A kind of processing method of photovoltaic module

A processing method and technology of photovoltaic modules, which are applied in the monitoring of photovoltaic systems, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of not knowing the actual location of defects, not being able to judge batches in time, space and capital resource occupation, etc., to prevent Batch defective products appear, improve reliability and accuracy, and achieve the effect of continuous upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

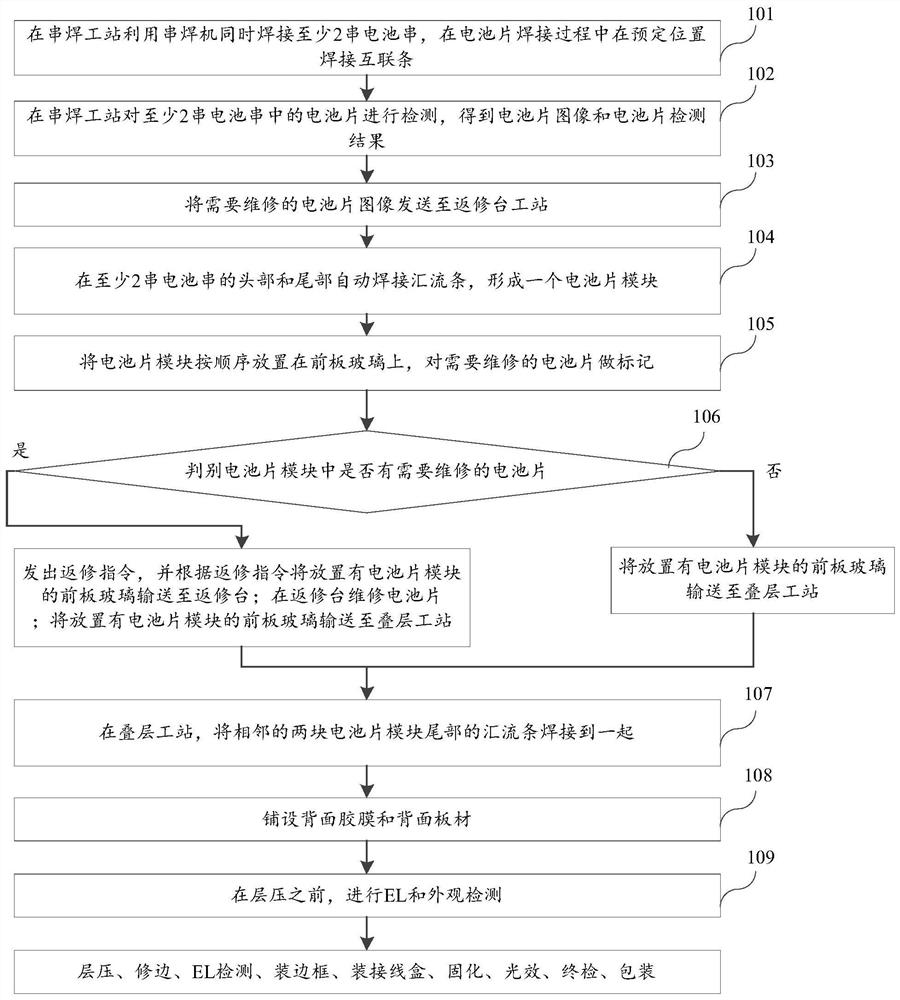

[0037] Please refer to figure 1 , which shows a flowchart of a method for processing a photovoltaic module provided by an embodiment of the present invention. Such as figure 1 As shown, the processing method of the photovoltaic module may include the following steps:

[0038] Step 101, use a stringer to simultaneously weld at least two strings of battery strings at a stringer station, and weld interconnection bars at a predetermined position during the battery sheet welding process.

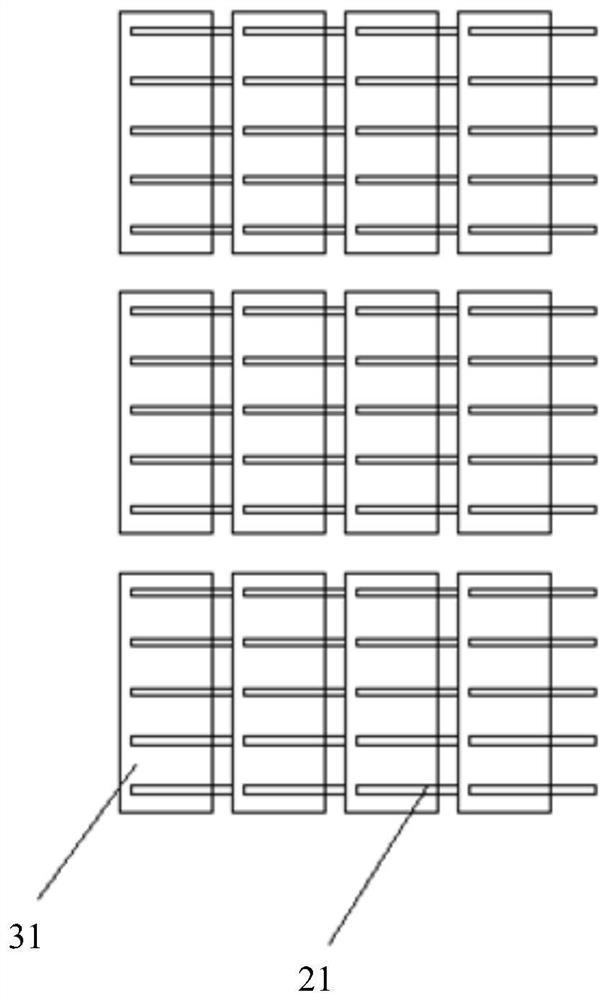

[0039] Interconnection strips are used to connect at least 2 battery strings in parallel, for example: interconnection strips are used to connect 3 battery strings in parallel. The number and sorting interval of interconnection strips are based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com