Battery electrode sheet and manufacturing method therefor

A manufacturing method and electrode sheet technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as cracks, wrinkles, frequent manufacturing processes, etc., and achieve the effect of increasing manufacturing processes and high-speed manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0043] (First embodiment)-Electrode sheet for wound type battery-

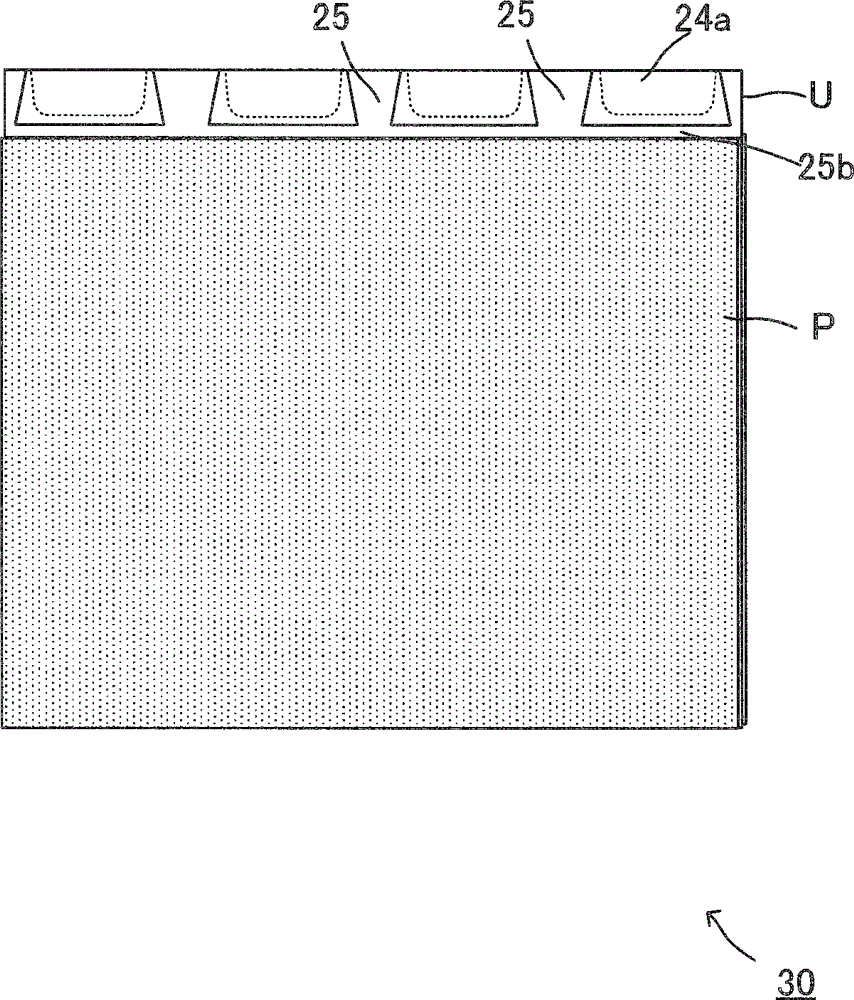

[0044] figure 1 It is a figure which shows the structure of the electrode sheet for wound-type batteries of 1st Embodiment. As shown in this figure, the electrode sheet 30 is formed by rolling an active material layer P on the entire surface of an electrode sheet formed of a sheet-like metal foil except for at least one end edge portion. In addition, the uncoated portion U of the end edge portion is intermittently provided with an extended portion 24a having a substantially rectangular shape, for example, a substantially trapezoidal shape, in the longitudinal direction of the electrode sheet. The extending portion 24a is formed by, for example, a batch-type roll press machine described later, and is obtained by extending the metal foil by pressing. The uncoated portion U is provided along the rolling direction of the active material layer P.

[0045] The electrode sheet 30 only needs to have a sheet-like metal t...

no. 2 approach

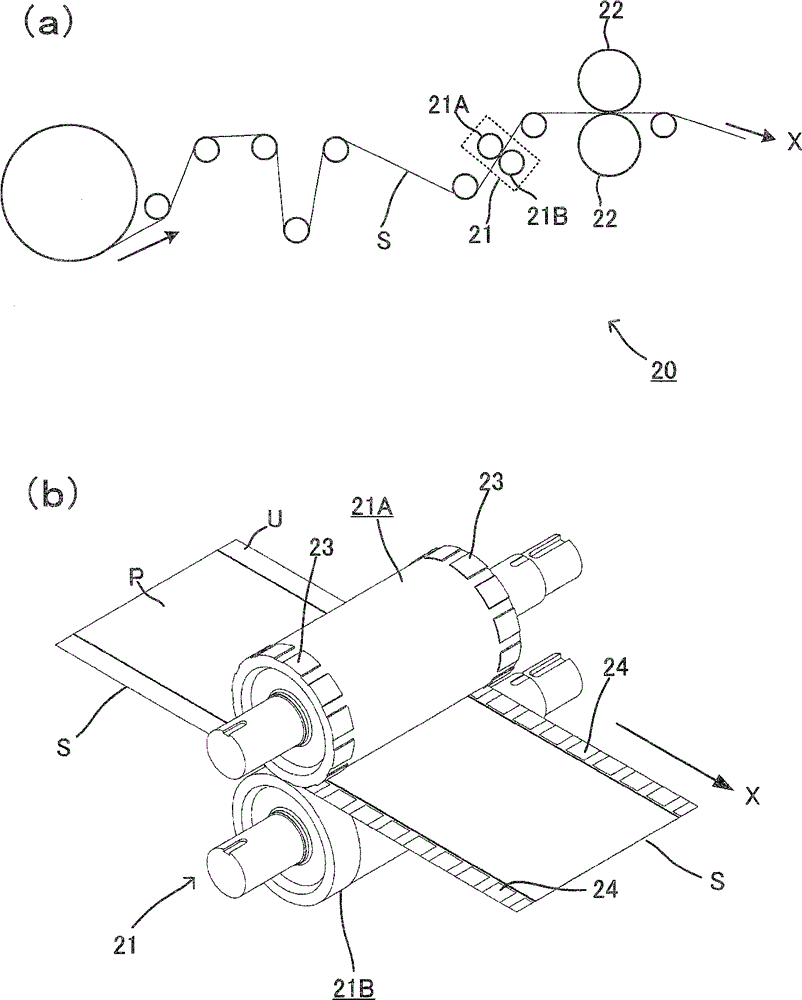

[0057] (Second embodiment)-Manufacturing method of electrode sheet for wound type battery-

[0058] Next, an embodiment of the method of manufacturing the electrode sheet of the first embodiment will be described as an example.

[0059] Figure 5 Shows the approximate procedure for manufacturing electrode sheets for wound batteries. First, a paste-like active material layer is applied to an electrode sheet formed of a sheet-like metal foil (step S1). Then, the uncoated portion of the active material layer is formed on the electrode sheet approximately simultaneously with step S1 (step S2). In the third step, the unpainted portions are intermittently pressed to form rectangular extensions at approximately equal intervals (step S3). Finally, the active material layer is rolled (step S4). The above steps are the characteristics of the above manufacturing method.

[0060] It should be noted that step S1 and step S2 may be omitted, and an electrode sheet coated with a paste-like activ...

Embodiment

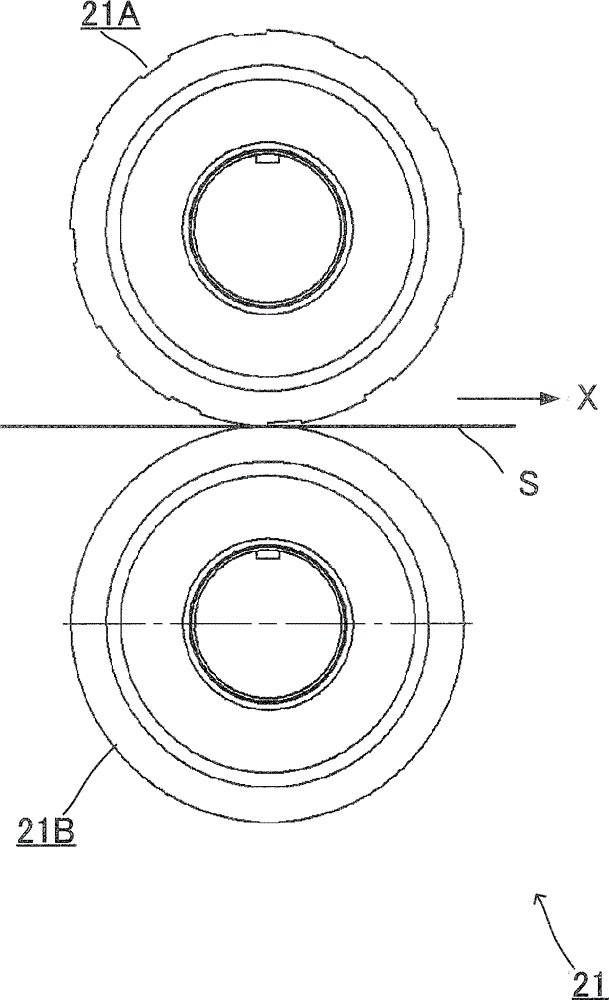

[0074] The diameter of each roll of the main roll press 22 and the intermittent roll press 21 is important because it determines the press line pressure. The inventors of the present invention conducted various experiments to investigate the relationship between press line pressure and bending amount.

[0075] Figure 7 It is a diagram for explaining an example of the method of measuring the amount of bending. In this measuring method, after the active material P is rolled, the electrode sheet 30 is cut to a predetermined size. In order to measure the amount of bending, in a state where one end (one side) of the electrode sheet 30 is fixed with the fixing tool 31, a weight of 850 g or the like is suspended on the other end (one side) side to apply a load. In this state, as shown in the figure, the metal gauge 32 is close to 1 m, and the bending amount is the largest in the center portion, and the bending amount is measured in the center portion.

[0076] In roll presses, generall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com