Improved cvr (glass resin composite) monofilament

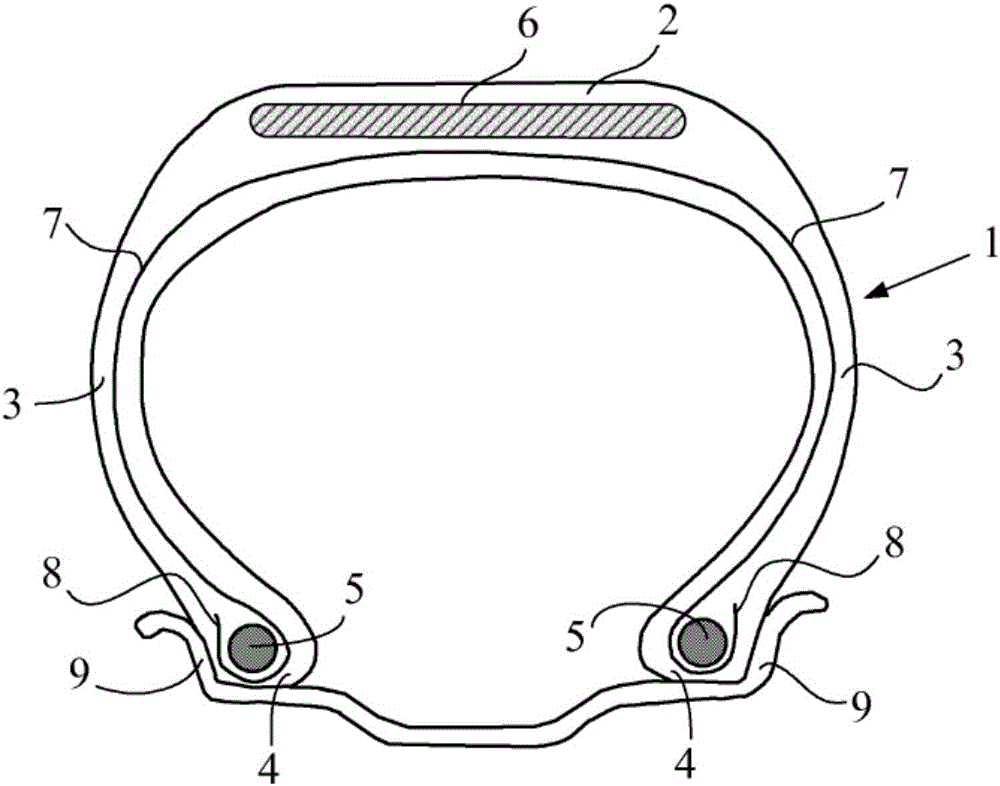

A composite material and glass resin technology, applied to the reinforcement layer of pneumatic tires, other household appliances, transportation and packaging, etc., can solve problems such as the collapse of CVR monofilament structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

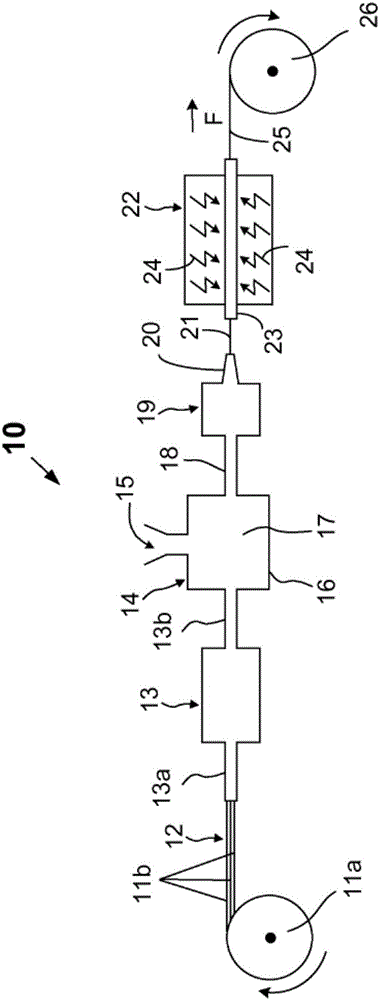

Method used

Image

Examples

Embodiment Construction

[0031] In this patent application, unless otherwise indicated, all percentages (%) shown are percentages by weight.

[0032] Furthermore, any numerical range represented by the expression "between a and b" represents a numerical range from greater than a to less than b (i.e., excluding endpoints a and b), while any numerical range represented by the expression "a to b" By range is meant a range of values extending from a to b (ie, including the strict endpoints a and b).

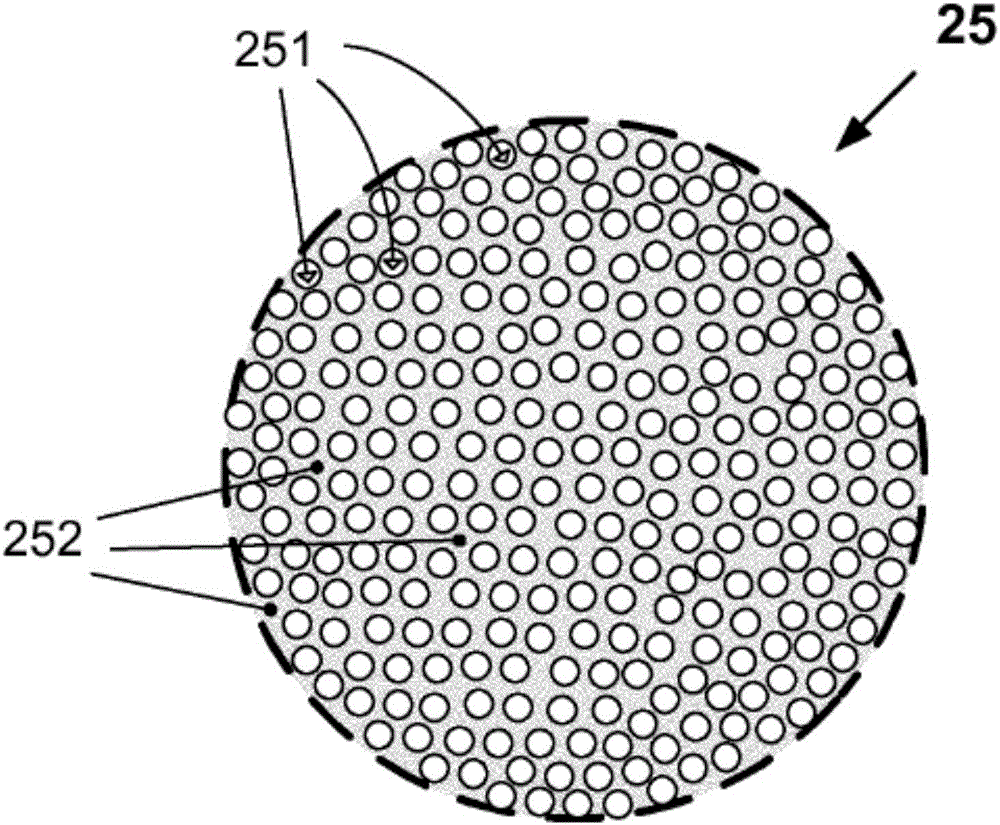

[0033] The present invention therefore relates to a monofilament made of glass resin composite (abbreviated CVR) comprising glass filaments embedded in a crosslinked resin, characterized in that:

[0034] - said resin has a glass transition temperature (expressed as Tg) equal to or greater than 190°C;

[0035] - said monofilament has an elongation at break (expressed as Ar) equal to or greater than 4.0% measured at 23°C;

[0036] - the initial tensile modulus (in E) of the monofilament measured at 23°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com