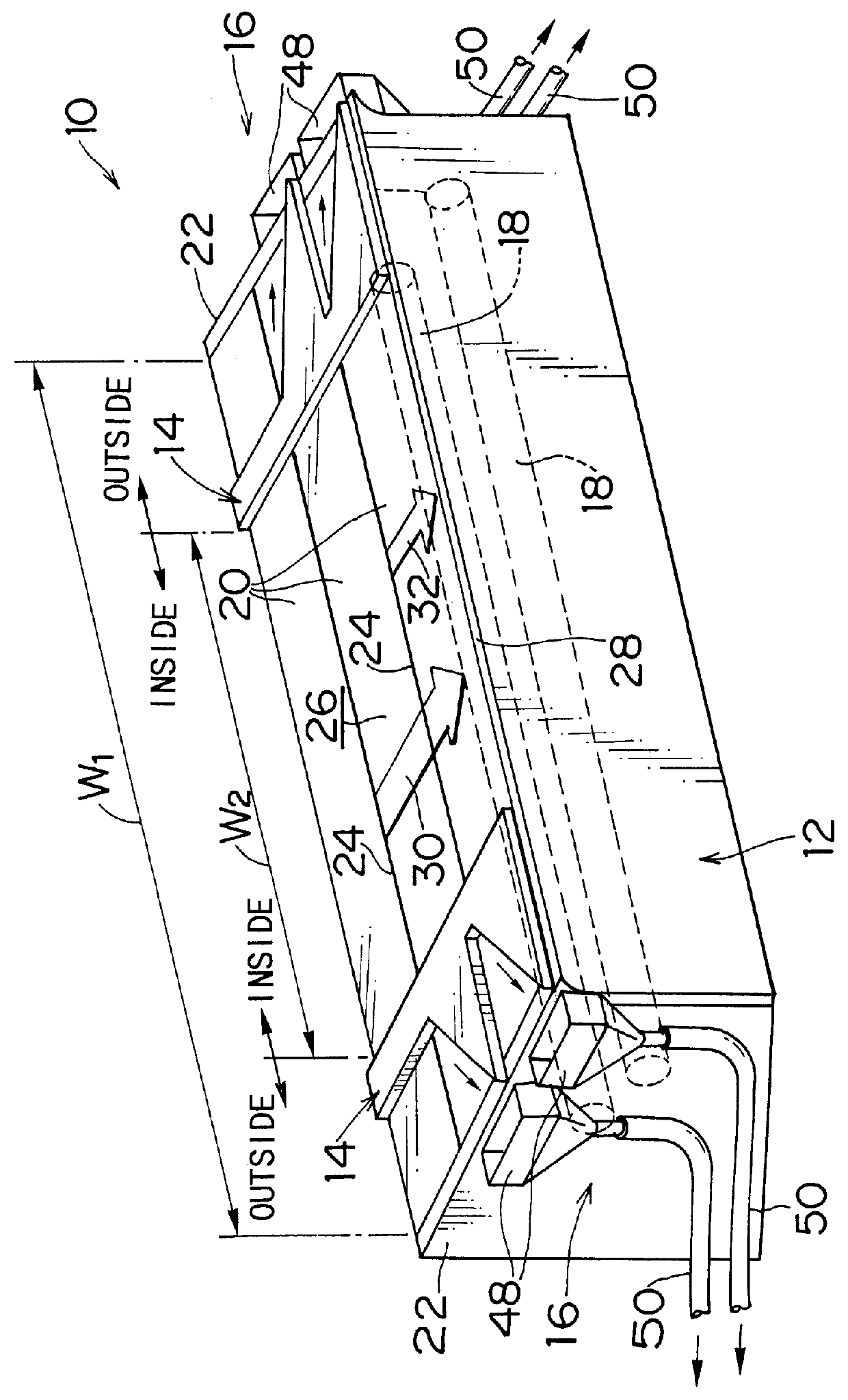

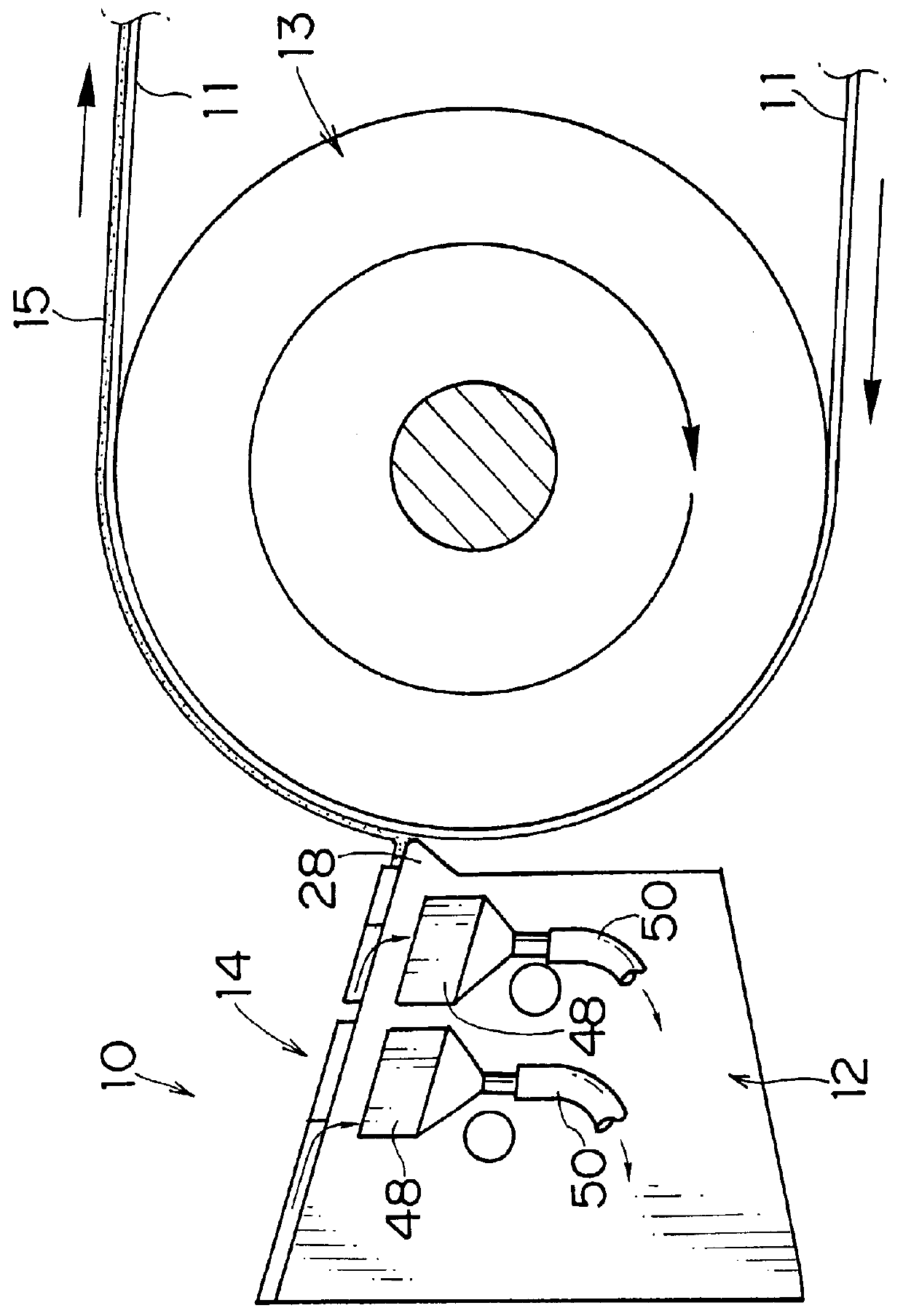

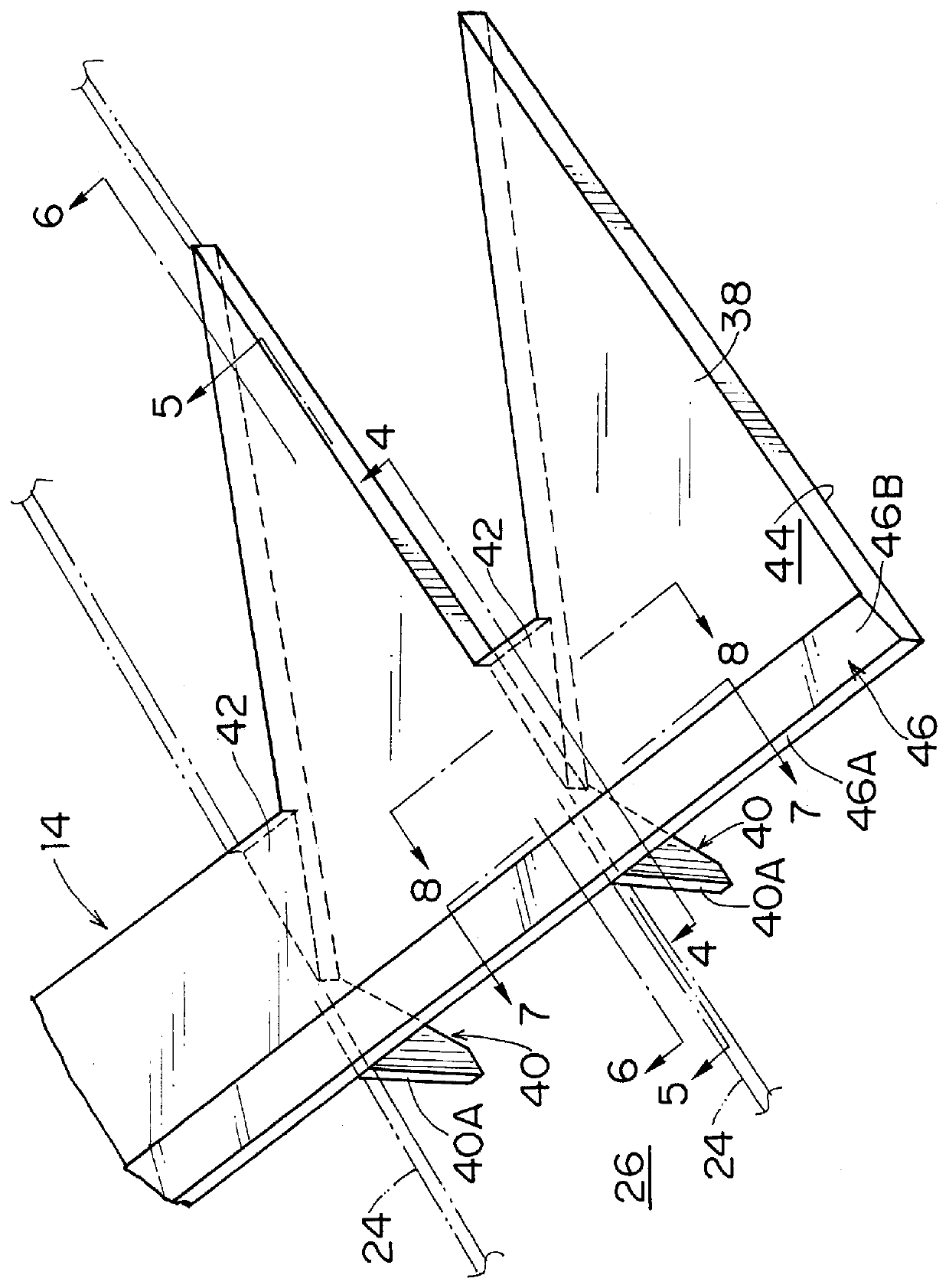

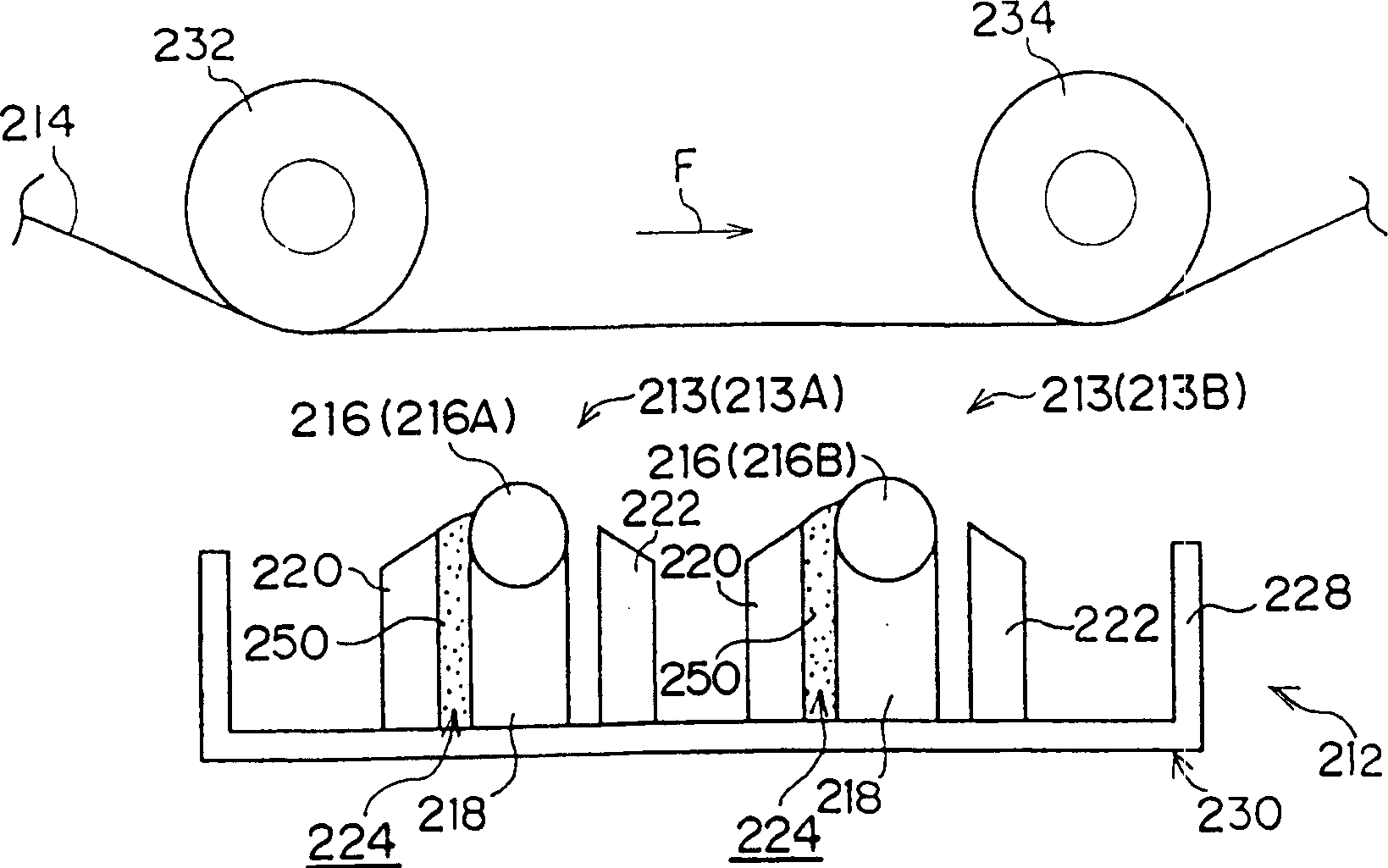

Coating method and apparatus

Coating liquids are supplied to a coating hopper, and are extruded onto a slide surface of the coating hopper through slits. A pair of guide members are provided at both sides of the slide surface. Side faces of the guide members are positioned at both ends of a desired width of the coating liquids flowing of the slide surface to be applied on a traveling web. Consequently, the coating liquids that flow over the whole width of the slits are divided into the inside and the outside of the desired width by the guide members, and the divided coating liquids are extruded onto the slide surface. The coating liquids within the desired width flow down between the guide members and coat the web, whereas the coating liquids outside the desired width are collected through channels, which are formed in the guide members.

Owner:FUJIFILM HLDG CORP +1

Coating method and apparatus

It is possible to give ultrathin and uniform coating on a flexible web in scraping-off type coating. The distribution of pressure in a web width direction is adjusted by a pressure distribution adjusting device when an excess of coating liquid excessively applied is scraped off by a doctor blade by giving relative pressure to a coating surface of a web and the doctor blade after applying the coating liquid that is more excessive than the desired quantity of the coating liquid on the web by a precoating apparatus while making the web continuously travel.

Owner:FUJIFILM HLDG CORP

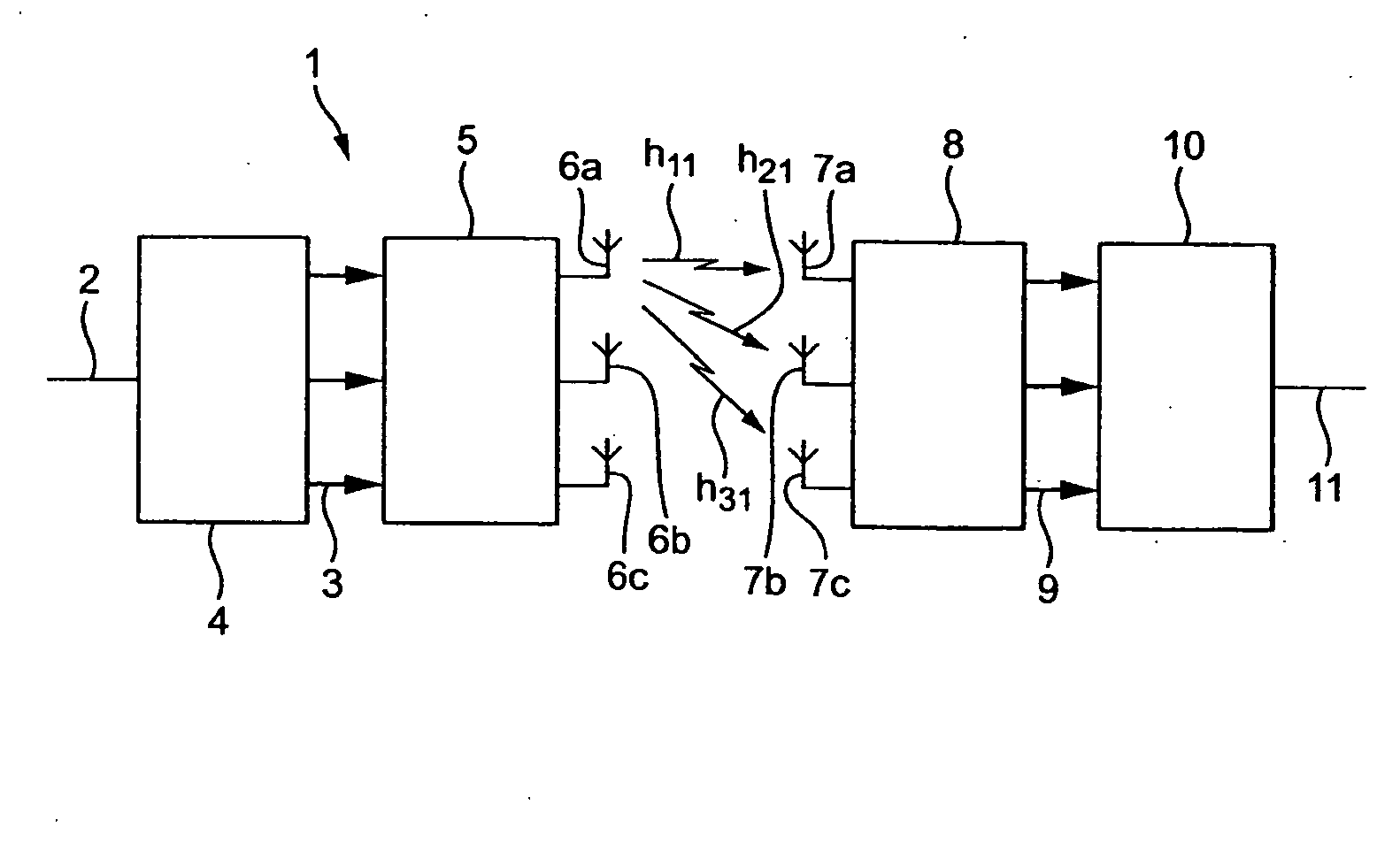

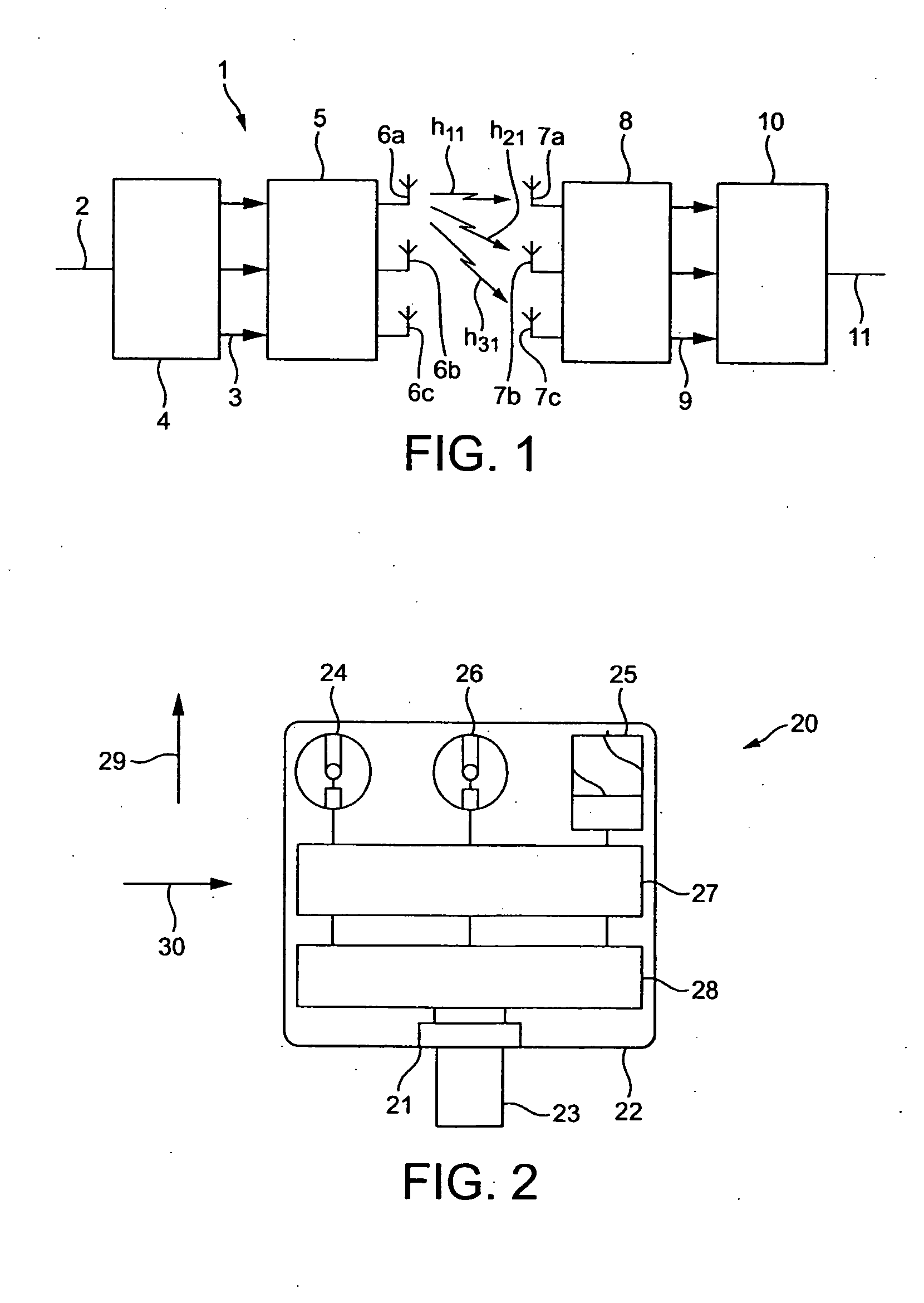

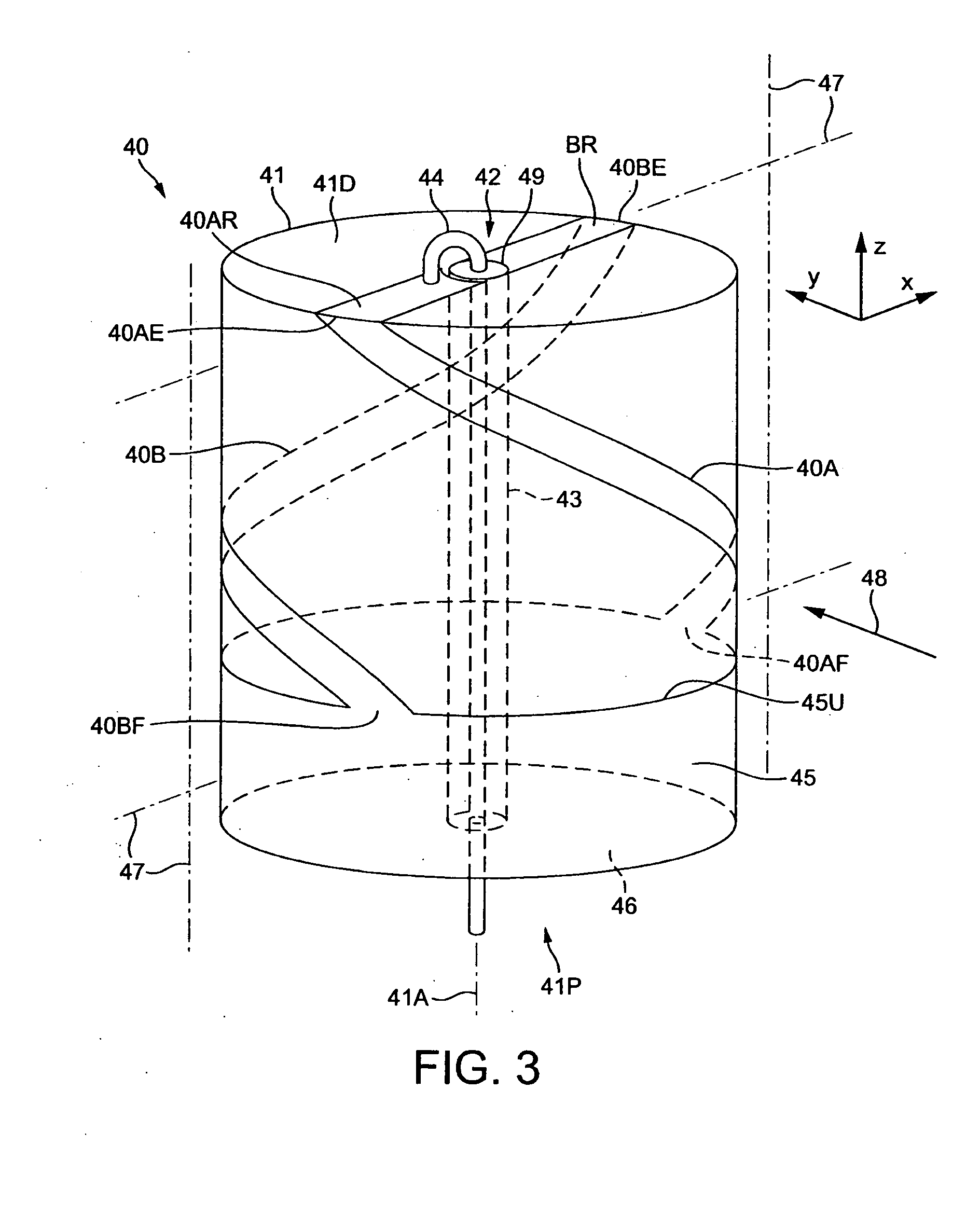

Radio communication system

ActiveUS20080291818A1Maintain its signal strengthProvide diversitySpatial transmit diversityRadiating elements structural formsElectricityData stream

A radio communication receiver which includes an antenna array having at least two antennas to provide antenna diversity. The receiver is for receiving signals containing orthogonally coded data sub-streams derived from a source data stream. The receiver also has receiver circuitry, coupled to the antenna array, having a detection stage to detect the data sub-streams and a combiner stage for combining the detected data sub-streams to recover the source data stream. Each antenna has an electrically insulative core of solid material having a dielectric constant greater than 5. Each antenna also has a three-dimensional antenna element structure disposed on or adjacent the outer surface of the core.

Owner:HELIX TECH

Coating method and apparatus

InactiveUS20070026156A1Improve recording densityLower performance requirementsPretreated surfacesCoating by liquid dispersionCoated surfaceBand shape

The present invention provides a coating method for coating one or more layers on a surface of a continuously moving belt-like substrate. The method includes a cleaning step of maintaining a cleanliness level of class 1000 or less near the substrate before a coating step. According to the present invention, any adhesion of extraneous material, dirt, dust and the like to a continuously moving web or coating layer surface can be prevented to reduce coating defects such as streak development.

Owner:FUJIFILM CORP +1

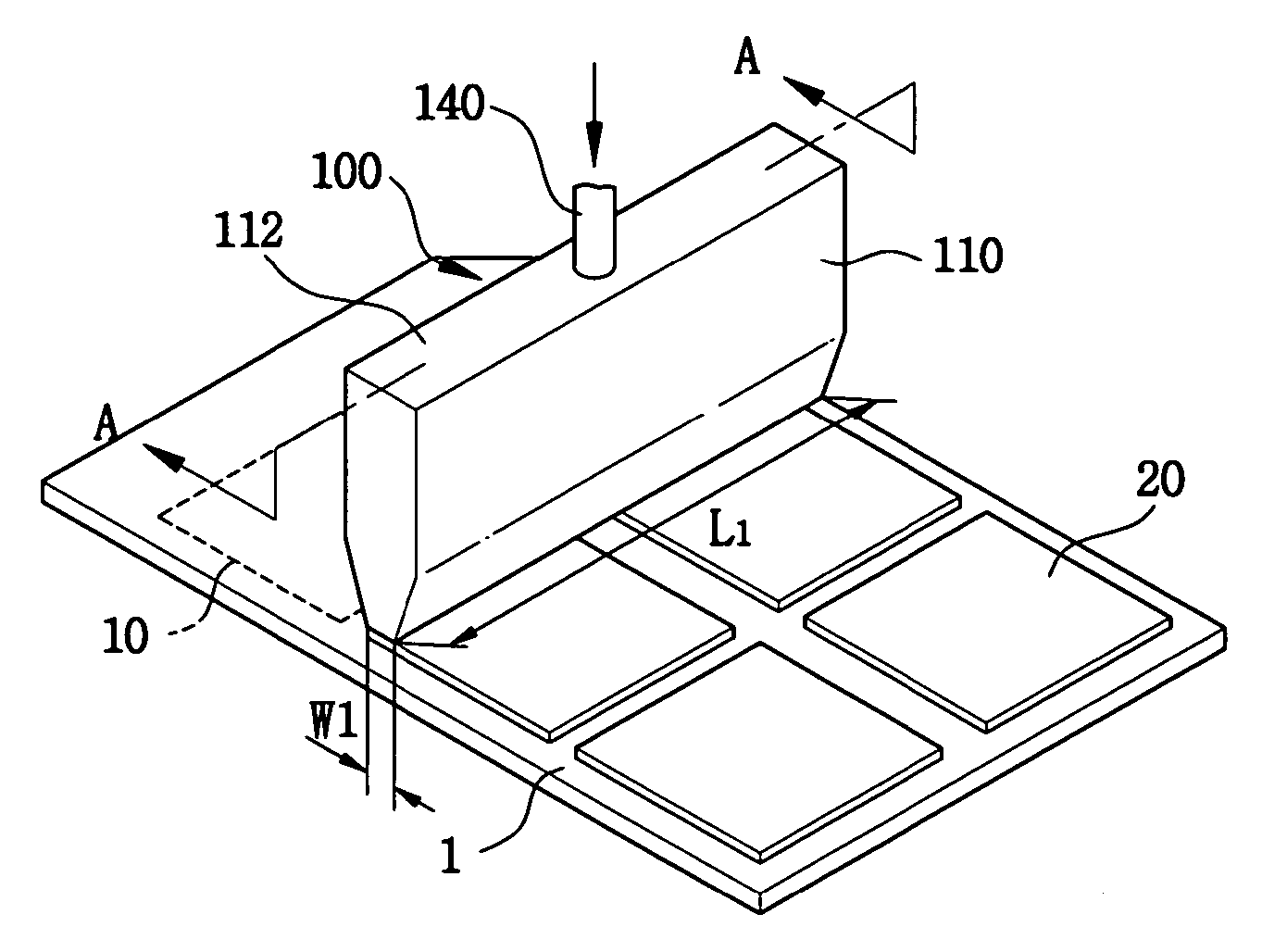

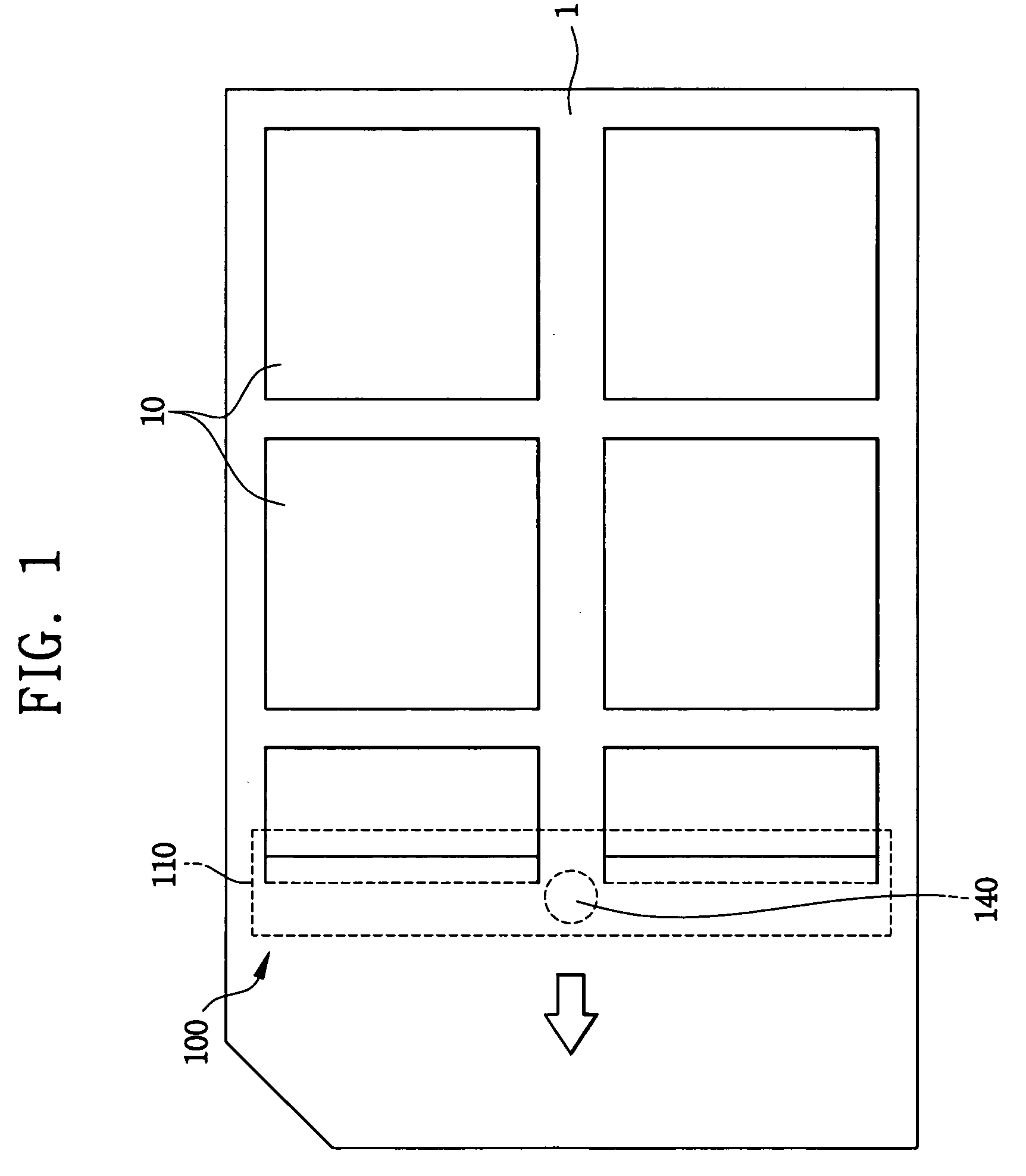

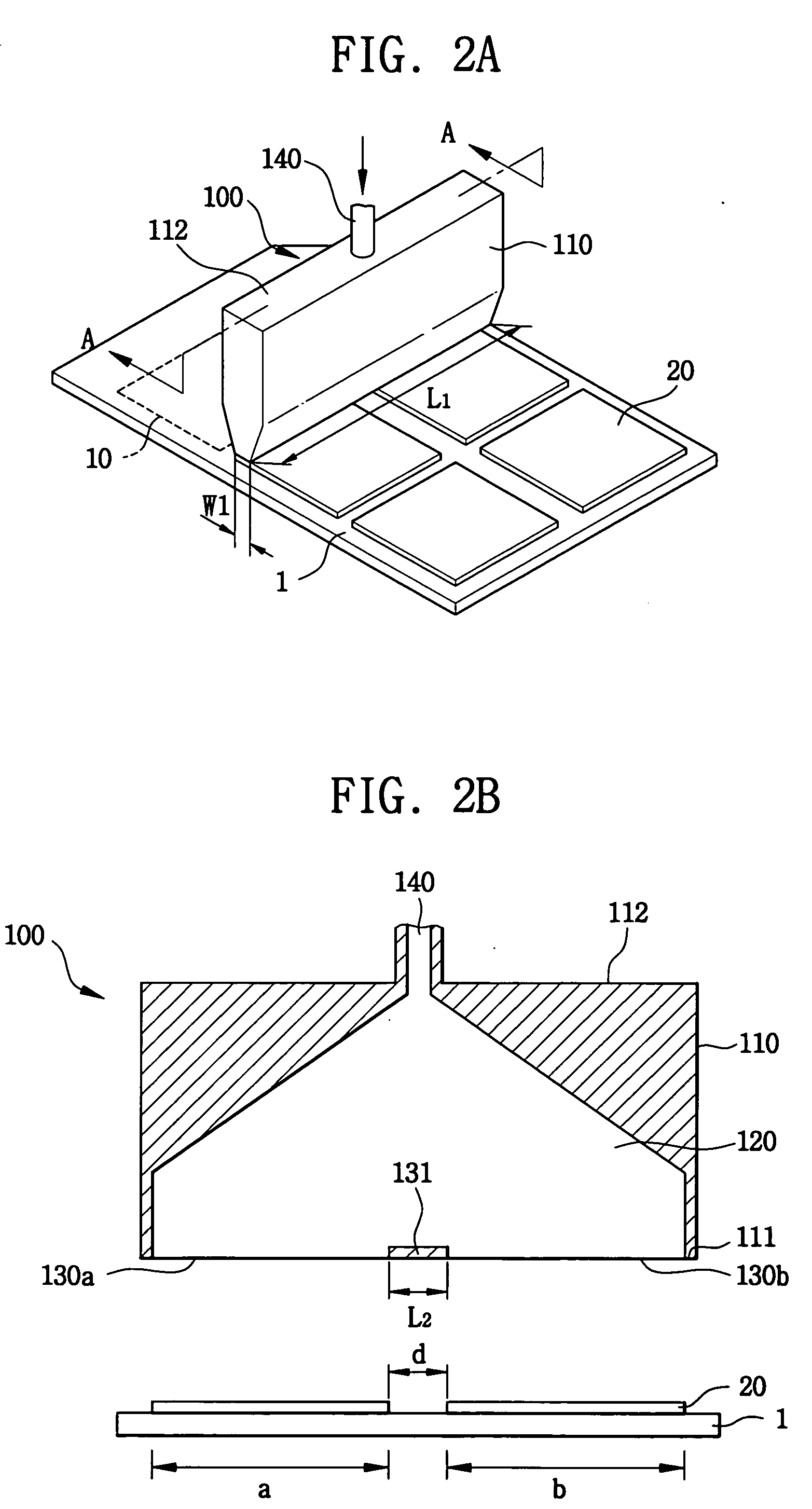

Discharging unit for discharging a photosensitive material, coater having the discharging unit, and apparatus for coating a photosensitive material having the coater

InactiveUS20040173148A1Reduce processing timeSubstrate fractureLiquid surface applicatorsSemiconductor/solid-state device manufacturingForeign matterEngineering

A coating apparatus includes support for supporting a mother substrate including unit substrates, a coater for coating the unit substrate with photosensitive materials, a detector for detecting foreign matters, a remover for removing the foreign matters from the unit substrate, and a controller for controlling the coater, detector, and remover. The coater includes a body containing the photosensitive materials, and inlet and outlet portions for inputting and outputting the photosensitive materials to / from the body. A width of the outlet portion is the same as that of the unit substrate. The detector is positioned at front of the coater to detect the foreign matters before the coating process. The remover removes the foreign matters. The coater discharges the photosensitive material only onto the unit substrate. Discharging of the photosensitive material is interrupted when the foreign matters are found. The coating apparatus requires less photosensitive material, and can be more efficient

Owner:SAMSUNG DISPLAY CO LTD

Coating device and coating method

InactiveCN1408483APrevent drying and stickingAvoid stickingLiquid surface applicatorsCoatingsLiquid layerBand shape

A coating device and a coating method are provided. The coating device comprises a coating station for coating a coating liquid on a band-shaped substrate running continuously, and a coat-adjusting station disposed downstream of the coating station for adjusting the coating liquid on the substrate so that the coating liquid layer is coated on the substrate at a predetermined thickness. The coating station and the coat-adjusting station comprise first and second bars for respectively coating and measuring the liquid agent. The coating liquid can be coated on evenly and in a stable manner even if the coating operation is performed with the substrate running at a high speed.

Owner:FUJIFILM CORP

Negative photosensitive resin composition

InactiveUS7267929B2Increased durabilityConvenient lightingRadiation applicationsSemiconductor/solid-state device manufacturingSolid componentSolubility

A negative photosensitive resin composition comprising an alkali-soluble photosensitive resin (A) having acidic groups and having at least three ethylenic double bonds per molecule, an ink repellent (B) made of a polymer having polymerized units (b1) having a C20 or lower alkyl group in which at least one of its hydrogen atoms is substituted by a fluorine atom (provided that the alkyl group may contain etheric oxygen), and polymerized units (b2) having an ethylenic double bond, and a photopolymerization initiator (C), wherein the fluorine content in the ink repellent (B) is from 5 to 25 mass %, and the proportion of the ink repellent (B) is from 0.01 to 20 mass %, based on the total solid content of the negative photosensitive resin composition. The negative photosensitive resin composition of the present invention is excellent in adhesion to a substrate, ink repellency and durability thereof and further excellent in alkali solubility and developability.

Owner:AGC INC

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050100677A1Low costShorten the timeLiquid surface applicatorsFilm/foil adhesivesBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

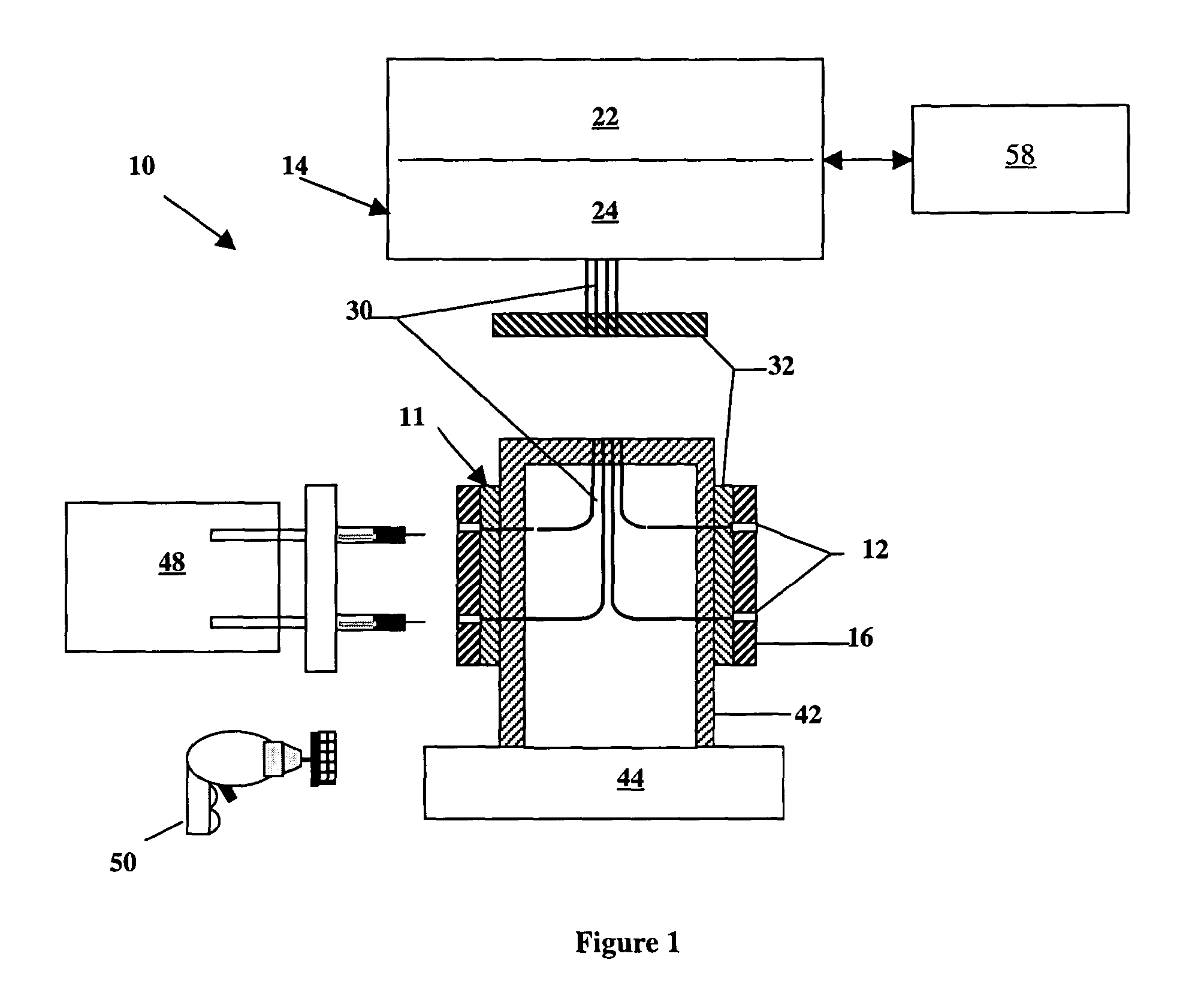

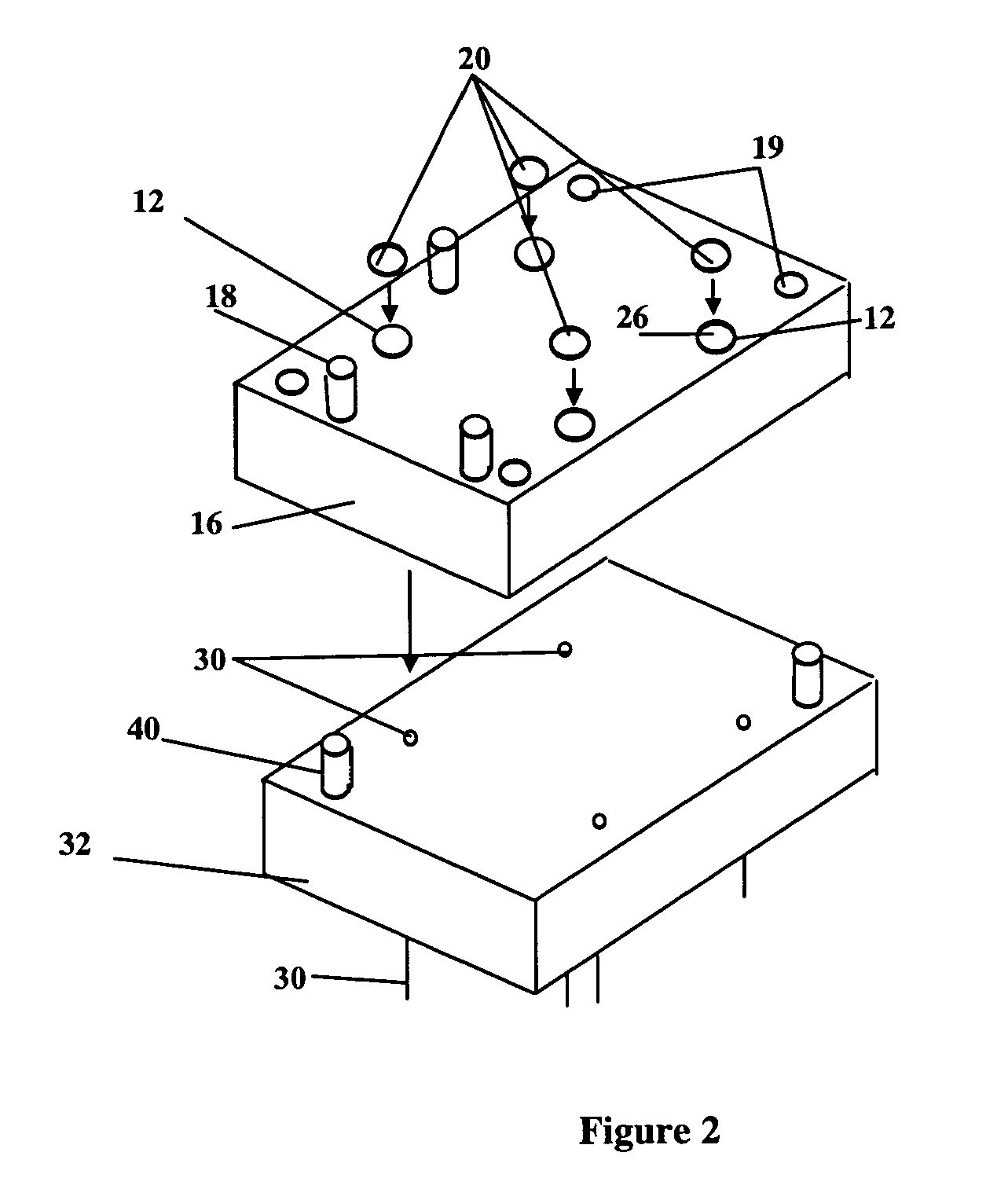

Method for bonding and debonding a workpiece to a manufacturing fixture

InactiveUS20080011416A1Minimum pre-load distortionSubstantial rigidityAdhesive processesLamination ancillary operationsAdhesiveEngineering

A system and a method by which workpieces are bonded to and debond from a manufacturing fixture using a radiation responsive adhesive as a bonding agent. The system includes curing the adhesive agent during loading within seconds, and structurally weakens the adhesive bond during unloading within seconds. During the workpiece loading cycle, an adhesive dispenser deposits radiation responsive adhesive on to a load bearing, light transmittive surface, known as gripper pins. The workpiece is subsequently pushed against the locators, and towards the gripper pins causing the adhesive to interpose between workpiece and gripper pins, curing radiant energy is transmitted through the gripper pins and on to the adhesive to cure adhesive and bond the workpiece to the fixture. Therefore, the bond is structurally weakened or debonded in order to remove the workpiece from the fixture after manufacturing.

Owner:PENN STATE RES FOUND

Popular searches

Photomechanical exposure apparatus Microlithography exposure apparatus Originals for photomechanical treatment Photosensitive composition application Photographic processes Photosensitive material processing Photosensitive materials for photomechanical apparatus Cold cathode manufacture Lamination Lamination apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com