Patents

Literature

32results about How to "High speed manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

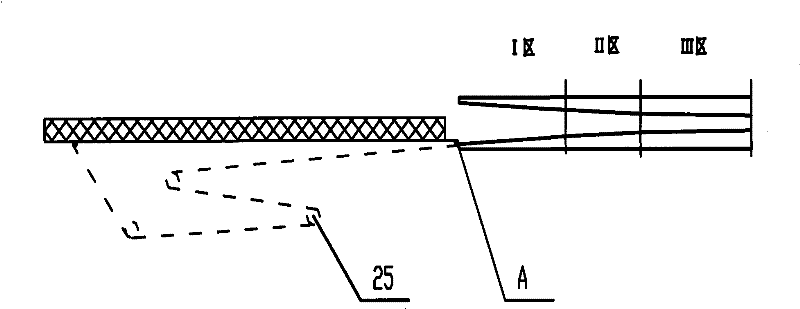

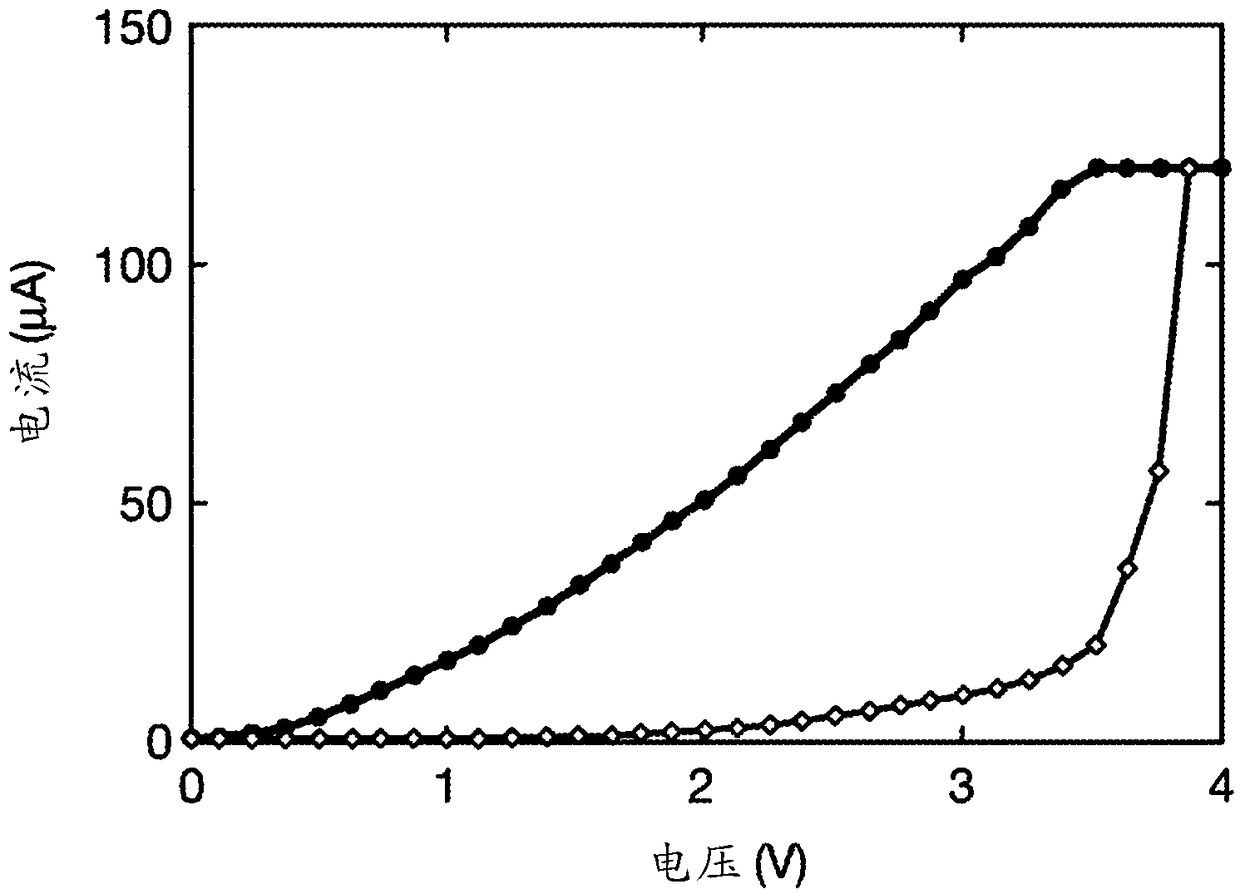

Display device based on phase-change materials

ActiveCN105849626AHigh speed manufacturingRun at high speedNon-linear opticsOptical elementsVanadium dioxideRefractive index

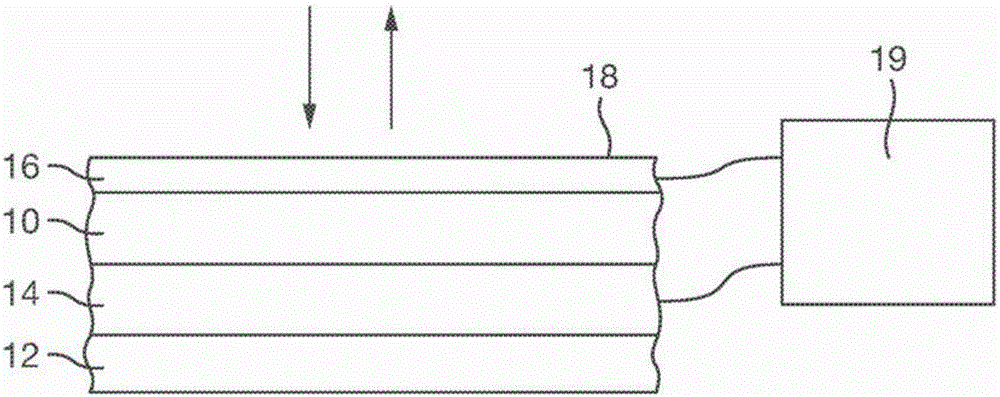

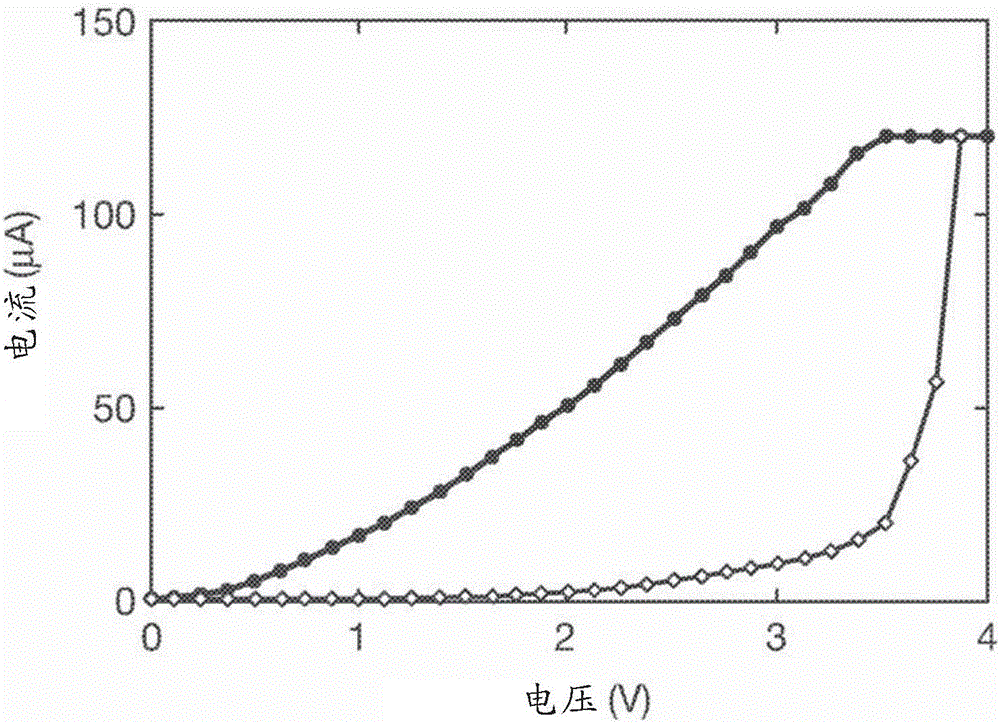

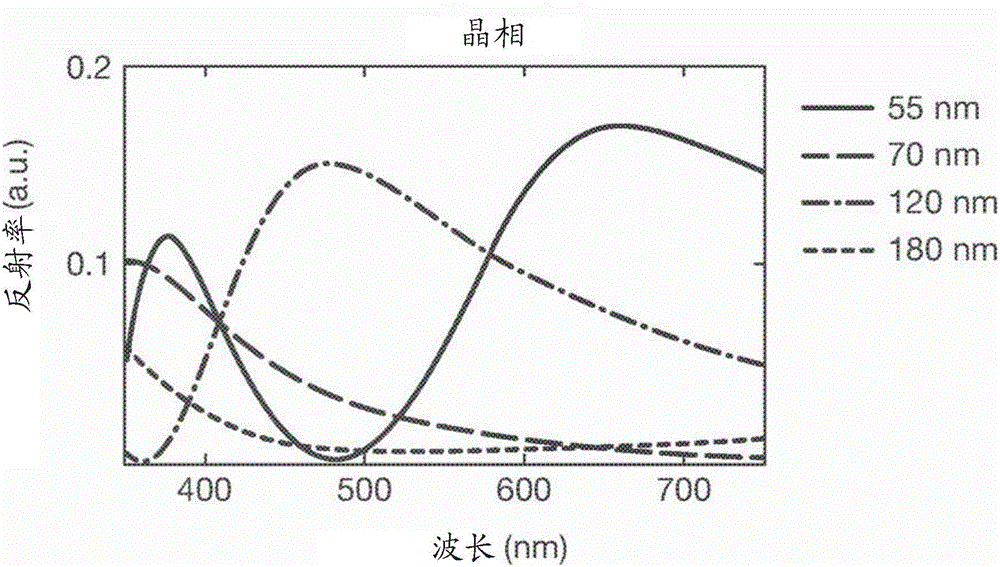

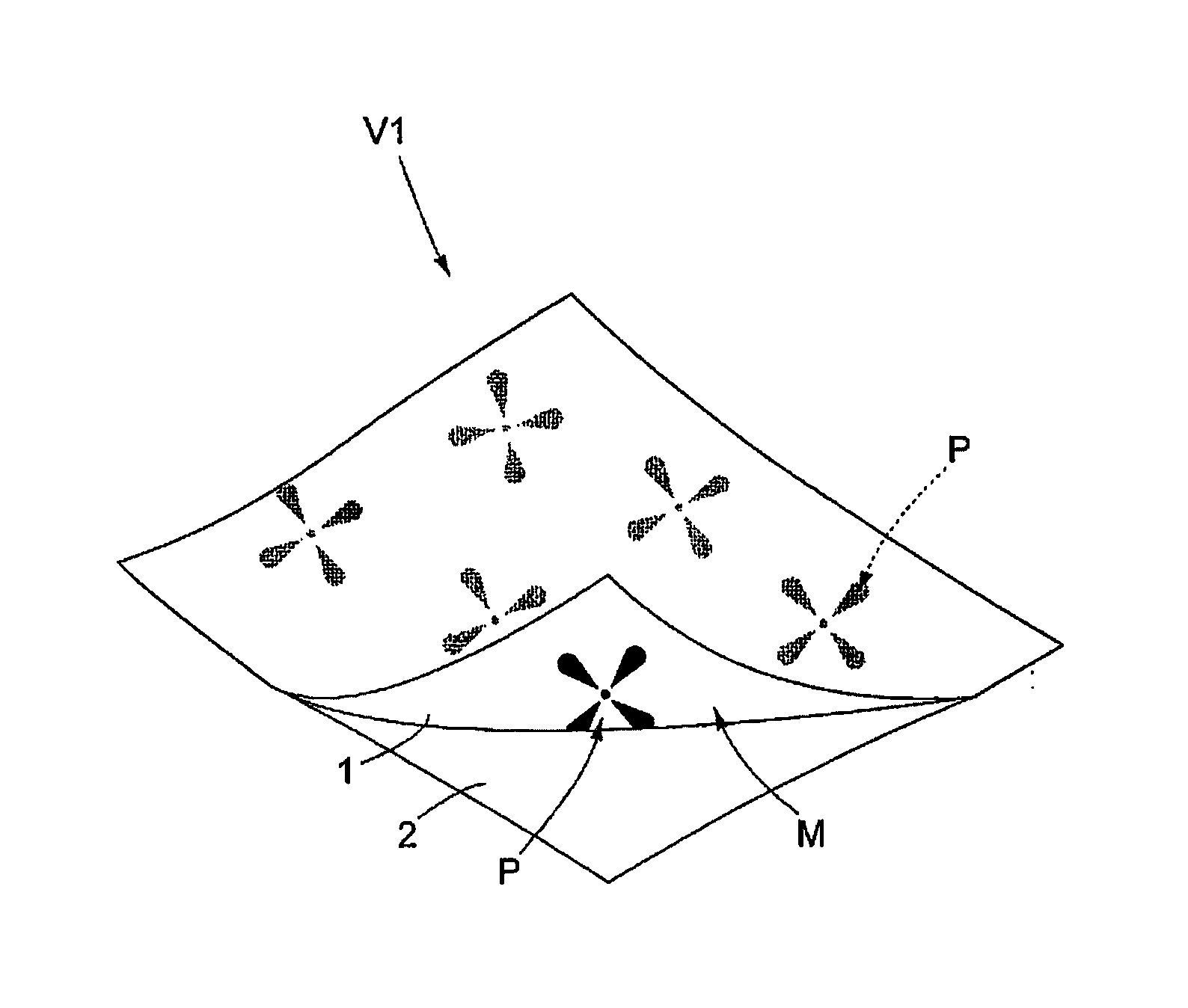

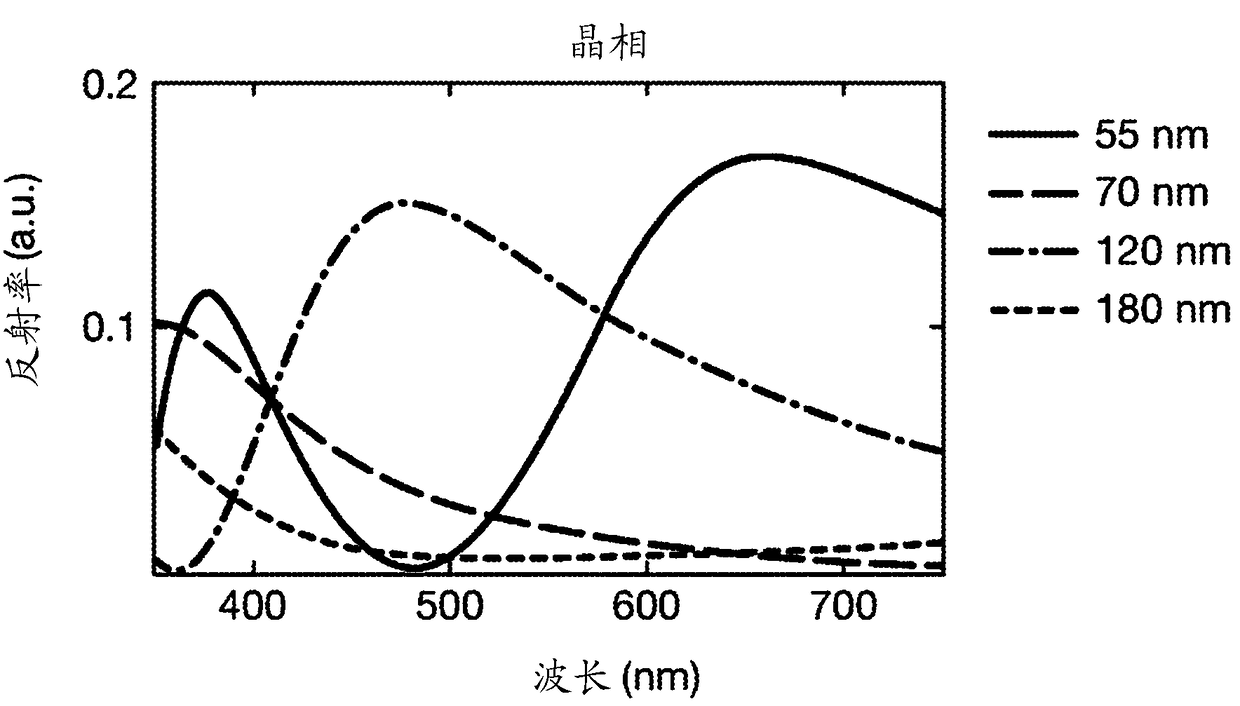

A display device comprises a plurality of pixels, each pixel having a portion (10) of a solid-state, phase-change material such as germanium-antimonium-telluride (GST) or vanadium dioxide, wherein the phase-change material can be reversibly brought into an amorphous state or a crystaline state and has a refractive index that is reversibly, electrically controllable. A plurality of electrodes (14, 16) are provided, at least two of which contact said portion of material (10). A controller (19) is provided that is adapted to apply at least one voltage to said material (10), via said electrodes (14, 16), to change said refractive index. An array of such portions of material can be arranged to make a pixellated display, for example a stereoscopic display of the volumetric type.

Owner:OXFORD UNIV INNOVATION LTD

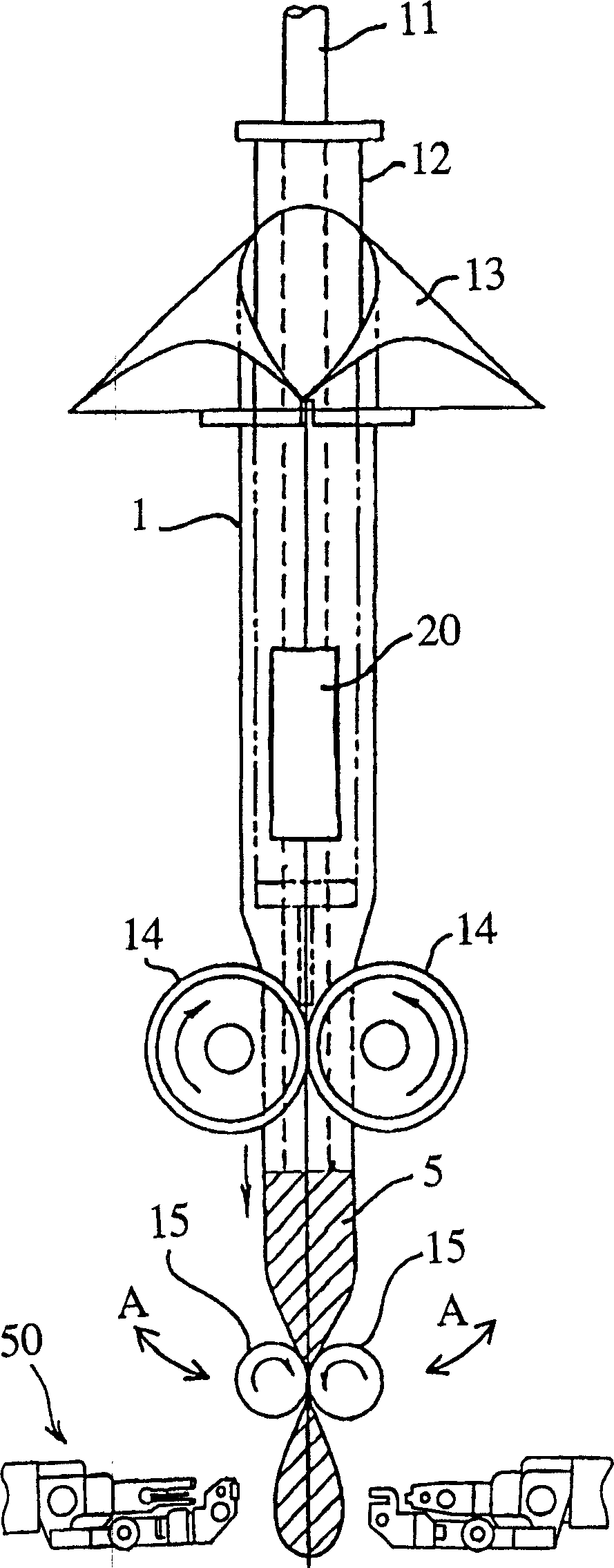

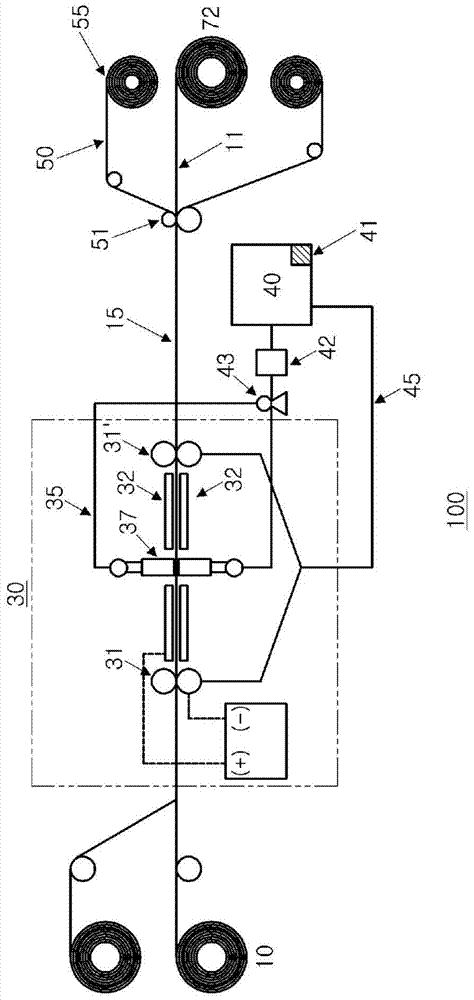

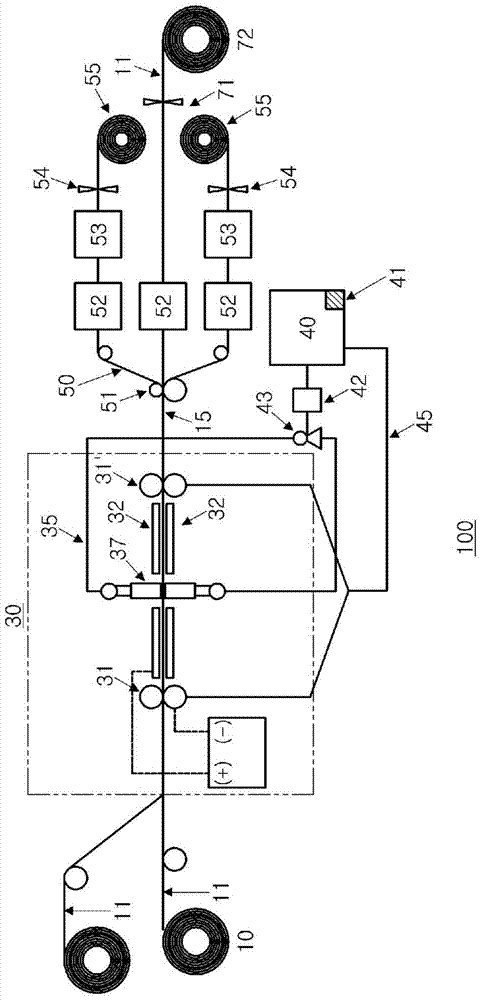

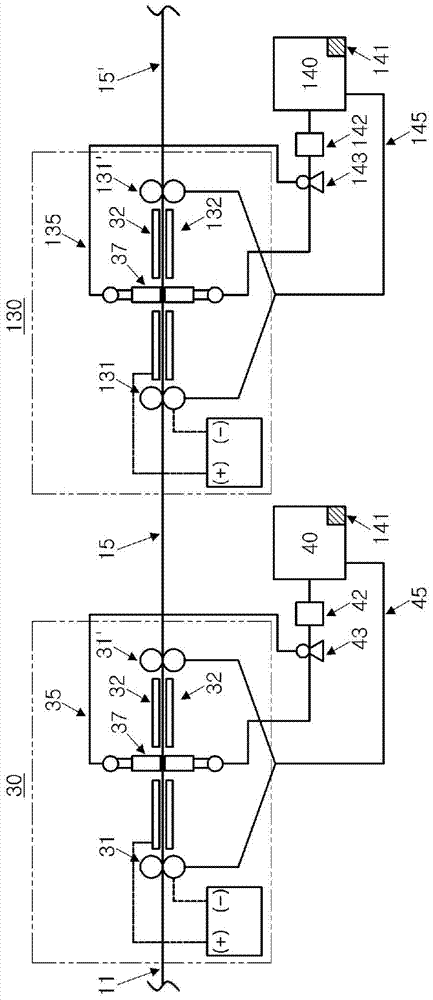

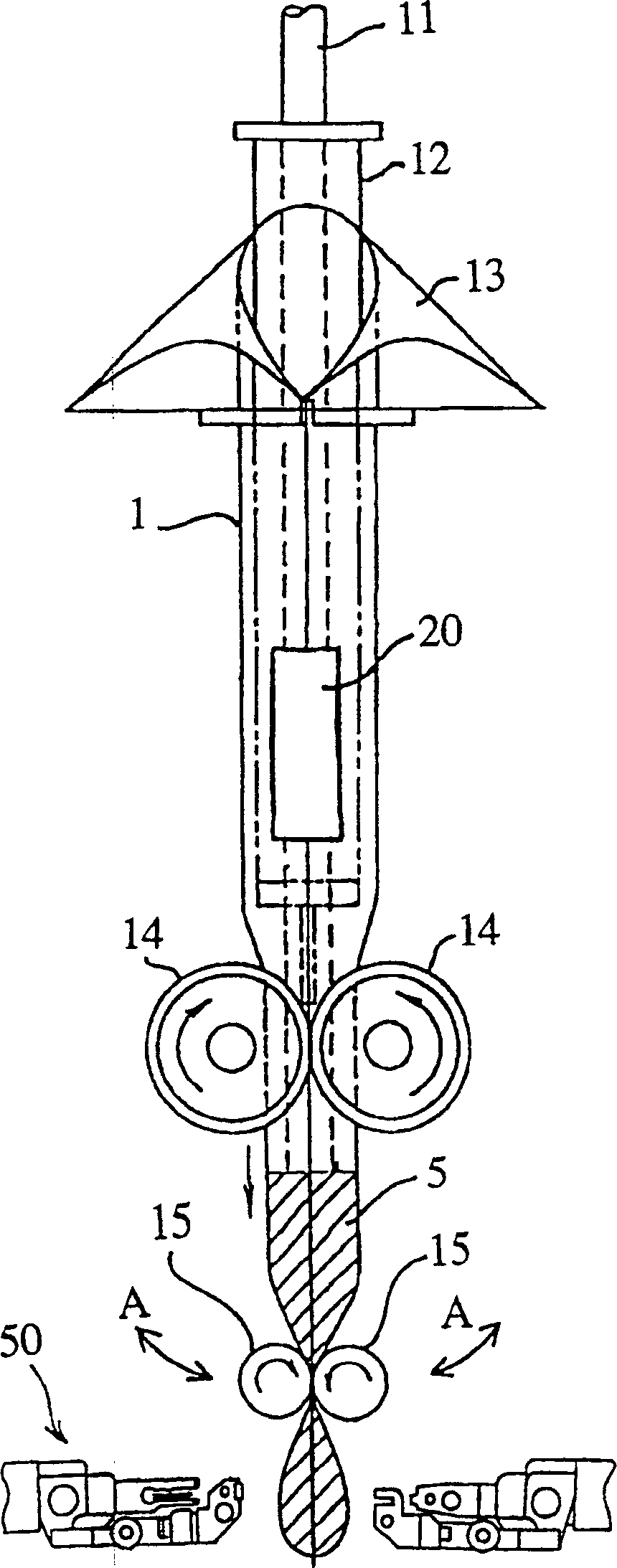

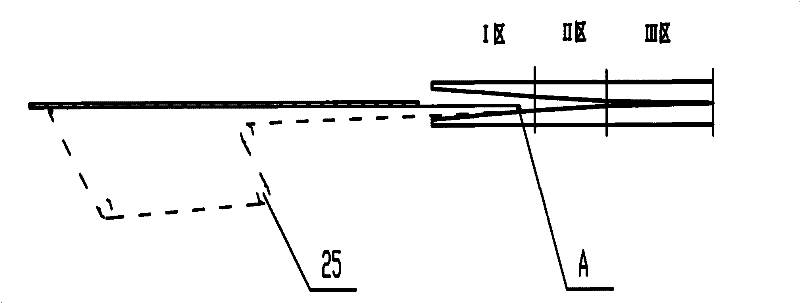

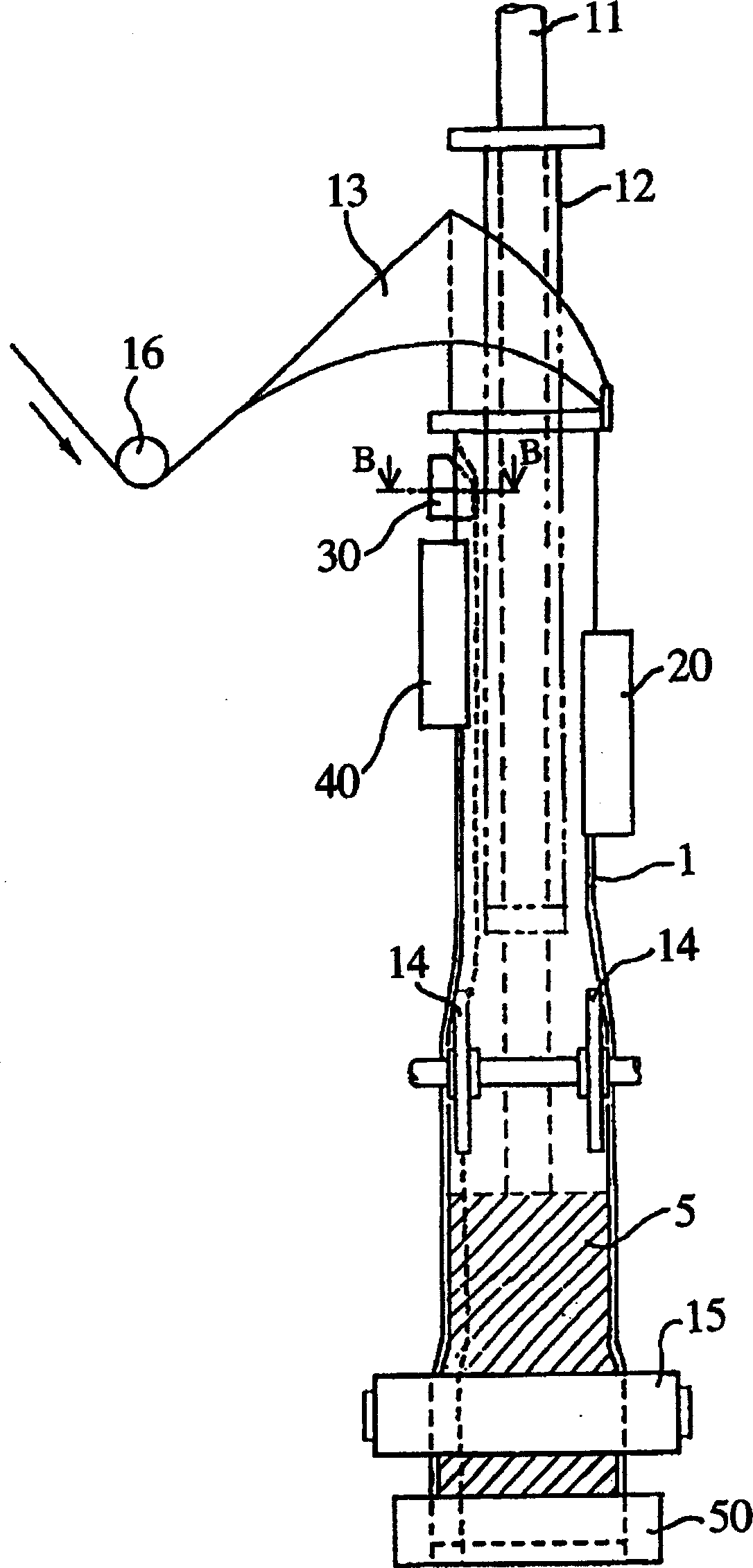

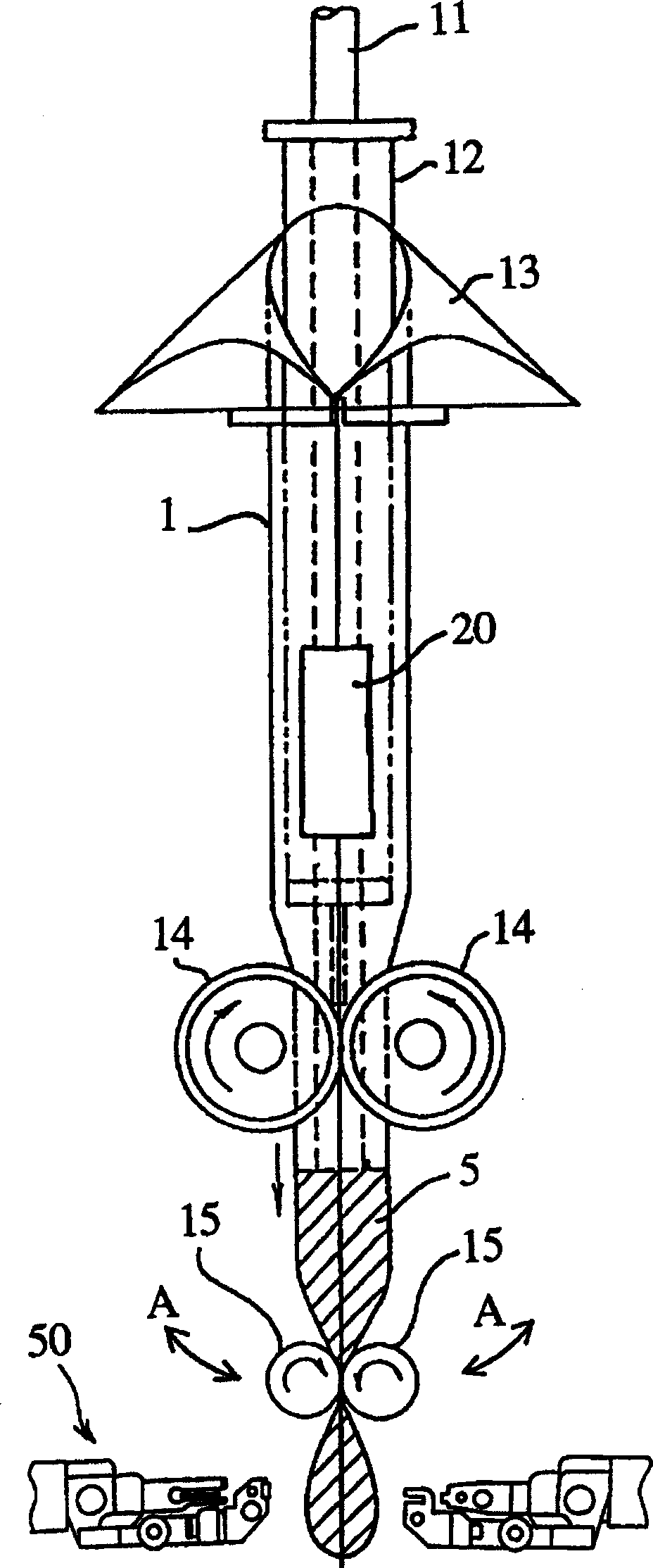

Moulding, filling and sealing appts. for self-standing bags

InactiveCN1519102AEfficient productionHigh speed manufacturingEnvelopes/bags making machineryWrappingThin membranePlastic bag

A shaping, filling and sealing apparatus for making the plastic bags able to stand up by itself is composed of three thermally sealing units, a folding mechanism, and a filling tube for filling the filler. The third sealing unit can also cut the thermally sealed part.

Owner:ORIHIRO ENGINEERING CO LTD

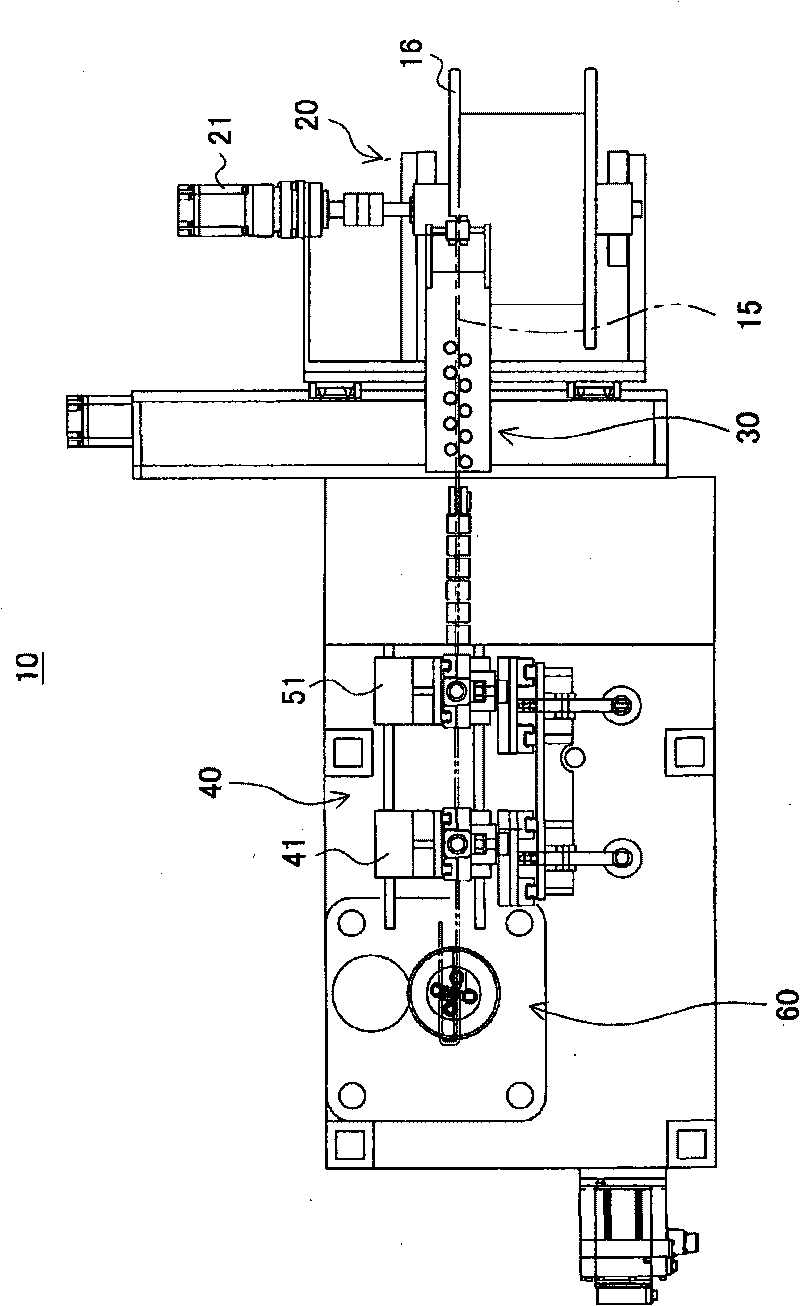

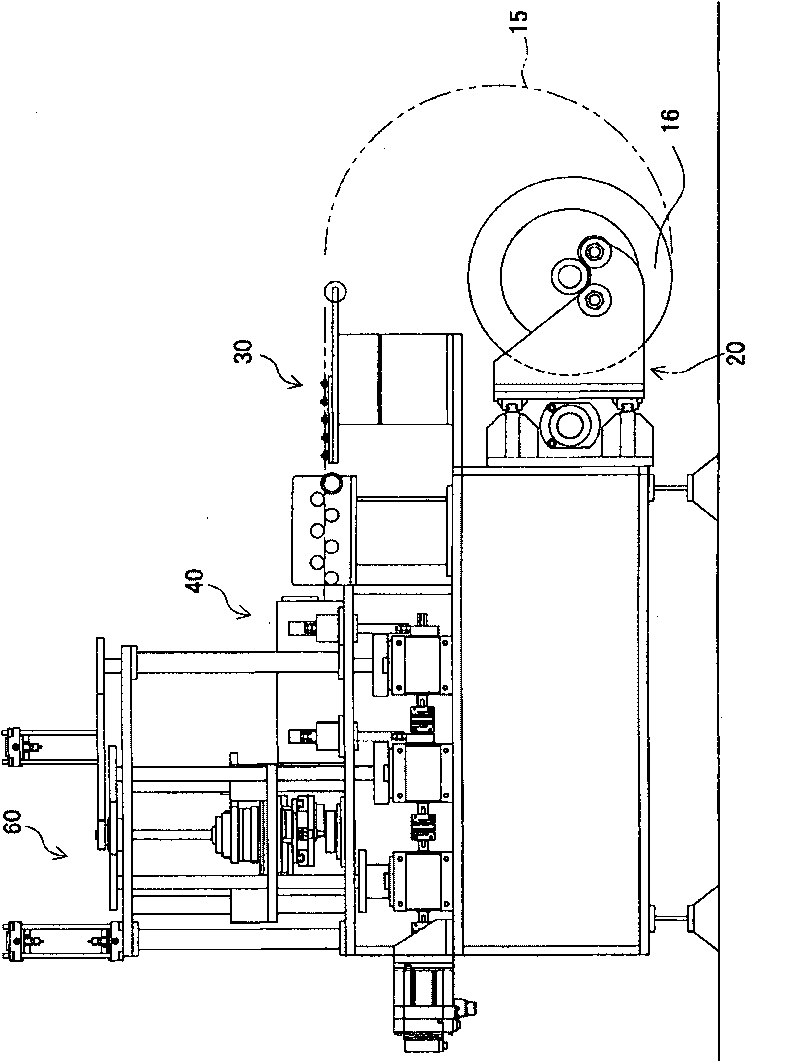

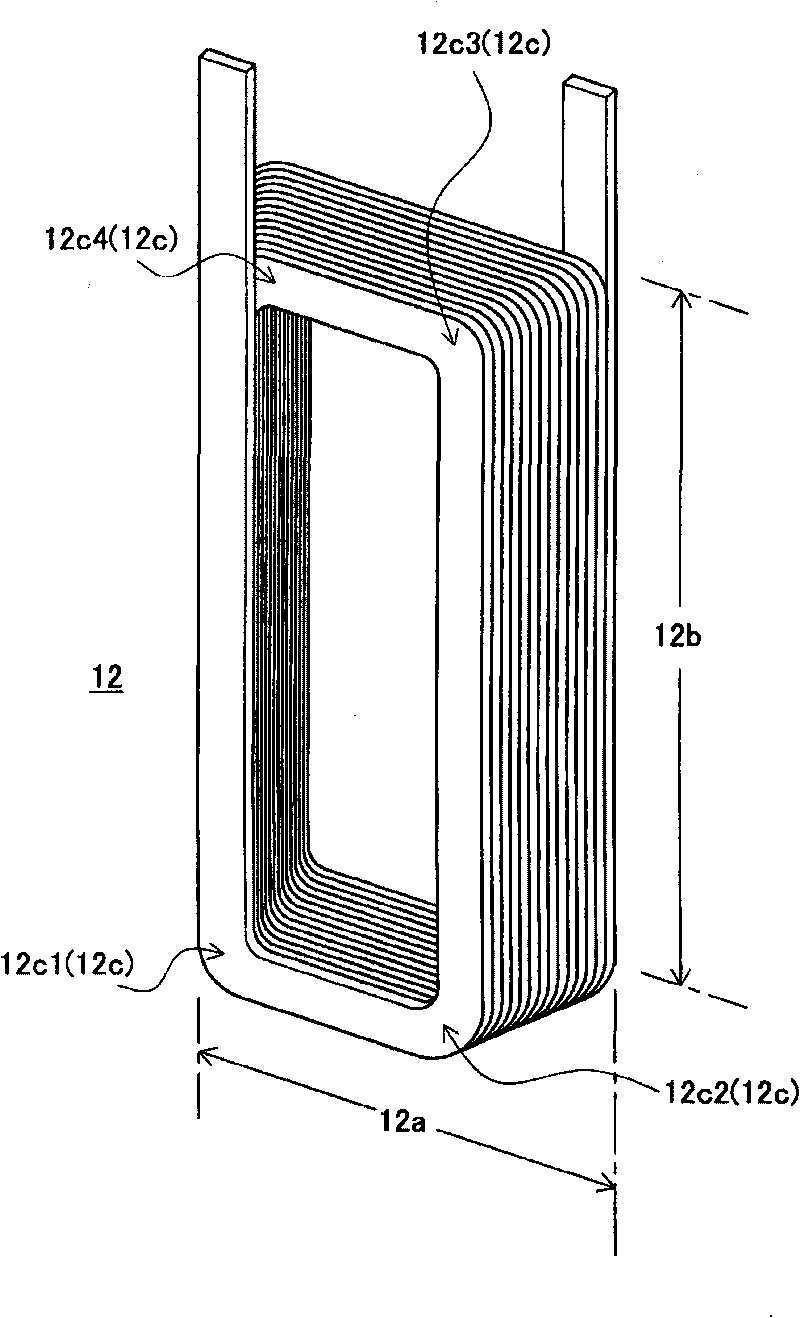

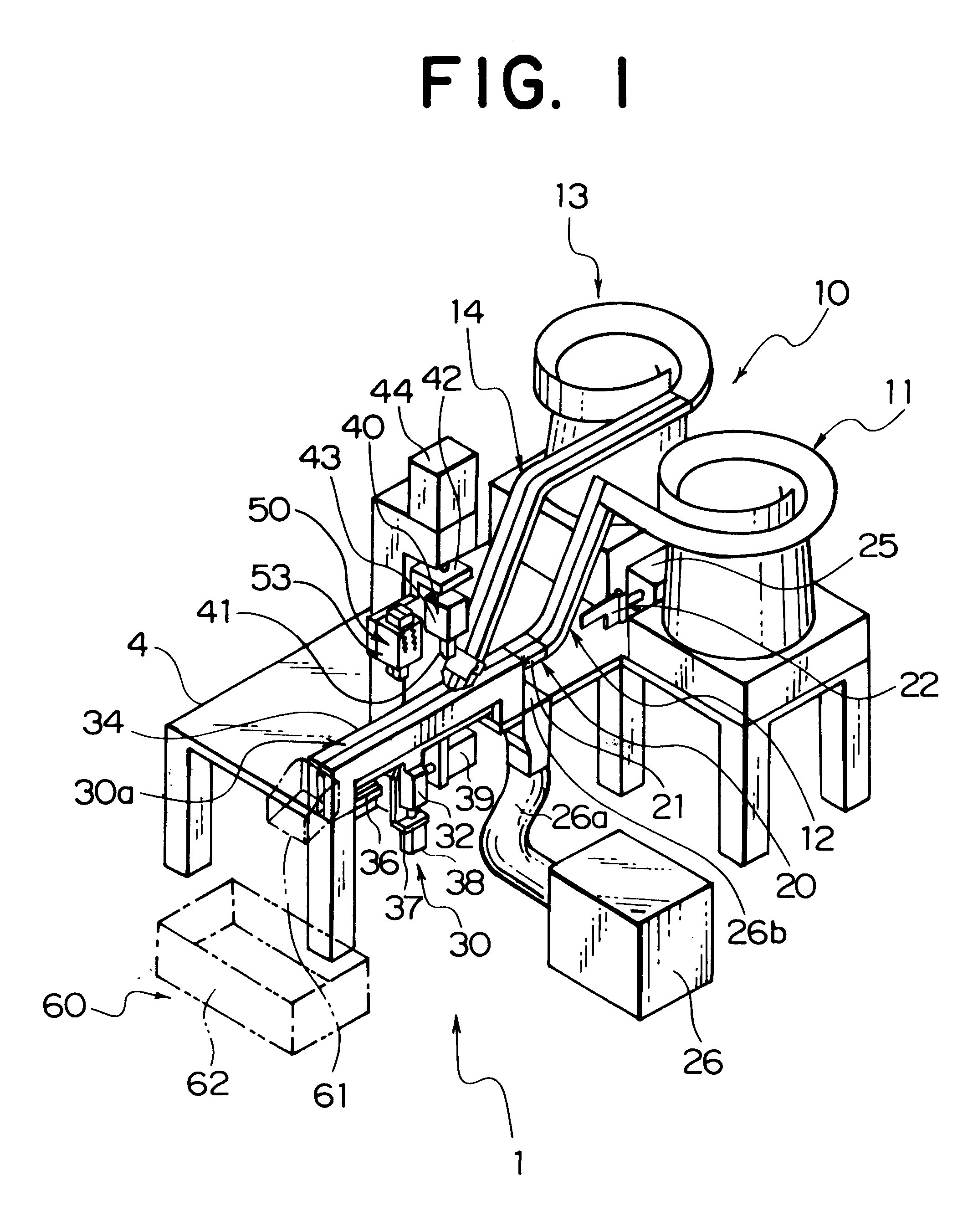

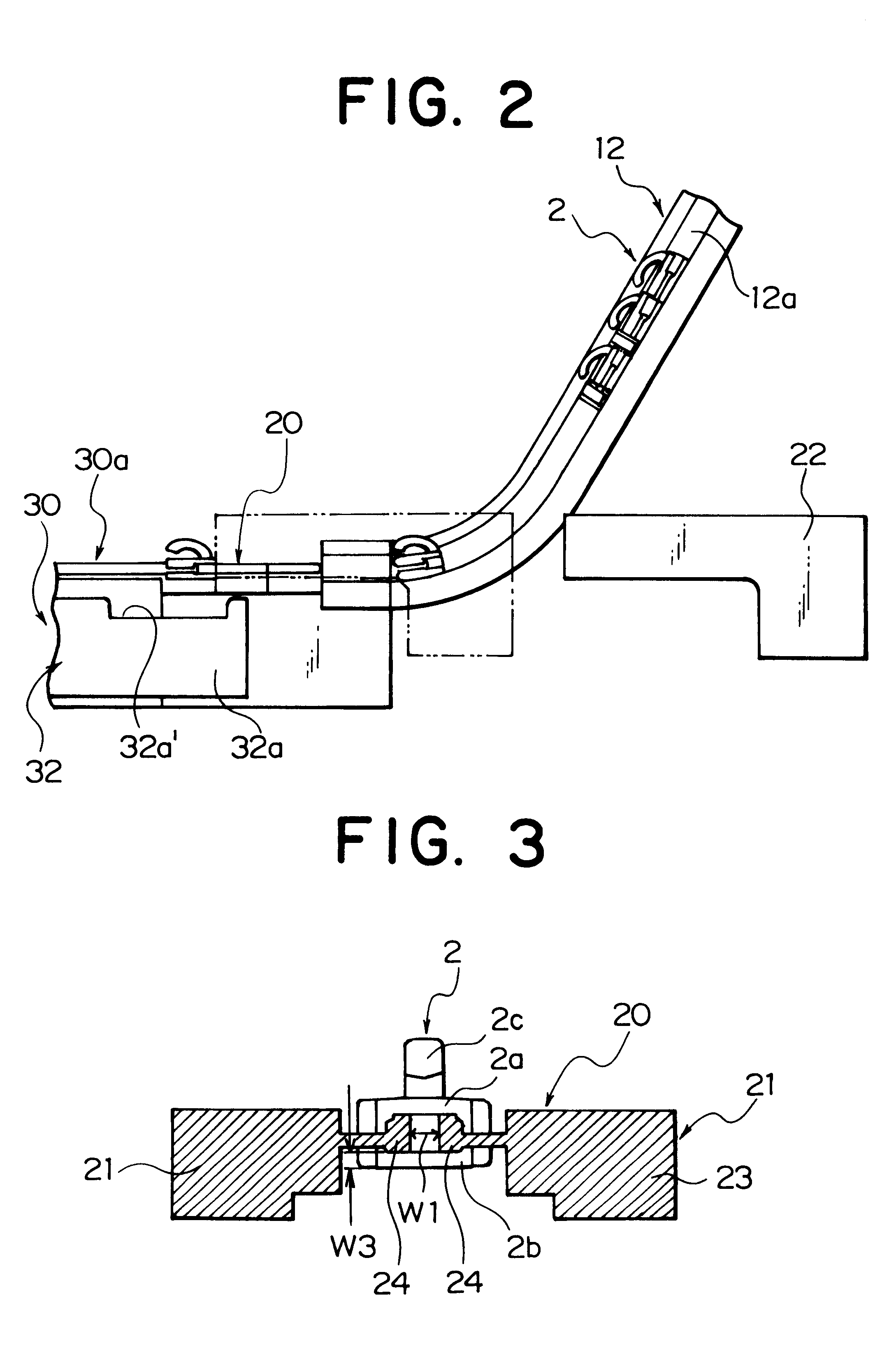

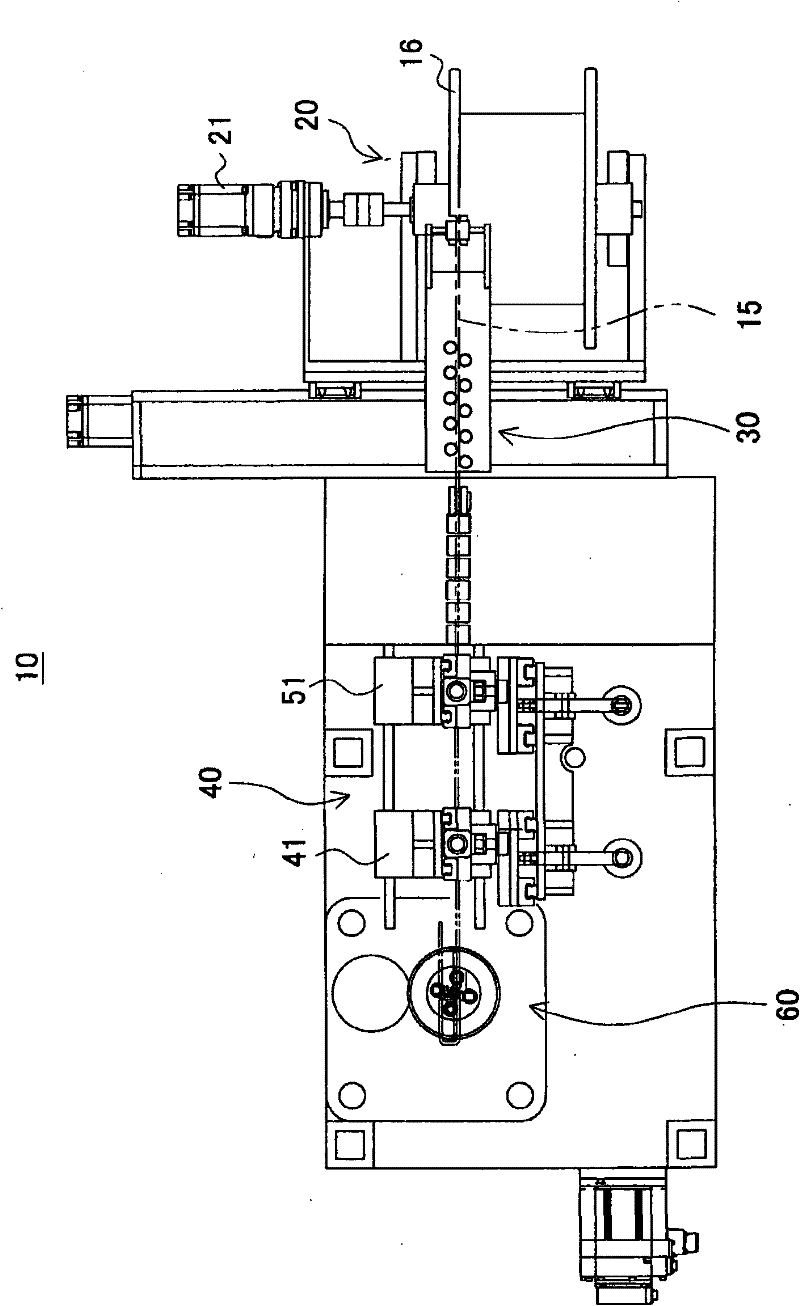

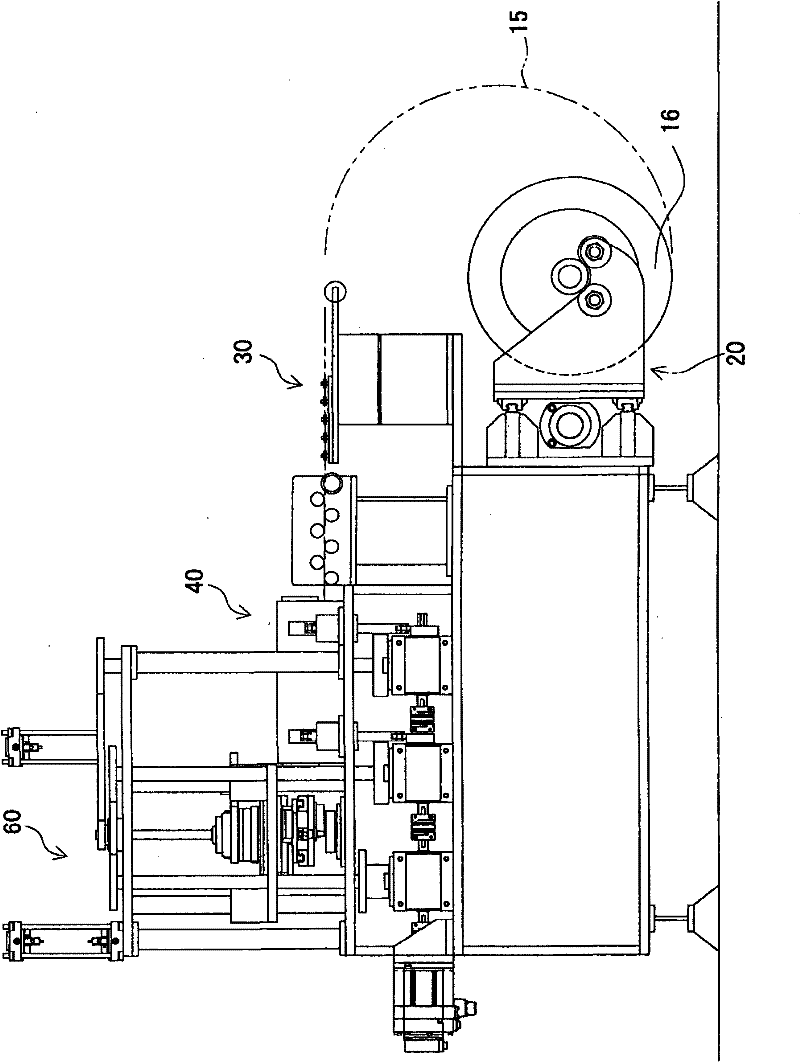

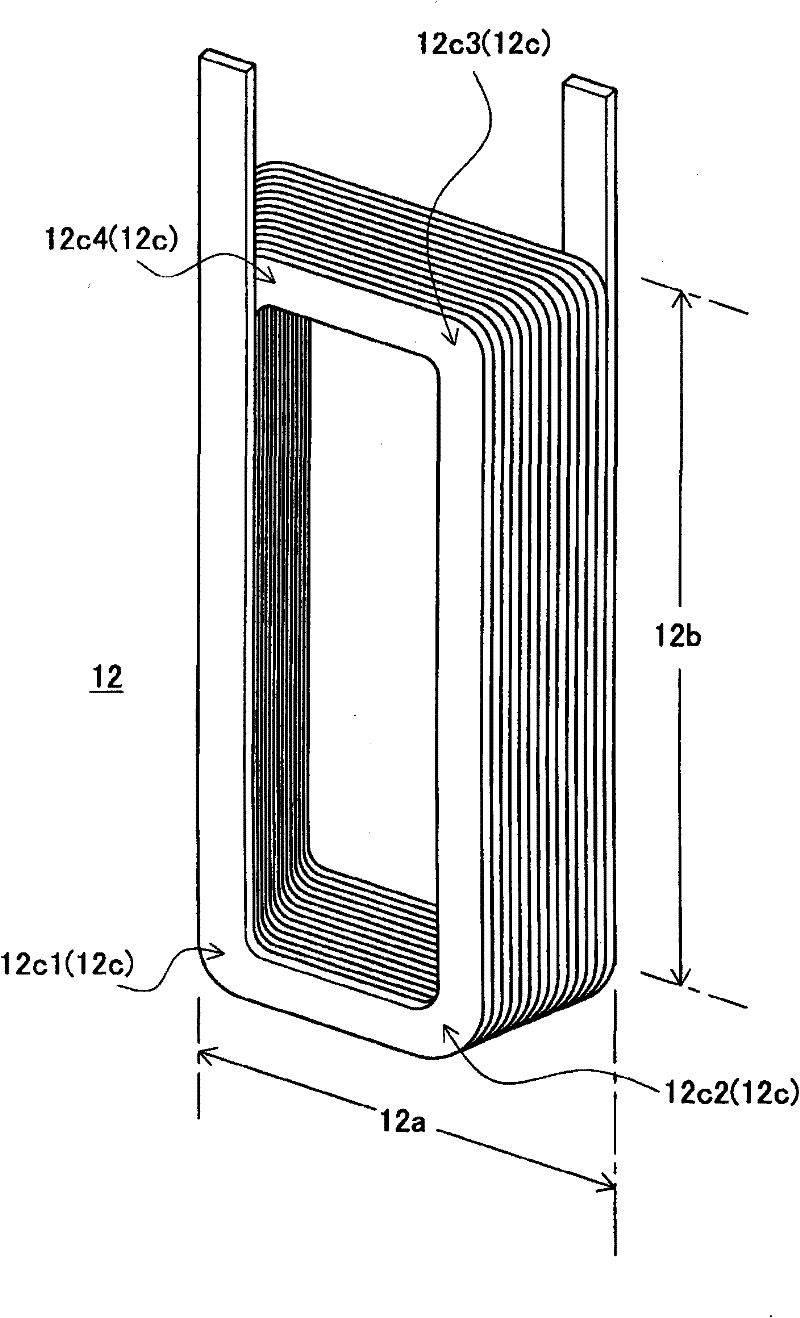

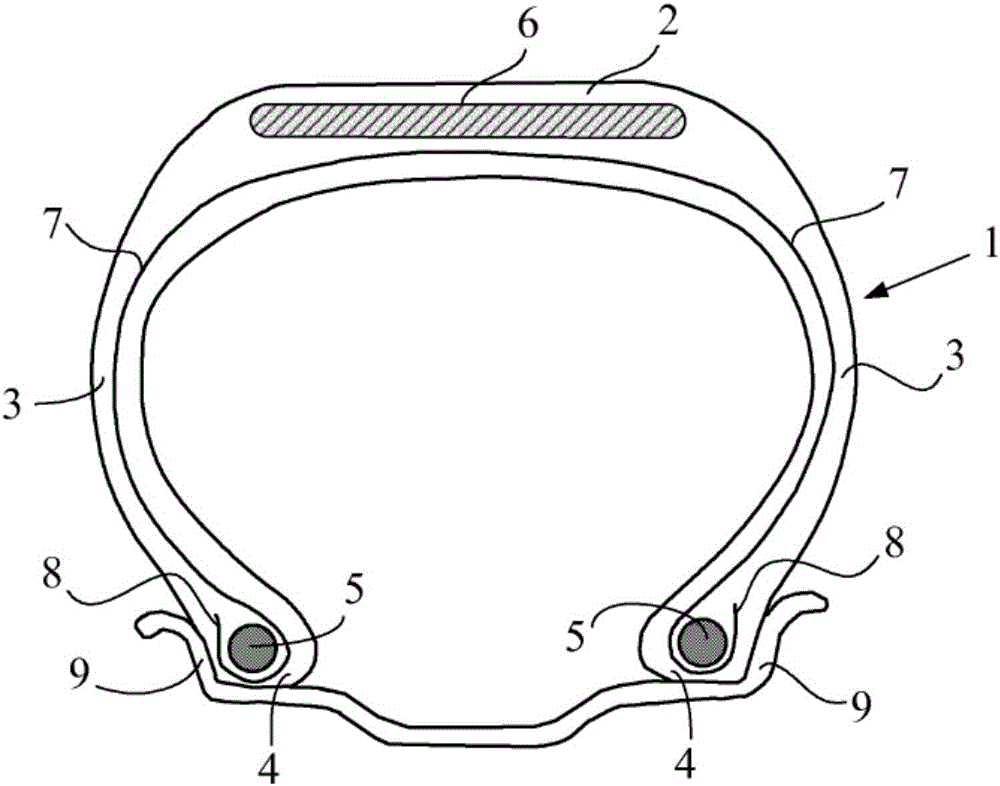

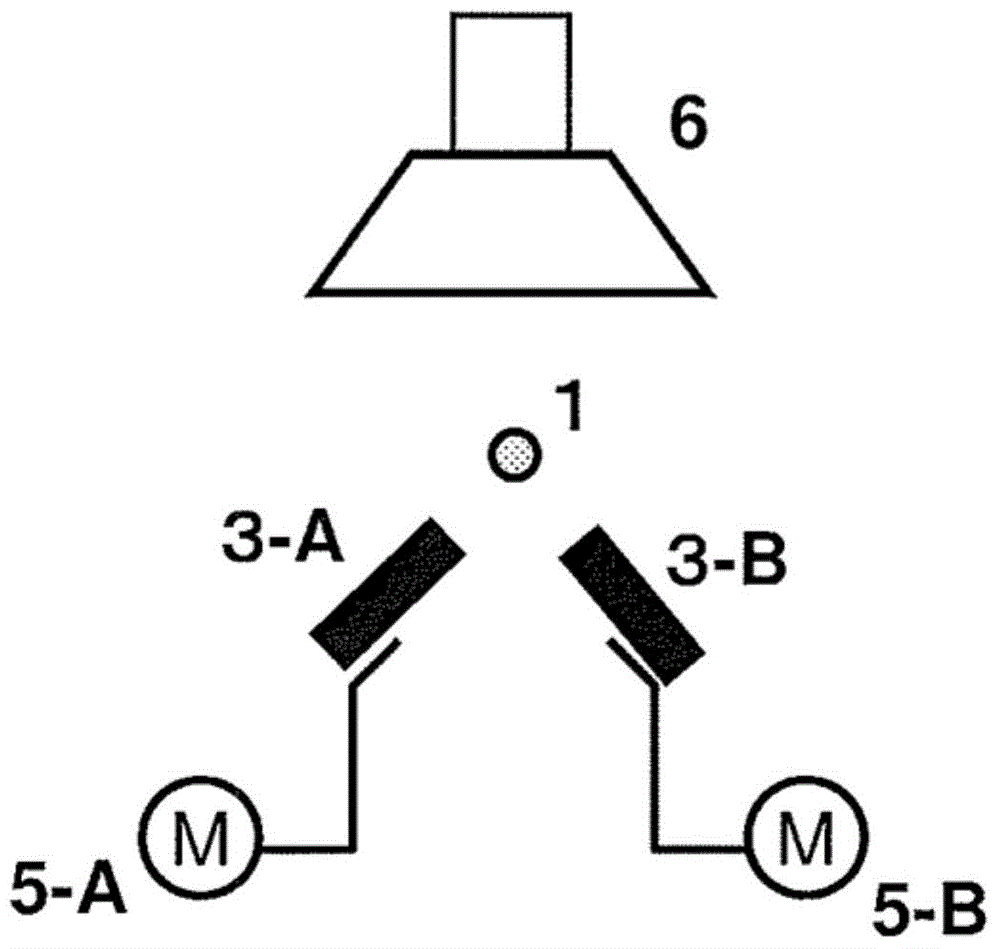

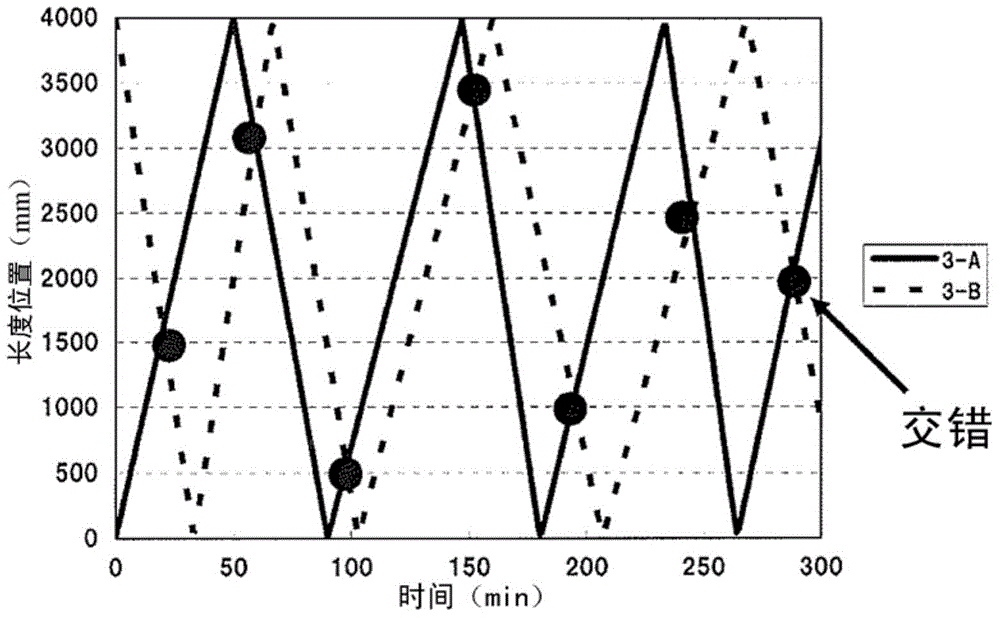

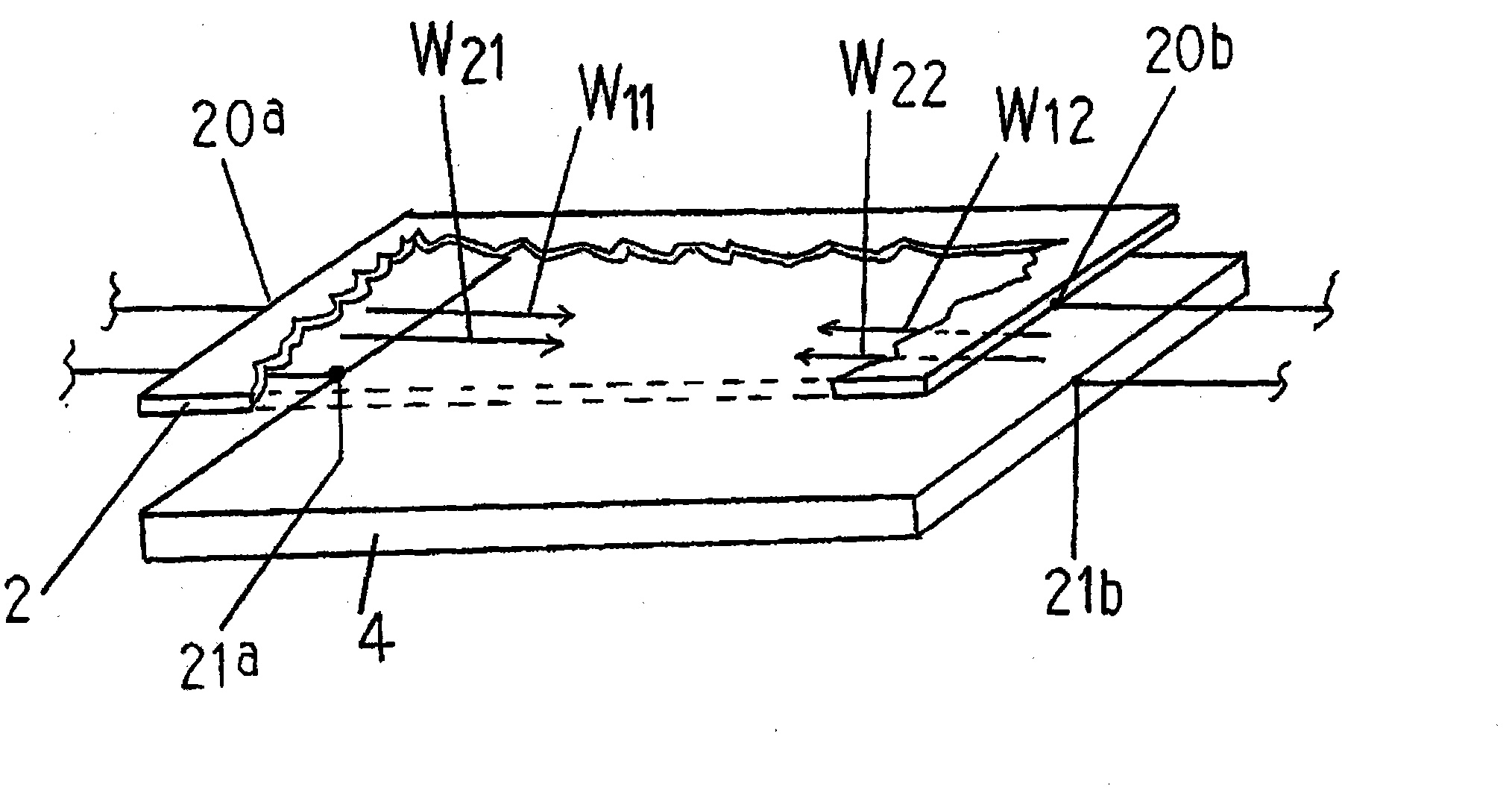

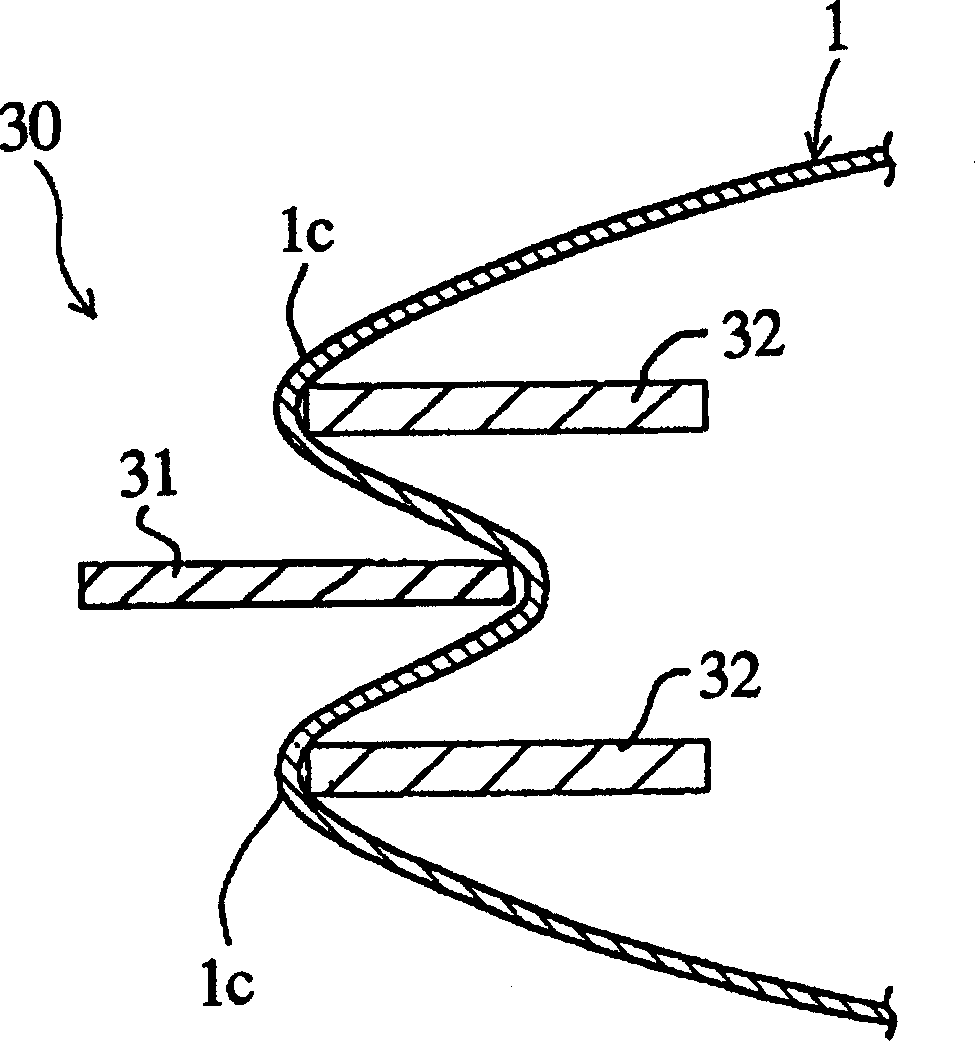

Winding apparatus

InactiveCN101765960ALow costHigh speed manufacturingManufacturing dynamo-electric machinesInductances/transformers/magnets manufactureEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

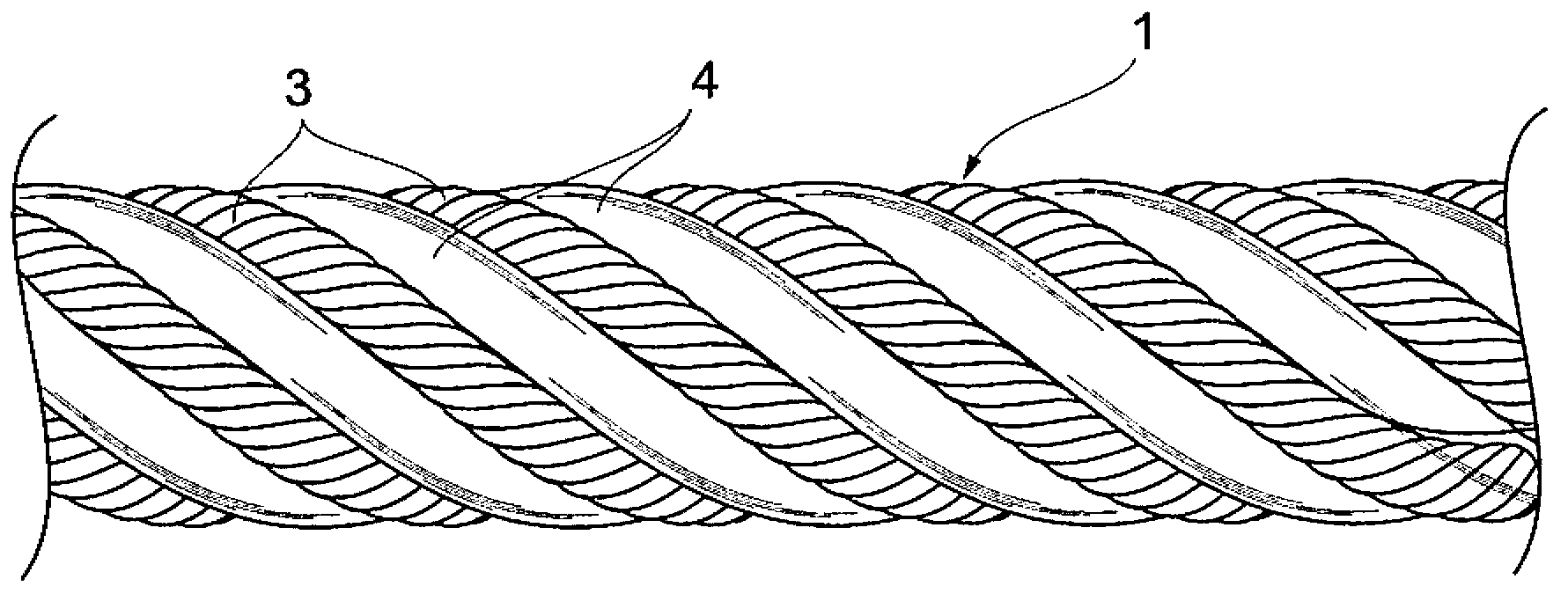

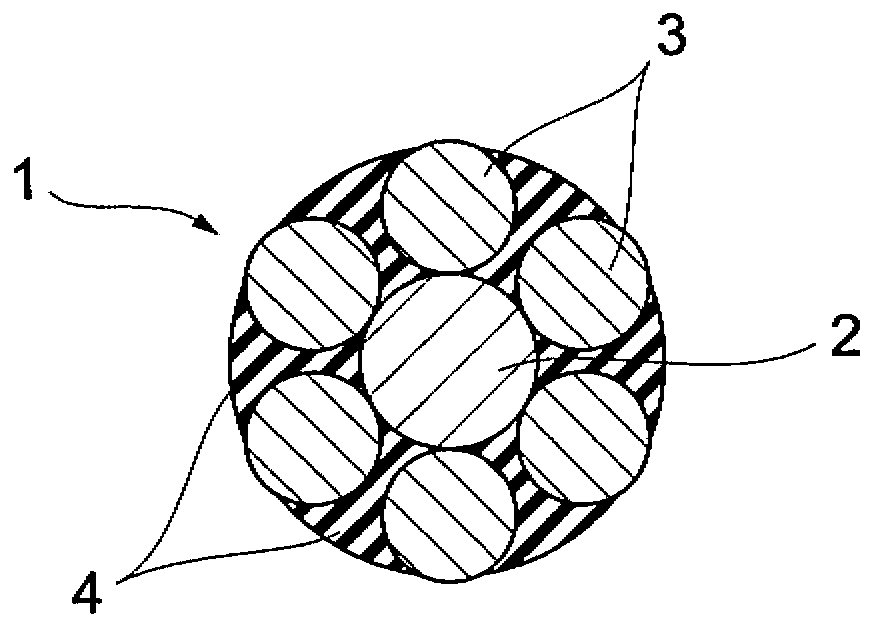

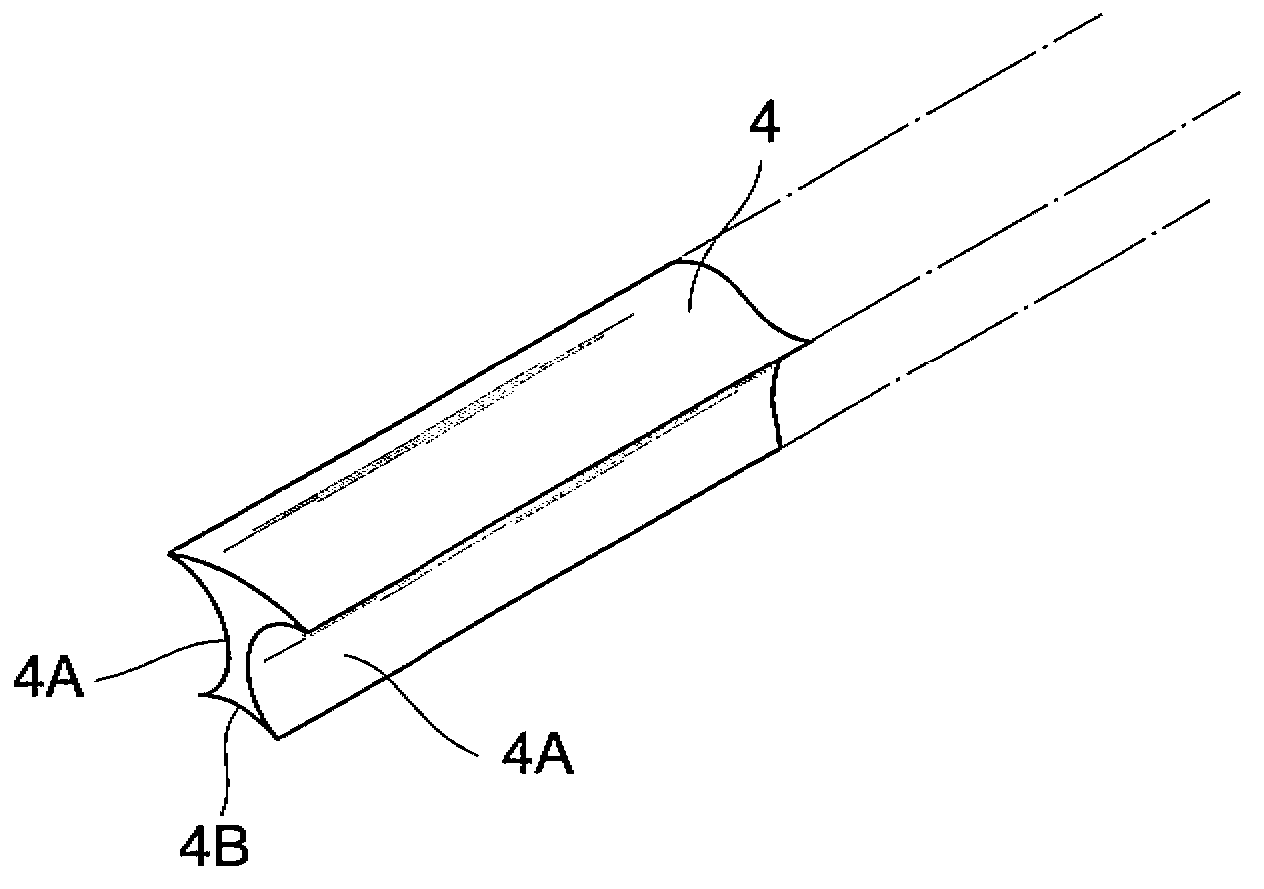

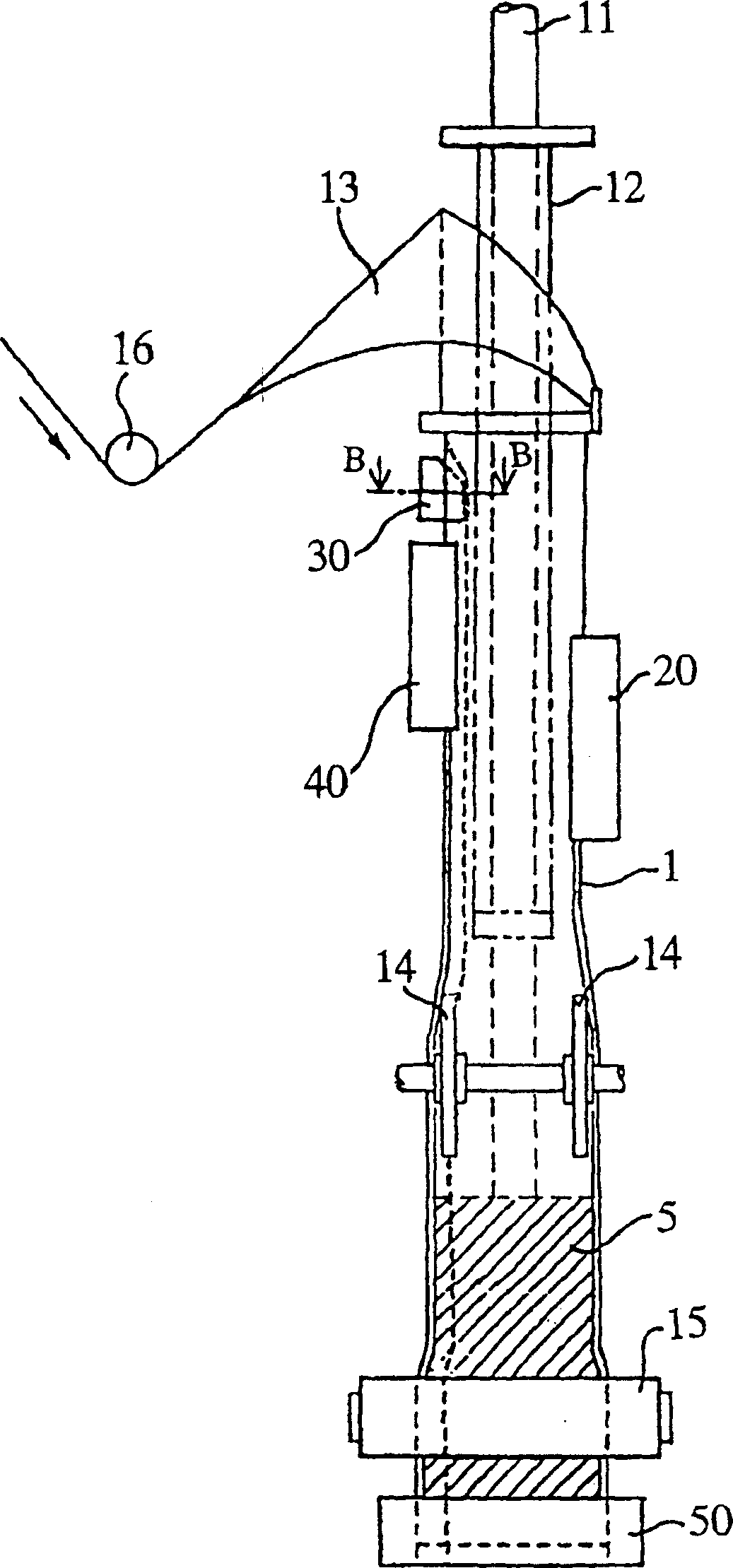

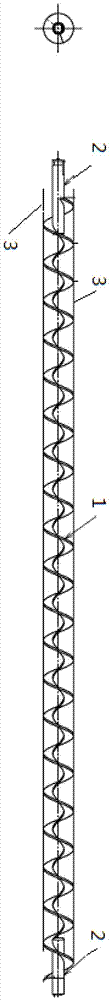

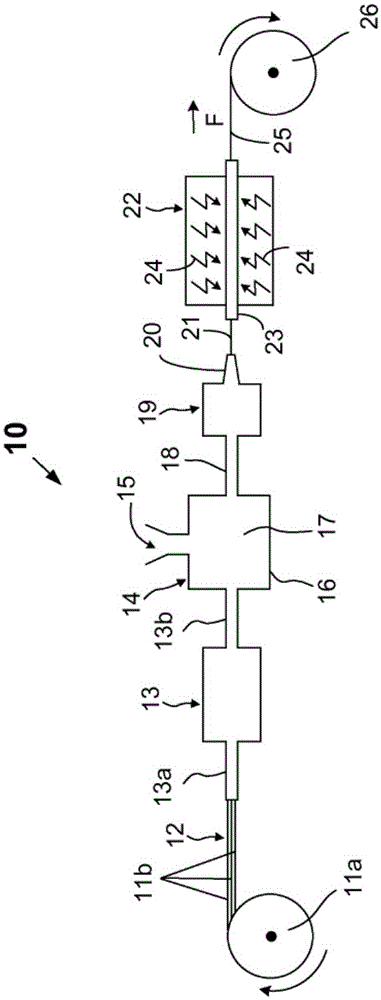

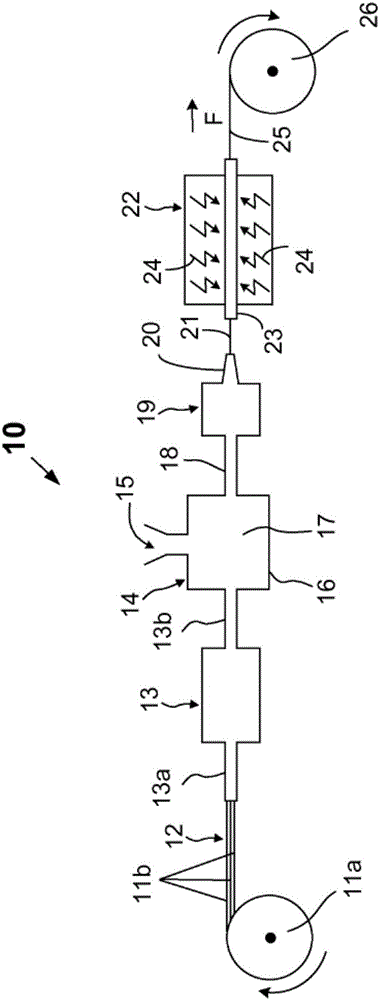

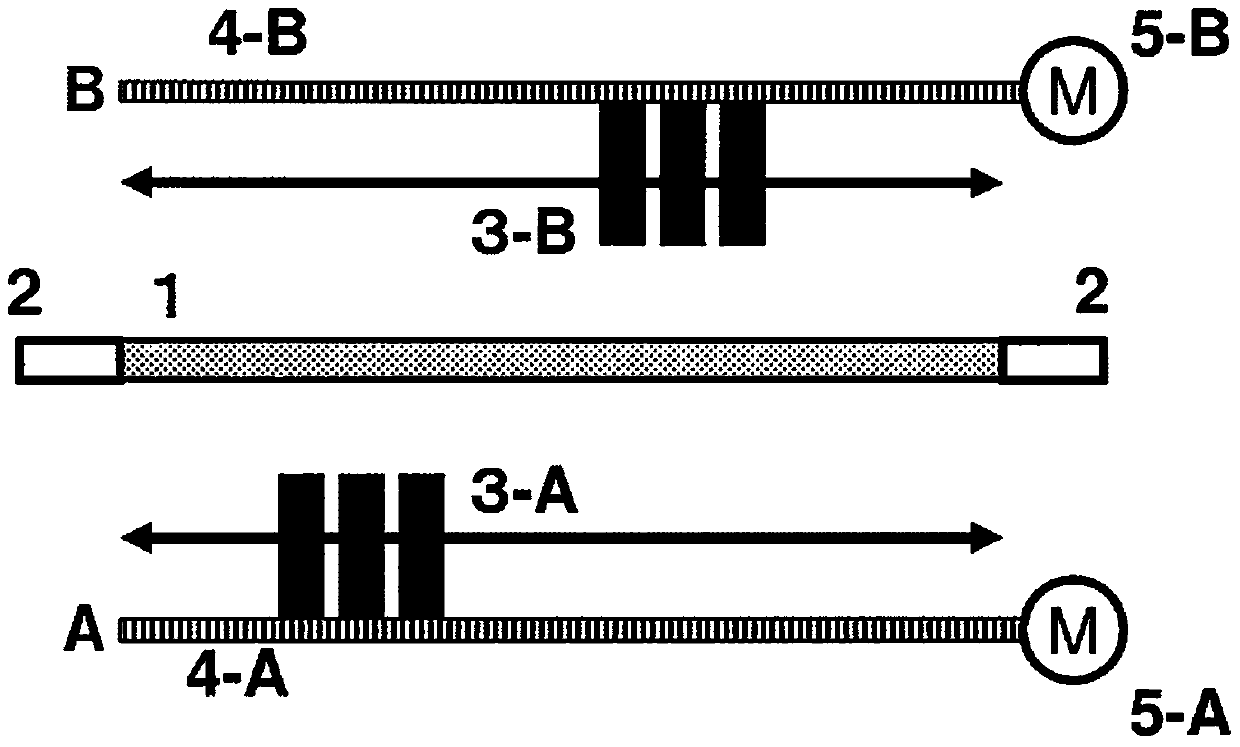

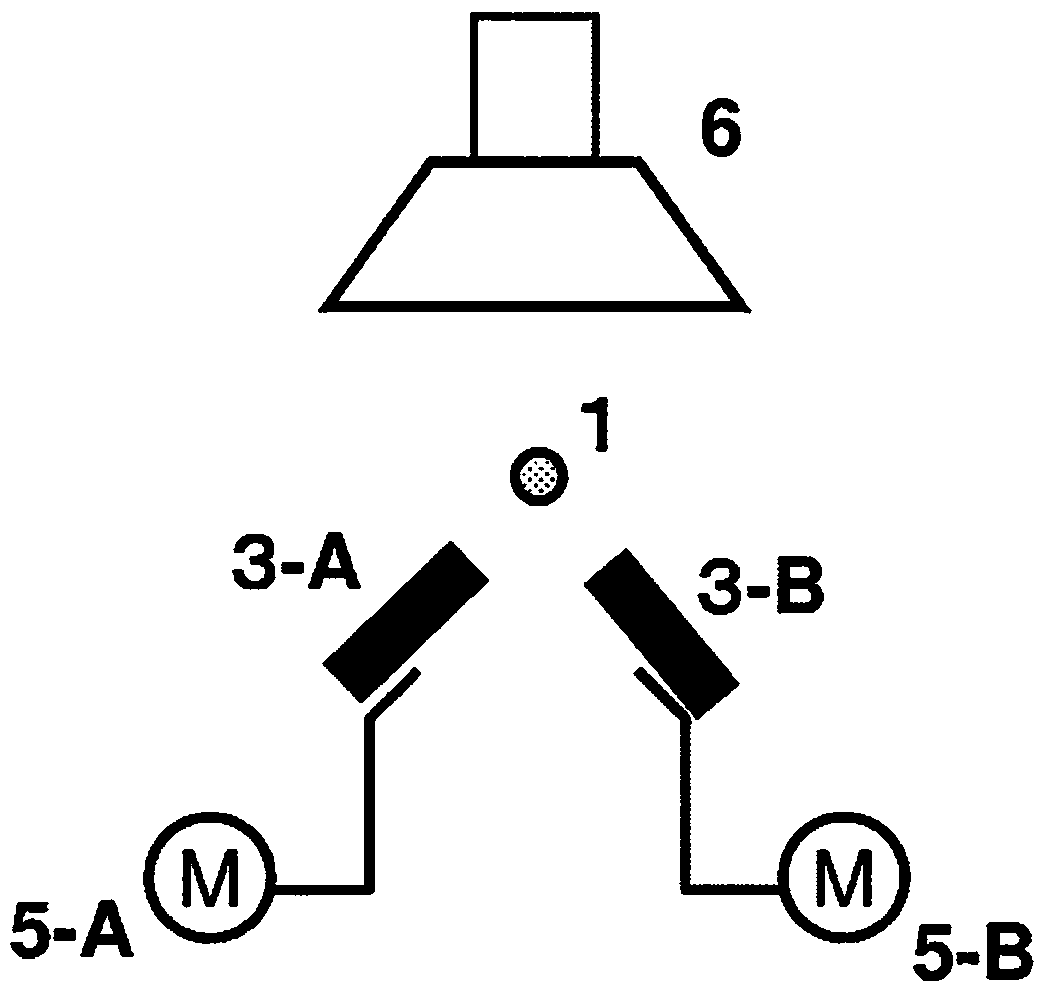

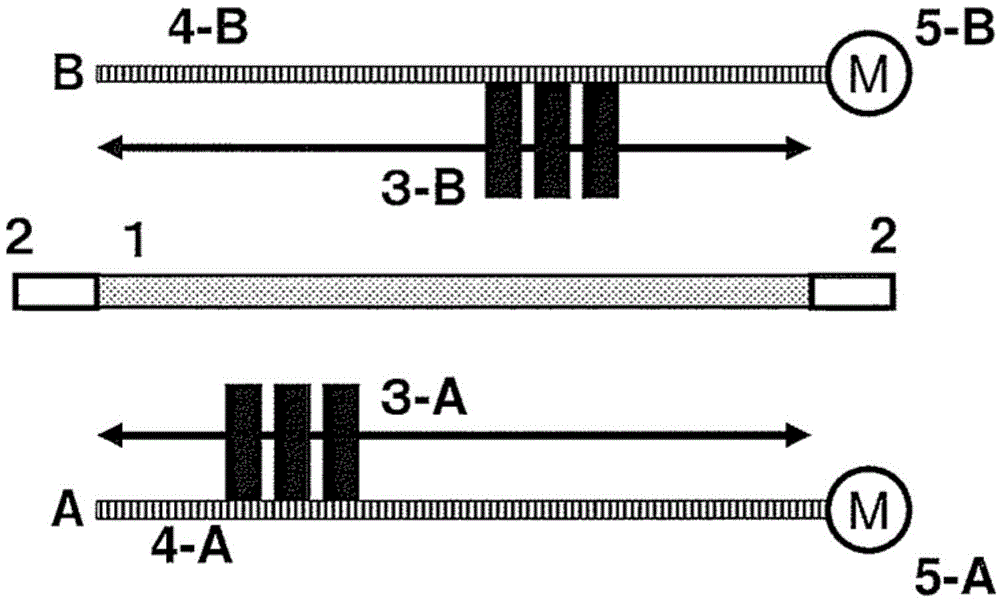

Device for producing wire rope

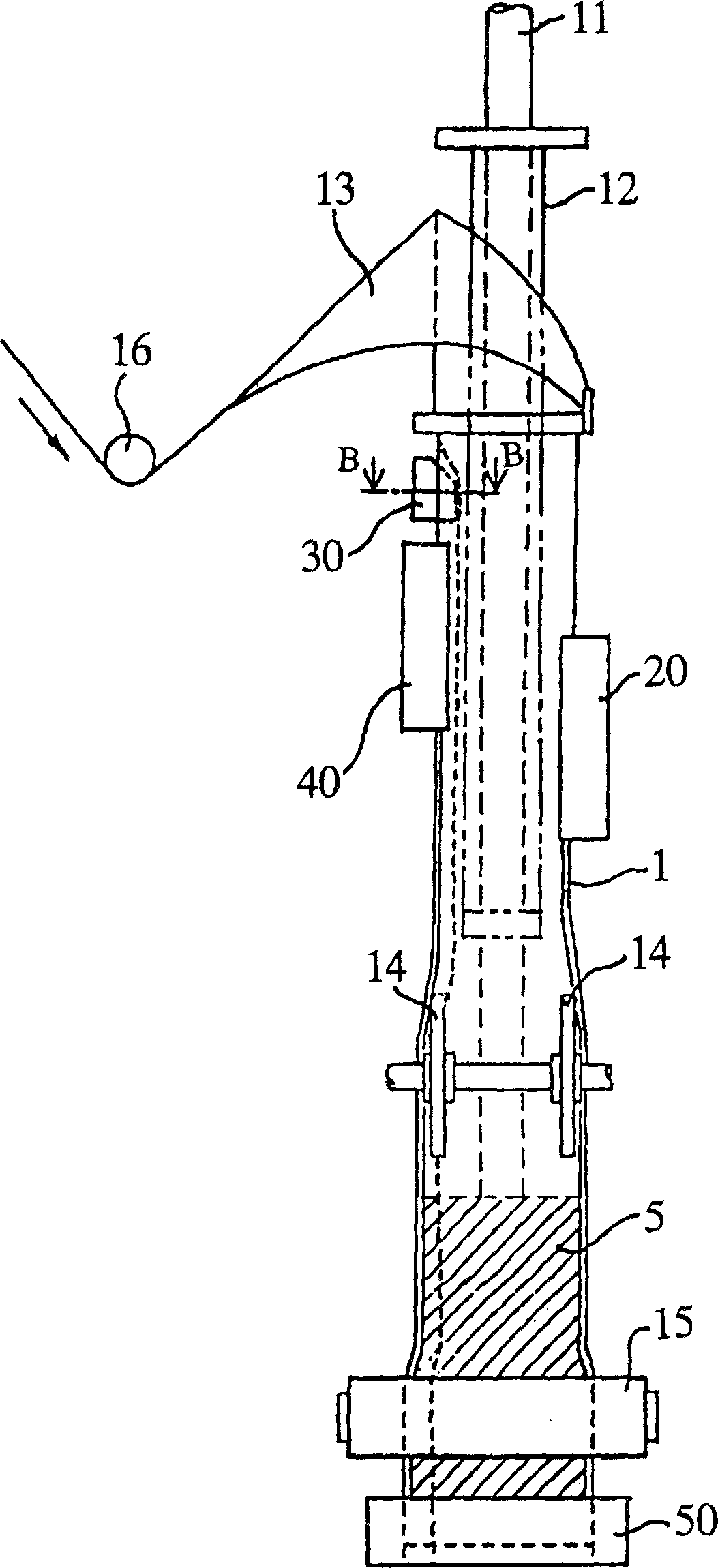

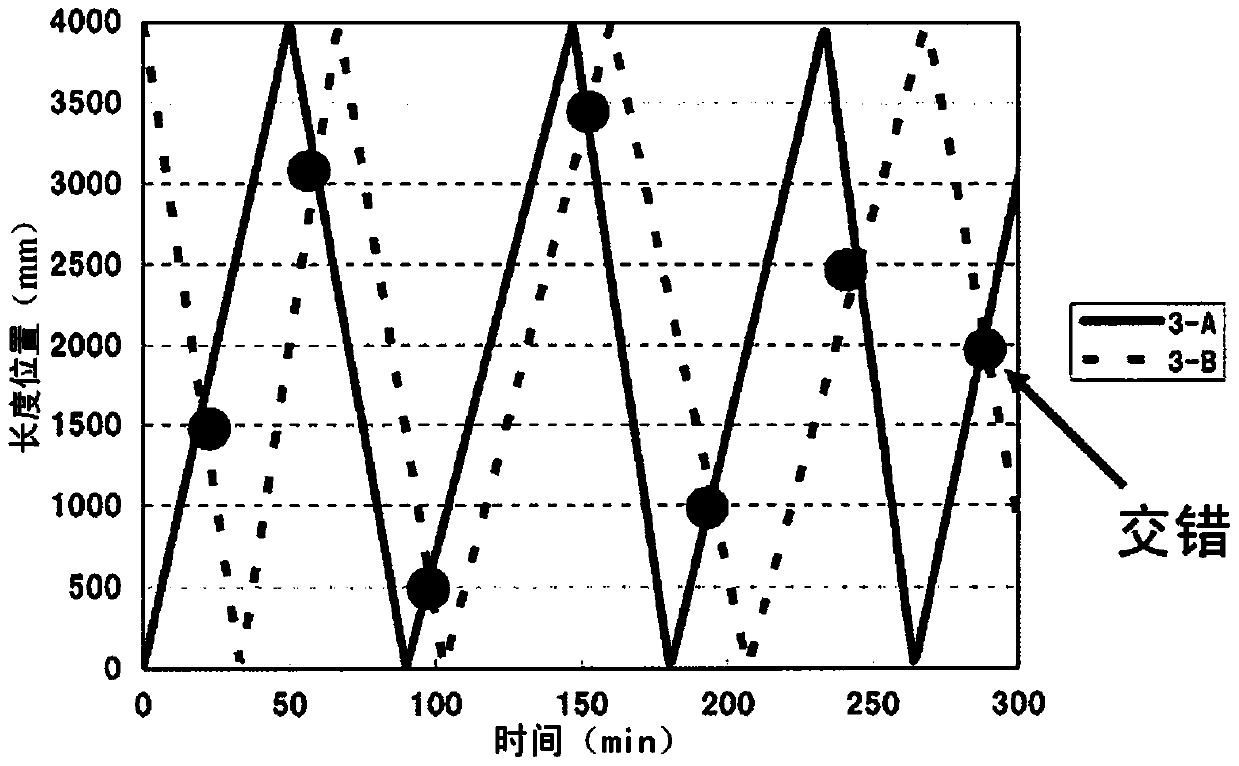

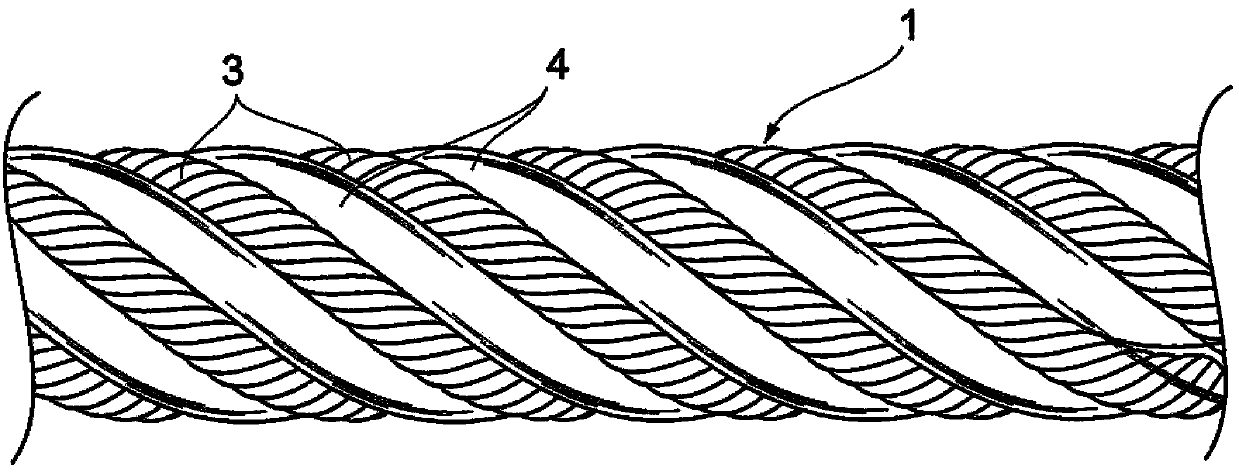

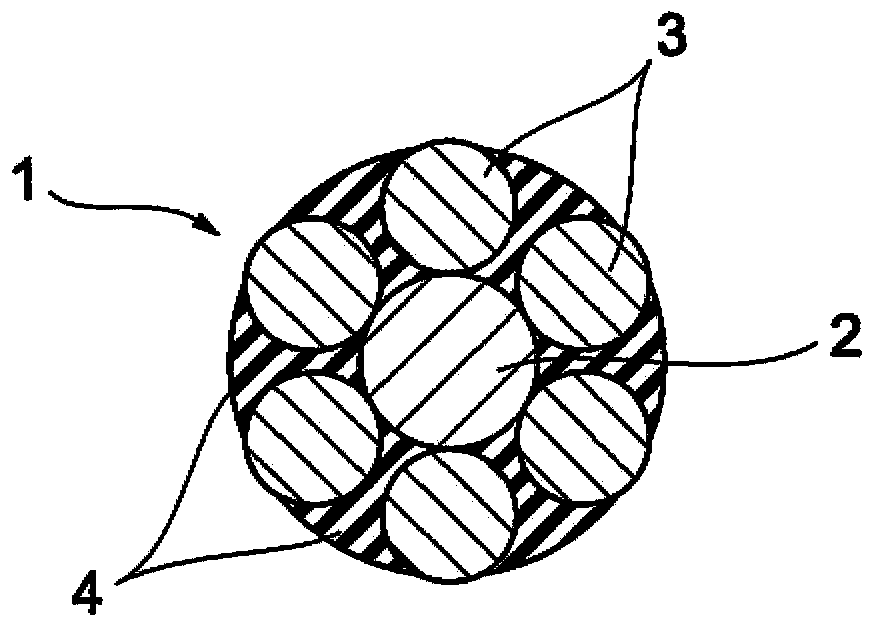

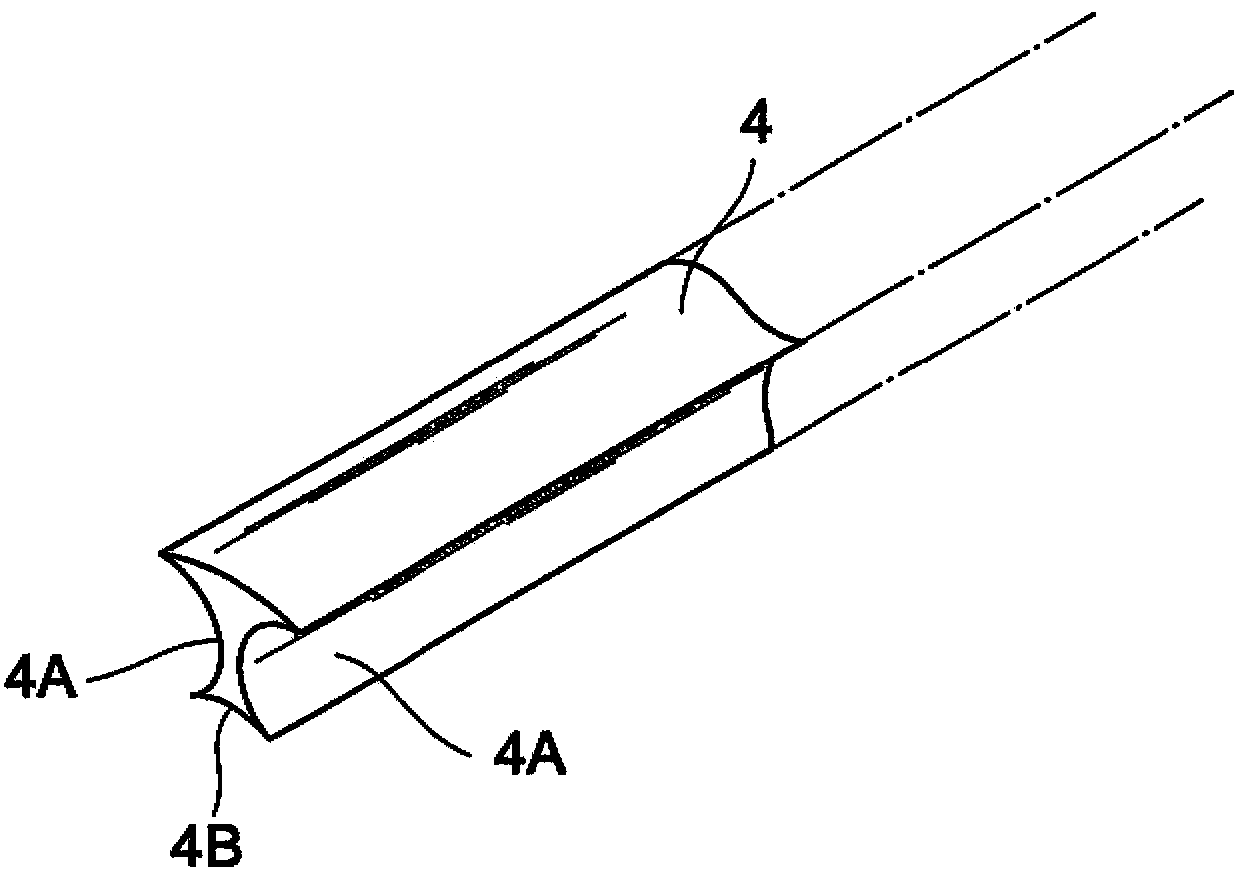

The disclosed device for producing wire rope produces a filler-filled wire rope comparatively quickly. A tubular wire twisting machine (10) and a cage wire twisting machine (20) are disposed in tandem. The rotating shaft (14) of the tubular wire twisting machine (10) and the rotating shaft (21) of the cage wire twisting machine (20) are linked. Six lateral strands (3) are wound by the feed bobbin (12) of the tubular wire twisting machine (10), and six strands of filler material (4) are wound by the feed bobbin (27) of the cage wire twisting machine (20). The six lateral strands (3) and the six strands of filler material (4) are alternately twisted around the periphery of a core rope (2) supplied from the outside, producing a filler-filled wire rope (1).

Owner:TOKYO ROPE MFG

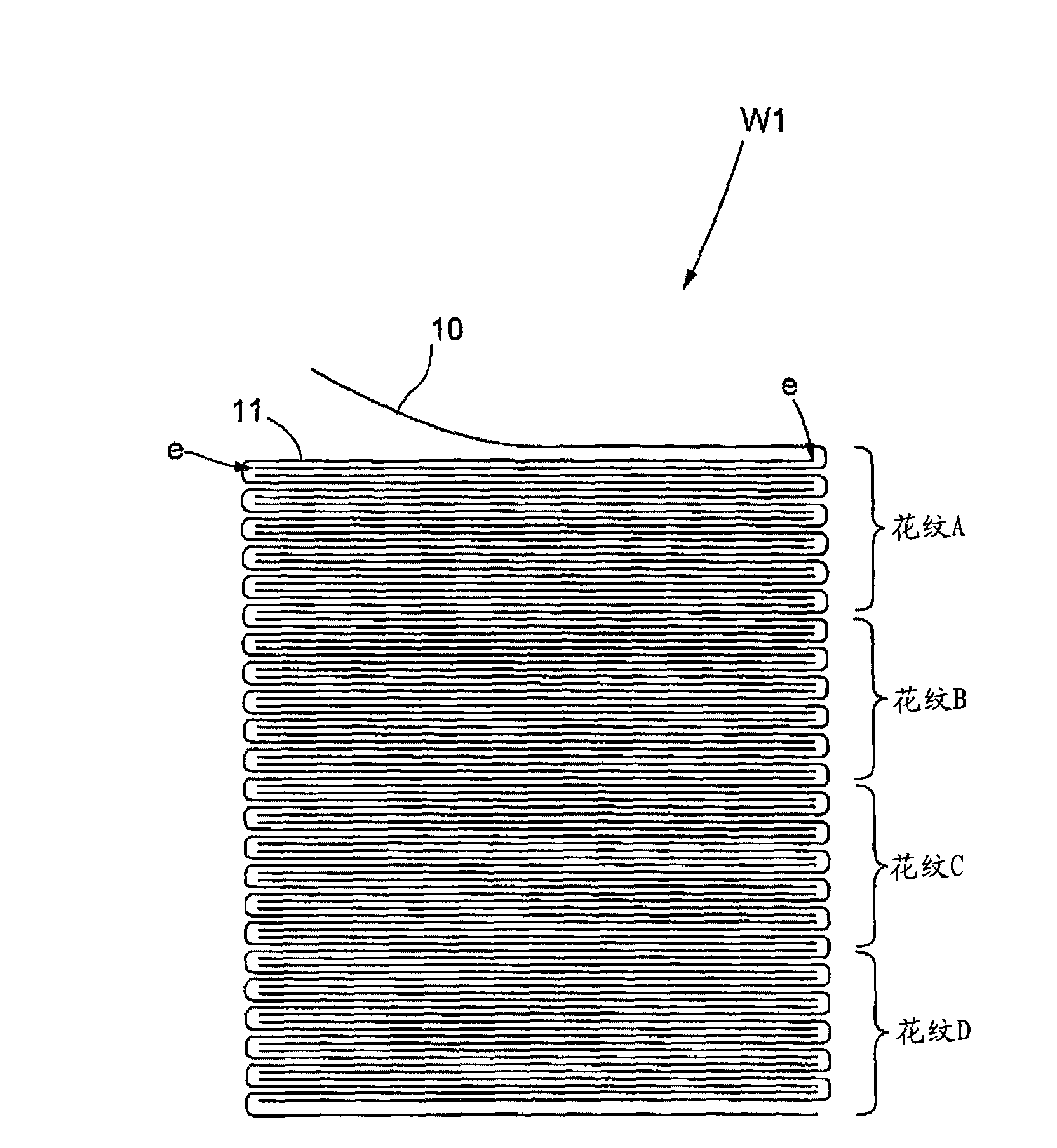

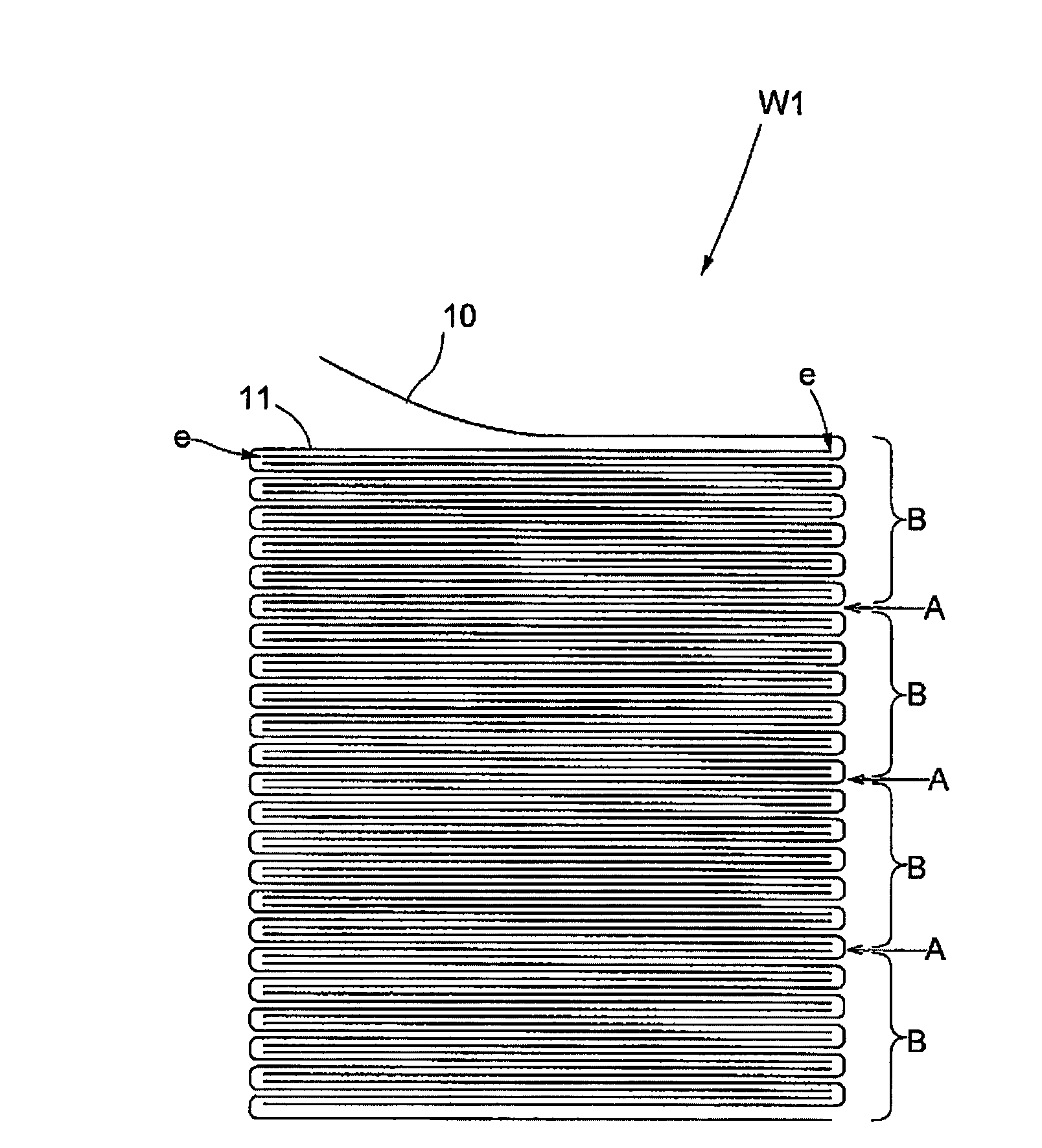

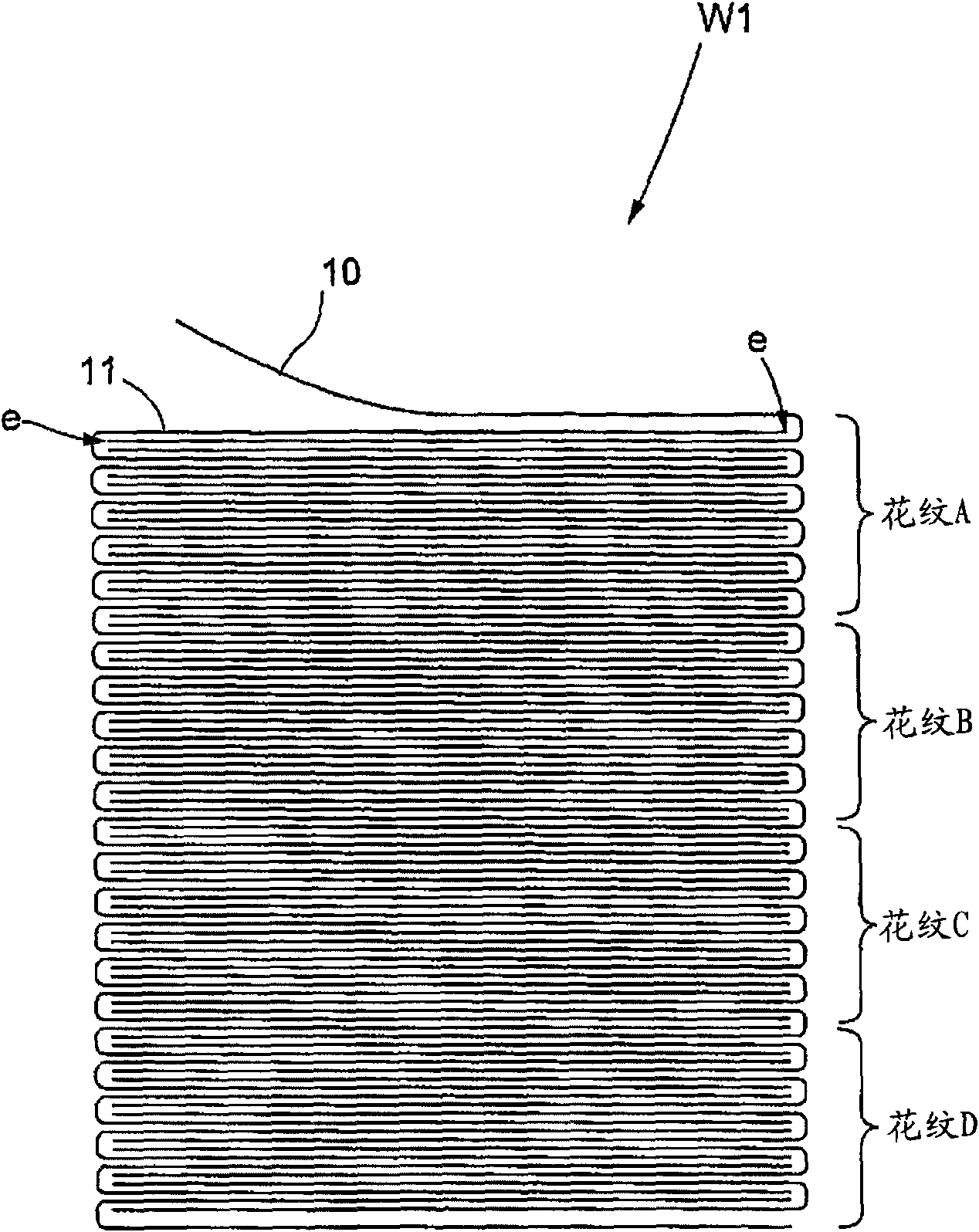

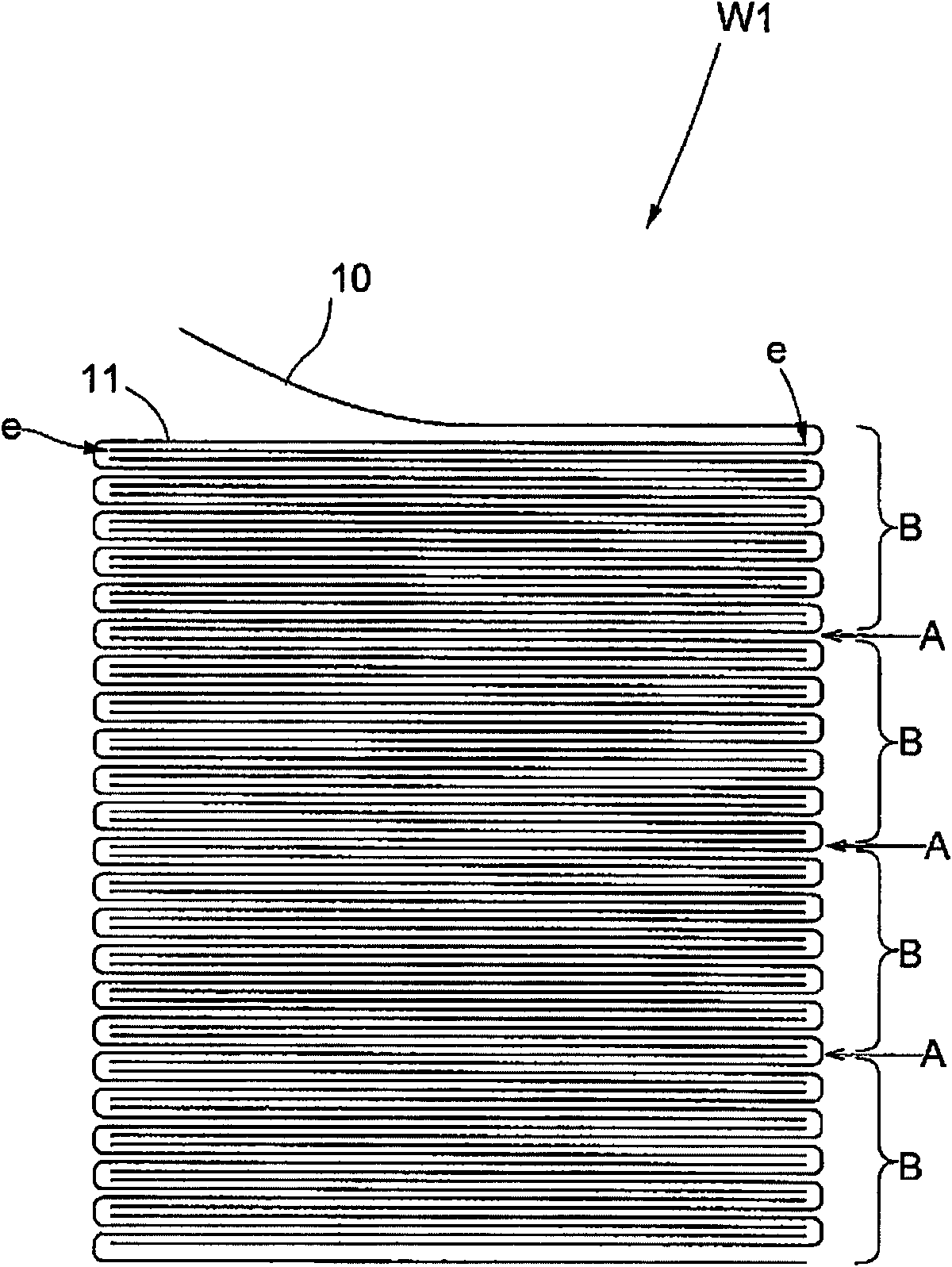

Hygienic tissue paper product and manufacturing method thereof

ActiveCN101637366AIncrease attractivenessKnow the amount remainingFlat article dispensingTissue/absorbent paperBiomedical engineeringPaper sheet

The present invention relates to a hygienic tissue paper product and a manufacturing method thereof. The hygienic tissue paper product provided by the invention has beautiful appearance, excellent amusement and excellent convenience and is of an extraction type. The hygienic tissue paper product is characterized in that: a packaging body which is formed with a taking outlet on the upper surface contains the tissue product for sanitation; when one piece of hygienic tissue paper is taken out from the taking outlet in using, one part of another piece which is laminated adjacently is exposed fromthe taking outlet; wherein, the hygienic tissue paper has a composite layer structure which is laminated with more than two pieces of tissue paper. For one part or total of the hygienic tissue paper,the laminated inner surfaces which form the outer random tissue paper in the laminated tissue paper are printed with patterns.

Owner:DAIO PAPER CORP

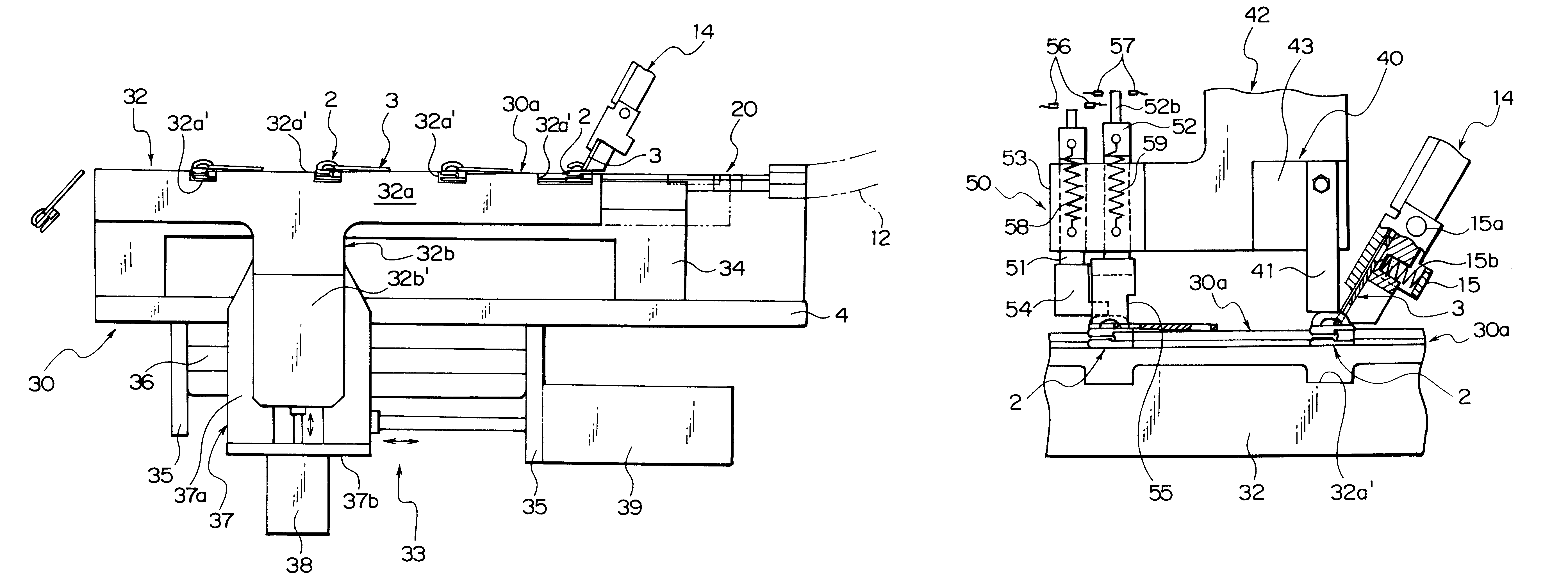

Slider-pull-assembling unit

InactiveUS6317969B1Simple structureIncrease speedAutomatic control devicesWire articlesLower limitVertical plane

In a pull-assembling unit for automatically assembling a pull onto a slider body of a slide fastener, a slider transporting means includes a slider-body-transportation plate member having rectangular notch portions spaced at intervals of plural assembling sections along a top end edge thereof, each for accommodating the slider body. The slider-body-transportation plate member is adapted to be actuated in the slider-transportation path so as to draw a rectangular trajectory in a vertical plane. An actuation upper limit position of a top end of the rectangular notch portion is set to be above a slider-body-placing surface of the slider-transportation path and an actuation lower limit position of the top end of the notch portion is set to be at a retreat position below the slider-body-placing surface. Therefore, the slider-pull-assembling unit has a simple structure and is capable of assembling a pull onto a slider body accurately and securely at a high speed.

Owner:YKK CORP

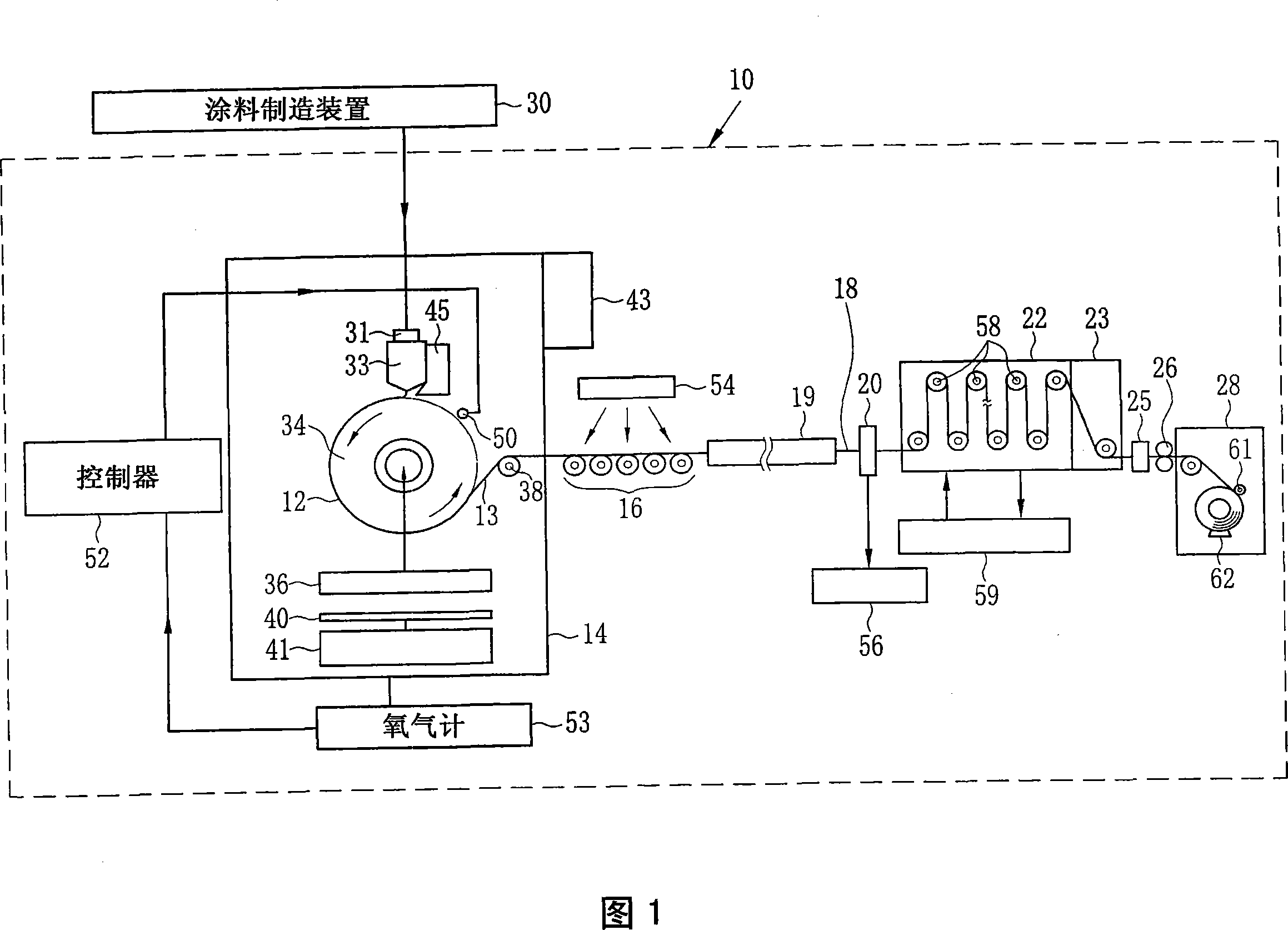

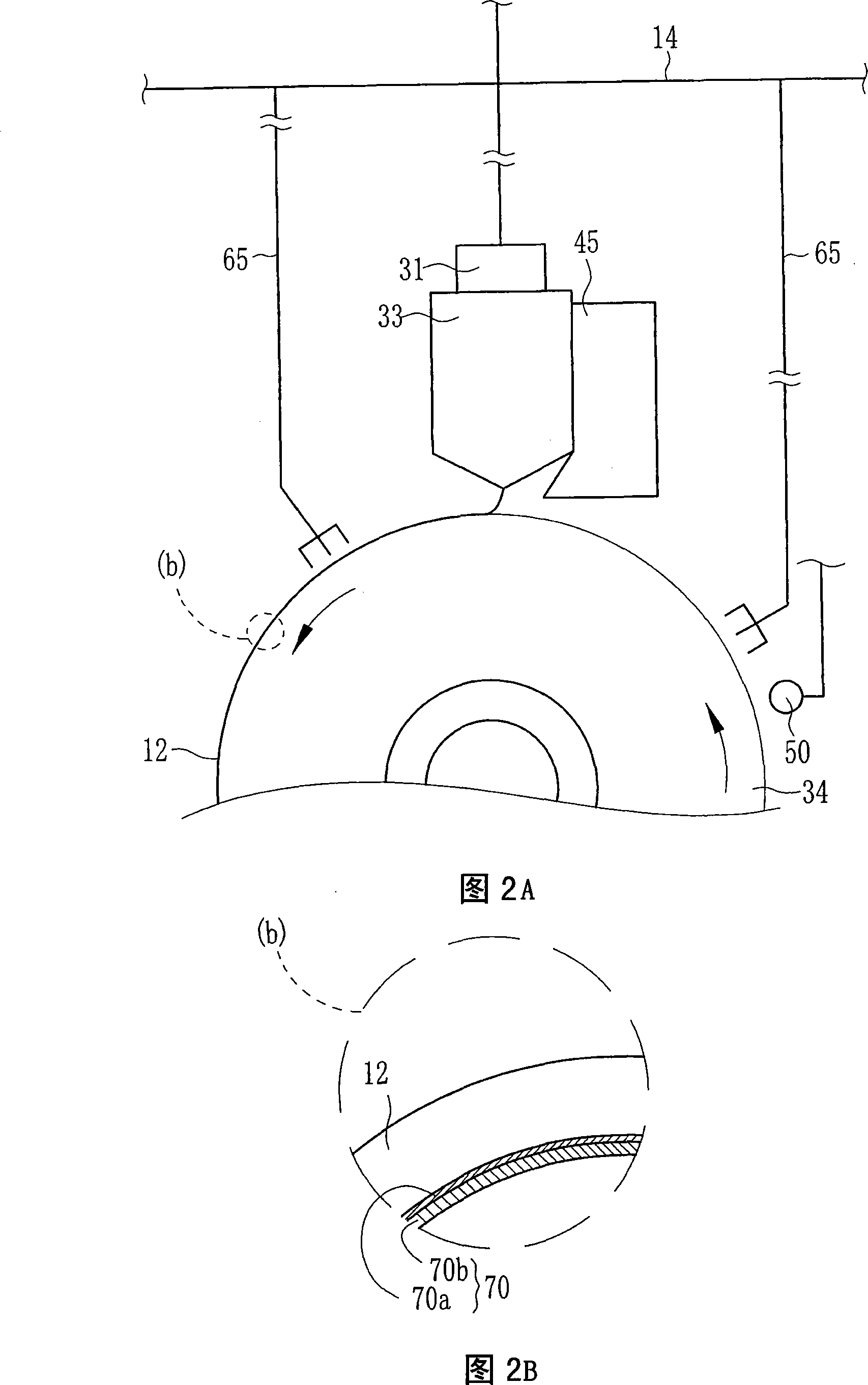

Production method of polymer film and production apparatus of the same

InactiveCN101224613AHigh speed manufacturingHigh-speed and stable manufacturingFlat articlesCoatingsAir entrainmentCast films

There is provided a casting drum having an outer peripheral surface provided with an electrical insulating layer. Direct-current high voltage is applied to an electrode bar disposed in an upstream side from a discharge port to discharge toward the casting drum. Bead is attracted to the charged casting drum by electrostatic attraction. Thereby, the adhesion between the bead and the casting drum is increased, and therefore the occurrence of phenomenon of air entrainment can be prevented. A wet film obtained by peeling a casting film from the casting drum is dried. Accordingly, it is possible to produce a film having few defects such as voids and high quality such as excellent smoothness at high speed and stably.

Owner:FUJIFILM CORP

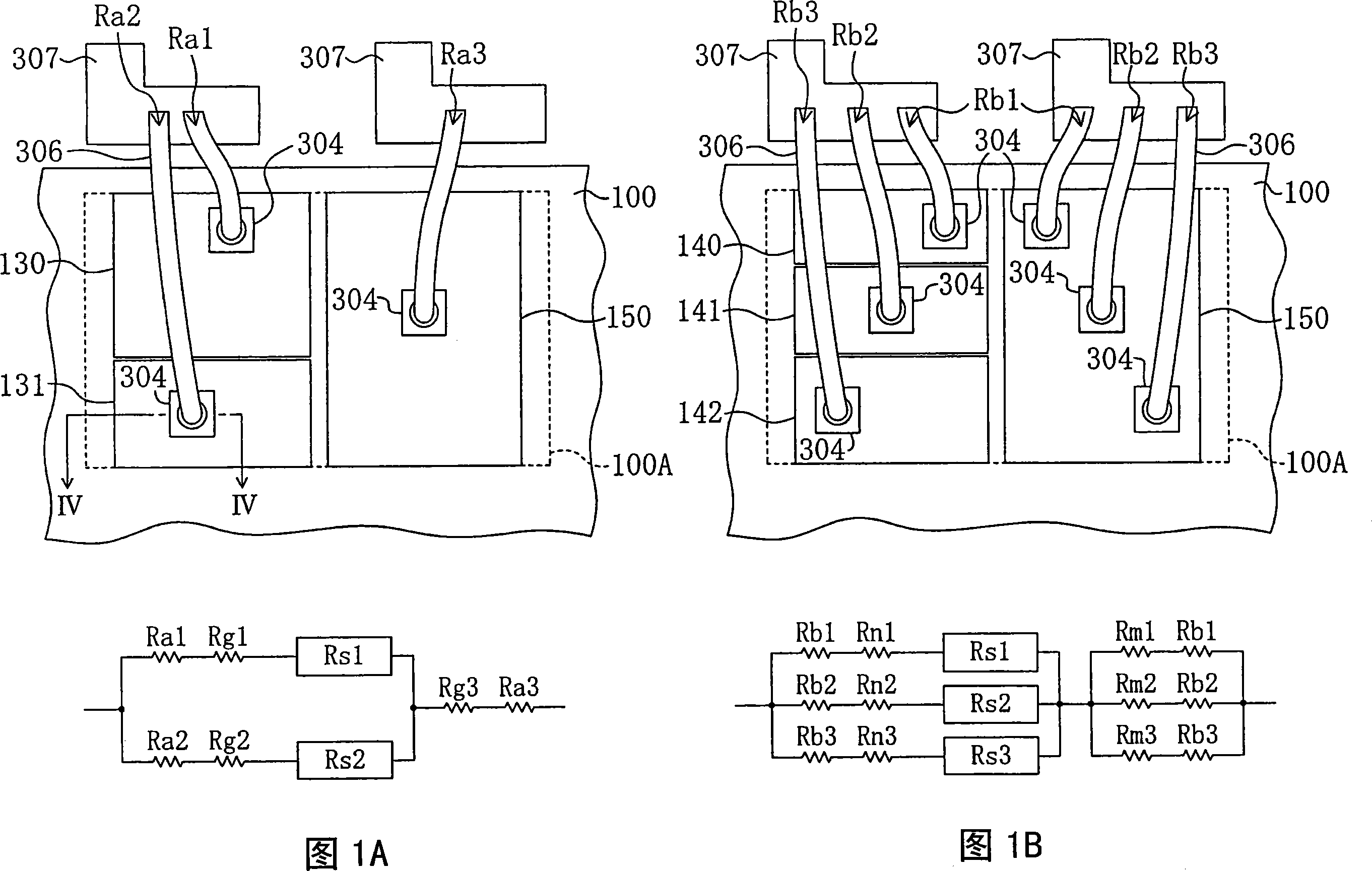

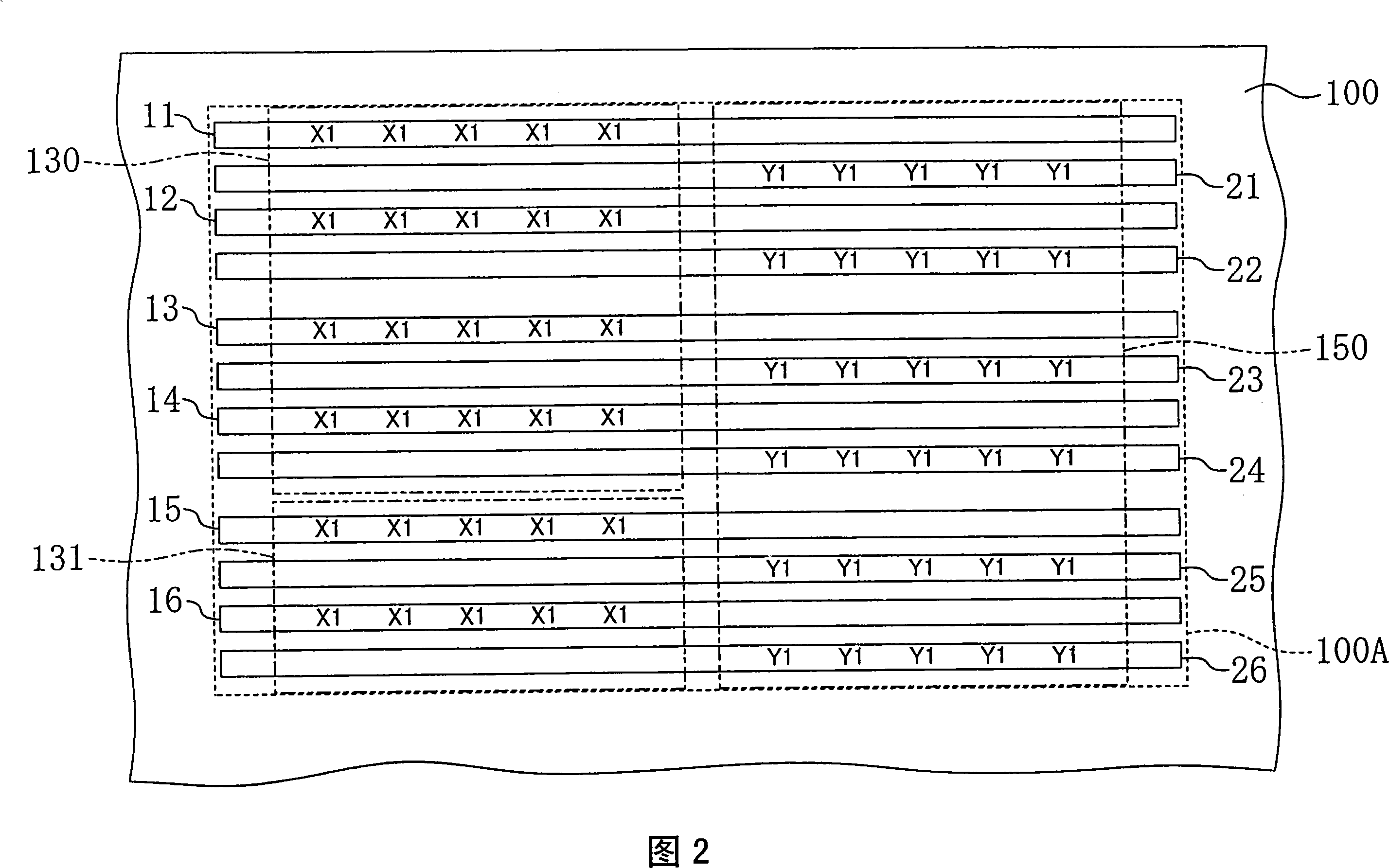

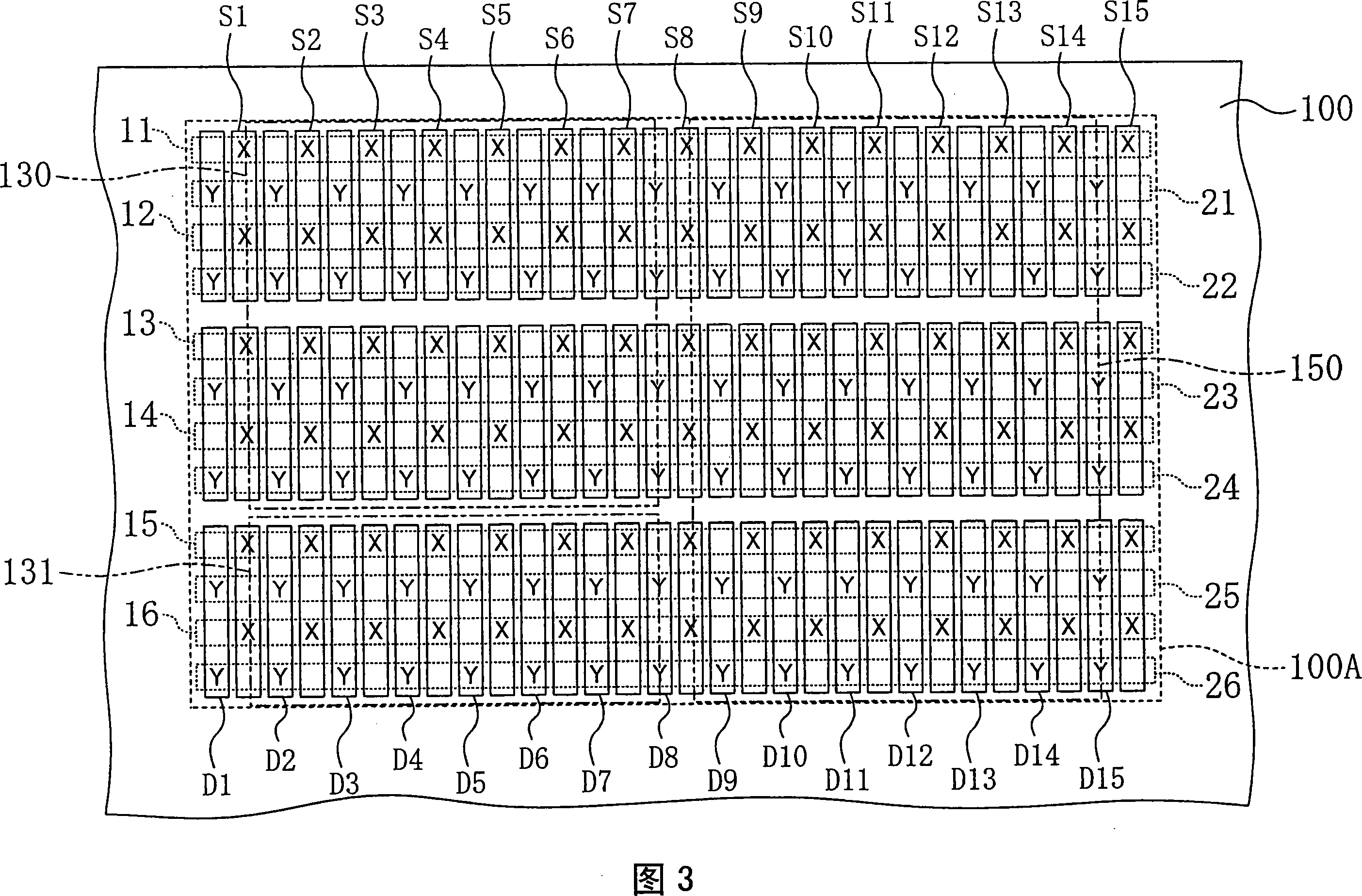

Semiconductor integrated circuit and manufacturing method thereof

InactiveCN101192608AImprove versatilityImprove reliabilityTransistorSemiconductor/solid-state device detailsContact padSemiconductor

A semiconductor integrated circuit relating to one aspect of the present invention includes a power transistor, at least one or more of first metal patterns functioning as a first electrode of the power transistor and at least one or more of second metal patterns functioning as a second electrode of the power transistor formed in an interlayer insulation film on the transistor, at least one or more of first busses electrically connected to a corresponding first metal pattern of the at least one or more of the first metal patterns, a single second bus electrically connected to the at least one or more of second metal patterns, and a contact pad provided to each of the at least one or more of first busses and the single second bus.

Owner:PANASONIC CORP

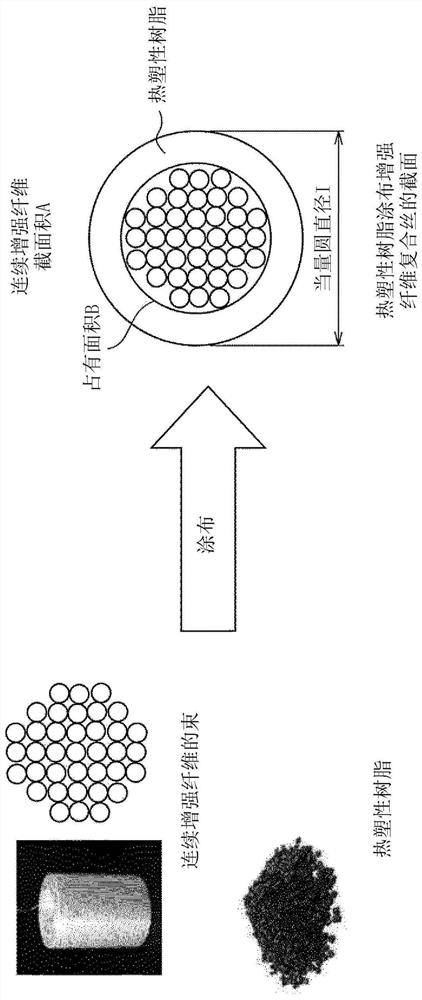

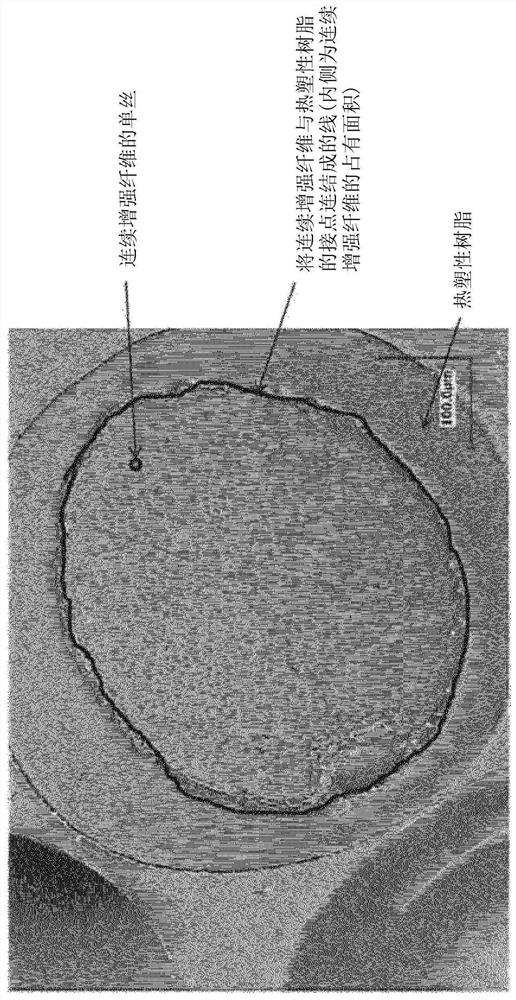

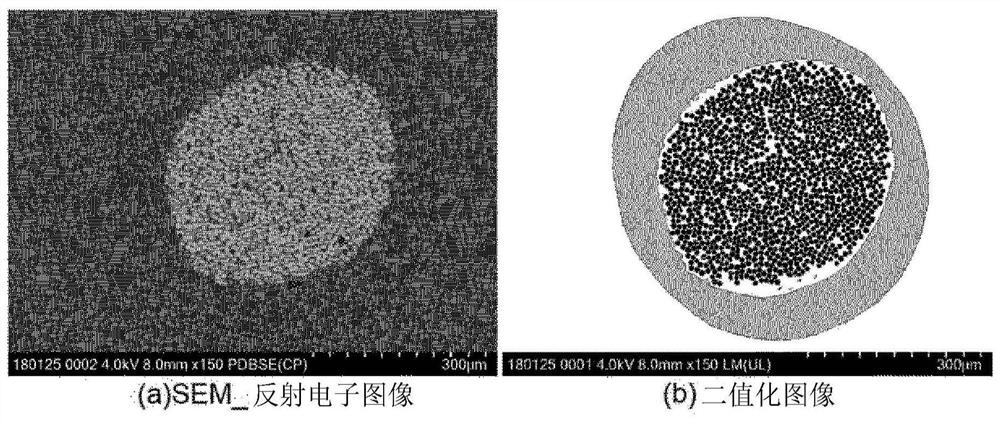

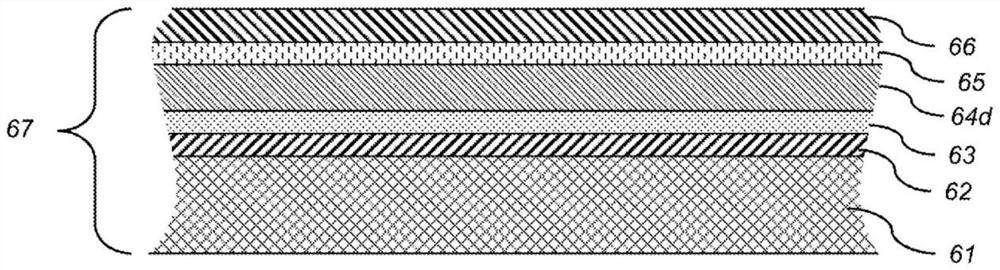

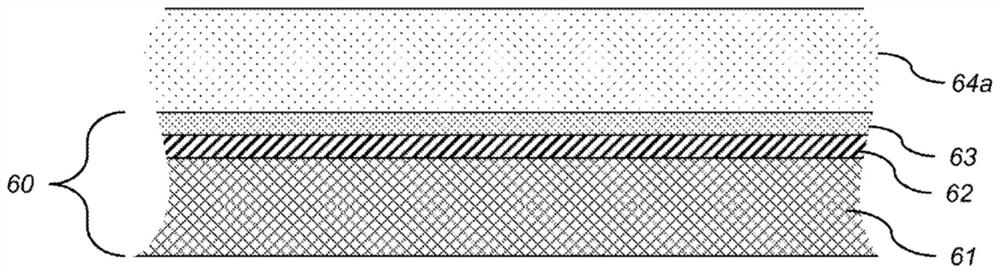

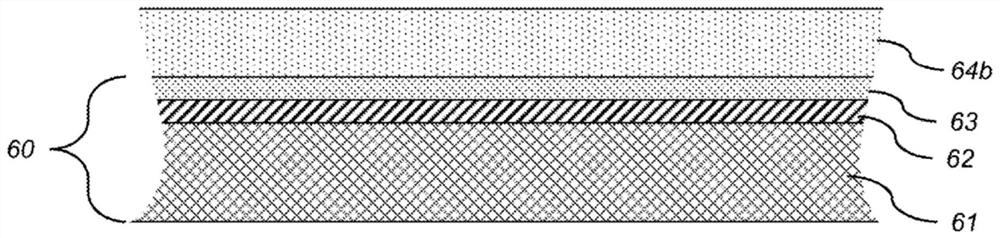

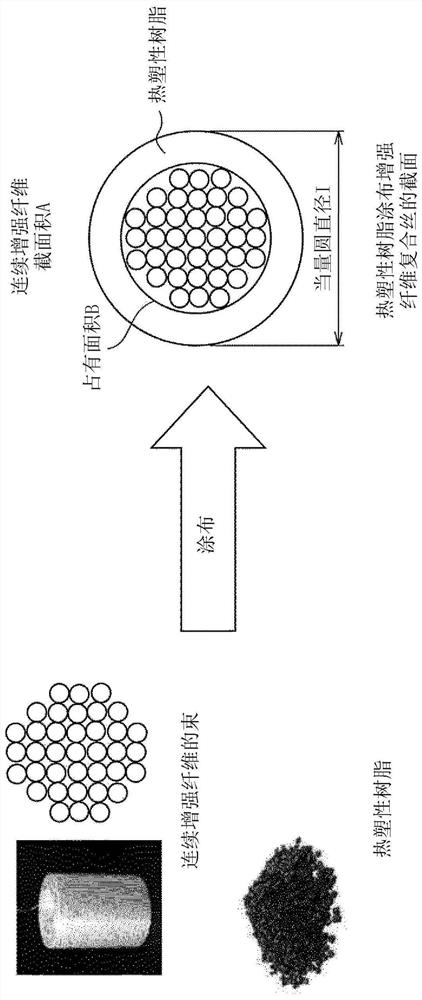

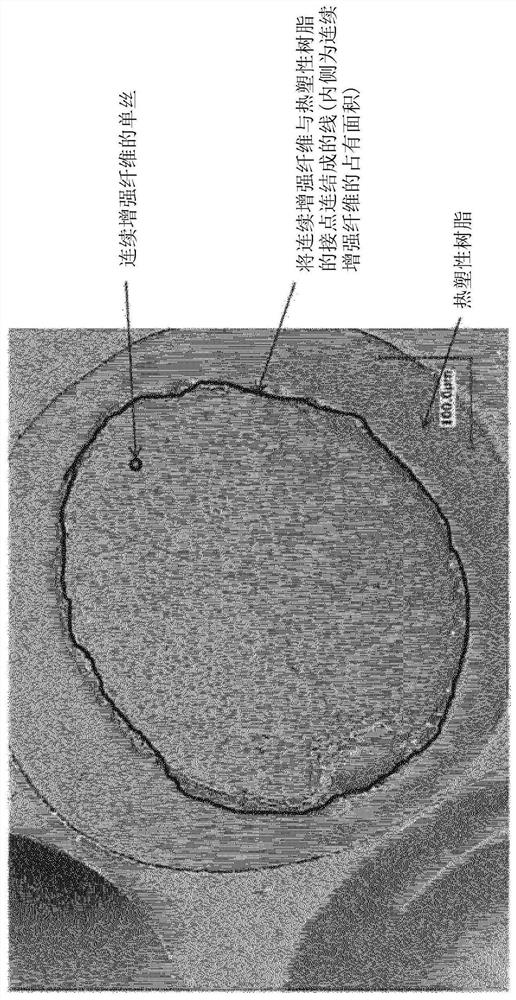

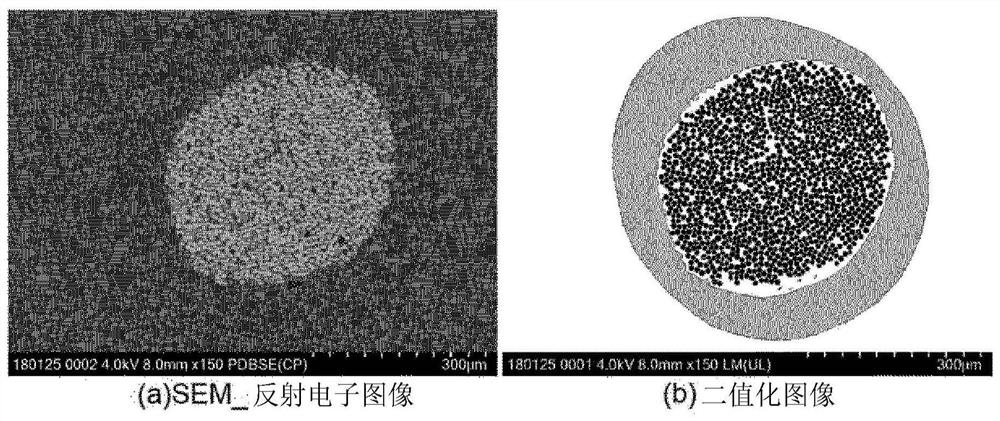

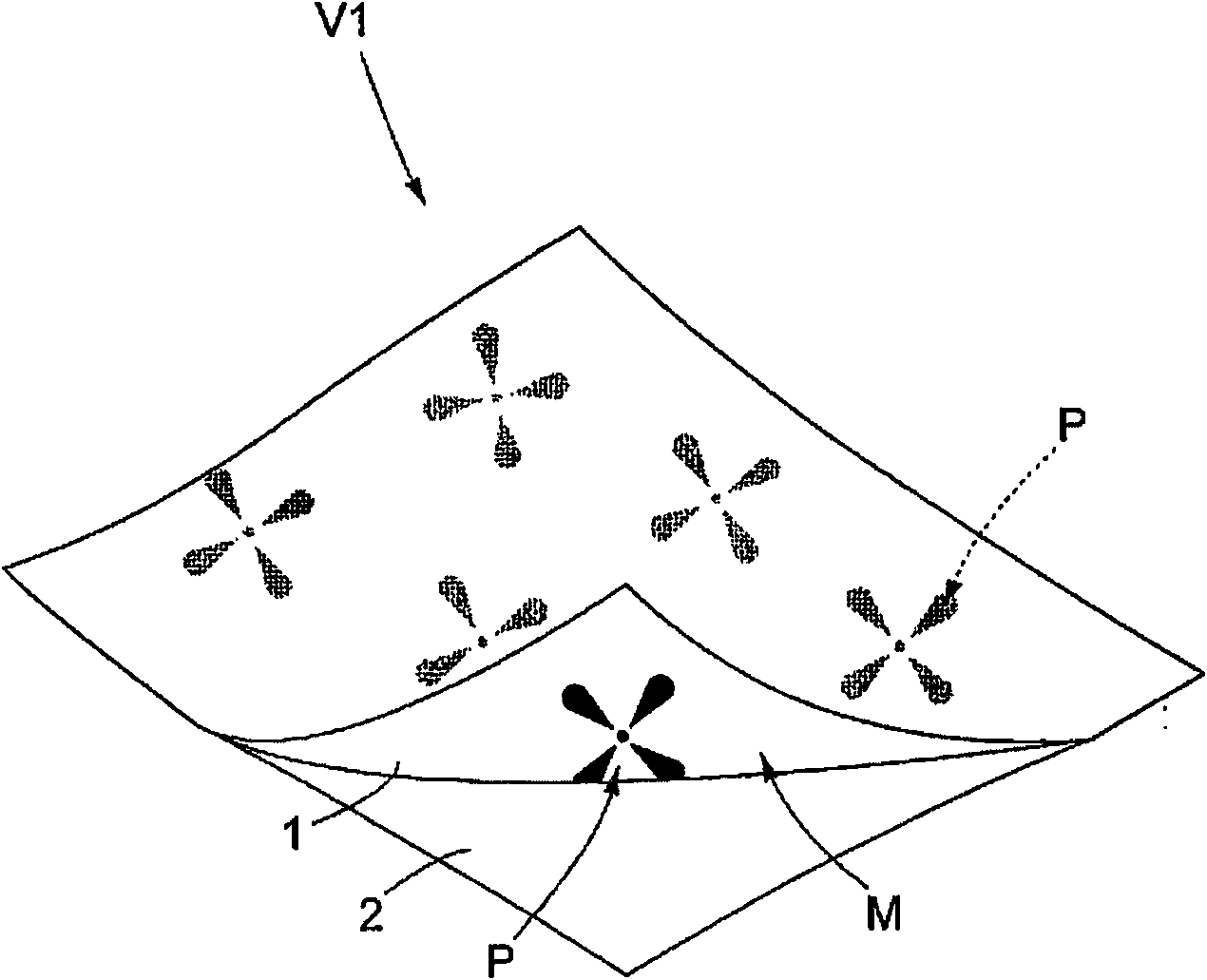

Thermoplastic resin-coated reinforcing fiber composite yarn, production method for said composite yarn, continuous fiber reinforced resin molding, and production method for composite material molding

Provided are: a thermoplastic resin-coated reinforcing fiber composite yarn, which has excellent resin-impregnation properties during molding, with which moldings of excellent properties can be produced even in short-time molding, and which, as a yarn, has excellent softness and excellent handling in weaving and knitting; a production method for said composite yarn; a continuous fiber-reinforced resin molding; and a production method for a composite material molding.

Owner:ASAHI KASEI KK

Method for manufacturing perovskite layer at high speed

PendingCN114514624AHigh speed manufacturingUniform preparationSolid-state devicesSemiconductor/solid-state device manufacturingSolvent evaporationPhysical chemistry

The invention discloses a method for preparing a perovskite layer. The method comprises the following steps: providing a flexible substrate; providing a perovskite solution comprising an initial amount of a solvent and a perovskite precursor material and having a total solids concentration of between 30% and 70% by weight of its saturation concentration; depositing the perovskite solution on a substrate; removing a first portion of the solvent from the deposited perovskite solution and increasing the total solids concentration of the perovskite solution to at least 75% of its saturation concentration by a first drying step; and removing a second portion of the solvent from the deposited perovskite solution by a second drying step having a higher solvent evaporation rate, which results in saturation and conversion reactions in the deposited perovskite solution, resulting in perovskite crystal formation or perovskite mesophase formation, wherein the residence time of the first drying step is at least 5 times longer than the residence time of the second drying step. A continuous in-line method for high-speed production of photovoltaic devices and a perovskite solution for high-speed fabrication of uniform perovskite layers to enable low-cost production of efficient perovskite devices are also described.

Owner:에너지머티리얼즈코퍼레이션

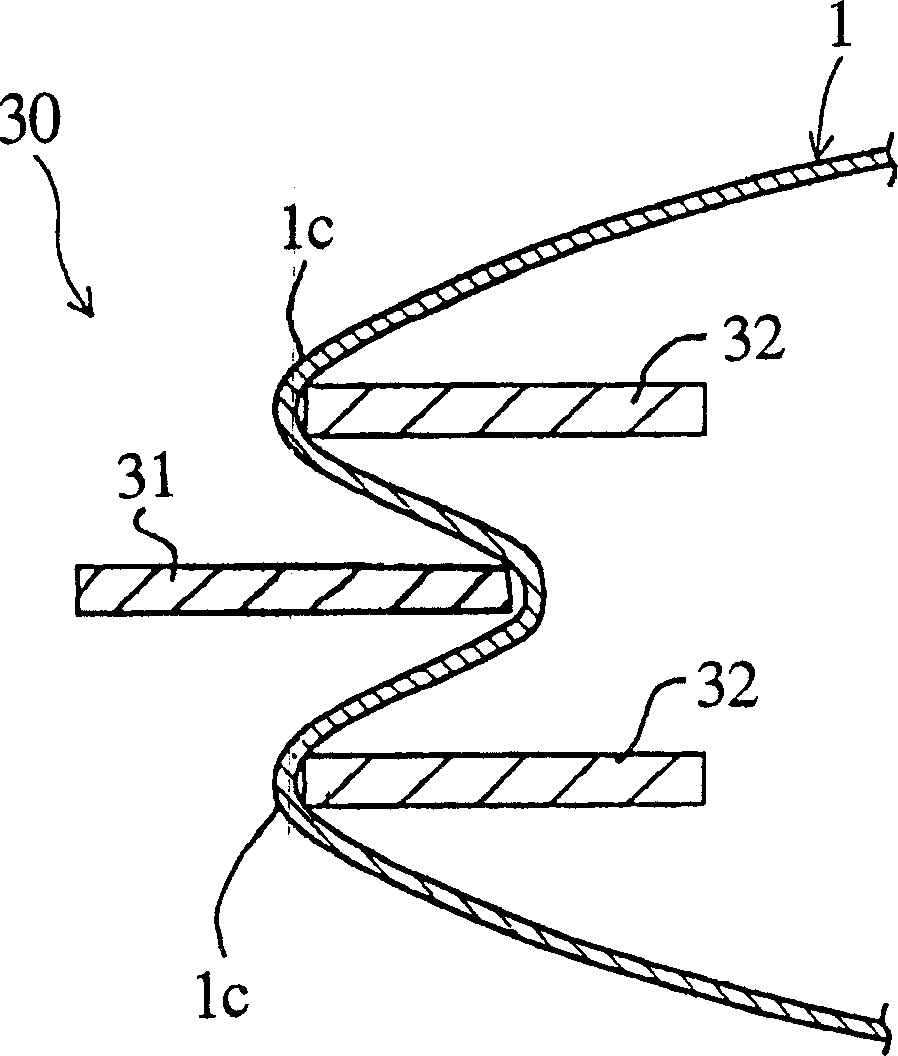

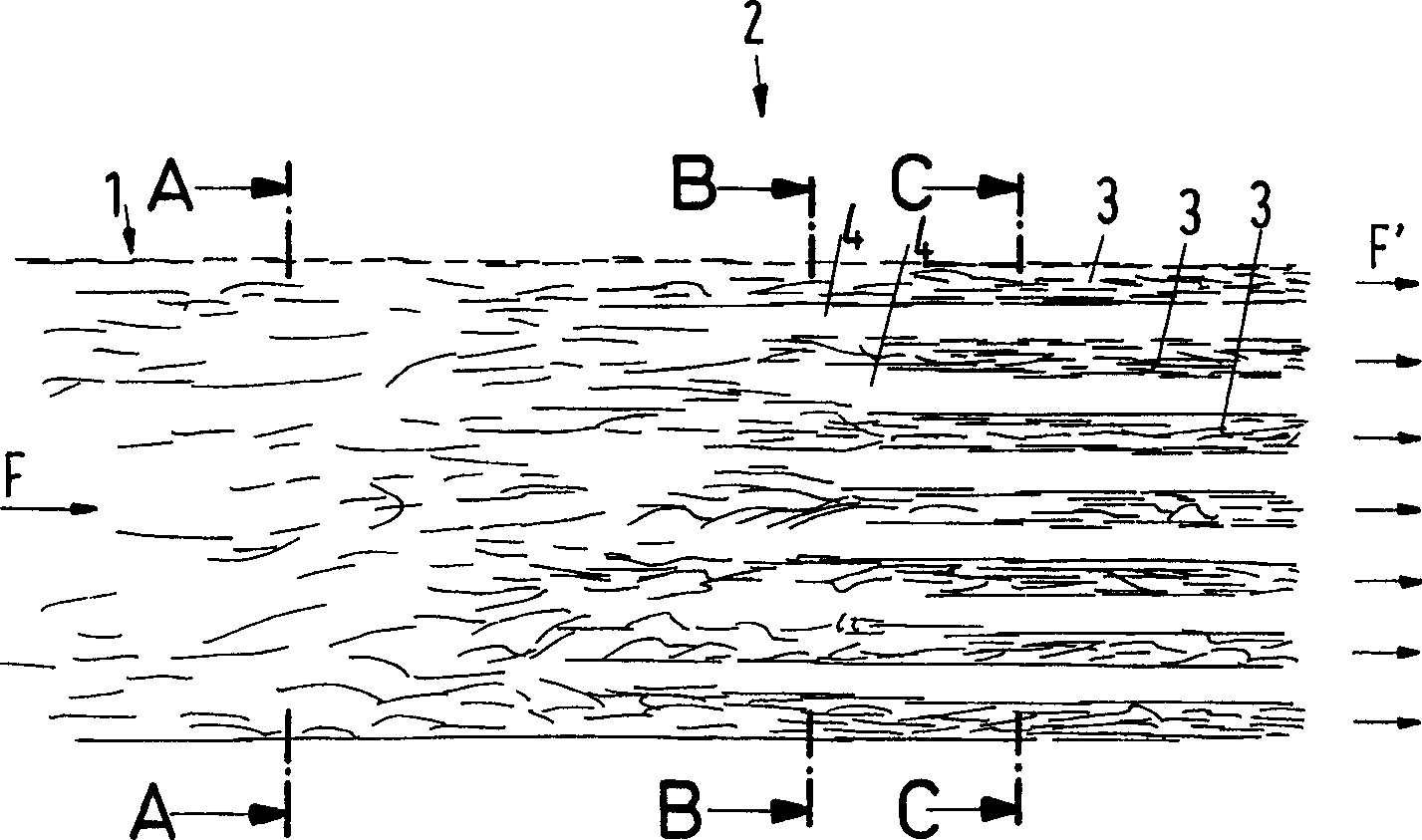

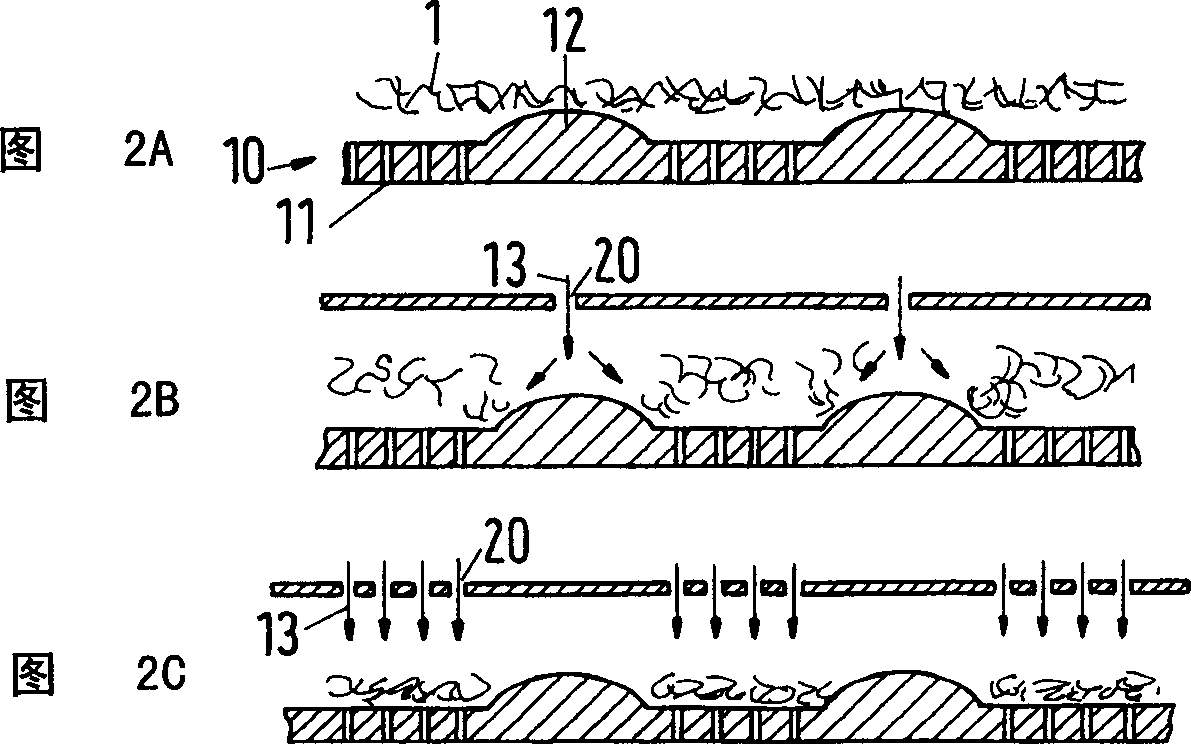

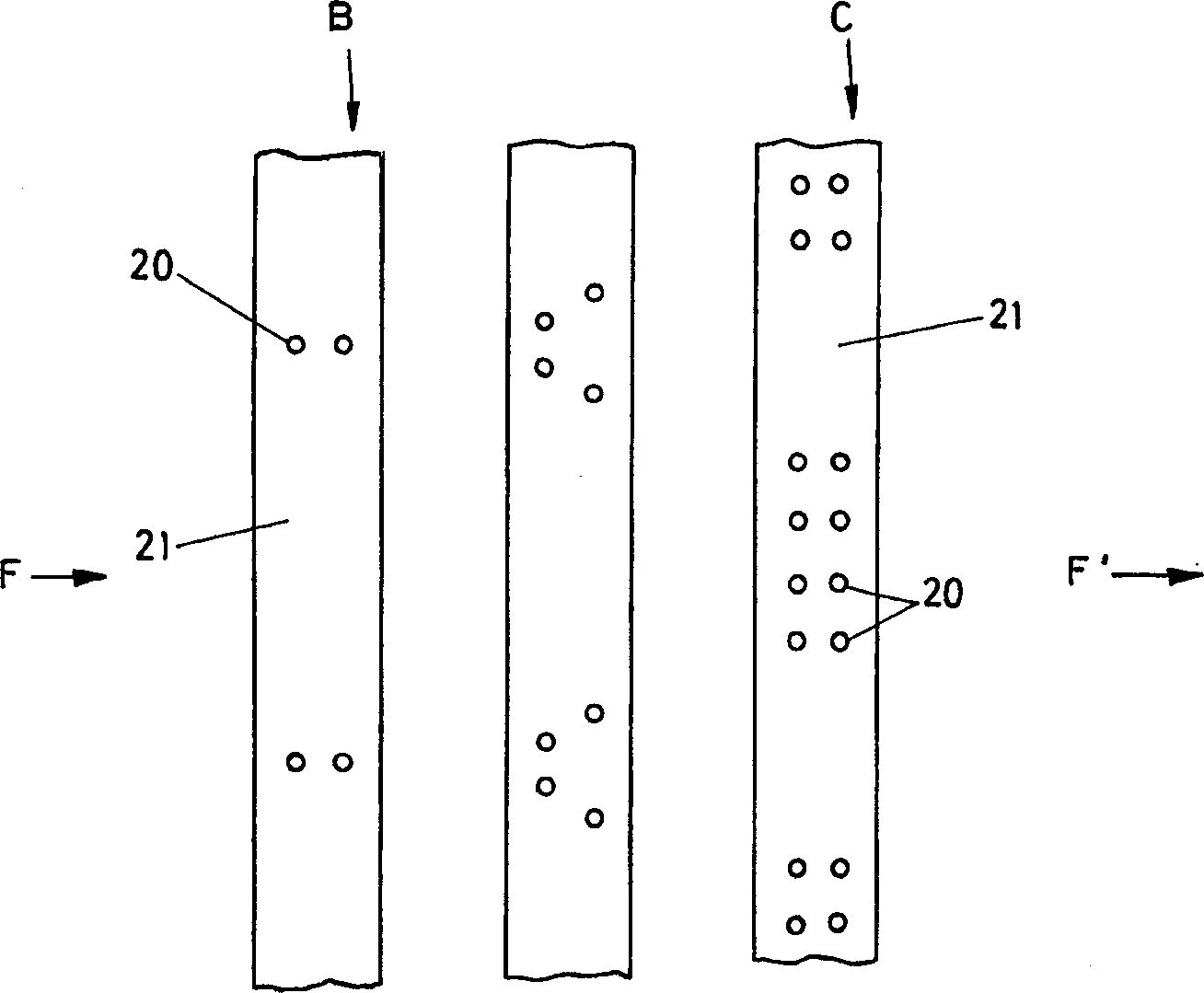

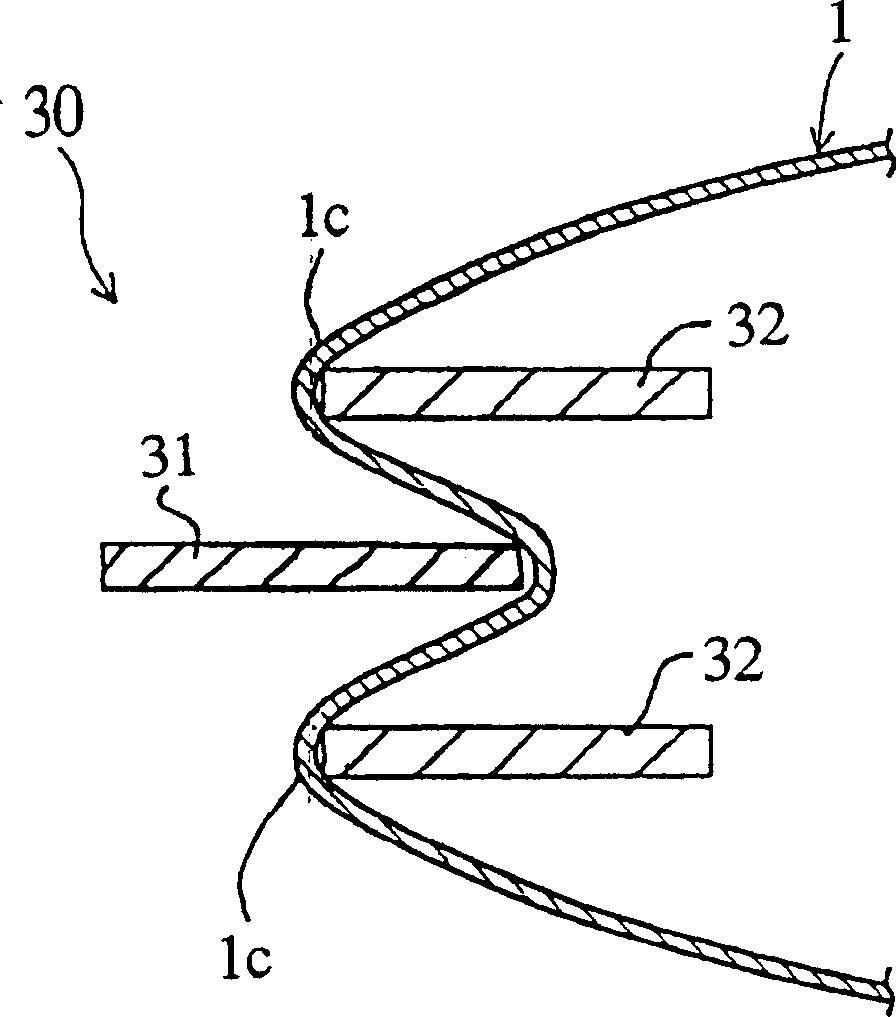

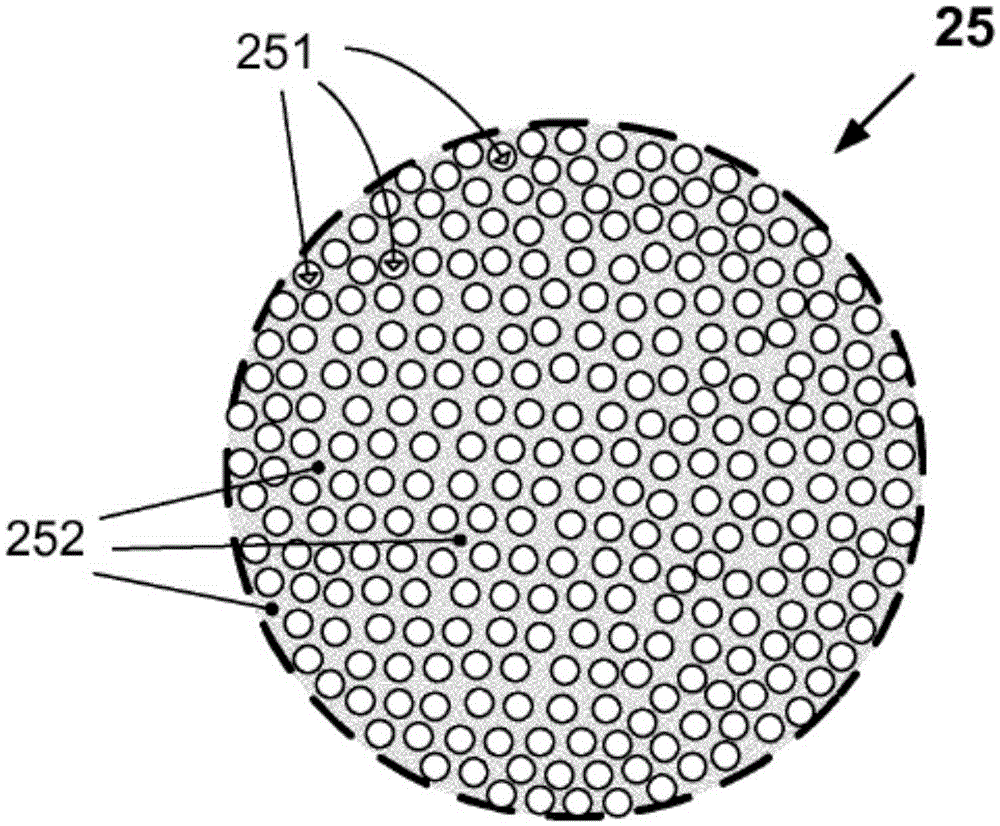

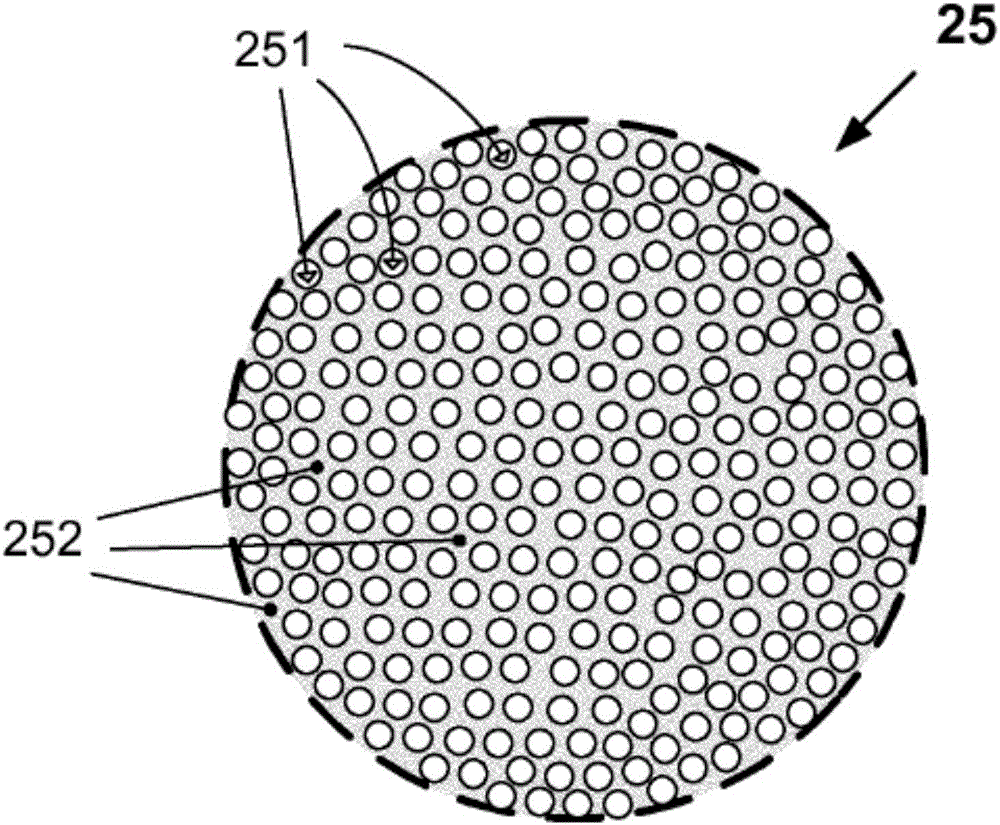

Method and apparatus for producing fiber-fabric material

InactiveCN1337485AHigh speed manufacturingCarding machinesNeedling machinesVolumetric Mass DensityMachining process

Filamentous textile structures are produced from a quasi continuous planar nonwoven (1) by subjecting the nonwoven (1) to fluid-dynamic forces, namely in such a way that the nonwoven (1) is split up longitudinally into a plurality of parallel slivers (3) and the fiber structure of the nonwoven (1) is bonded in the slivers. For the treatment with fluid-dynamic forces, the nonwoven (1) is placed for example against a treatment template (10) which is structured in a strip-like manner by perforations (11) and elevations (12) and fine water, saturated steam or air jets (13) are directed against the nonwoven (1) and the template (10). The slivers produced during the treatment with the fluid-dynamic forces can be processed without any further treatment into a planar textile structures or they can be subjected to a further treatment prior to said processing in order to increase their strength. Said further treatment can preferably be performed without any application of additives (false twist, rubbing) or it is a further treatment which can be reversed after the production of the planar structure (treatment with glue). The slivers (3) have a relatively large volume and can therefore be weaved into covering fabrics with relatively low thread densities. They are suitable for example as weft yarns in fabrics for low-quality needs such as fabrics for disposable linens.

Owner:MASCHINENFABRIK RIETER AG

High speed horizontal electroforming apparatus for manufacturing metal foil and method for manufacturing metal foil

InactiveCN103930599AHigh speed manufacturingImprove surface roughnessCellsElectroforming processesPower flowMetal foil

Owner:POHANG IRON & STEEL CO LTD

Moulding, filling and sealing appts. for self-standing bags

InactiveCN1219681CEfficient productionHigh speed manufacturingEnvelopes/bags making machineryWrappingThin membranePlastic bag

A shaping, filling and sealing apparatus for making the plastic bags able to stand up by itself is composed of three thermally sealing units, a folding mechanism, and a filling tube for filling the filler. The third sealing unit can also cut the thermally sealed part.

Owner:ORIHIRO ENGINEERING CO LTD

Long straight cylindrical helical spring type powder conveying piece

InactiveCN102819210AReduce consumptionSimple structureElectrographic process apparatusPackagingMaterial consumptionCoil spring

The invention discloses a long straight cylindrical helical spring type powder conveying piece, which relates to the technical field of parts of a duplicating machine. The main parts for conveying the carbon powder in the conventional duplicating machine are all long bolt type parts, based on multiple helical surfaces outside the body of the bolt, each long bolt type part rotates around an axis to push the powder and conveys the powder in a powder box to a further powder utilization place. But the long bolt type parts also have too many defects. The invention uses a long straight cylindrical helical spring, which has large length-width ratio and rectangular cross section, as the powder conveying piece, wherein the plane of a long side of the rectangular cross section of the belt material is similar to the helical surface on the long bolt structure, when the helical spring rotates, the powder conveying piece has the same function of pushing and conveying the powder, but the powder conveying piece has a simpler structure, is very easy to produce and process, and can realize high-speed manufacturing, moreover, a hollow inner bore has no bolt body, the powder conveying piece can be more light, the material consumption is relatively low, and the cost (including manufacturing) is reduced obviously.

Owner:TAIZHOU STRONKIN ELECTRONICS

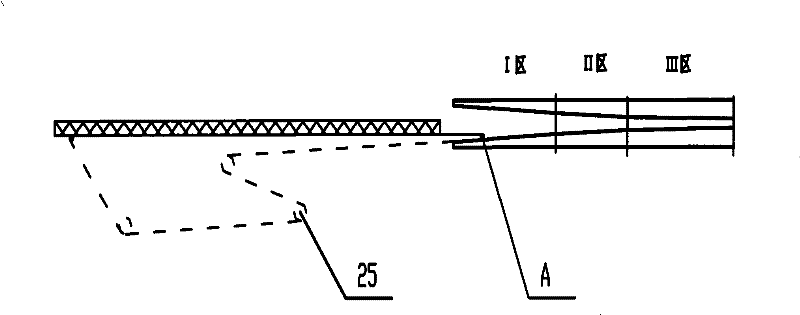

Compact pressing method using continuous press and device for actualizing the method

InactiveCN101508128BManufactured at high speed and qualityHigh speed manufacturingPlywood pressesVeneer pressesControl systemEngineering

The invention provides a method for pressing pressed products by using a continuous flat press, which comprises the following steps: detecting the thickness of plate blanks on a conveyor belt; comparing the detected thickness value of the plate blank with the preset thickness value of the plate blank to determine the starting point position of a feed opening (E) of the conveyor belt fixed relative to the shape of the curved surface of the press and the press clearance between an upper hot press board and a lower hot press board; and controlling a drive device of the conveyor belt to drive theconveyor belt to move by a control system so that the front end of the conveyor belt reaches the starting point position and controlling a control oil cylinder of the press to adjust the press clearance between the upper hot press board and the lower hot press board of the flat press to the preset value by the control system. The invention also provides equipment for implementing the method. The method of the invention can produce high-quality pressed plates.

Owner:CHINA FOMA GROUP +2

Display devices based on phase change materials

ActiveCN105849626BHigh speed manufacturingRun at high speedNon-linear opticsOptical elementsVanadium dioxideDisplay device

A display device comprising a plurality of pixels each having a portion (10) of a solid state phase change material, such as germanium-antimony-tellurium (GST) or vanadium dioxide, wherein the phase change material Reversibly enters amorphous or crystalline state and has a reversibly electrically controlled refractive index. A plurality of electrodes (14, 16) are provided, at least two of which are in contact with said portion (10) of material. A controller (19) is provided adapted to apply at least one voltage to said material (10) via said electrodes (14, 16) to change said refractive index. Arrays of portions of this material can be arranged to make pixelated displays, eg, volumetric stereoscopic displays.

Owner:OXFORD UNIV INNOVATION LTD

Winding apparatus

InactiveCN101765960BLow costHigh speed manufacturingManufacturing dynamo-electric machinesInductances/transformers/magnets manufactureMechanical engineering

Owner:TOYOTA JIDOSHA KK

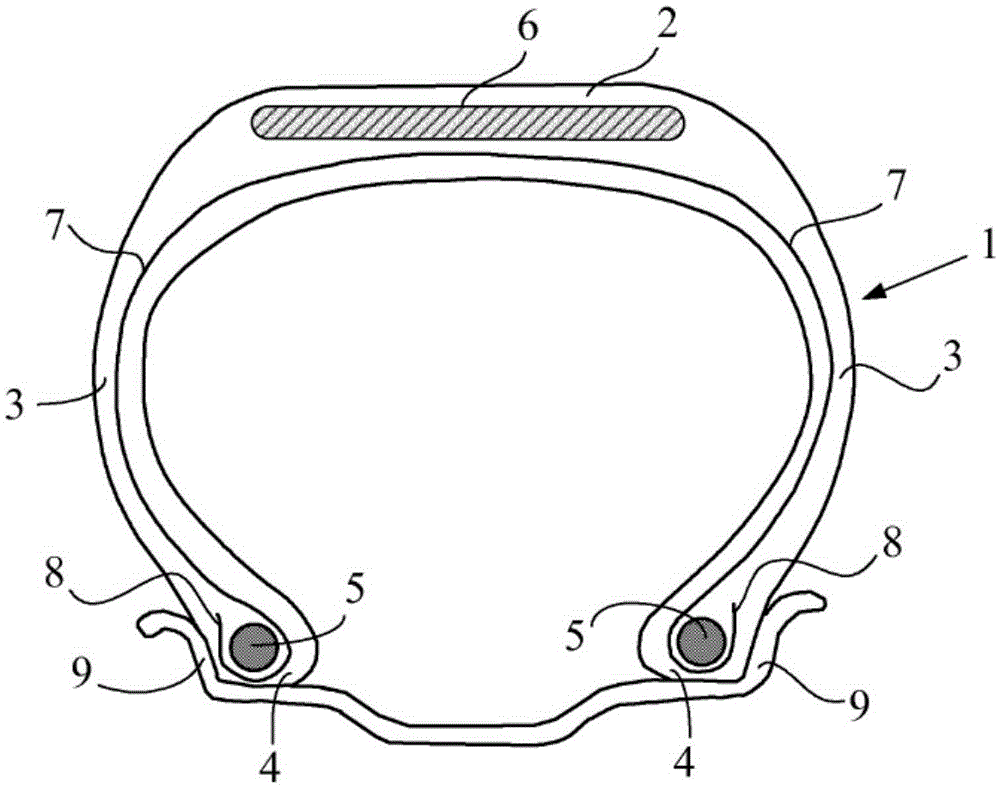

Improved grp (glass-fiber-reinforced plastic) monofilament

The invention relates to a monofilament made of glass-fiber-reinforced plastic having improved compression properties, particularly at a high temperature. Said monofilament comprises glass filaments encased in a cured resin and is characterized in that: the glass transition temperature of the resin no lower than 190DEG C; the monofilament rupture elongation, measured at 23DEG C, is no lower than 4.0%; the initial monofilament extension module, measured at 23DEG C, is greater than 35 GPa; and the actual portion of the complex module of the monofilament, measured at 190DEG C by the DTMA method, is greater than 30 GPa. The invention is useful in pneumatic and non-pneumatic tires reinforced with such a composite monofilament.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Improved cvr (glass resin composite) monofilament

The present invention relates to monofilaments made of glass resin composites having improved compressive properties, especially at elevated temperatures. The monofilament comprises a glass filament wrapped in a cured resin, and the monofilament is characterized in that: the glass transition temperature of the resin is not lower than 190°C; the elongation at break of the monofilament measured at 23°C is not lower than 4.0%; the initial monofilament elongation modulus measured at 23°C is greater than 35 GPa; and the real part of the complex modulus of the monofilament measured by the DTMA method at 190°C is greater than 30 GPa. The present invention is applicable to pneumatic tires and non-pneumatic tires reinforced with such composite monofilaments.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

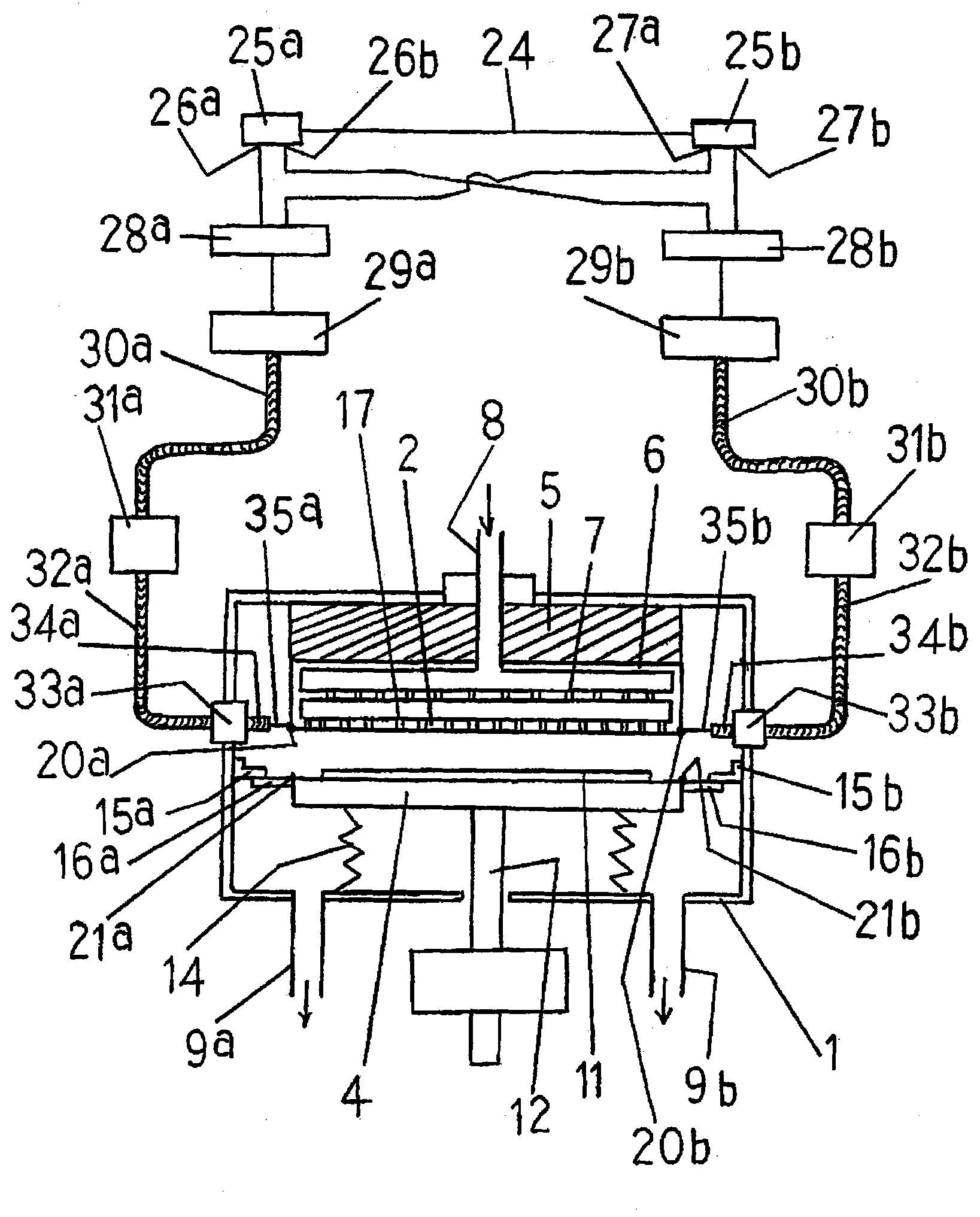

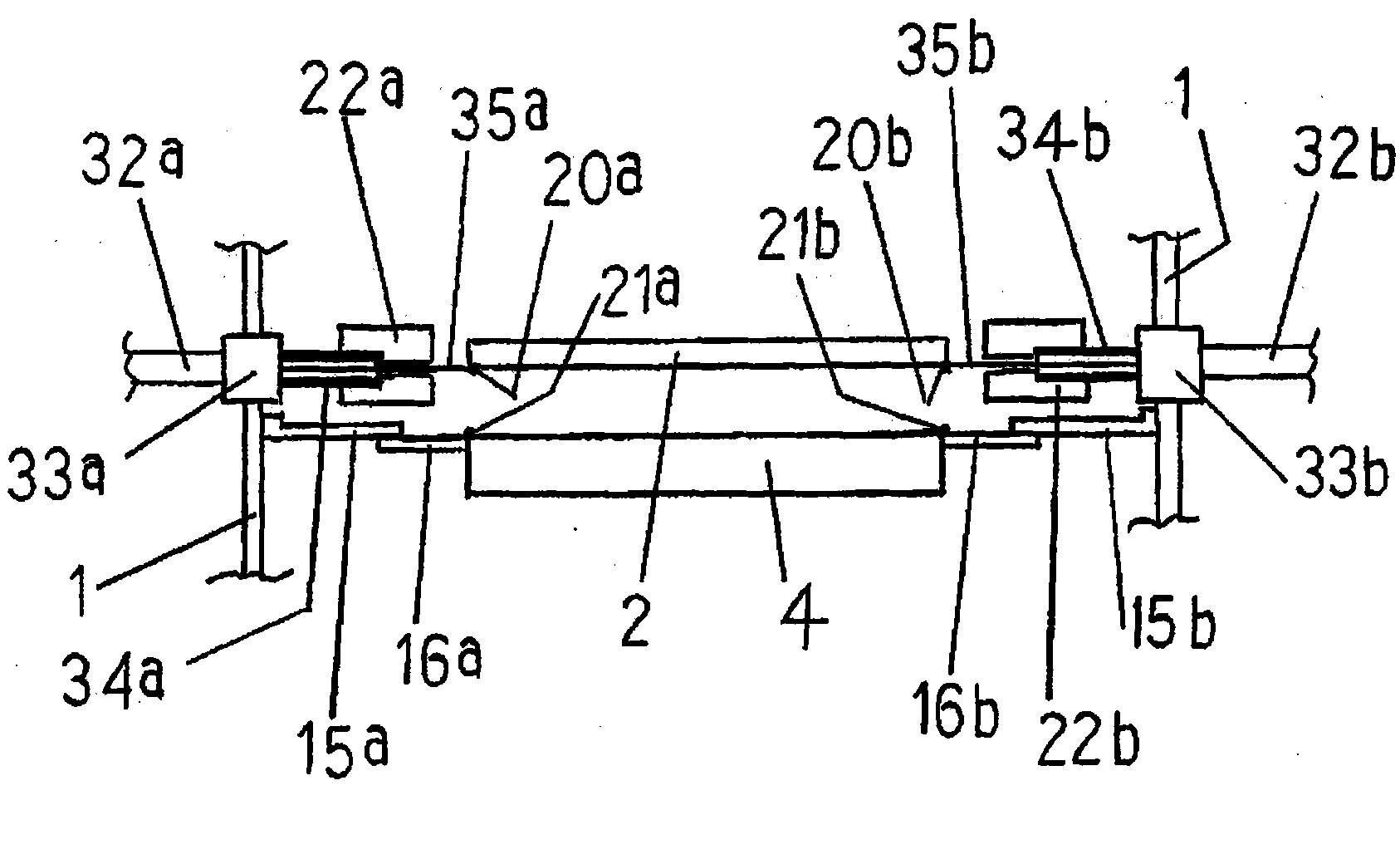

Manufacturing method of optical fiber base material

ActiveCN105314841BHigh speed manufacturingEvenly stackedGlass deposition burnersGlass productionEngineeringMechanical engineering

Owner:SHIN ETSU CHEM CO LTD

Device for producing wire rope

The disclosed device for producing wire rope produces a filler-filled wire rope comparatively quickly. A tubular wire twisting machine (10) and a cage wire twisting machine (20) are disposed in tandem. The rotating shaft (14) of the tubular wire twisting machine (10) and the rotating shaft (21) of the cage wire twisting machine (20) are linked. Six lateral strands (3) are wound by the feed bobbin (12) of the tubular wire twisting machine (10), and six strands of filler material (4) are wound by the feed bobbin (27) of the cage wire twisting machine (20). The six lateral strands (3) and the six strands of filler material (4) are alternately twisted around the periphery of a core rope (2) supplied from the outside, producing a filler-filled wire rope (1).

Owner:TOKYO ROPE MFG

Composite yarn and method for producing the same, continuous fiber-reinforced resin molded product, and method for producing composite molded product

The present invention provides a thermoplastic resin-coated reinforced fiber composite yarn, a method for producing the composite yarn, a continuous fiber-reinforced resin molded body, and a method for producing a composite molded body, which are excellent in resin impregnation during molding, even in short A molded article with high physical properties can be produced even during molding over time, and it is also excellent in flexibility as a thread and excellent in handleability during weaving and weaving.

Owner:ASAHI KASEI KK

Optical fiber base material manufacturing method

ActiveCN105314841AHigh speed manufacturingEvenly stackedGlass deposition burnersGlass productionMicroparticleEngineering

Owner:SHIN ETSU CHEM CO LTD

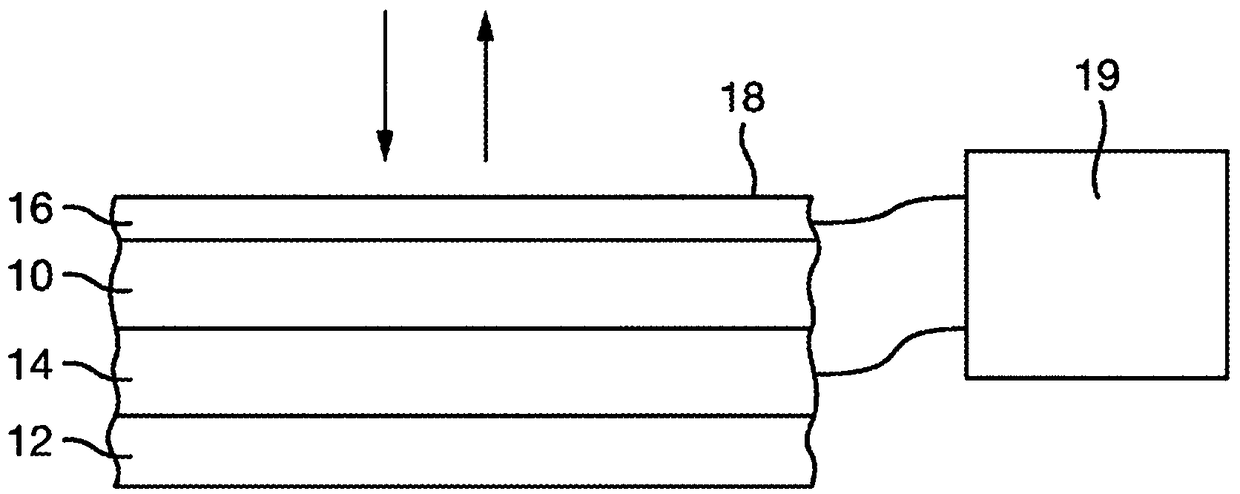

High frequency plasma CVD apparatus, high frequency plasma CVD method and semiconductor thin film manufacturing method

InactiveCN101897005AEfficient consumptionSuppress power lossElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerSilicon solar cell

Provided are large area and uniform VHF plasma CVD apparatus and method wherein a plasma generating source constitutes the VHF plasma CVD apparatus for manufacturing a tandem-type thin film silicon solar cell, and influences of standing waves, generation of harmful plasma other than between a pair of electrodes and supply power consumption other than between the pair of electrodes are suppressed. First and second power feed points are arranged on an electrode at positions facing each other. A distance between the power feed points is set at an integral multiple of a half of the wavelength of the using power, and a pulse power separated interms of time is supplied. The pulse power is outputted from two phase-variable double output high frequency power supplies which can perform pulse modulation. Thus, a first standing wave wherein the anti-node position accords with the positions of the first and the second power feed points, and a second standing wave wherein the node position accords with the positions of the first and the second power feed points are alternately generated in terms of time.

Owner:村田 正义

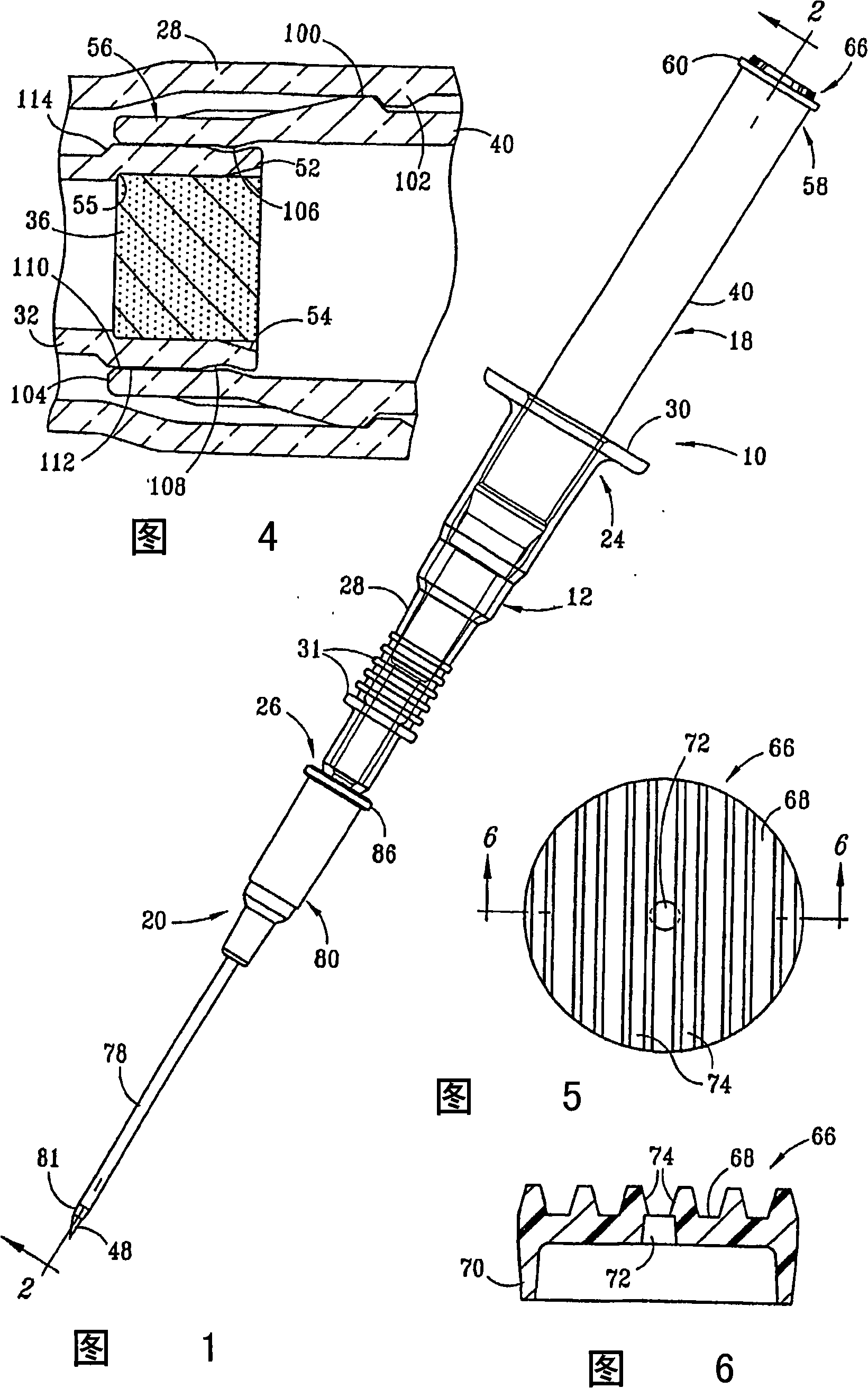

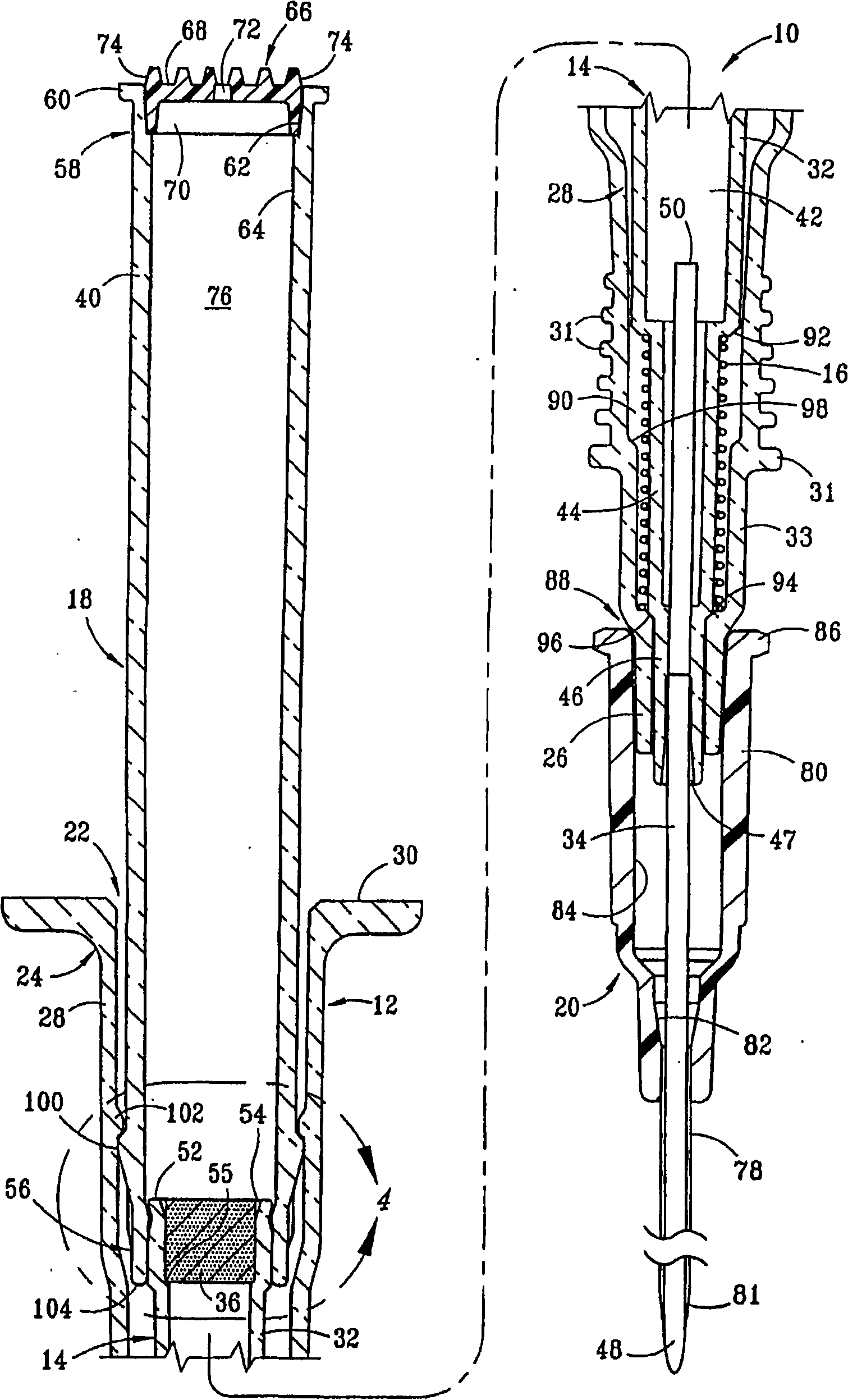

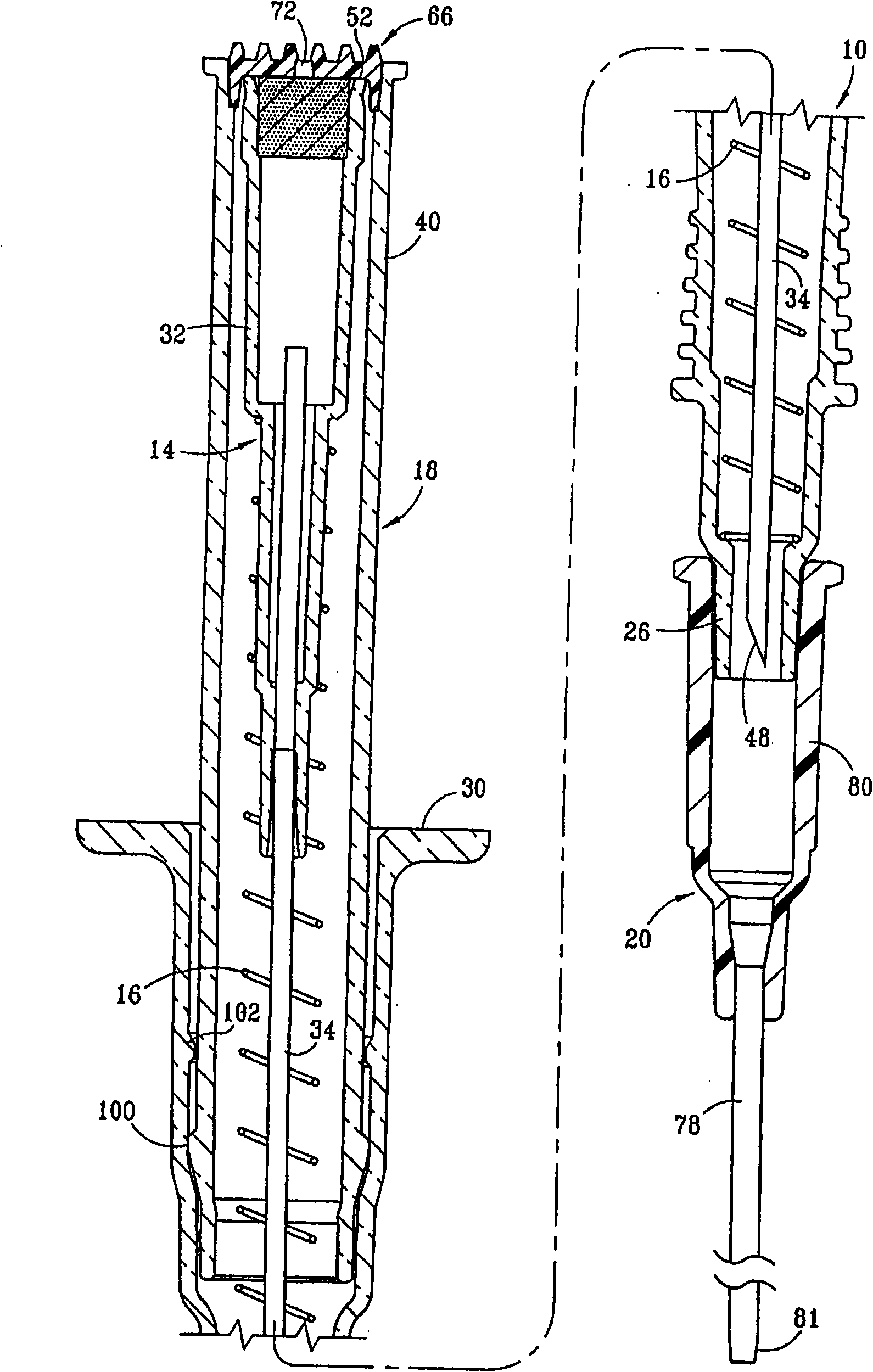

IV duct intubator with retraction needle

InactiveCN101306223AAvoid infectionReliable brake structureGuide needlesInfusion needlesCatheterGuide tube

The invention discloses an IV conduit tube inserter with a retractable needle remaining part and a tubular plunger, the needle remaining part and the plunger are kept into an optimum positioning relation by a braking structure before a conduit tube is inserted and during the inserting period. After the conduit tube is inserted, the plunger is pushed, to ensure that a compression spring drives the needle remaining part to upwardly enter the plunge through the braking structure. An aeration end cover in the plunger is allowed to quickly discharge movable air during the retractable period of the needle remaining part. The needle remaining part comprises a displaying chamber which can be easily observed through a transparent plastic casing body. An alar part is arranged on the casing body, for facilitating the operation of the device with a hand. The invention also discloses a method for assembling the conduit tube inserter.

Owner:RETRACTABLE TECH INC

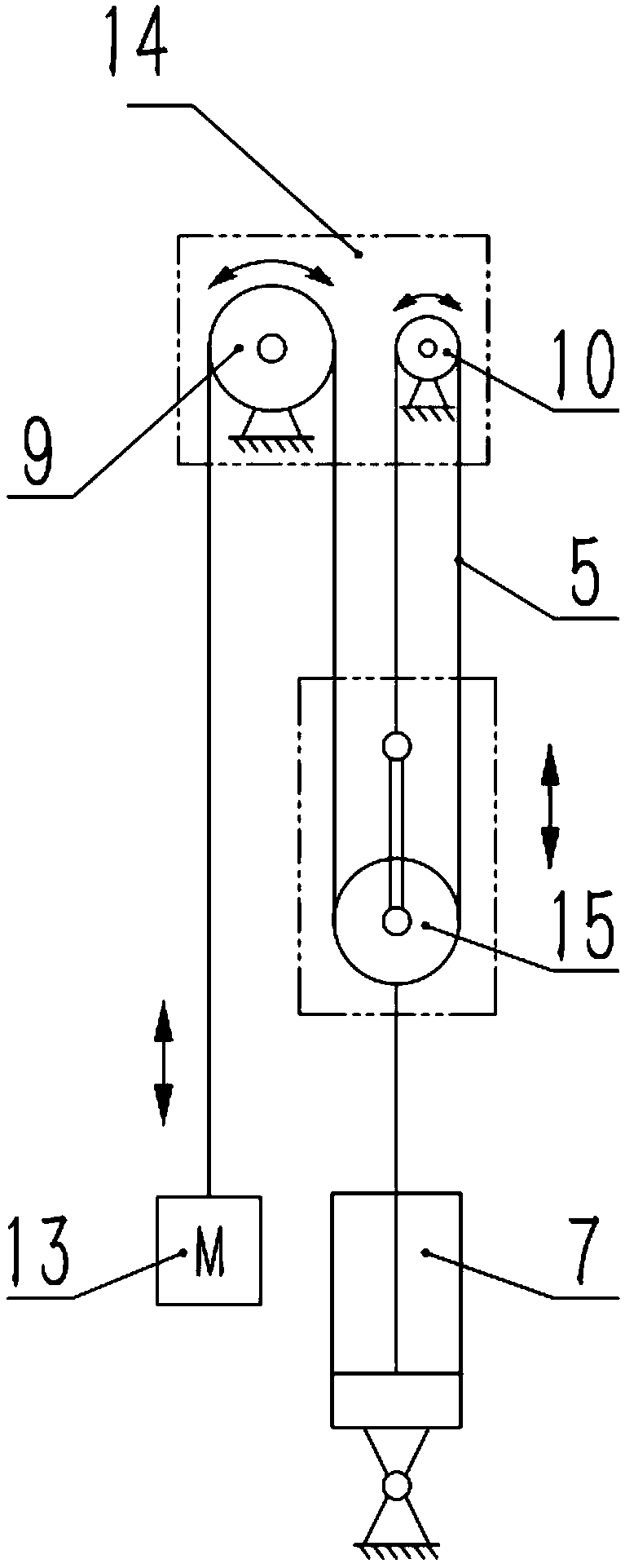

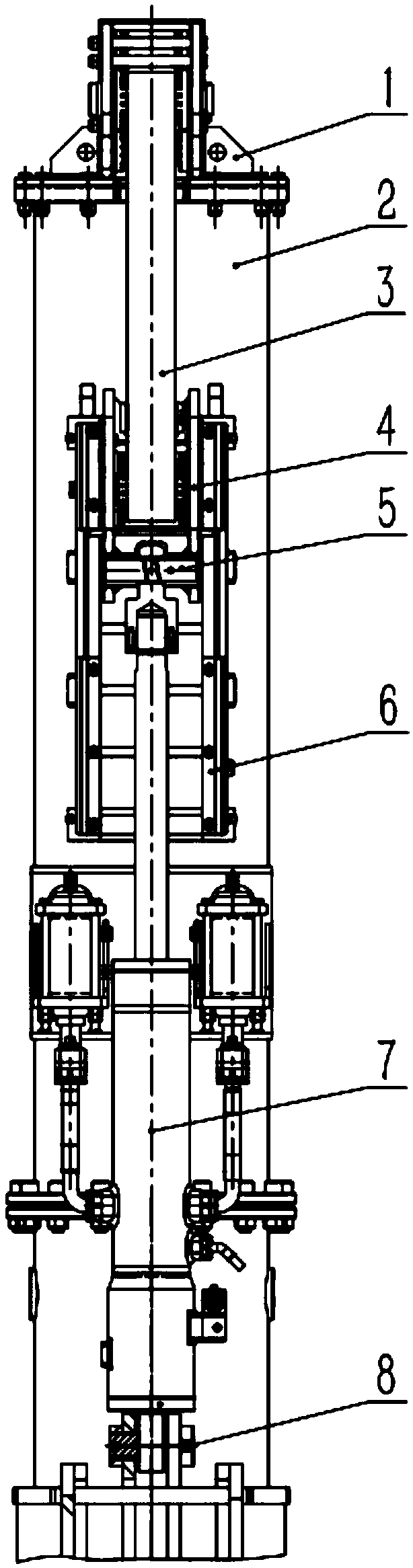

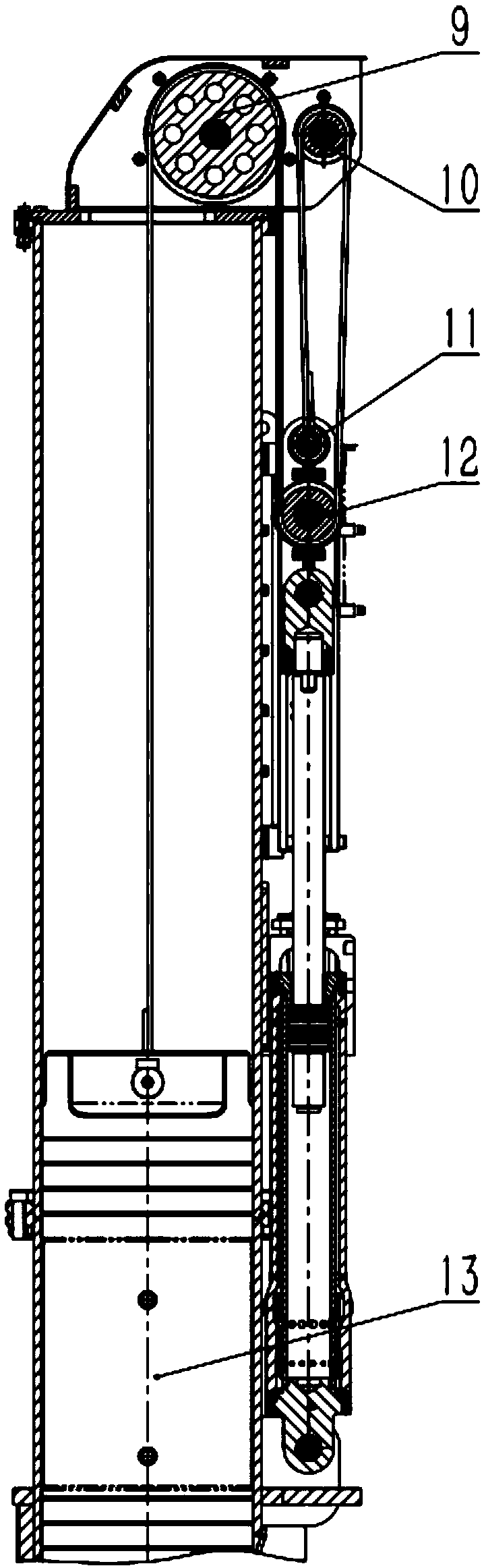

Hydraulic pile-driving hammer fast lifting-up method and device

The invention discloses a hydraulic pile-driving hammer fast lifting-up method. By arranging pulley mechanisms, the oil cylinder travel or flow is not improved, and the power or efficiency is improved. When a hammer lifting-up oil cylinder piston rod performs retraction operation, under the downward acting force of the movable pulley mechanism, a pile-driving hammer core at the other end of a pulley belt is driven to do hammer lifting-up action, and the pile-driving hammer core is fast lifted up to a predetermined height; and when a hammer lifting-up oil cylinder works again, downward pull force originally applied on the movable pulley mechanism by the hammer lifting-up oil cylinder piston rod is released, the pile-driving hammer core connected to the other end of the pulley belt does thehammer falling action in a free falling mode, and the pile-driving hammer core fast and precisely falls to strike an anvil block. The invention further discloses a hydraulic pile-driving hammer fast lifting-up device implementing the method, the device can be widely applied to manufacturing of high-power, high-speed and efficient pile drivers, and the overall operating reliability of the pile drivers is improved, and the overall service lives of the pile drivers are prolonged.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

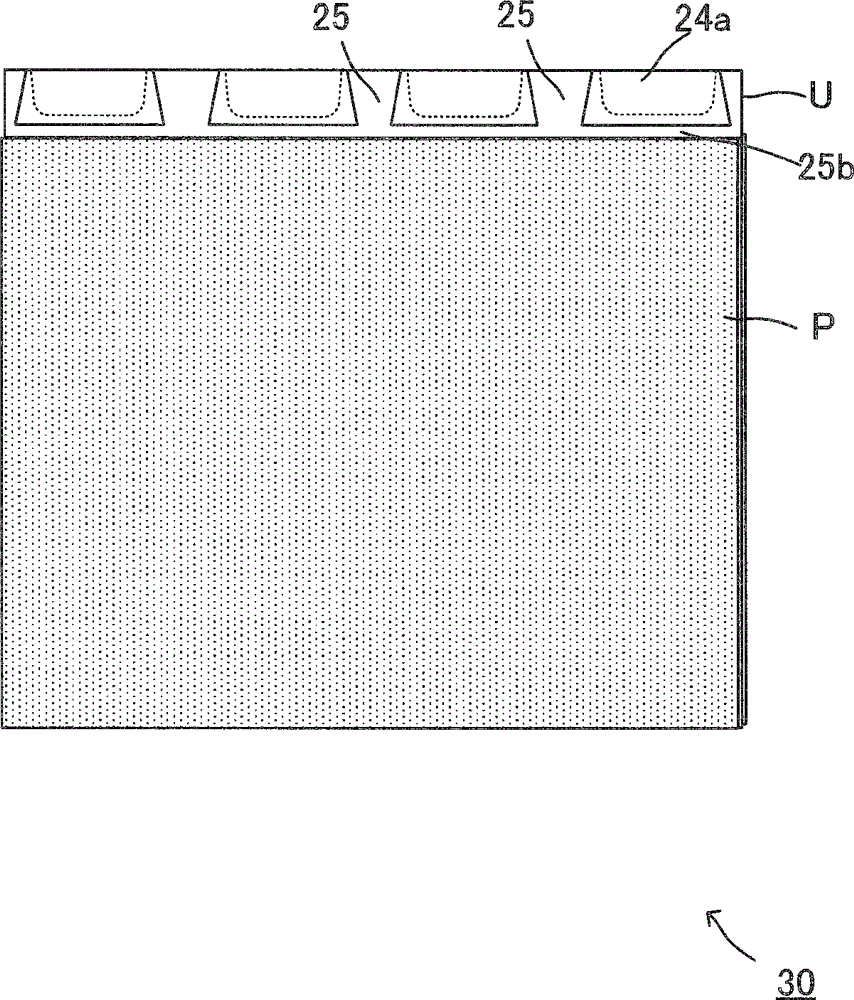

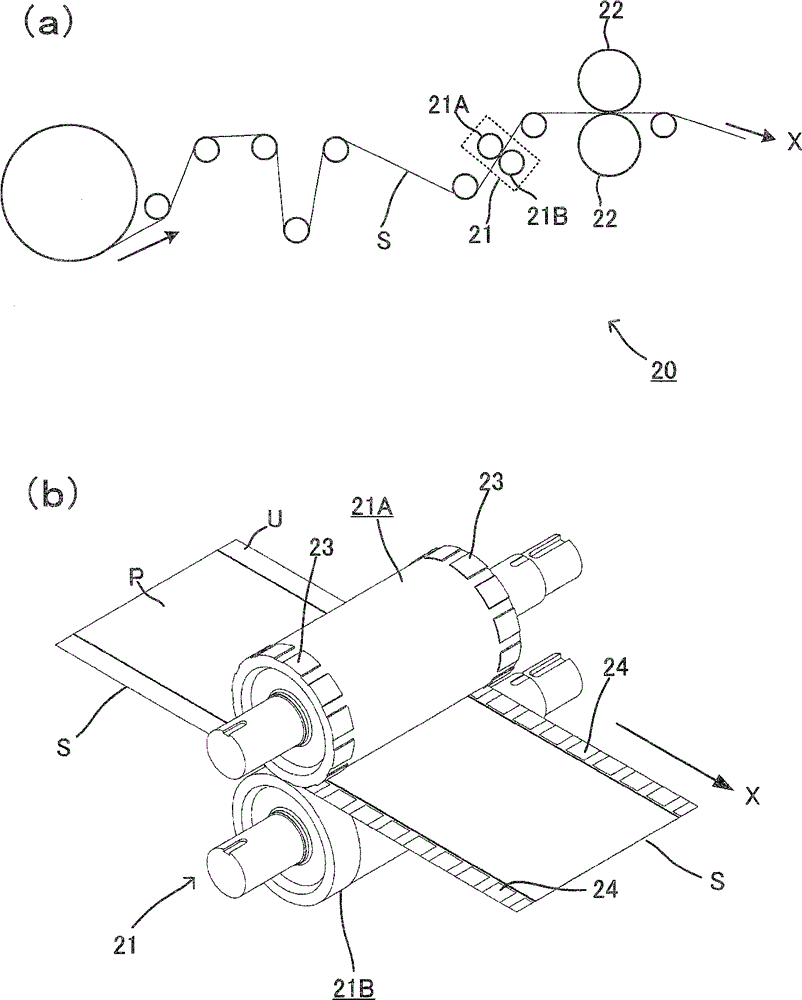

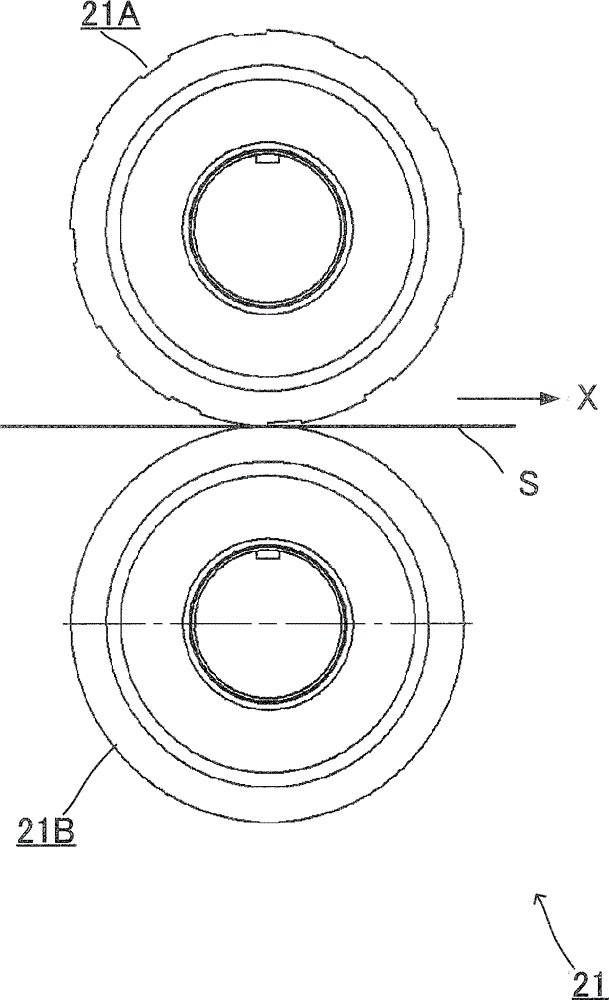

Battery electrode sheet and manufacturing method therefor

ActiveCN102376935BLess bendingHigh speed manufacturingElectrode rolling/calenderingFinal product manufactureMetal foilSpiral wound

Embodiments of the present invention provide such things as an electrode sheet having little curl for a spiral wound battery and a manufacturing method therefor. An electrode sheet is such that active material layer(s) is / are present and has / have been subjected to working by rolling at entire surface(s) thereof, except for at least one uncoated region U, of electrode sheet(s) comprising sheet(s) of metal foil(s) S. Moreover, drawn region(s) is / are provided at region(s) uncoated with active material layer(s) in such uncoated region(s) U. By thus creating drawn region(s) at uncoated region(s) of the electrode sheet, curling of the electrode sheet is suppressed, and furthermore, when tension is applied to carry out winding of the electrode sheet and / or convey the electrode sheet to subsequent operation(s), there is reduced likelihood of occurrence of wrinkling and / or tearing in the long direction of the electrode sheet.

Owner:GS YUASA INT LTD

Apparatus for forming, filling and sealing self-supporting pocket

InactiveCN1165458CEfficient productionHigh speed manufacturingWrappingWrapper twisting/gatheringThin membraneEngineering

A shaping, filling and sealing apparatus is composed of three sealing mechanisms for hot-sealing a film, a fold mechanism for longitudinally and inward folding the film at its central position, and an injection tube for injecting filler. Said three sealing mechanisms can respectively seal two sides, top and horizontal line under injection tube while cutting.

Owner:ORIHIRO ENGINEERING CO LTD

Hygienic tissue paper product and manufacturing method thereof

ActiveCN101637366BHigh speed manufacturingWill not polluteFlat article dispensingDomestic applicationsBiomedical engineeringPaper sheet

The present invention relates to a hygienic tissue paper product and a manufacturing method thereof. The hygienic tissue paper product provided by the invention has beautiful appearance, excellent amusement and excellent convenience and is of an extraction type. The hygienic tissue paper product is characterized in that: a packaging body which is formed with a taking outlet on the upper surface contains the tissue product for sanitation; when one piece of hygienic tissue paper is taken out from the taking outlet in using, one part of another piece which is laminated adjacently is exposed fromthe taking outlet; wherein, the hygienic tissue paper has a composite layer structure which is laminated with more than two pieces of tissue paper. For one part or total of the hygienic tissue paper,the laminated inner surfaces which form the outer random tissue paper in the laminated tissue paper are printed with patterns.

Owner:DAIO PAPER CORP

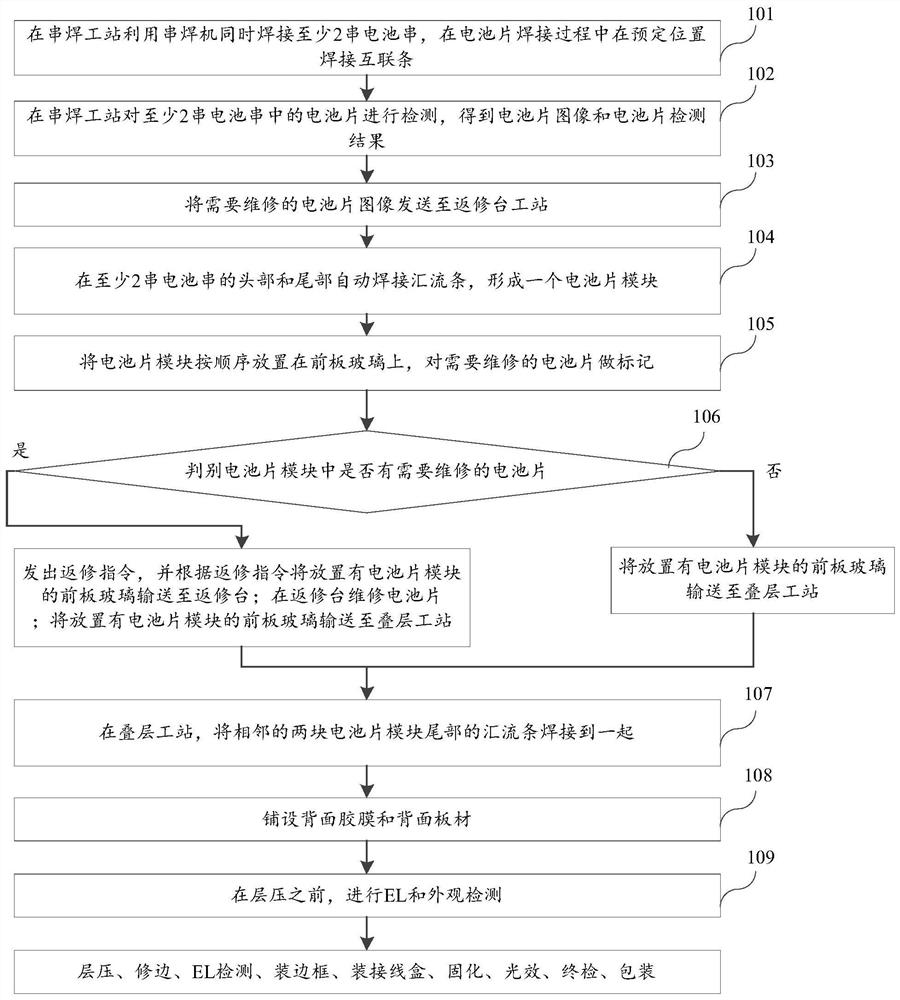

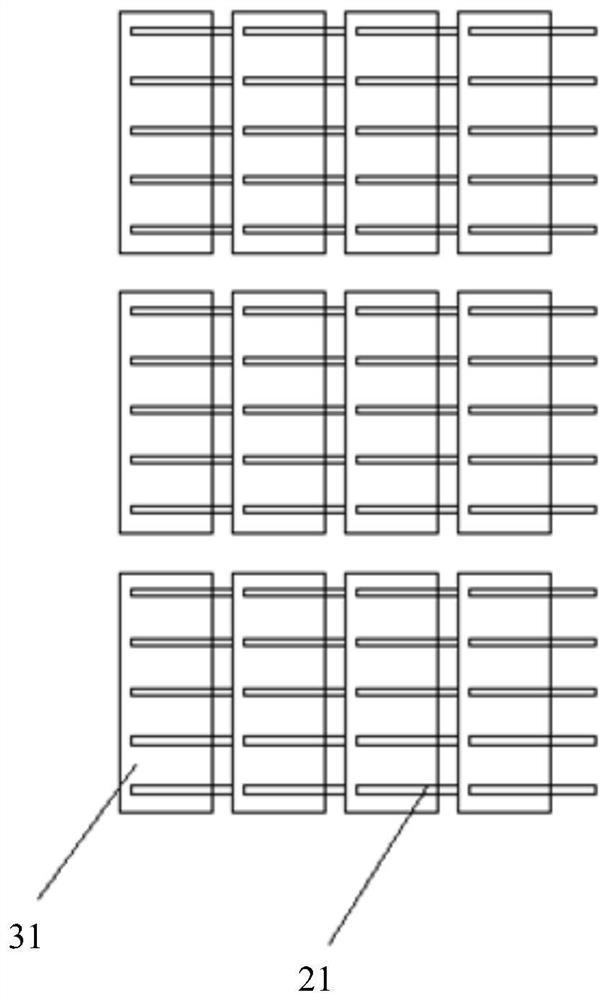

A kind of processing method of photovoltaic module

ActiveCN109950362BAvoid problemsRealize continuous upgradePhotovoltaic monitoringSemiconductor/solid-state device testing/measurementElectrical batteryRework

Owner:SUZHOU COOP & INNO GREEN ENERGY TECHNOLOGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com