Patents

Literature

304results about How to "Unique appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine product meat sausage and making method thereof

The invention discloses a marine product meat sausage and a making method thereof. The marine product meat sausage is characterized by comprising the following raw materials proportioning by weight: 30-85 portions of marine product, 0-30 portions of edible meat, 10-30 portions of edible water, 1-12 portions of edible vegetable oil, 2-6 portions of soybean protein isolate, 0.5-1.6 portions of saltand 2.0-7.5 portions of starch; the marine product meat sausage is prepared according to the steps of raw material processing, twisting, chopping, stirring, filling, sterilizing and packaging. The invention is prepared by adopting the marine products (scallop muscle, oyster meat, sleeve-fish meat, salmon meat, shrimp meat, trepang, abalone, yellow croaker meat, hairtail meat, fish seeds, ling meat, waste fish meat and the like) or adding the edible meat (chicken, pork, mutton, beef and the like) as the main raw materials, has abundant and balanced nutrition, meets the requirement of a consumeron the marine products and increases the appetite, and the product has strong seafood taste and unique flavor, does not contain nitrite, is beneficial to health, is packaged in vacuum, has unique appearance and is ready to be enjoyed when a bag is opened.

Owner:青岛农博农食品科技有限公司

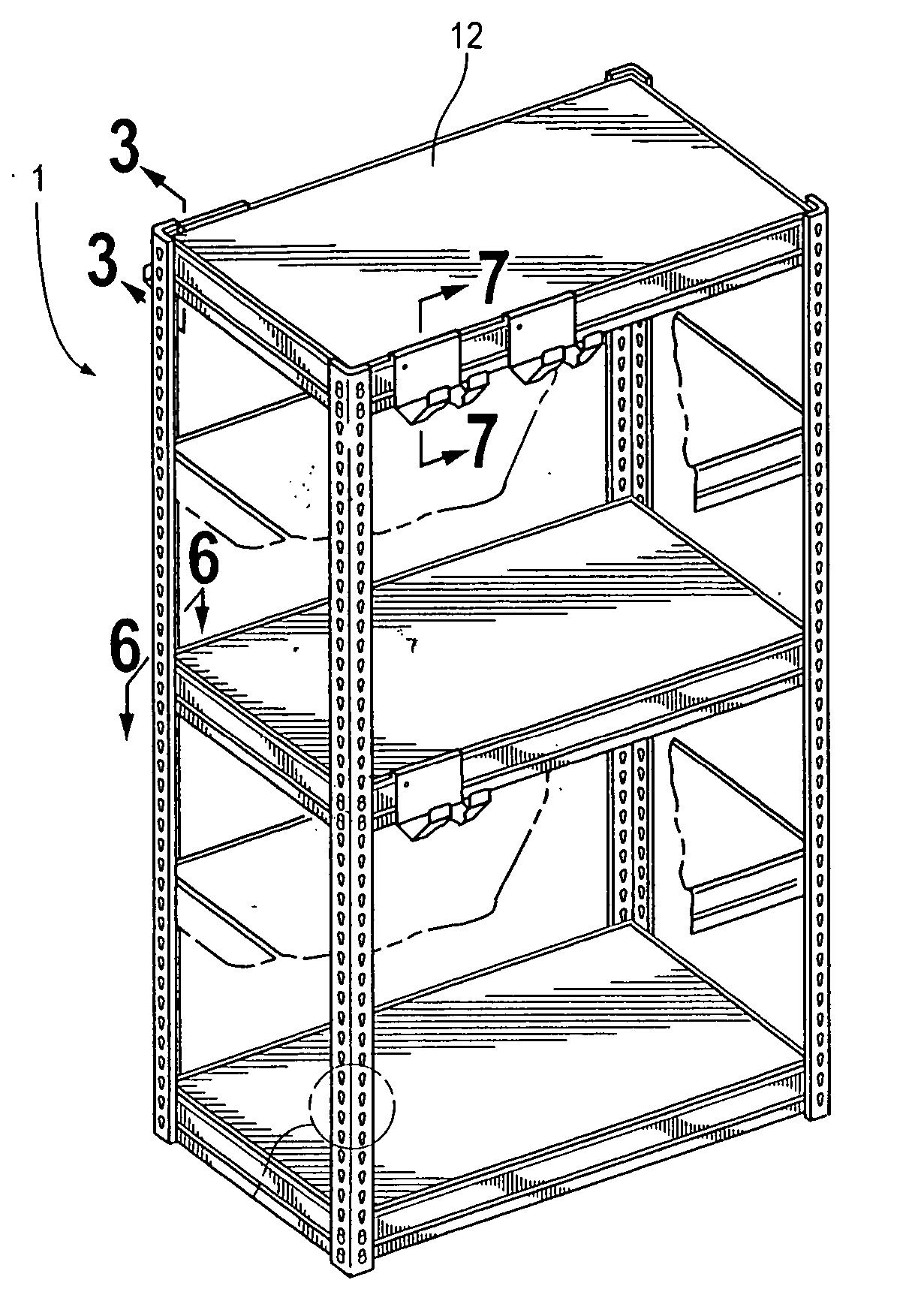

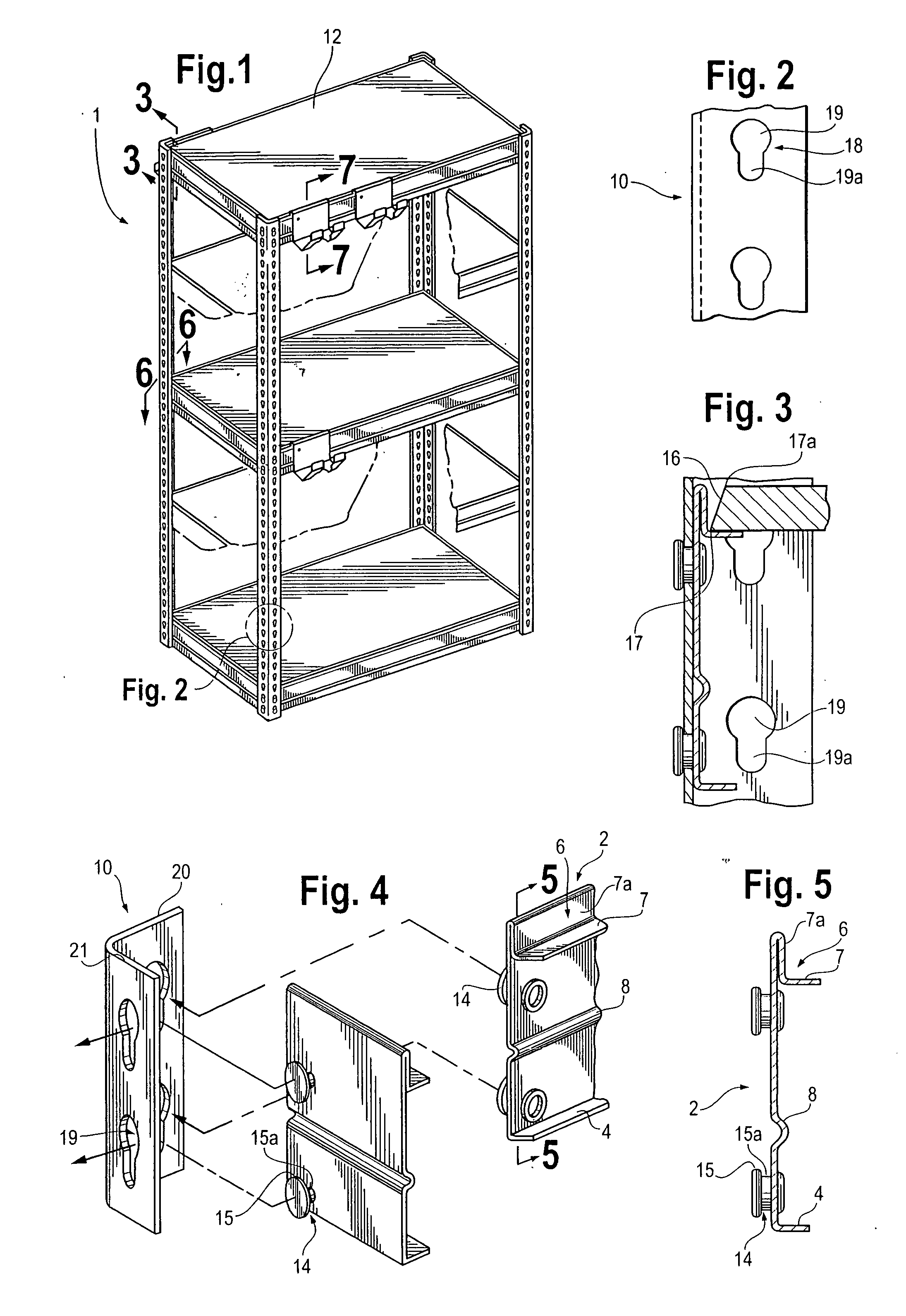

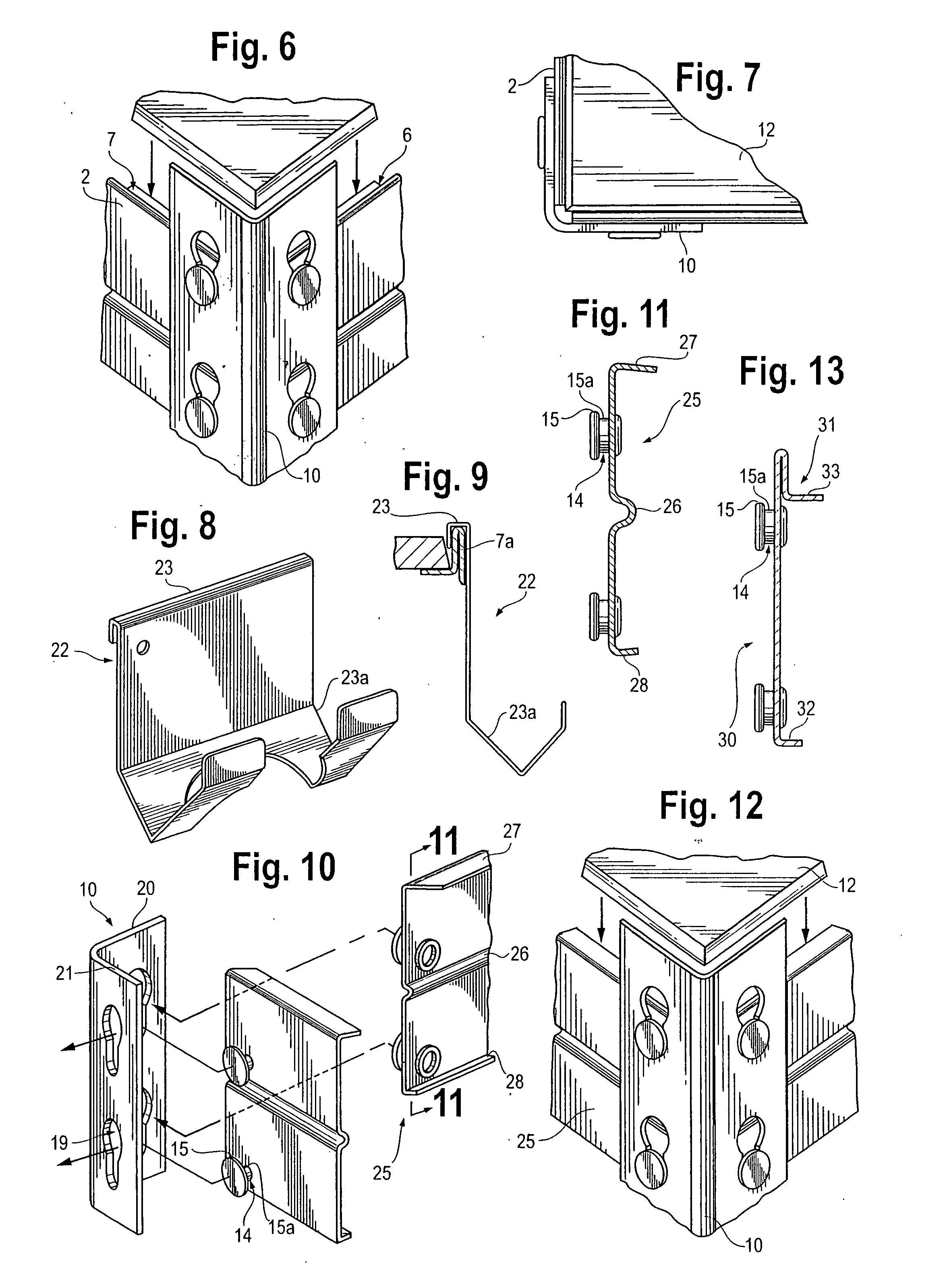

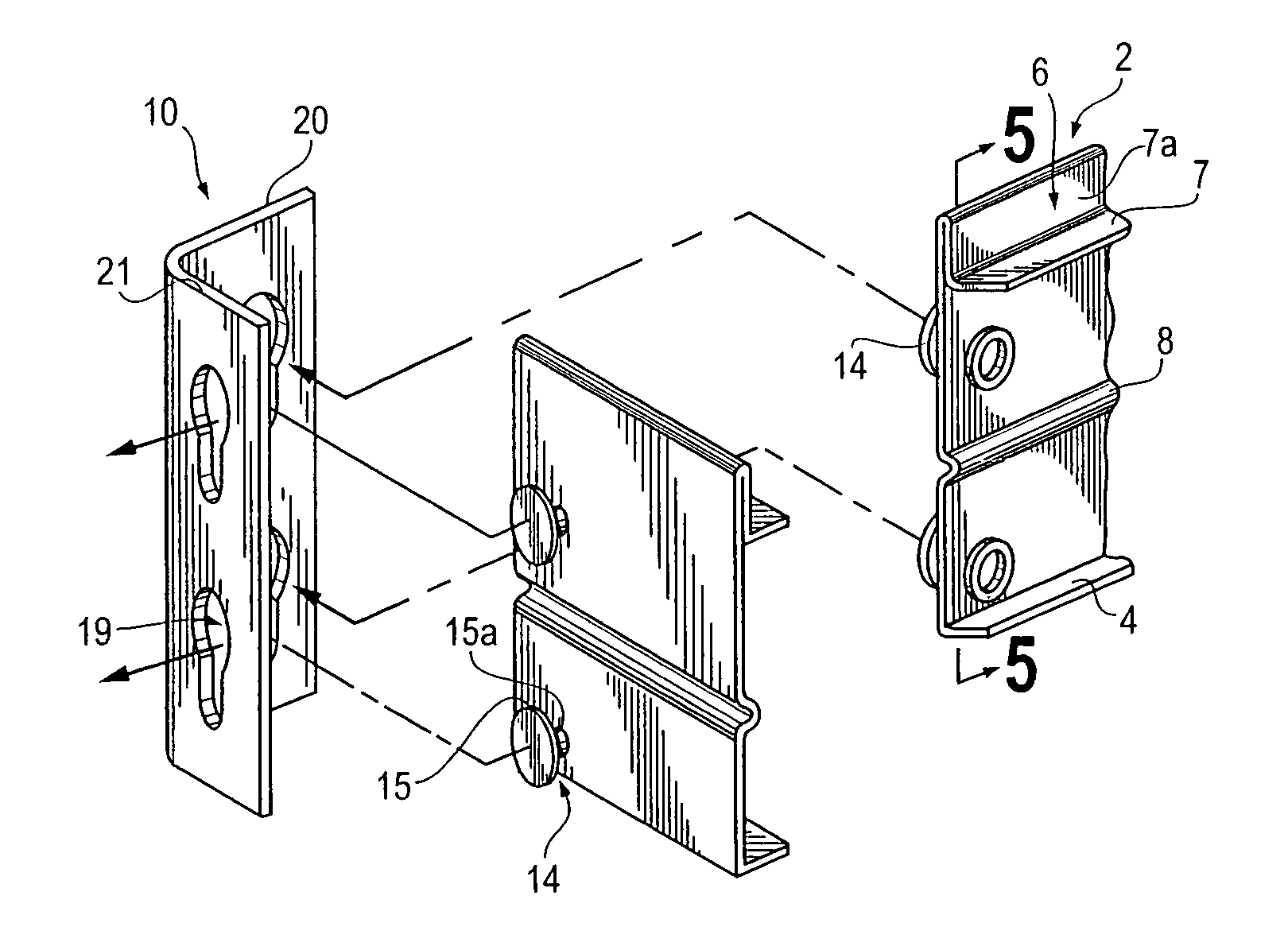

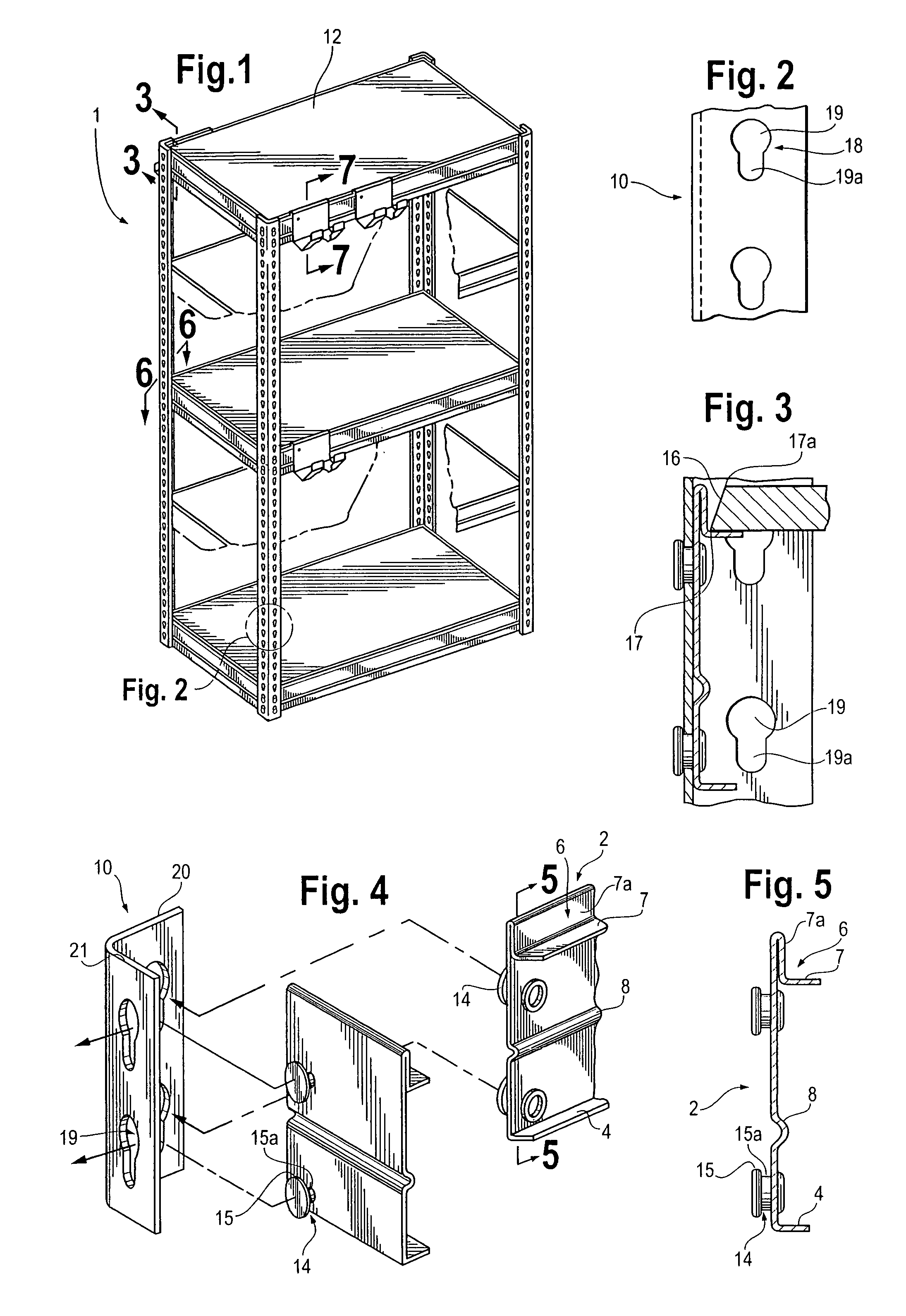

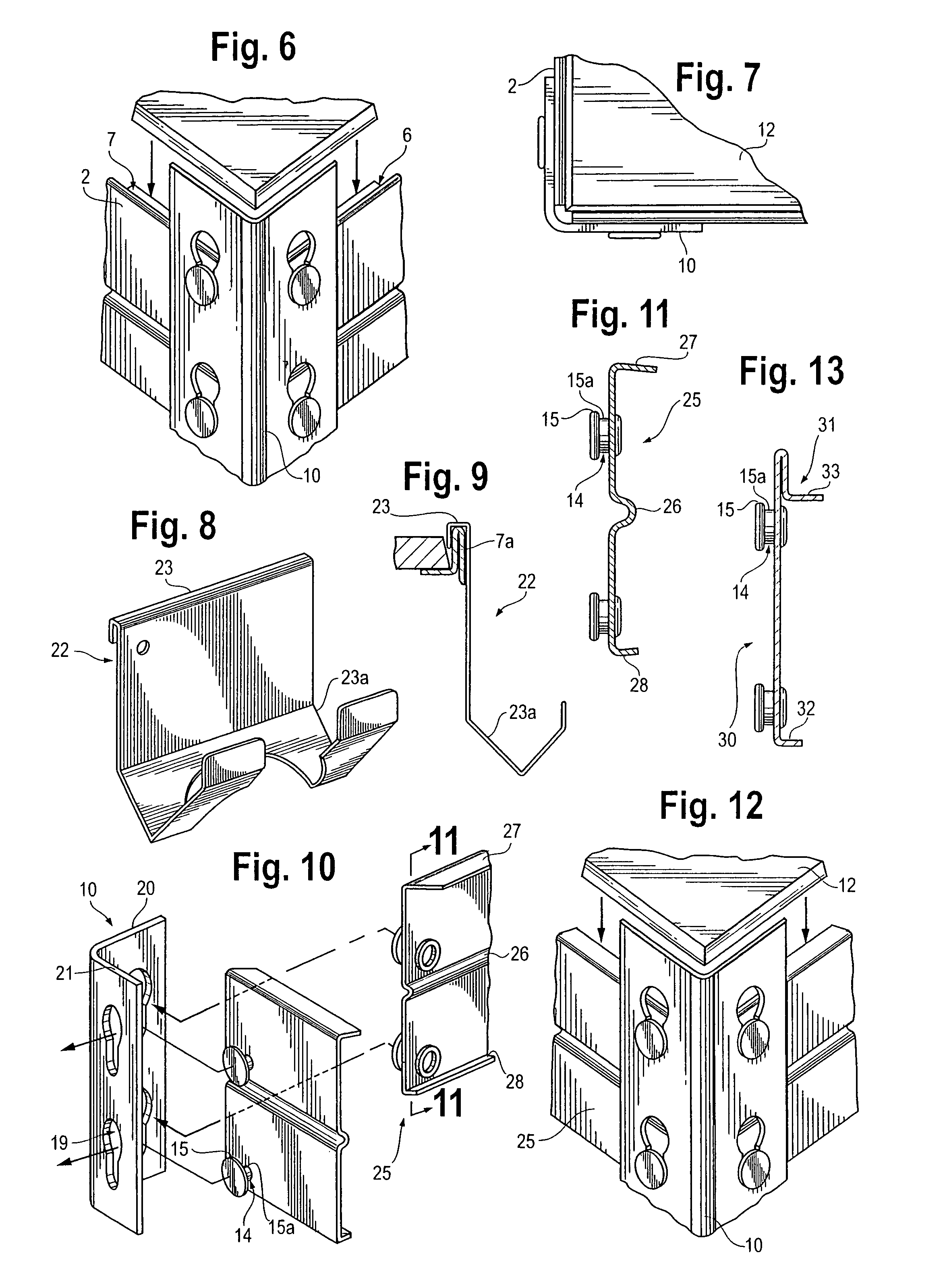

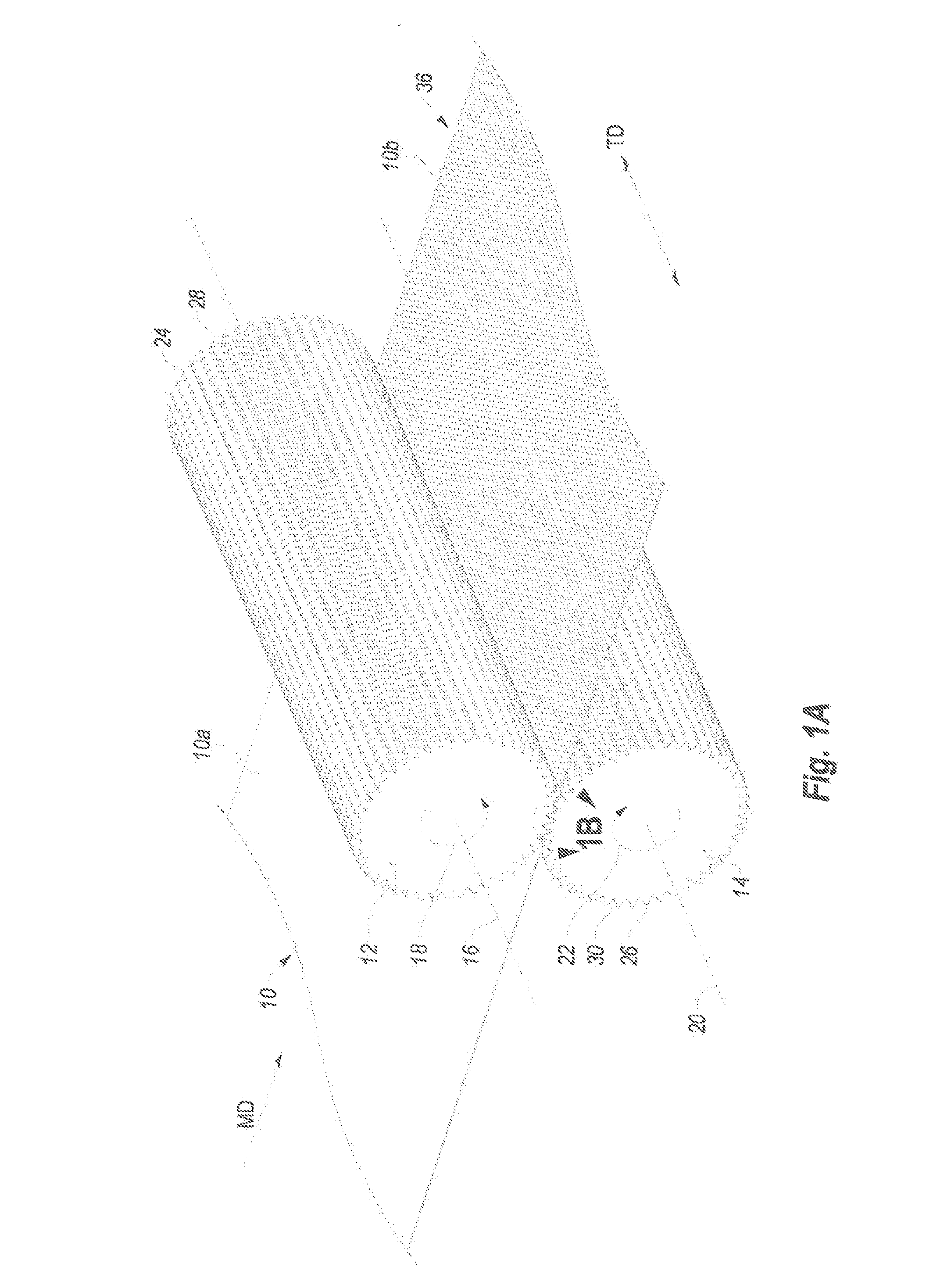

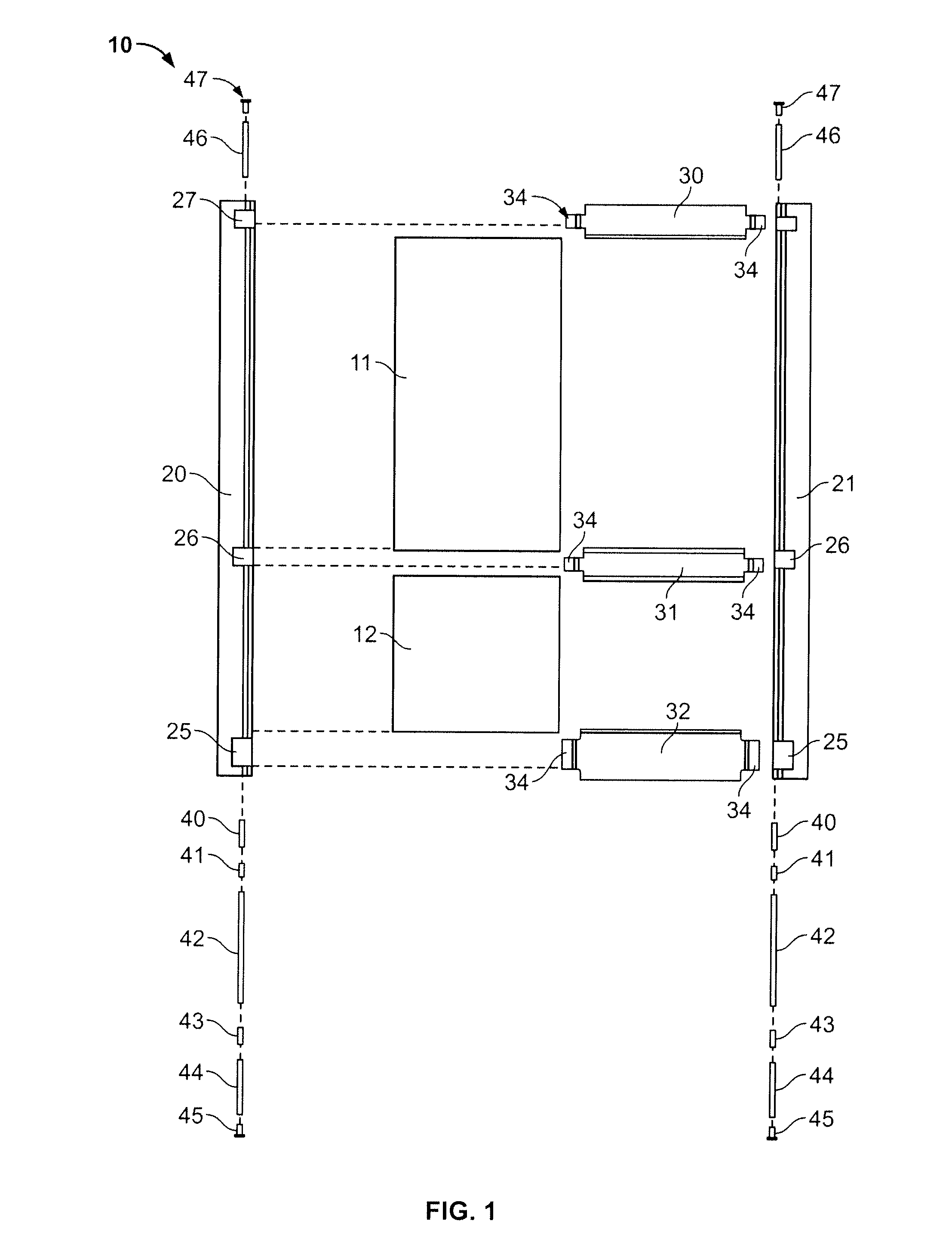

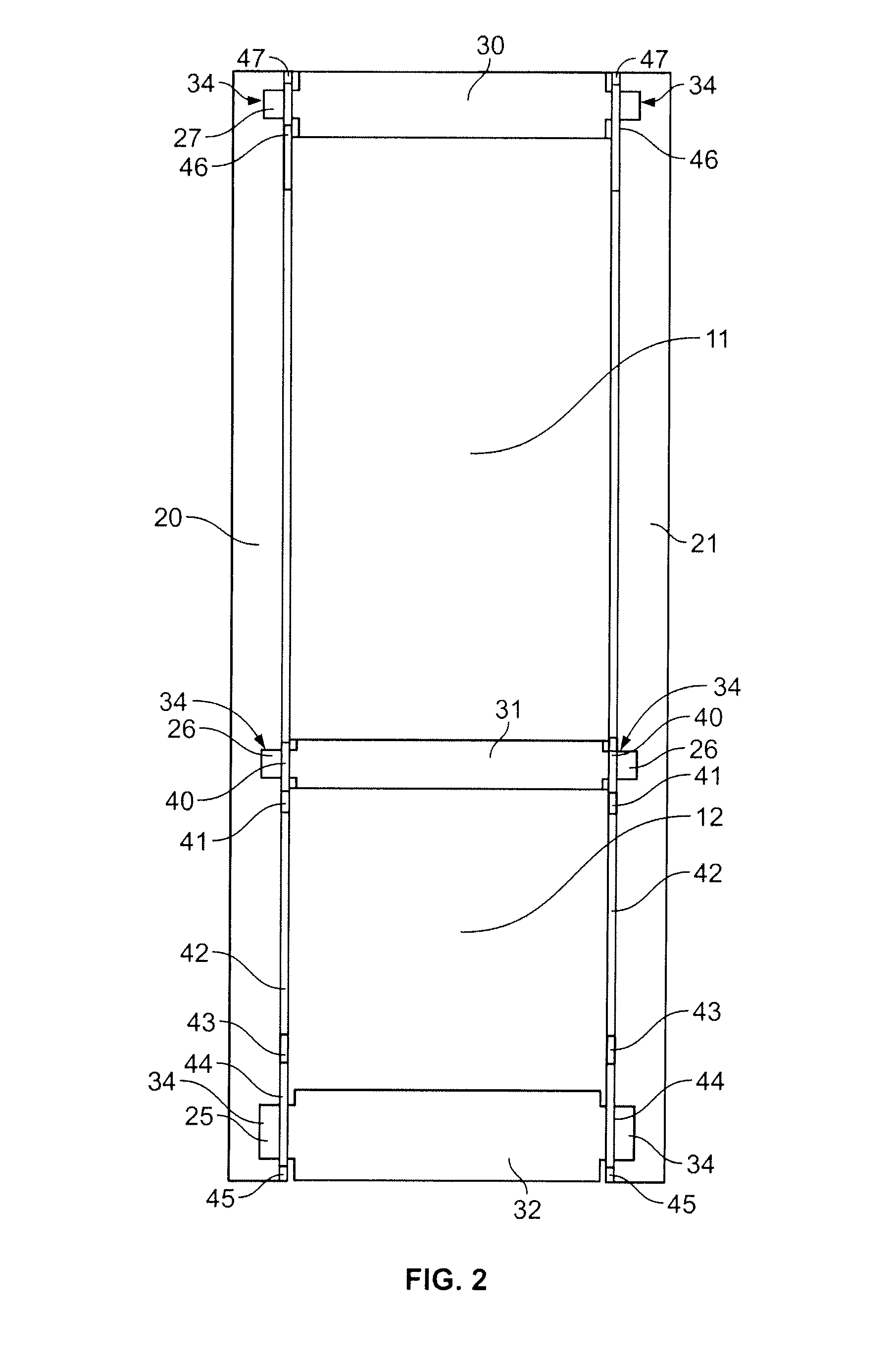

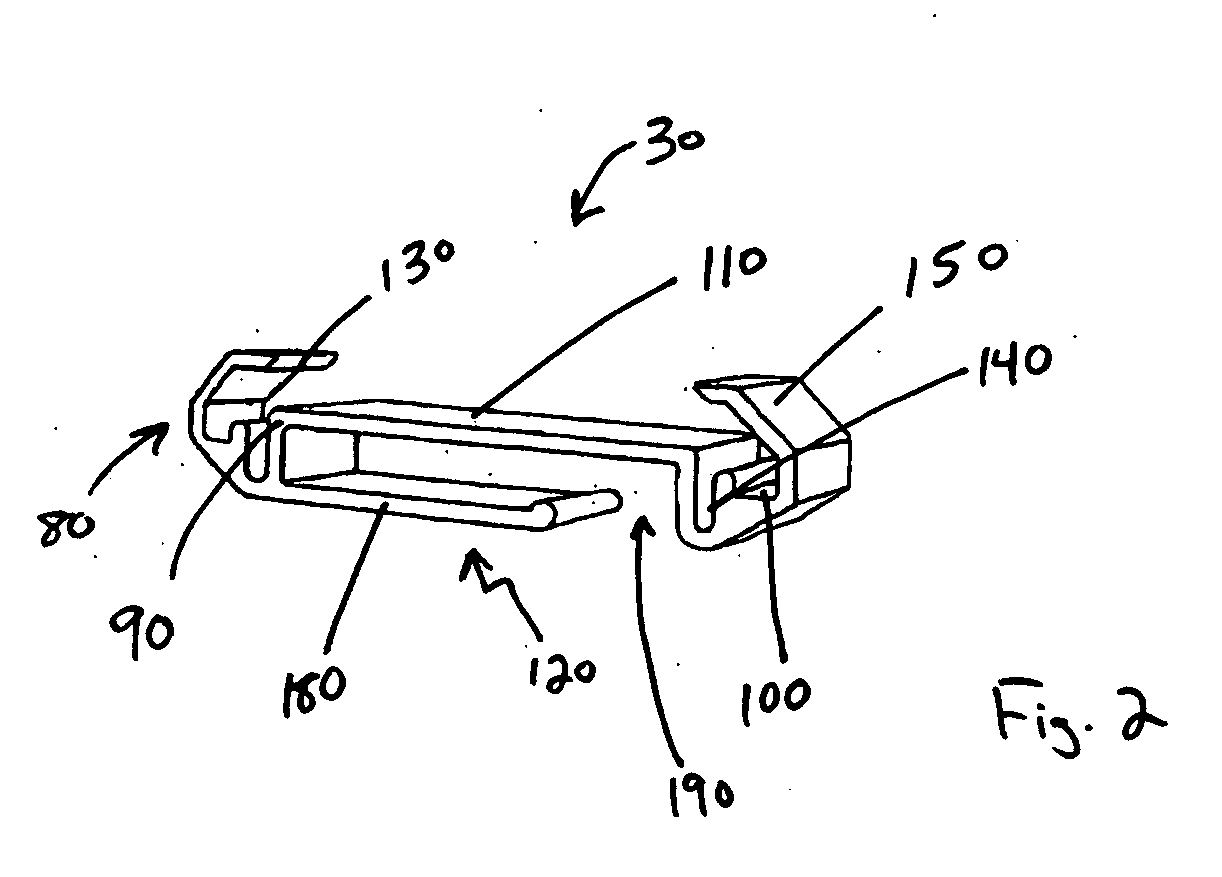

Cargo rack

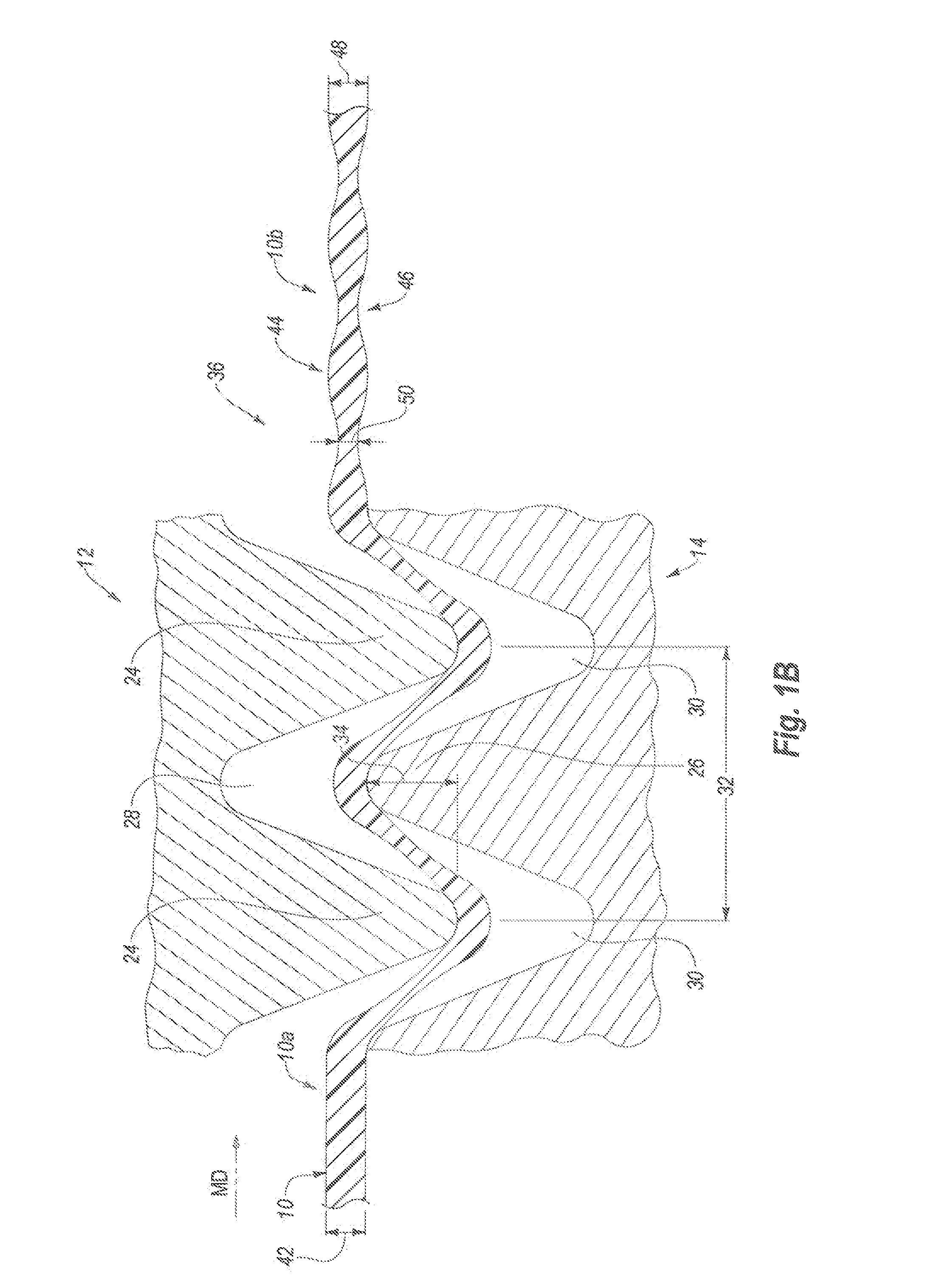

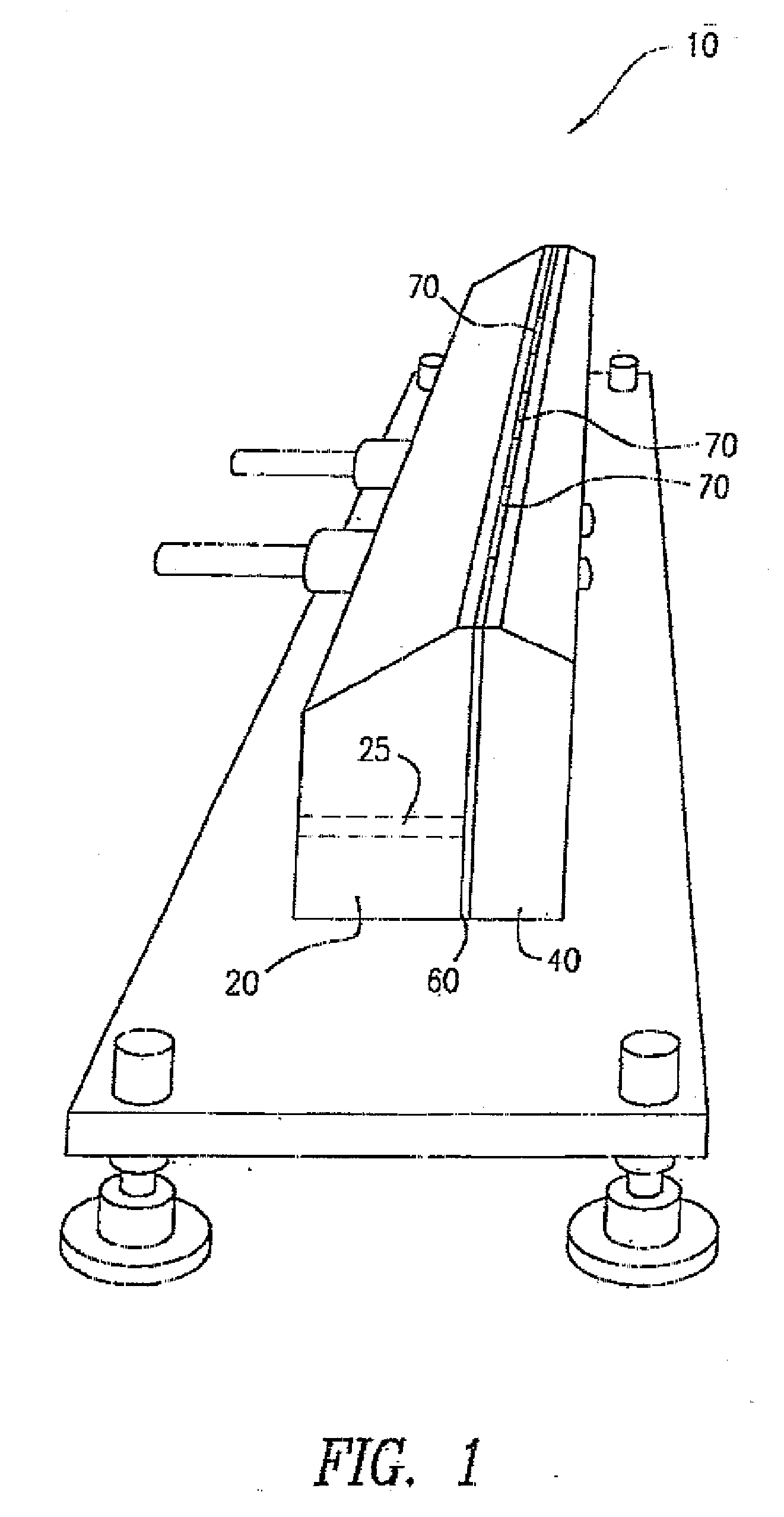

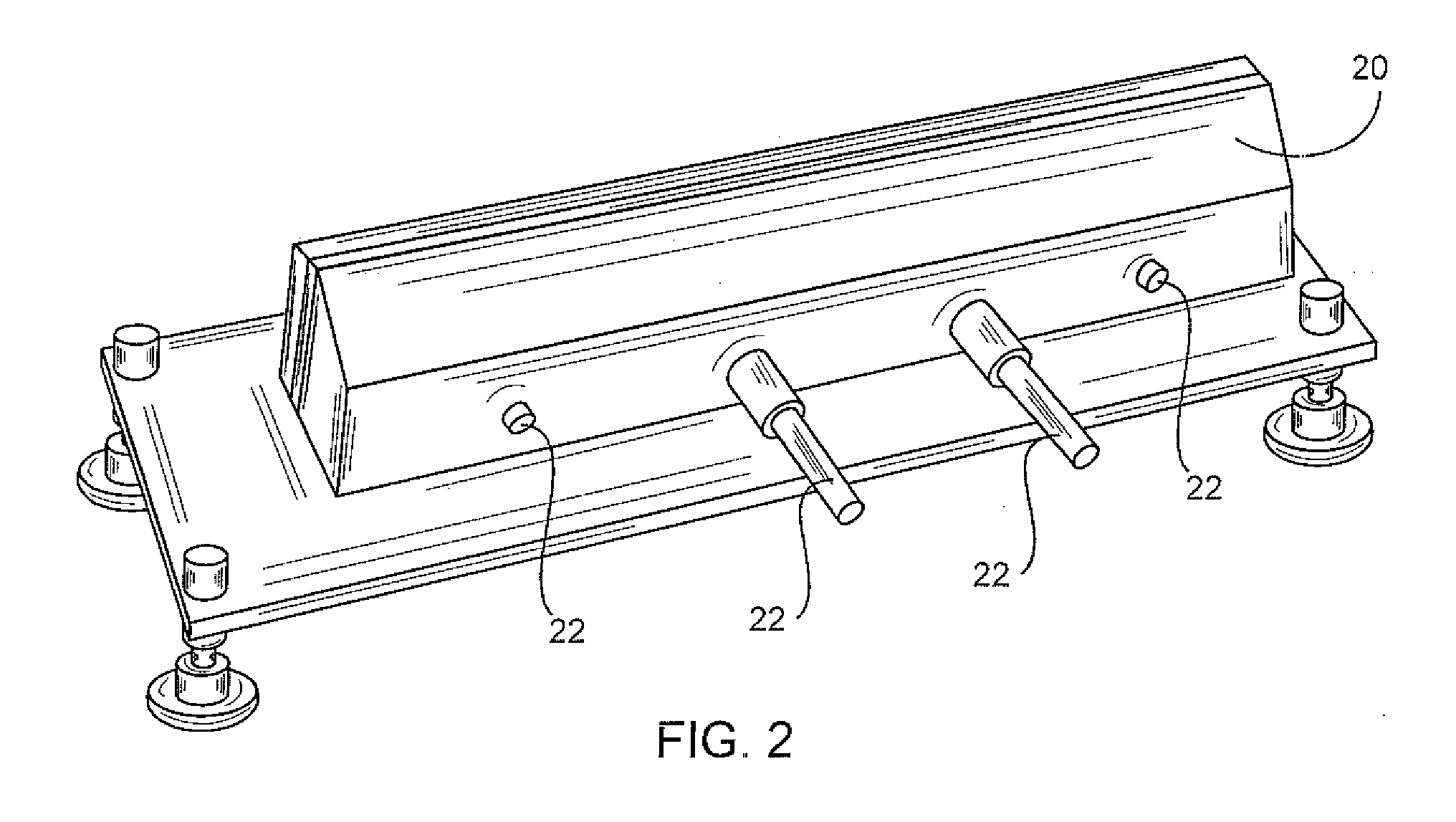

ActiveUS20050103733A1Minimizes cost per unitMaximizes strength to material weight ratioFurniture partsStands/trestlesEngineeringFlange

A cargo rack utilizing a structural beam in the form of three embodiments, two of the embodiments comprising a rib, one of which includes a recessed flange and a horizontal return flange, the other includes a standard angled flange and an angled return flange, the third embodiment includes a recessed flange and a horizontal return flange, structural beams used in a framework comprising a plurality of vertical posts containing key shaped apertures and a plurality of horizontal shelving members, structural beams contain nubs enabling structural beams to connect to vertical posts via key shaped apertures thereby enabling horizontal shelving members to be associated with structural beams and vertical posts, various attachments may be added to cargo rack when recessed structural beams are used via a slight clearance that is formed between the recessed edge and a slight taper on horizontal shelving member sides.

Owner:EDSAL MANUFACTURING COMPANY INC

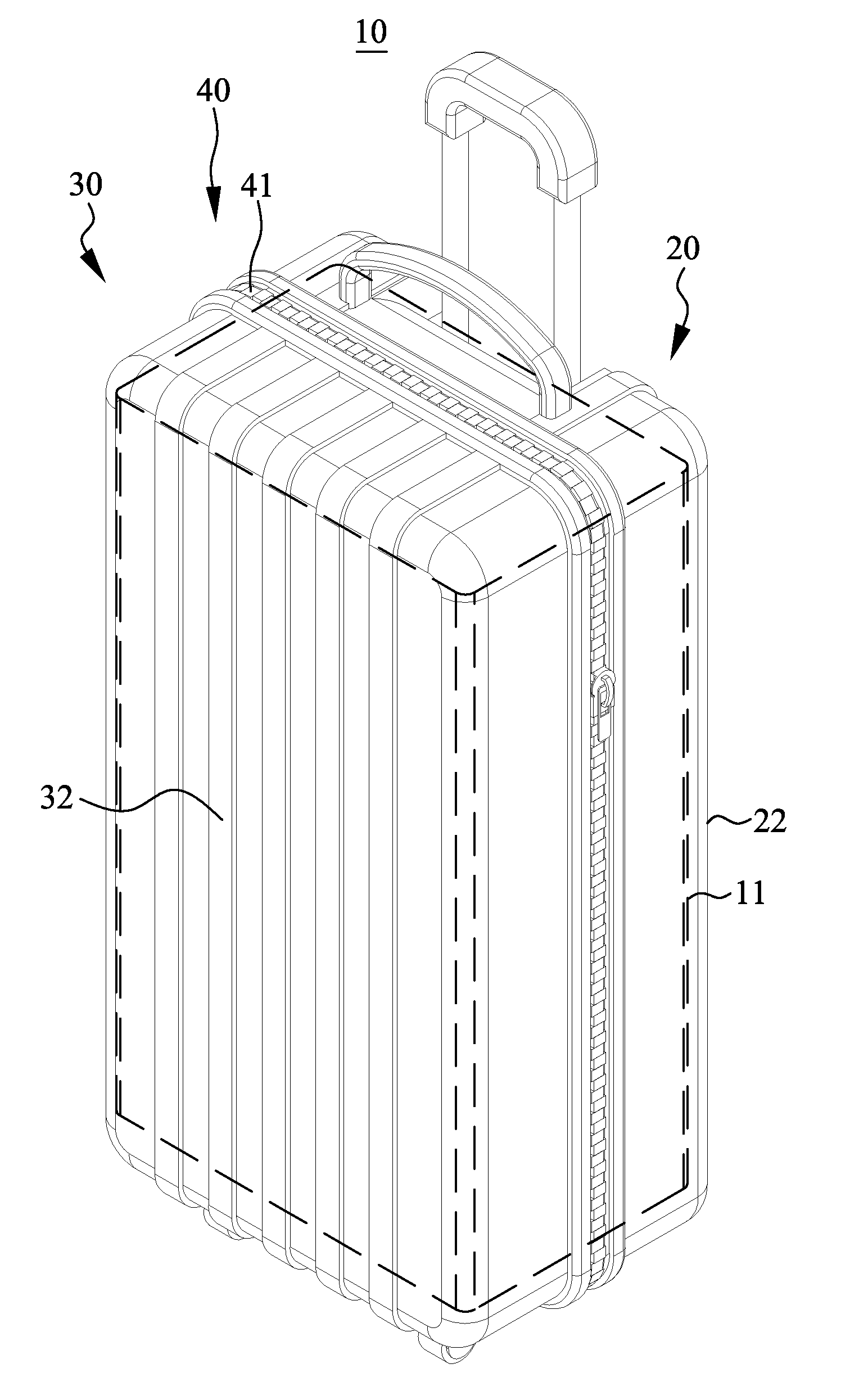

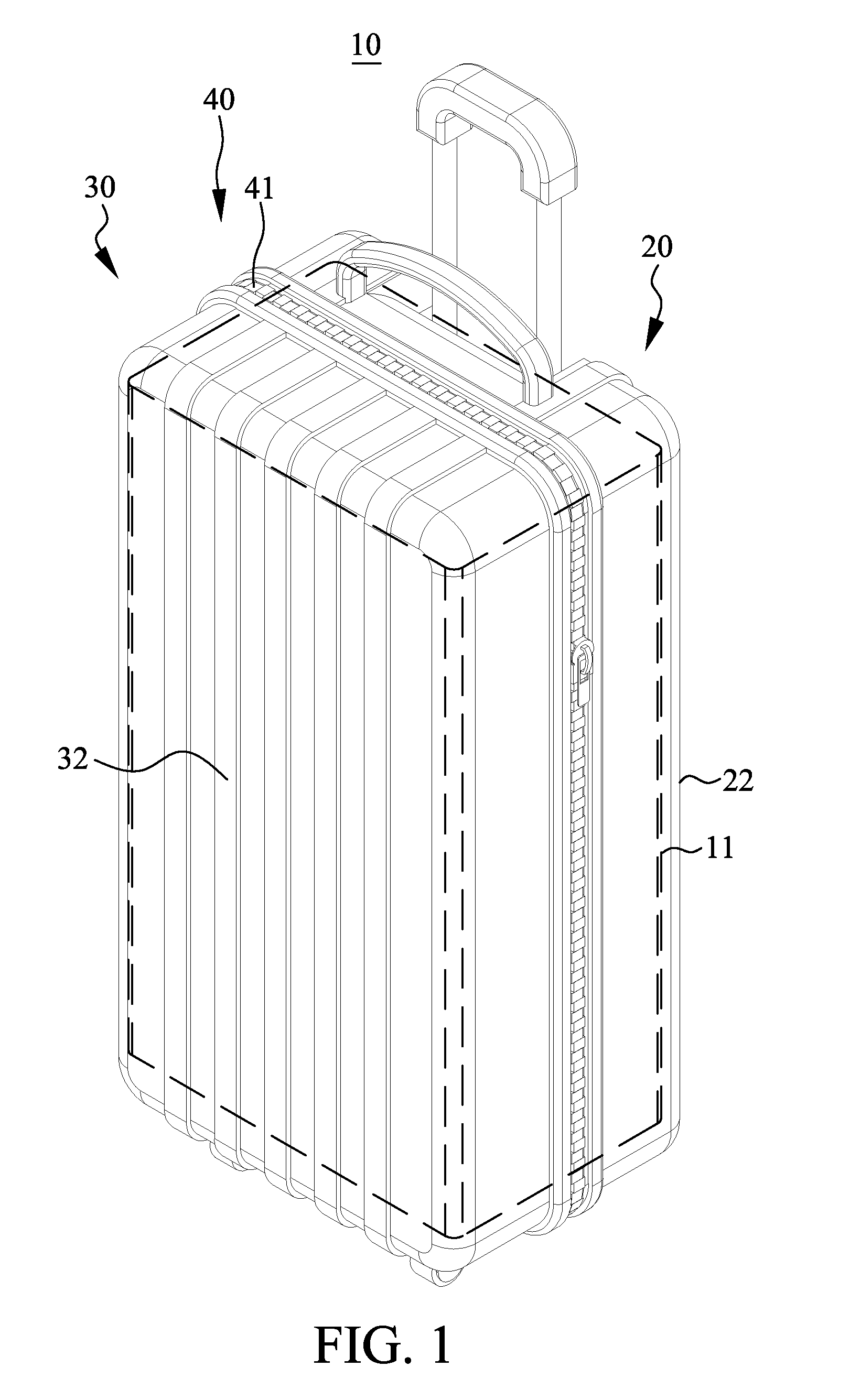

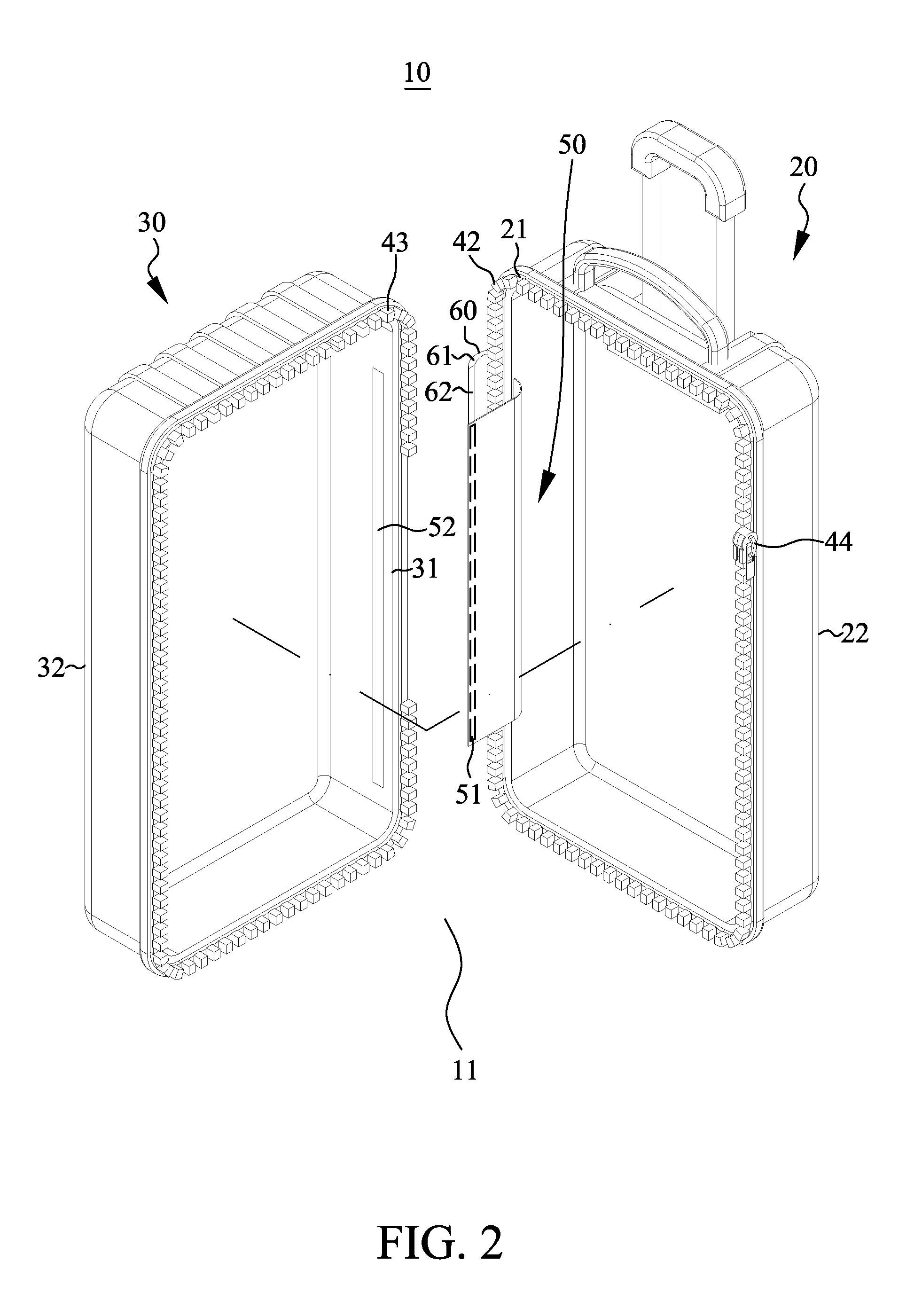

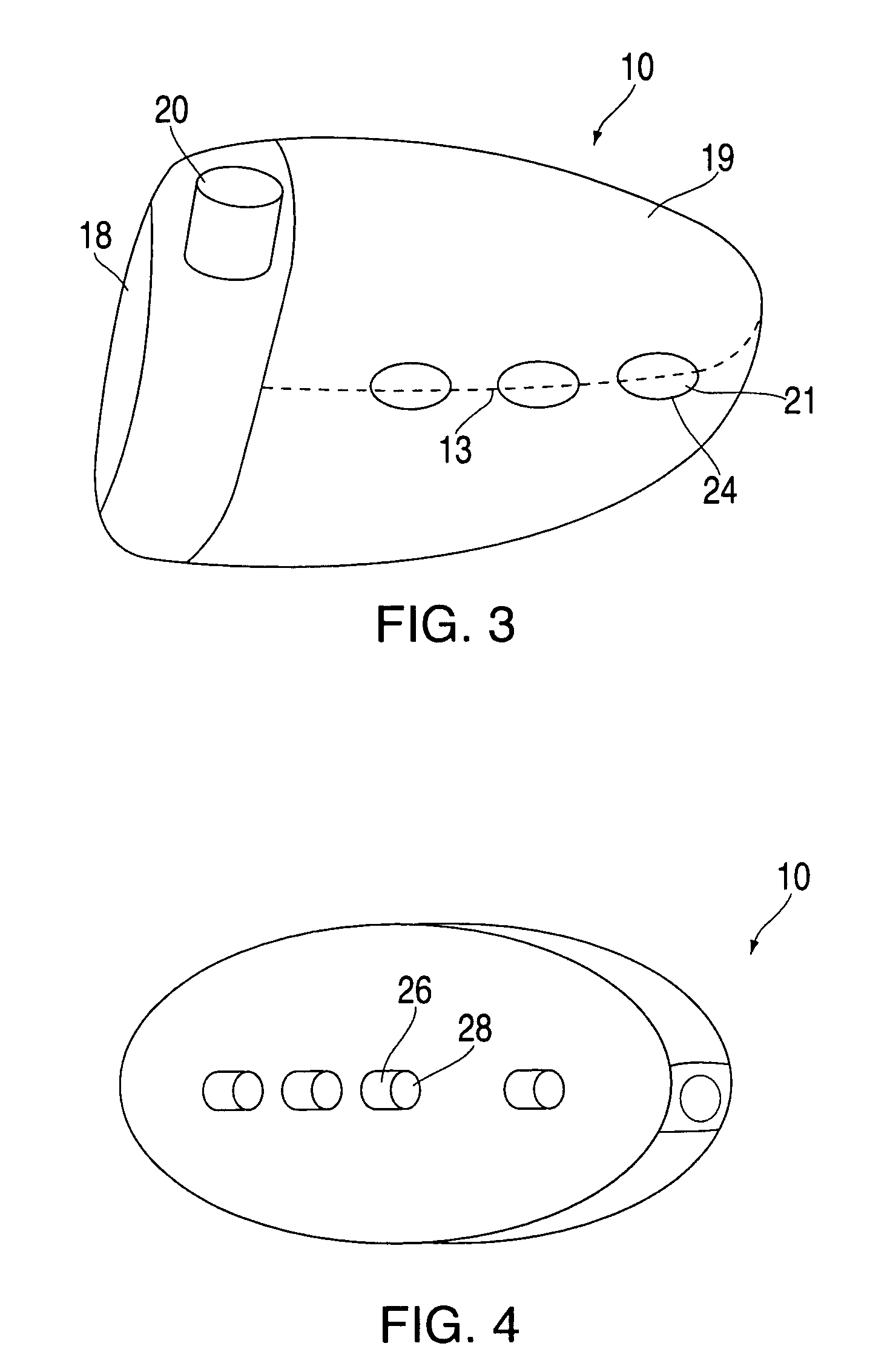

Hard luggage case with changeable case portion

A hard luggage case with changeable case portion includes a first and a second case portion; a closure structure connected to between the first and the second case portion for binding them together to form the luggage case; a coupling structure provided in the luggage case with one longitudinal edge fixedly connected to the first case portion and another longitudinal edge detachably connected to the second case portion; and a covering structure externally provided on the luggage case corresponding to the coupling structure, and having one longitudinal edge externally fixedly connected to the first case portion and another longitudinal edge forming a free end. When the coupling structure and the covering structure are detached from the second case portion, the closure structure allows the second case portion to completely separate from the first one and be replaced with a structurally identical third case portion that shows a different exterior design.

Owner:FTI GROUP HLDG

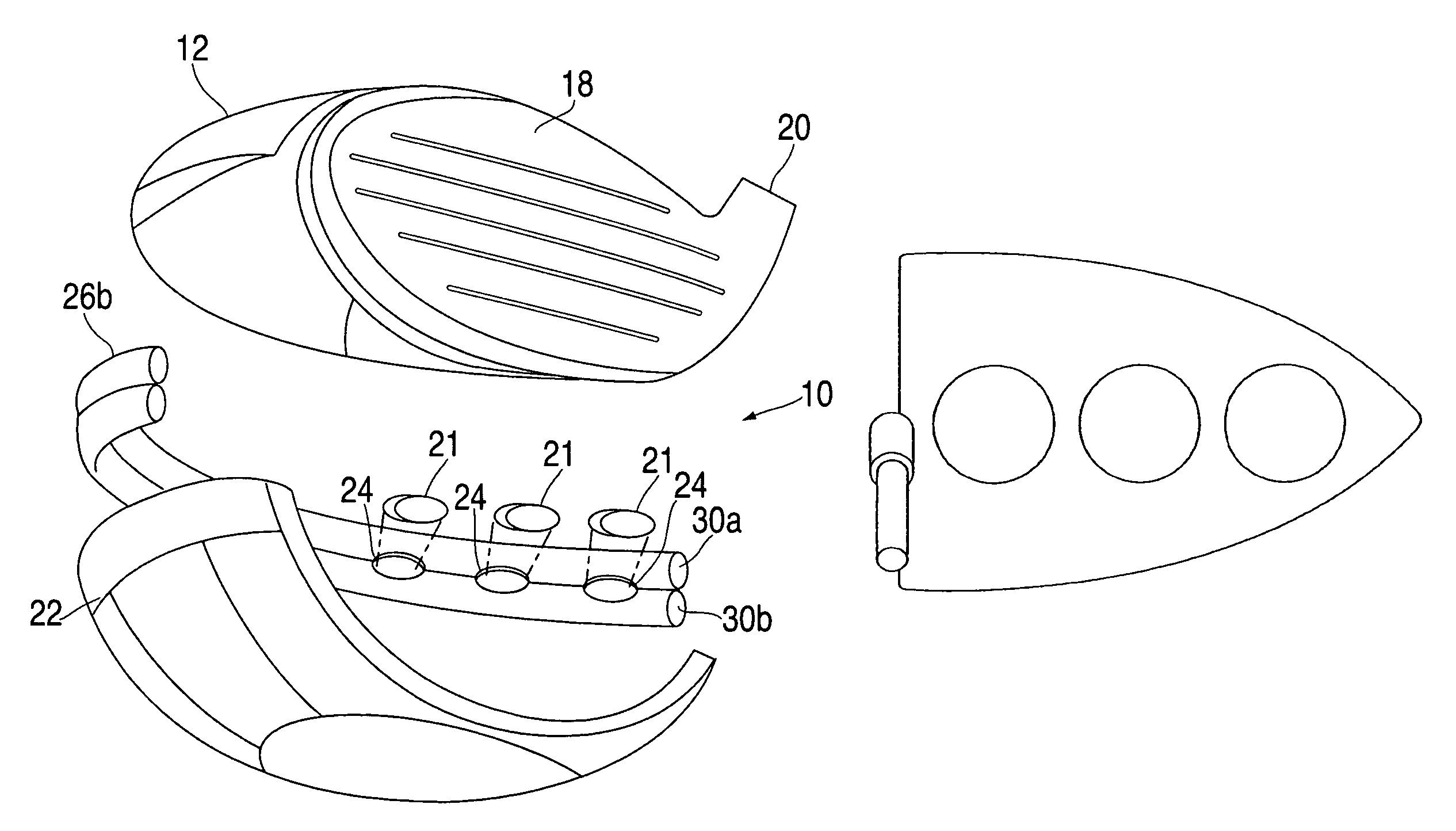

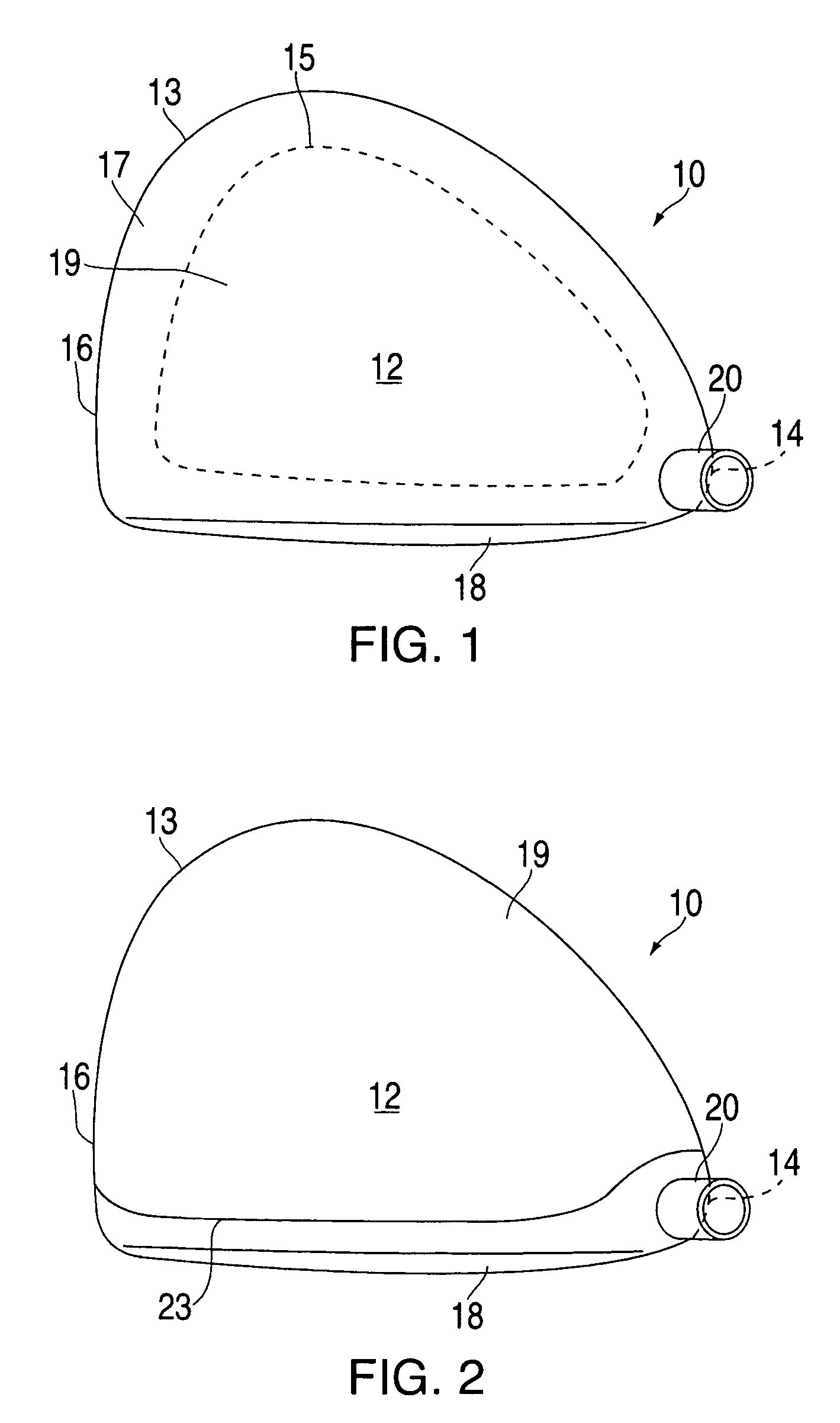

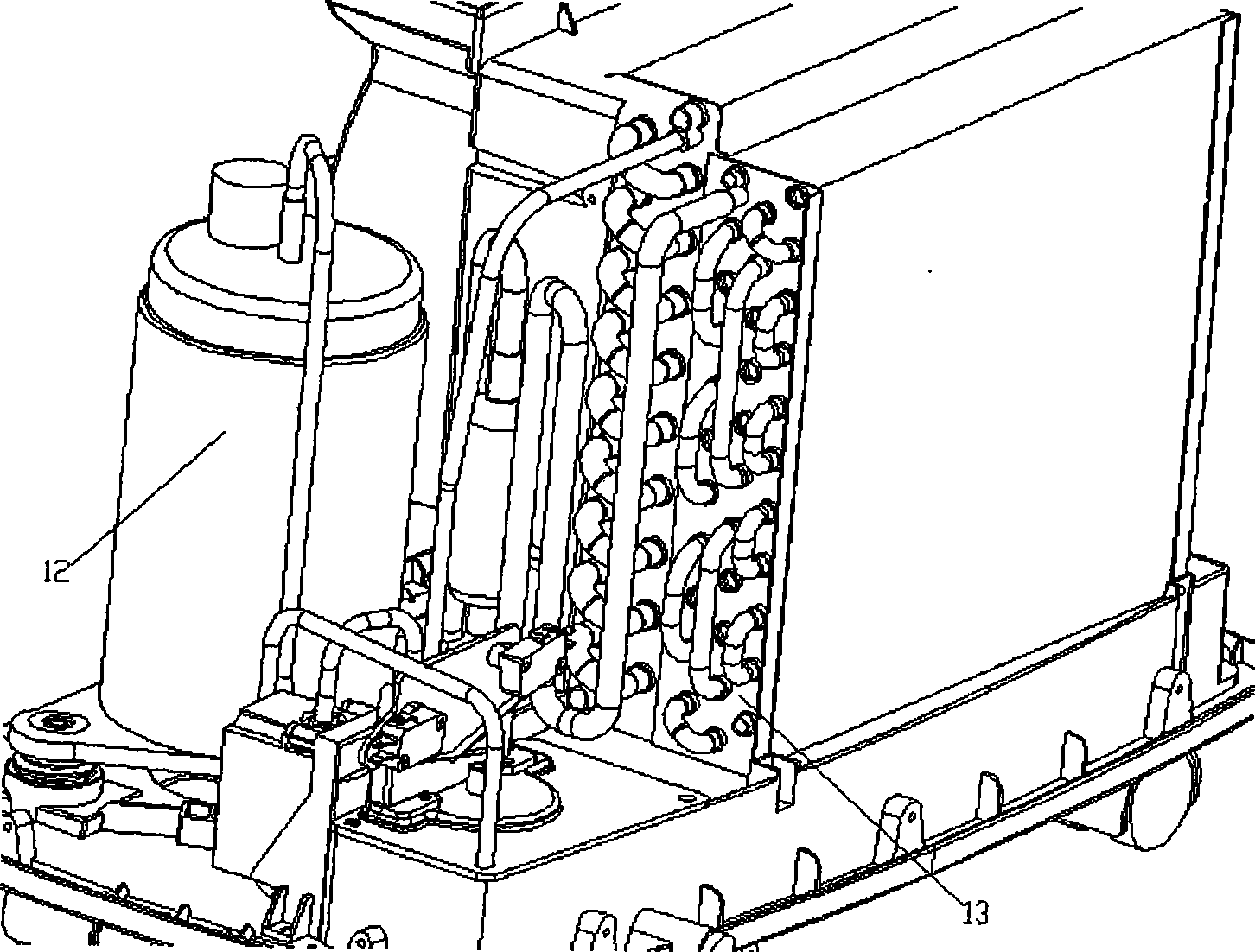

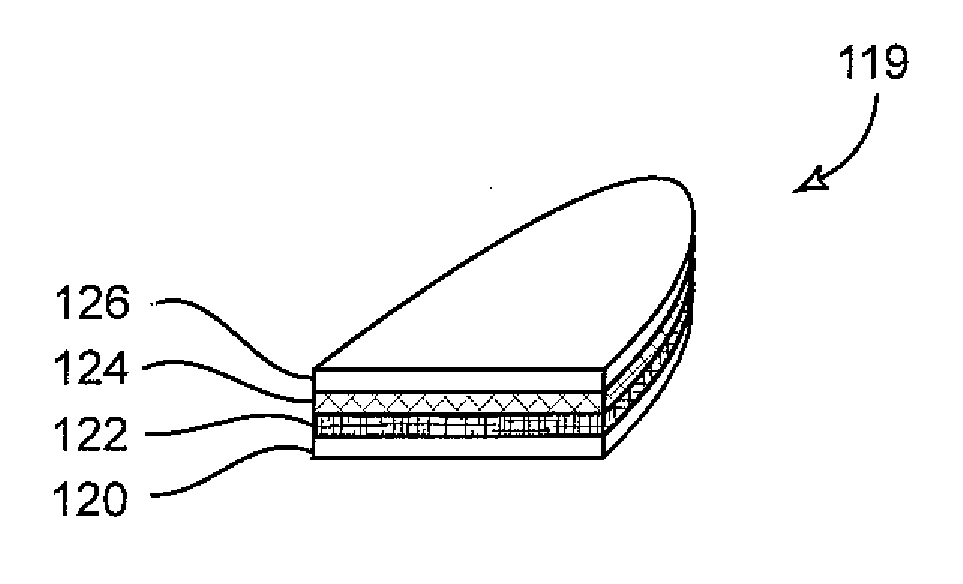

Golf head having a ported construction

A golf club head has a face, a hosel, and a hollow body. The body includes an outer peripheral region, when viewed from above, and center portions on the upper surface and sole, respectively. The outer peripheral region has a weight-per-unit of surface area which is greater than the weight-per-unit of surface area of the center portions. The weight differential may be accomplished by molding ports into the hollow body around the periphery, which contain weight plugs. Alternately or in addition, a vertically oriented port may extend through the center portions to reduce weight.

Owner:PRINCE SPORTS LLC

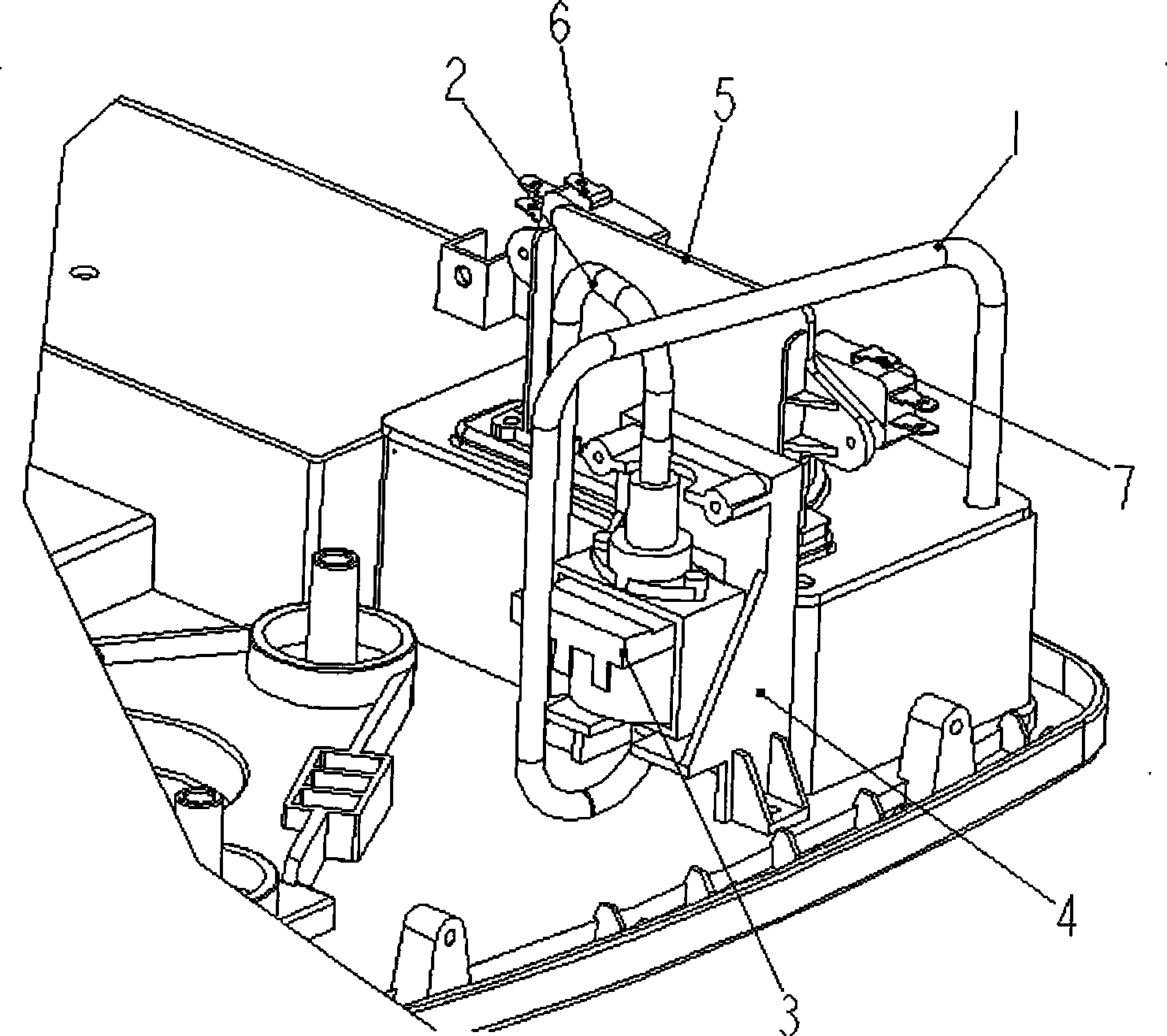

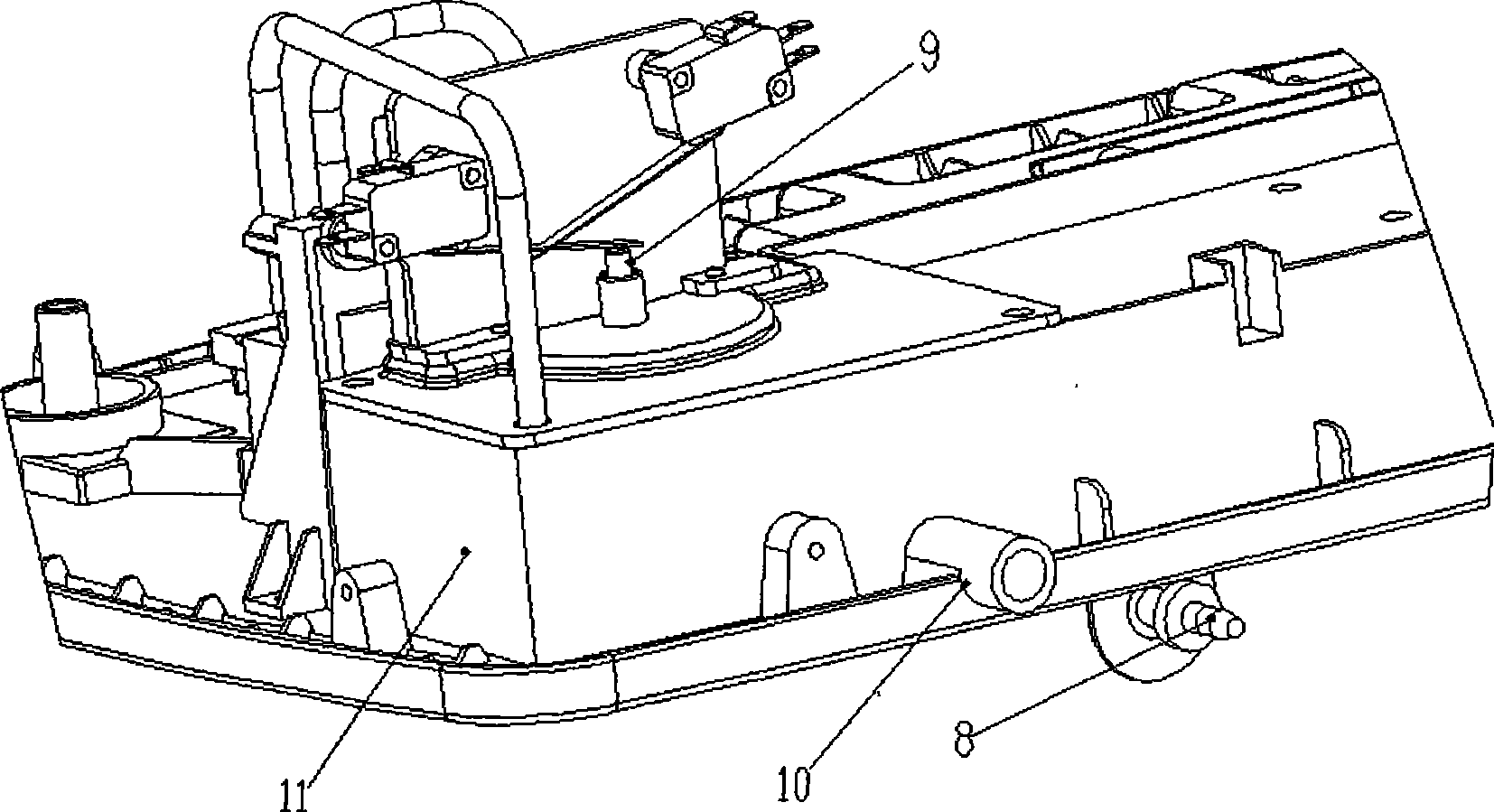

Automatic level-controlling draining dehumidifier and draining method thereof

InactiveCN101520214AReduce structure use spaceTimely exclusionCondensate preventionLighting and heating apparatusEngineeringDrainage tubes

An automatic level-controlling draining dehumidifier mainly comprises a water pump suction pipe, a water pump drainage pipe, an electromagnetic water pump, a water pump fixing cover, an inductive switch fixing part, a water fullness alarming switch, a pumping alarming switch, a drainage quick adapter assembly, a level measuring floater, a water-collecting tray, an osculum, an osculum plug, a compressor and a heat exchanger; the connection is as follows: one end of the water pump suction pipe is connected with the water-collecting tray and the other end is connected with the electromagnetic water pump; one end of the electromagnetic water pump is connected with the water pump suction pipe; the other end of the water pump drainage pipe is connected with the quick adapter assembly; the level measuring floater is arranged below the water pump fixing cover; and the water fullness alarming switch and the pumping alarming switch are fixed by the inductive switch fixing part. The draining method of the dehumidifier comprises the following steps: one electromagnetic water pump is arranged on the side surface of the water-collecting tray; when the dehumidifier is working, the condensed water is generated by the heat exchanger and falls into the water-collecting tray; the level measuring floater rises slowly under the effect of buoyancy with the increase of water quantity so as to measure the height of the water collected in the water-collecting tray; the floater firstly touches the pumping alarming switch with the rising of level and then the electromagnetic water pump starts to work; the quick adapter at the bottom of a chassis can be connected with a rubber drainage tube with length of about 5M; then the electromagnetic water pump drains the water inside the water-collecting tray out of the room through the water pump suction pipe and the water pump drainage pipe; if the floater touches the pumping alarming switch firstly but the electromagnetic water pump does not work.

Owner:NINGBO ERYE & ELECTRONICS

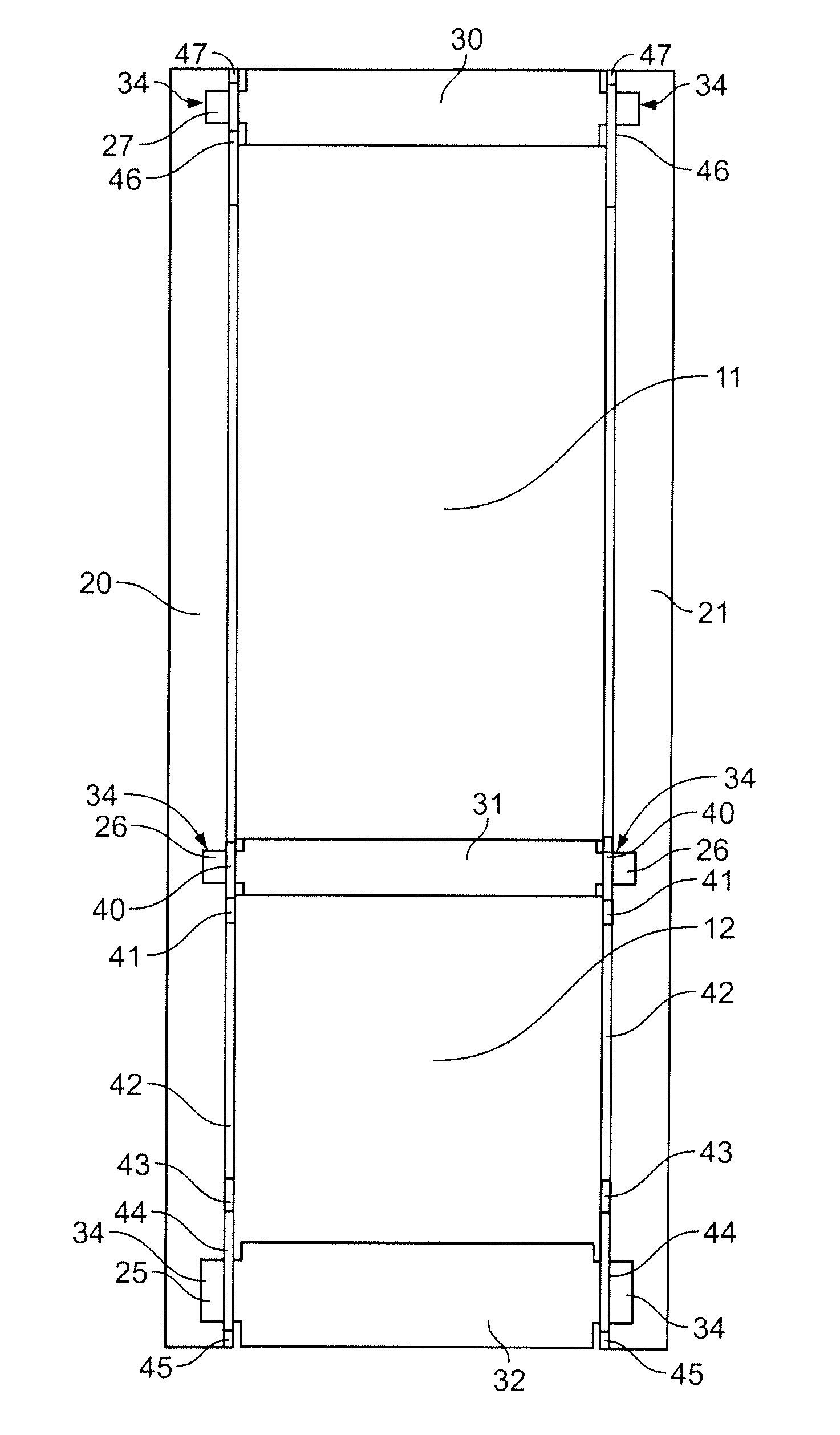

Cargo rack

ActiveUS7128225B2Minimizes cost per unitEasy to assembleFurniture partsStands/trestlesFlangeVertical path

A cargo rack utilizing a structural beam in the form of three embodiments, two of the embodiments comprising a rib, one of which includes a recessed flange and a horizontal return flange, the other includes a standard angled flange and an angled return flange, the third embodiment includes a recessed flange and a horizontal return flange, structural beams used in a framework comprising a plurality of vertical posts containing key shaped apertures and a plurality of horizontal shelving members, structural beams contain nubs enabling structural beams to connect to vertical posts via key shaped apertures thereby enabling horizontal shelving members to be associated with structural beams and vertical posts, various attachments may be added to cargo rack when recessed structural beams are used via a slight clearance that is formed between the recessed edge and a slight taper on horizontal shelving member sides.

Owner:EDSAL MANUFACTURING COMPANY INC

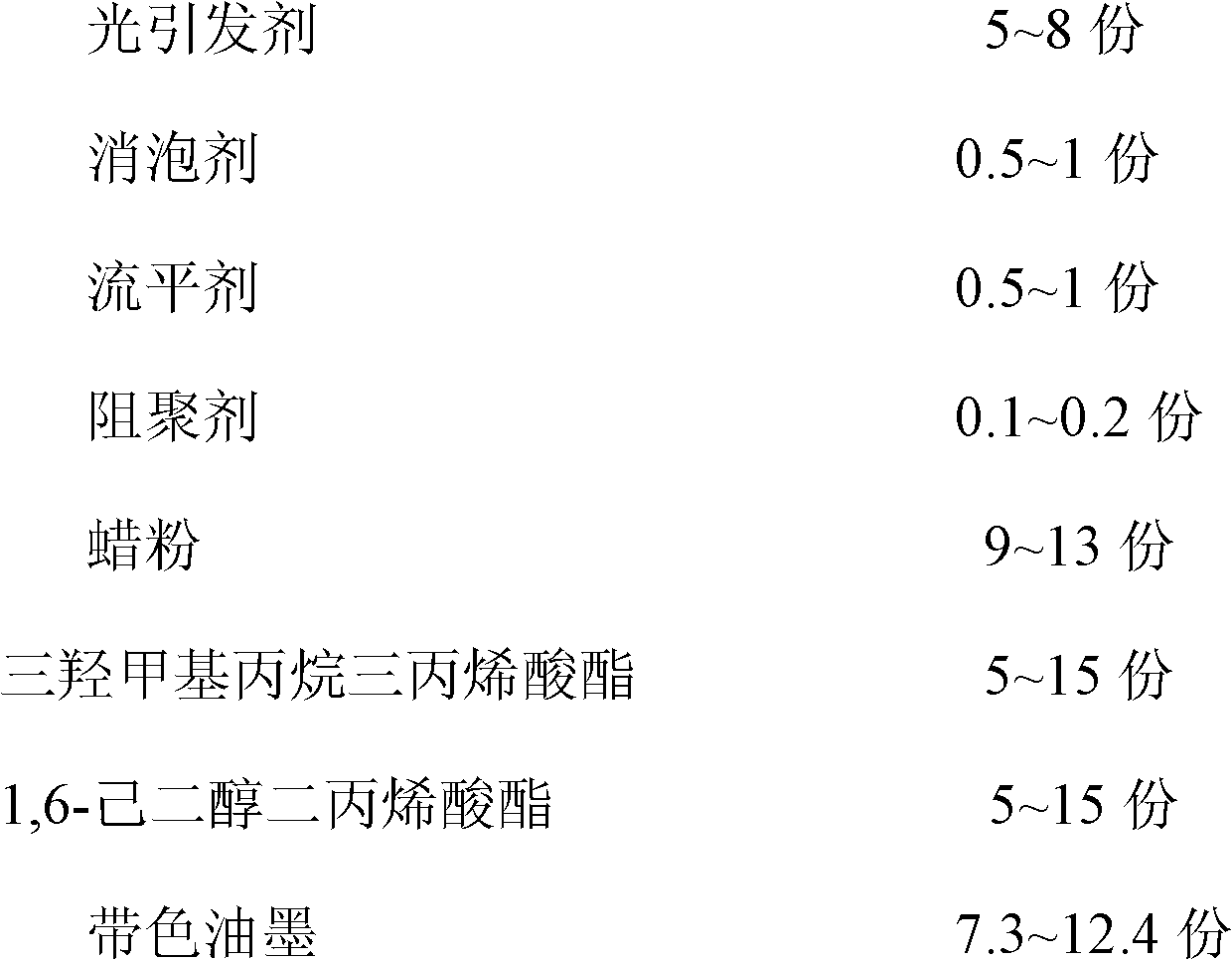

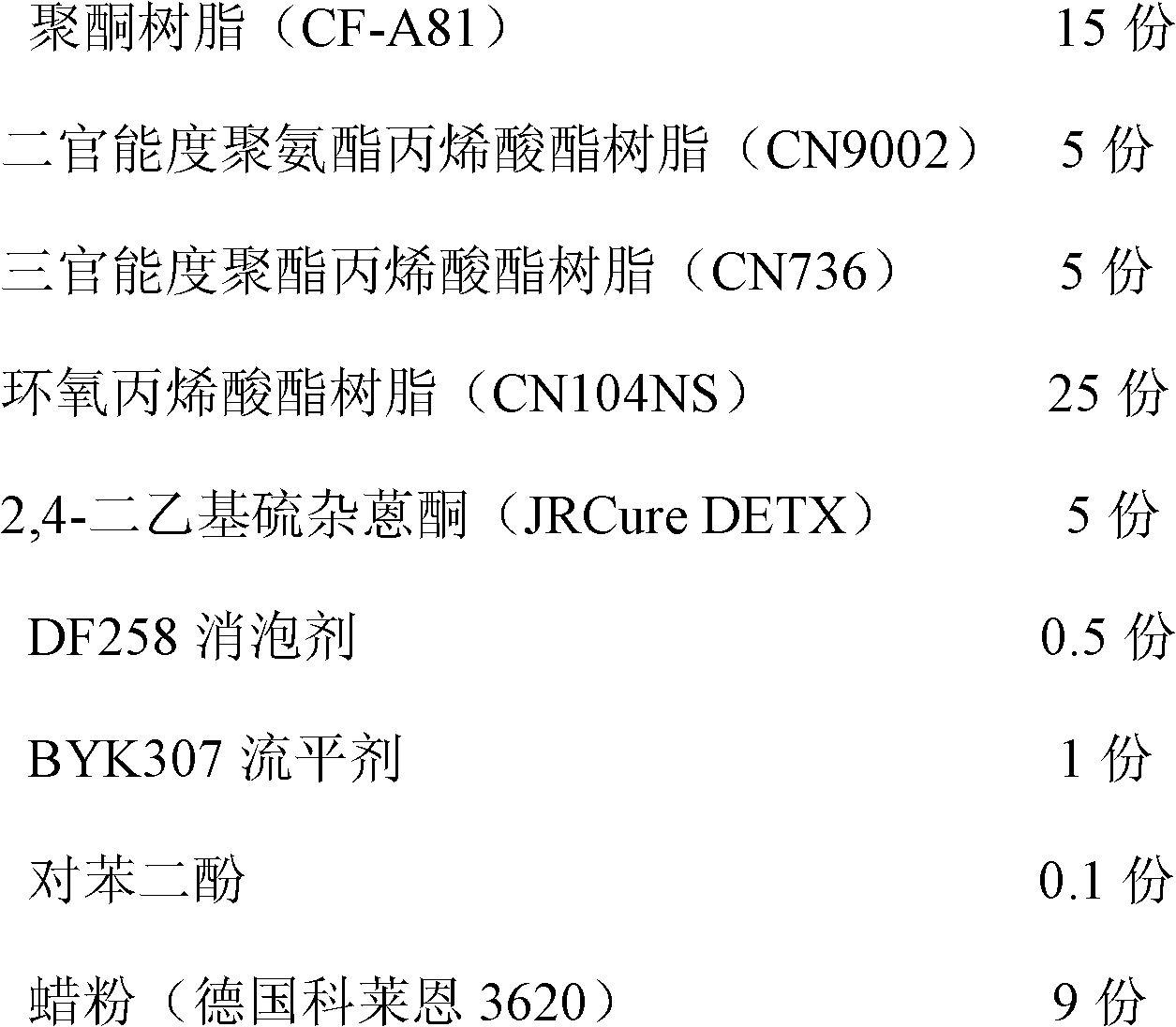

Ultraviolet light cured silk screen snowflake printing ink and preparation method thereof

The invention provides an ultraviolet light cured silk screen snowflake printing ink and a preparation method thereof. The ultraviolet light cured silk screen snowflake printing ink which has a viscosity of 1500-3000cps at the temperature of 25 DEG C is prepared by materials of 50-60 parts of ultraviolet light curable resins, 5-8 parts of photoinitiators, 0.5-1 part of defoamers, 0.5-1 part of flatting agents, 0.1-0.2 part of polymerization inhibitors, 9-13 parts of wax powders, 5-15 parts of trimethylolpropane triacrylate, 5-15 parts of 1, 6-hexanediol diacrylate and 7.3-12.4 parts of colored printing ink which are firstly subjected to a predispersion at a medium speed of 200rpm to 500rpm for 30 minutes in a disc mixer, and then subjected to a dispersion at a high speed of 3000rpm to 3500rpm for one hour. The ultraviolet light cured silk screen snowflake printing ink has the advantages that the appearance is unique, the decorative pattern is delicate, the weather resistance is good, the smell is mild, the printing ink is environment-friendly, printed products touch smooth, and the like.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

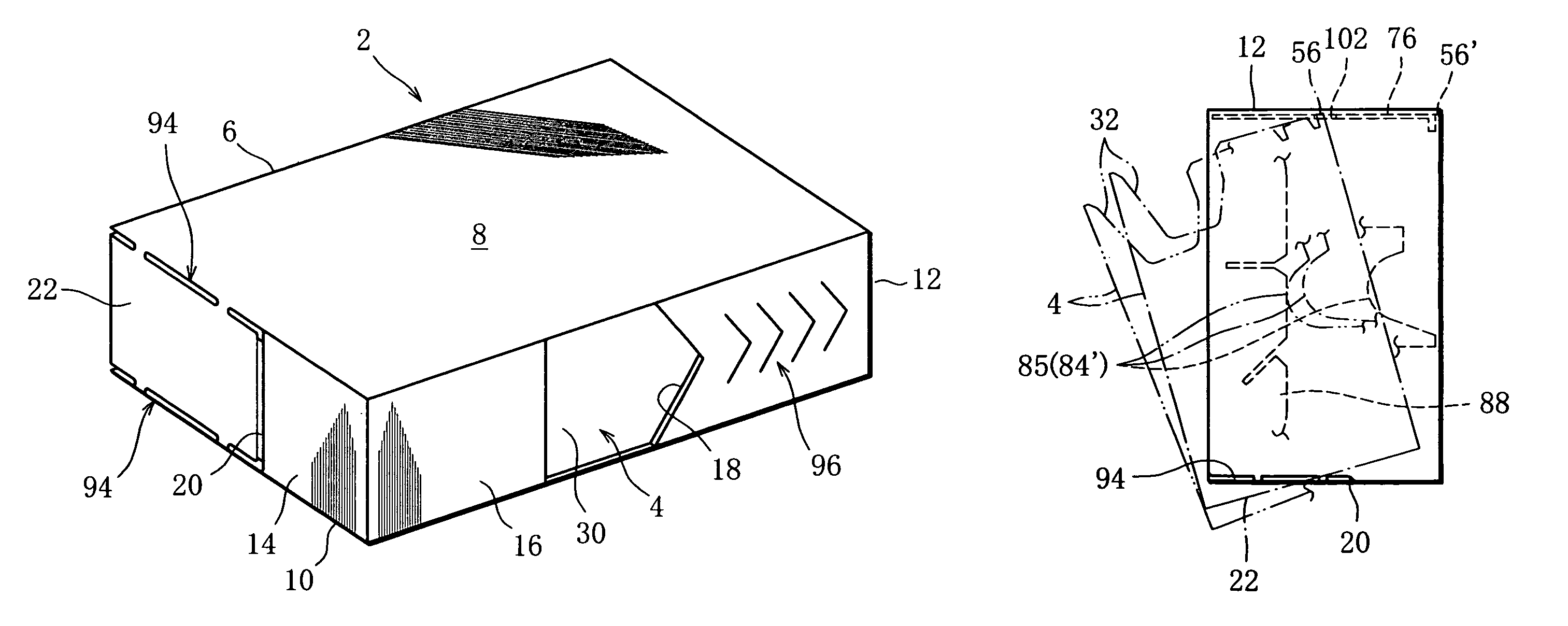

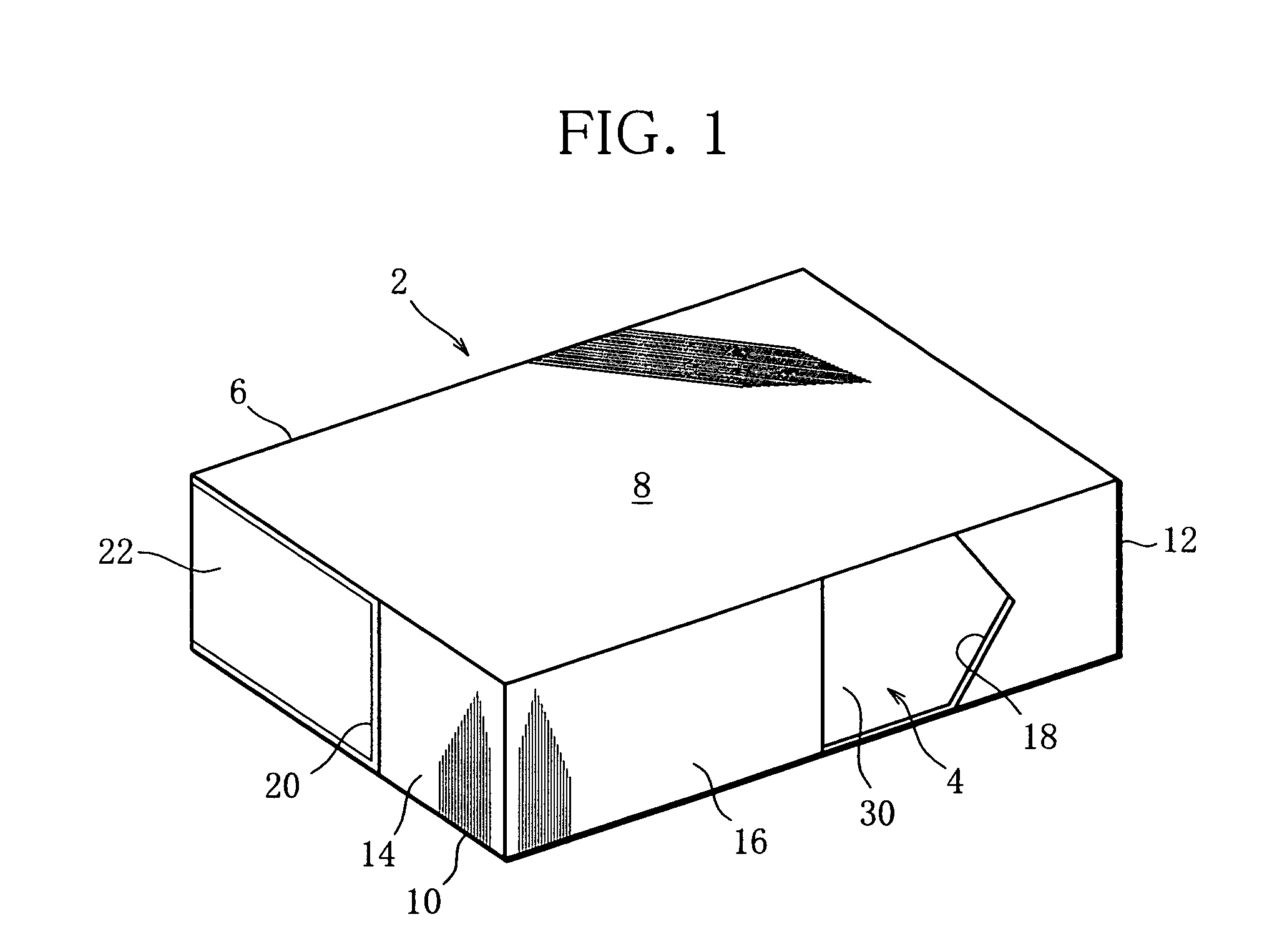

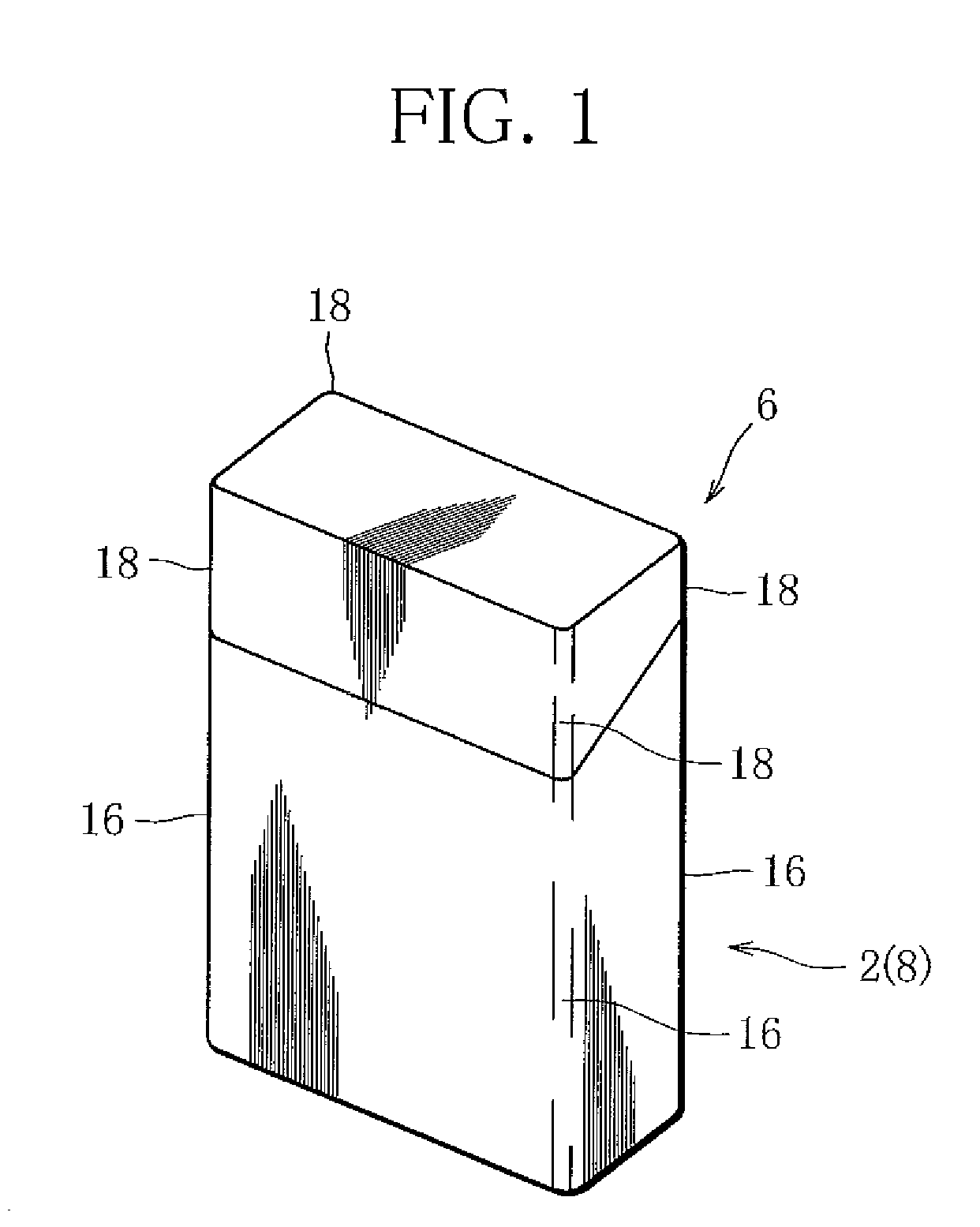

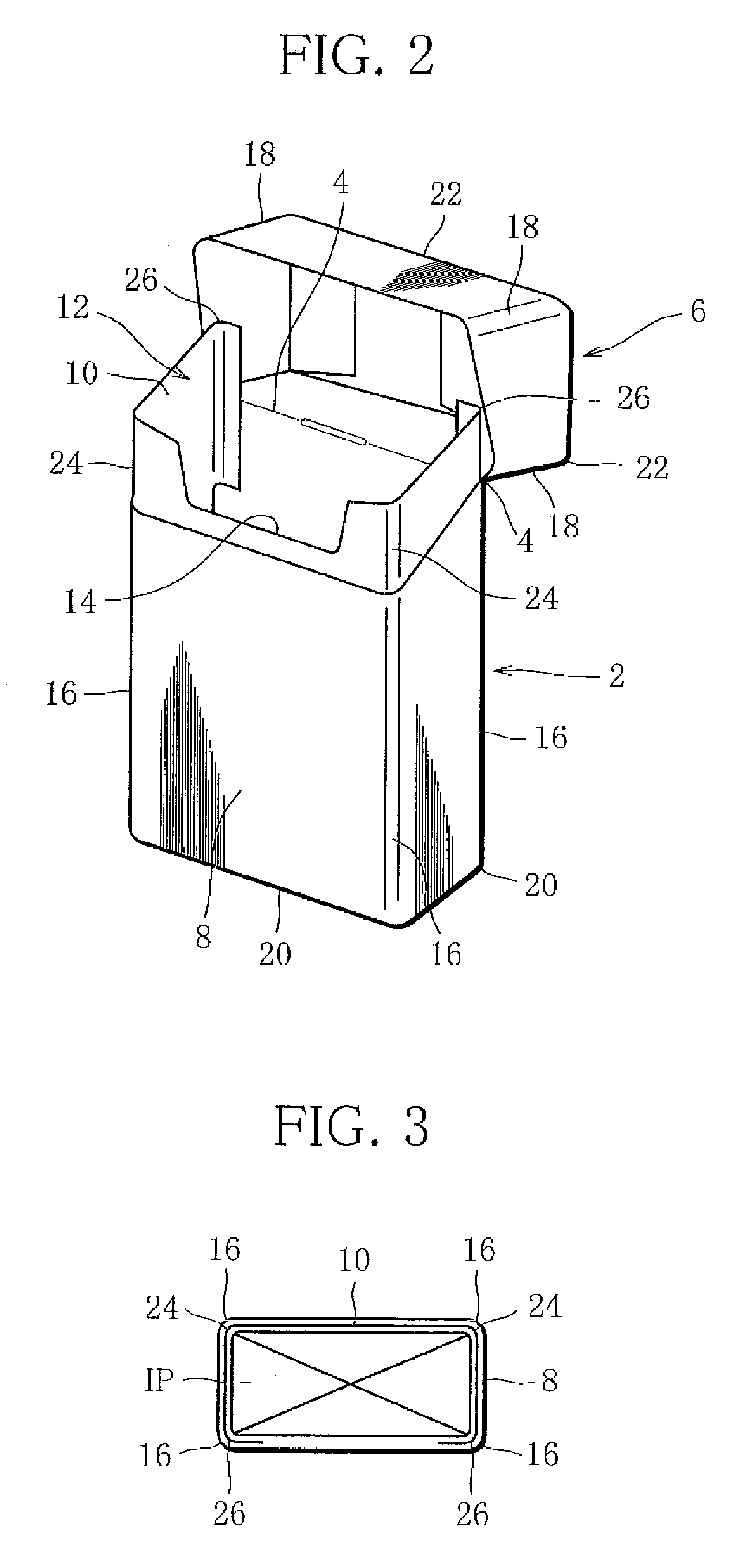

Cigarette box and a blank set therefor

ActiveUS8418845B2Increase motivationUnique appearanceContainers for flexible articlesPackaging cigaretteEngineeringCigarette pack

Owner:JAPAN TOBACCO INC

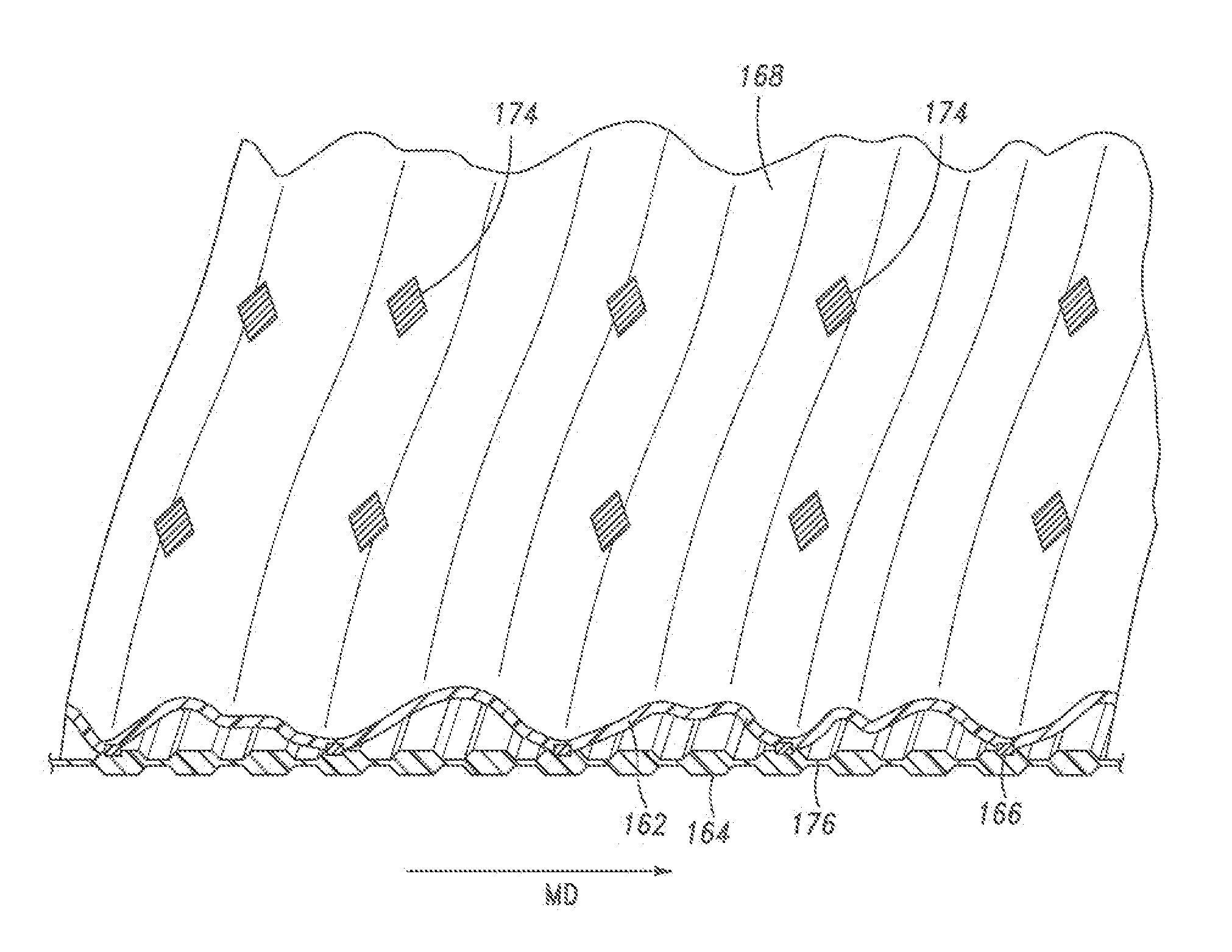

Thermoplastic Multi-Ply Film with Metallic Appearance

ActiveUS20140119679A1High strengthReduce the amount requiredWrappersDecorative surface effectsThermoplasticEngineering

Owner:THE GLAD PROD CO

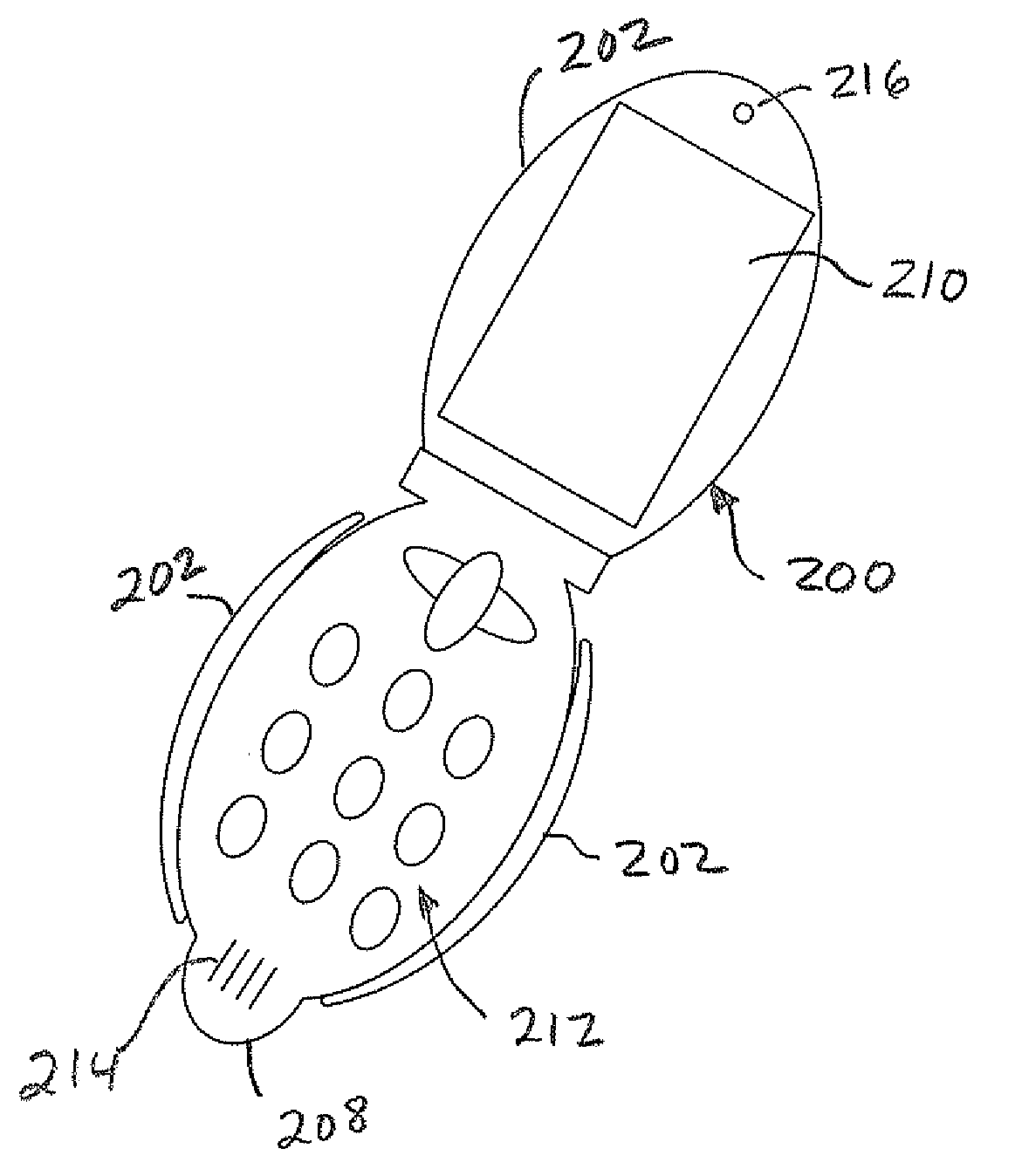

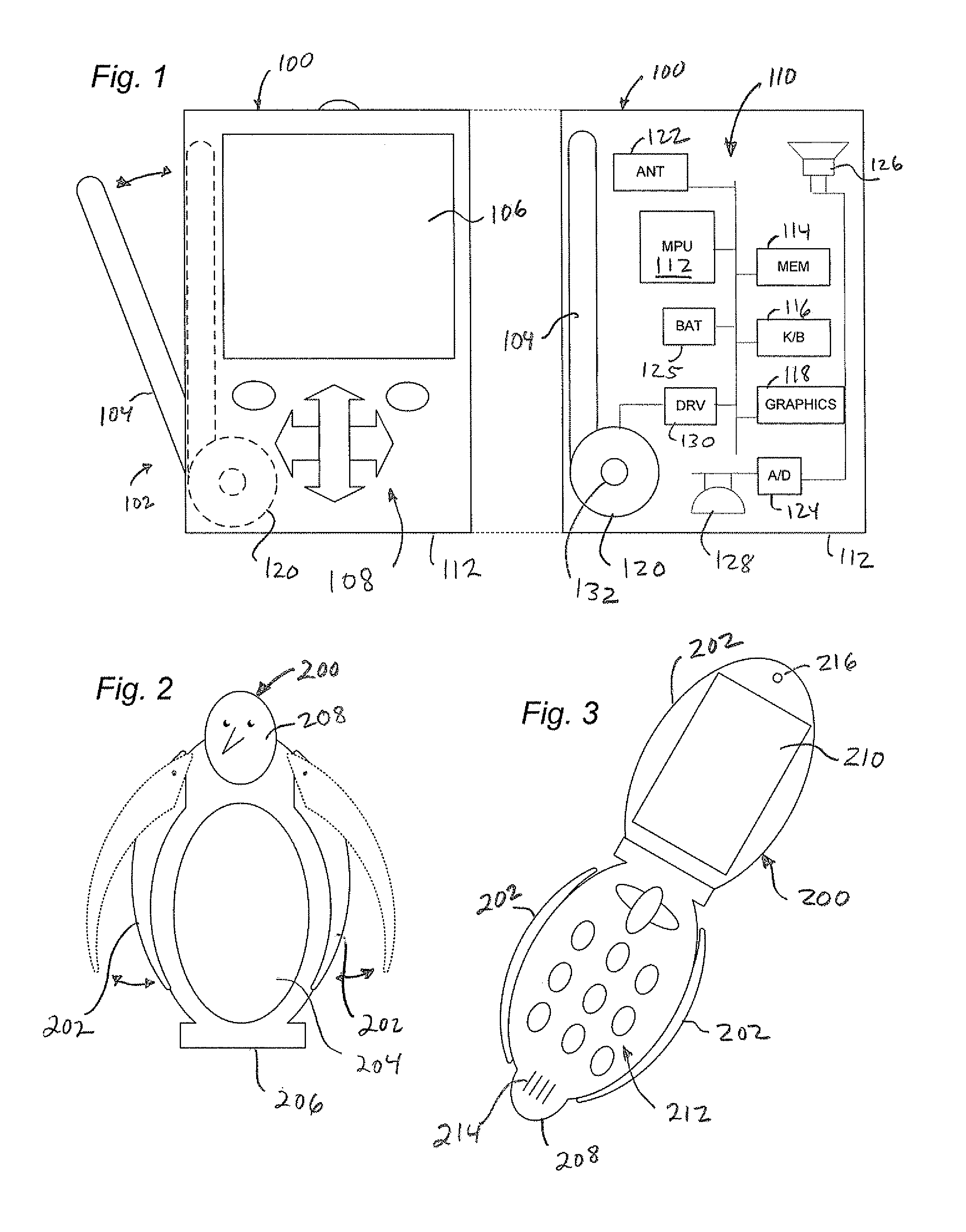

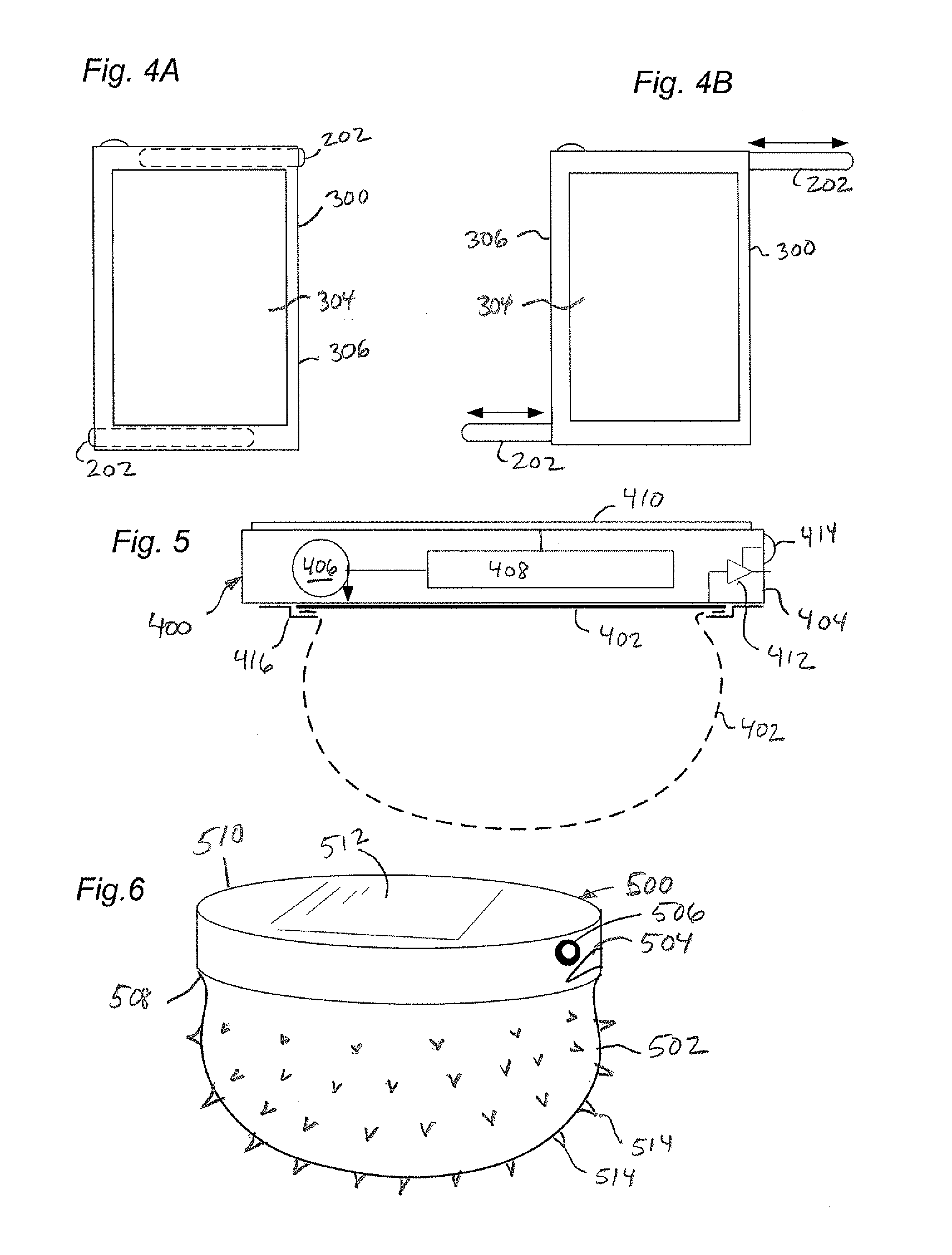

Tactile alerting mechanism for portable communications device

ActiveUS20100245062A1Optimization rangeKeep for a long timeCurrent supply arrangementsRepeater circuitsEngineeringCommunication device

A portable communications device, such as a mobile phone, includes a novel tactile alerting mechanism capable of alerting the user of an incoming communication or other event. In some embodiments, a mechanical actuator causes a rod or lever to pulsate, rotate, or protrude out of a static housing for the communications device. In other embodiments, a pneumatic actuator inflates a bladder that protrudes out of the housing. The alerting mechanism may be configured as a movable part of a decorative fanciful housing for the communications device.

Owner:SHUSTER GARY STEPHEN

Thermoplastic multi-ply film with metallic appearance

ActiveUS8865294B2High strengthReduce the amount requiredWrappersDecorative surface effectsThermoplasticEngineering

Owner:THE GLAD PROD CO

Coating composition, preparation method and application thereof

InactiveCN101531853AImprove wear resistanceImprove anti-corrosion performancePretreated surfacesCoatingsVinyl etherImide

The invention relates to a coating composition, a preparation method and an application thereof. The coating composition comprises (a) priming paint which consists of (i) fluor resin, (ii) inorganic filler and (iii) bonding resin, and (b) surface layer coating. The fluor resin is selected from polytetrafluoroe thylene resin, tetrafluoroethylene-perfluorinated alkey vinye copolymer, fluorinated ethylene propylene copolymer and combinations thereof, with a content of 30 to 70 parts by weight, calculated by the total solid weight of the priming paint; the inorganic filler has a grain size of 0.1 to 50 microns and a content of 5 to 30 parts by weight, calculated by the total solid weight of the priming paint; the bonding resin is selected from daiamid-imide copolymer, polyimide, polyphenylene sulfide, polyethersulfone and combinations thereof, with a content of 10-40 parts by weight, calculated by the total solid weight of the priming paint; the surface layer coating comprises (i') tetrafluoroethylene-perfluorinated alkey vinye copolymer with a content of 80-100 parts by weight, calculated by the total solid weight of the surface layer coating; (ii') assisted film forming organic resin with a content of 0-20 parts by weight, calculated by the total solid weight of the surface layer coating; and (iii') mica flashlight powder with a content of 0-3 parts by weight, calculated by the total solid weight of the surface layer coating.

Owner:科慕有限公司

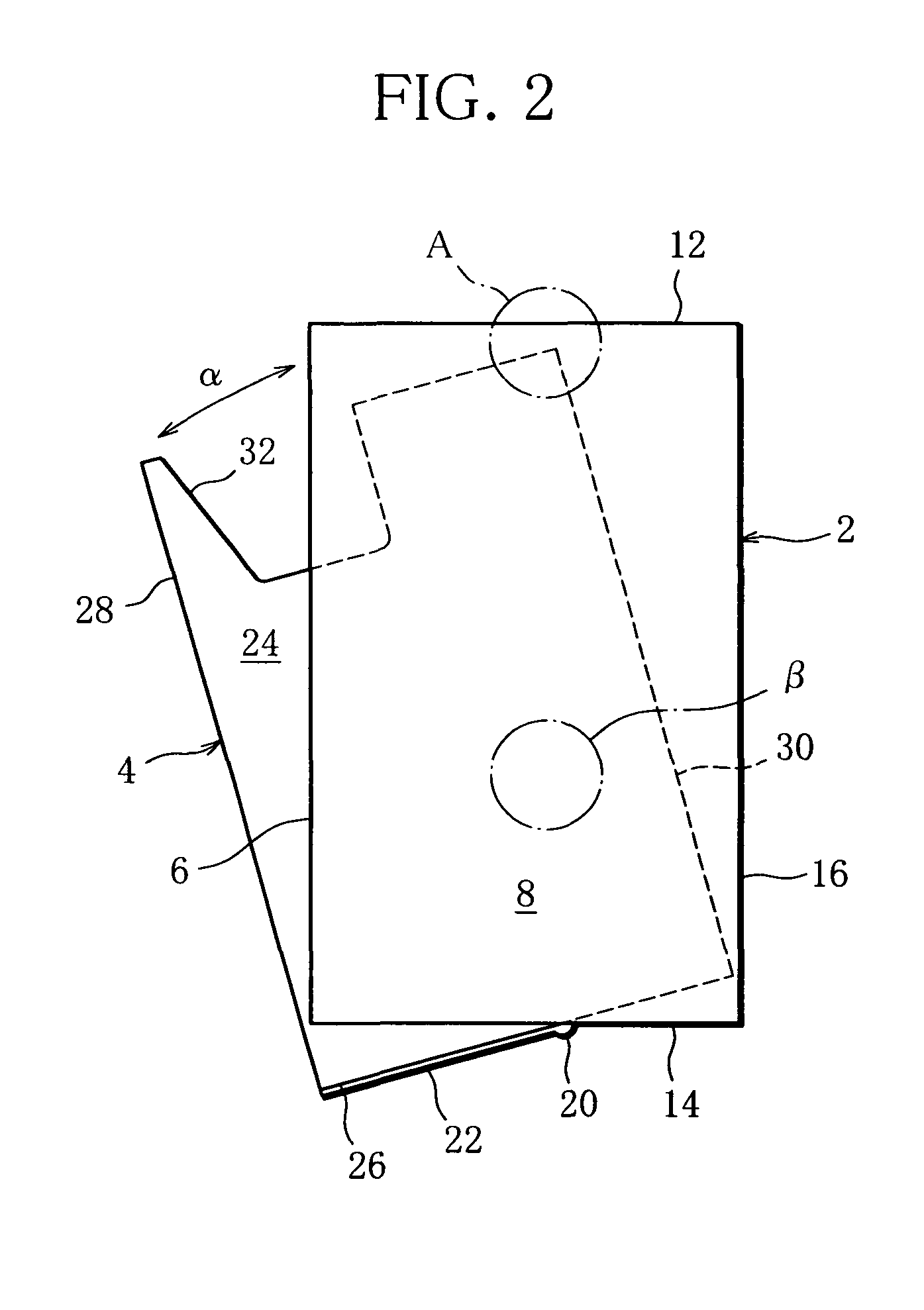

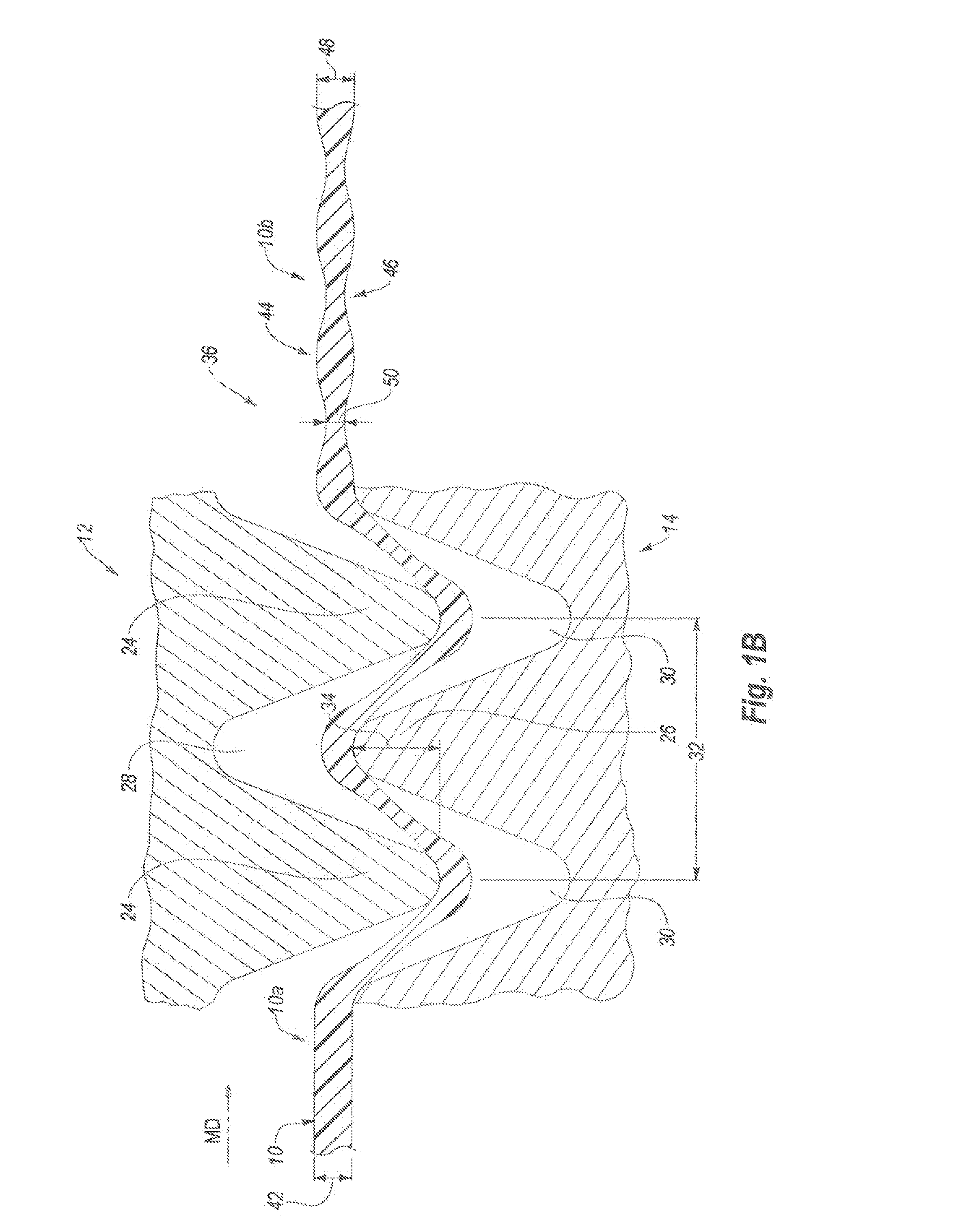

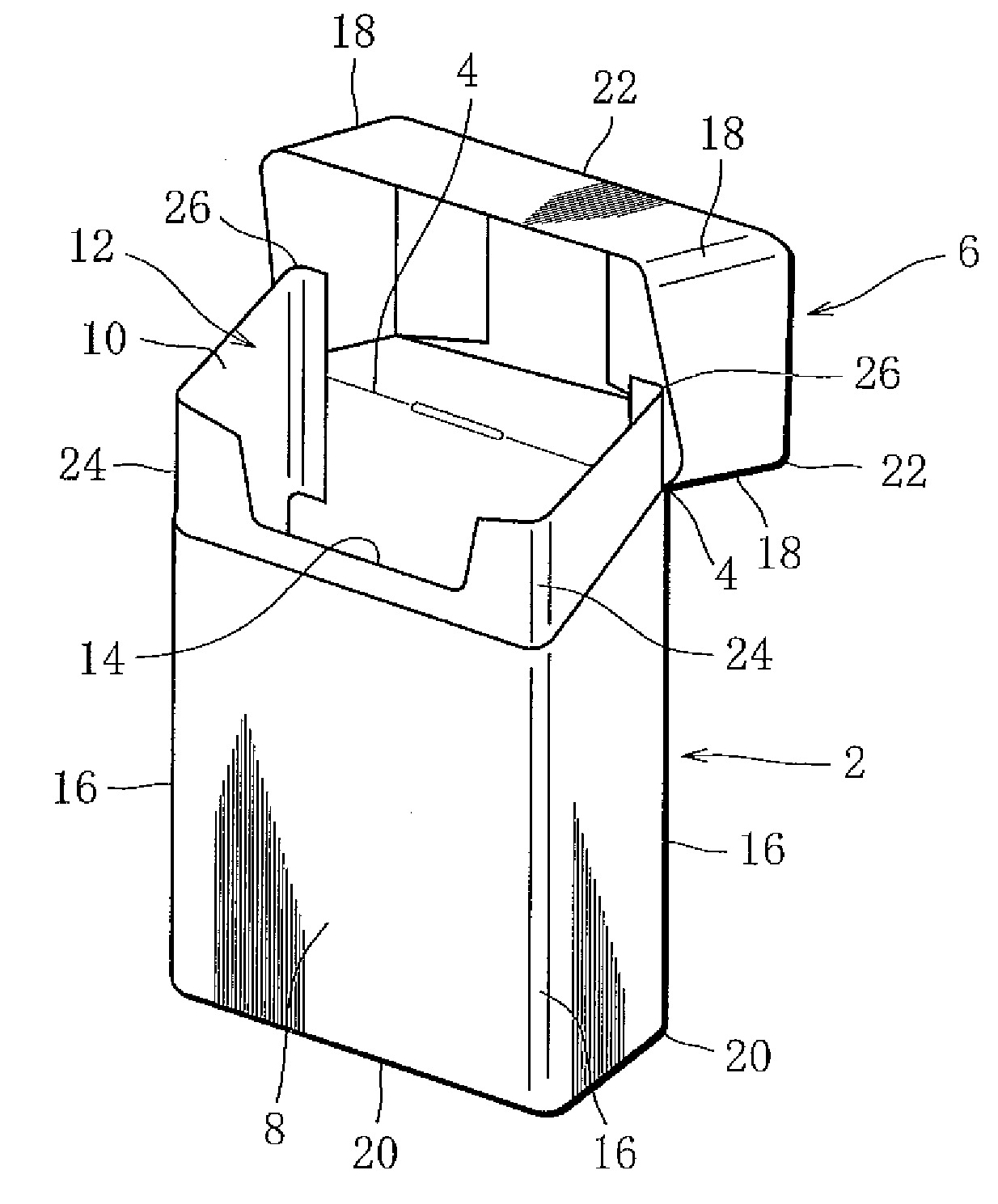

Package of rod-shaped smoking articles and a blank therefor

ActiveUS20090078599A1Unique appearanceGood lookingContainers for flexible articlesMechanical working/deformationEngineeringMechanical engineering

A hinged-lid package of filter cigarettes has a box (2) with an inner frame (10) and a lid (6) that opens / closes the box (2). Four corner edges of the box (2) which extend in the longitudinal direction of the box (2), are formed into longitudinal edges (16) having an arc-like shape in cross section of the box (2). The arc-like shape of the longitudinal edges (16) is formed with a plurality of longitudinal grooves made only in the inner surface of the box (2). The package has a reinforcement patch (64) arranged in the box (2) across the longitudinal grooves.

Owner:JAPAN TOBACCO INC

Multi-Layered Color-Enhancing Nail Applique

ActiveUS20100212681A1Unique textureUnique appearanceCurling devicesManicure/pedicureComputer scienceSemi transparent

A thy nail polish appliqué to be applied to a fingernail. The nail appliqué has several layers. A bottom layer hides the color of the natural nail upon which the appliqué is applied. A top layer of a different color is applied on top of the color-hiding layer. The color of the top layer is, as such, uninfluenced by the natural nail color and it therefore appears sharp and crisp. The top layer could be of a translucent quality such that the top layer and bottom layer visually combine to produce a unique appearance

Owner:PARK FA YOUNG

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

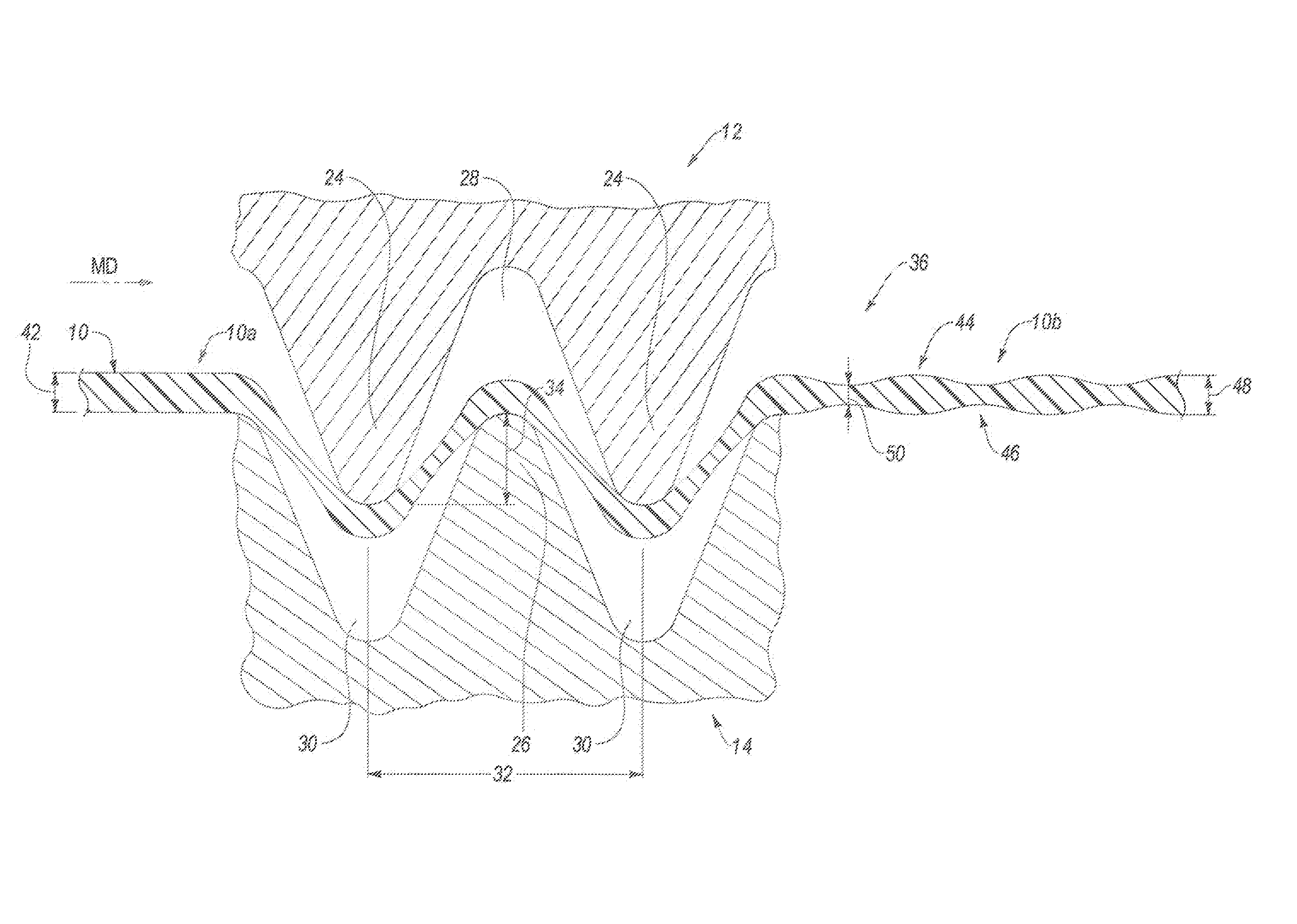

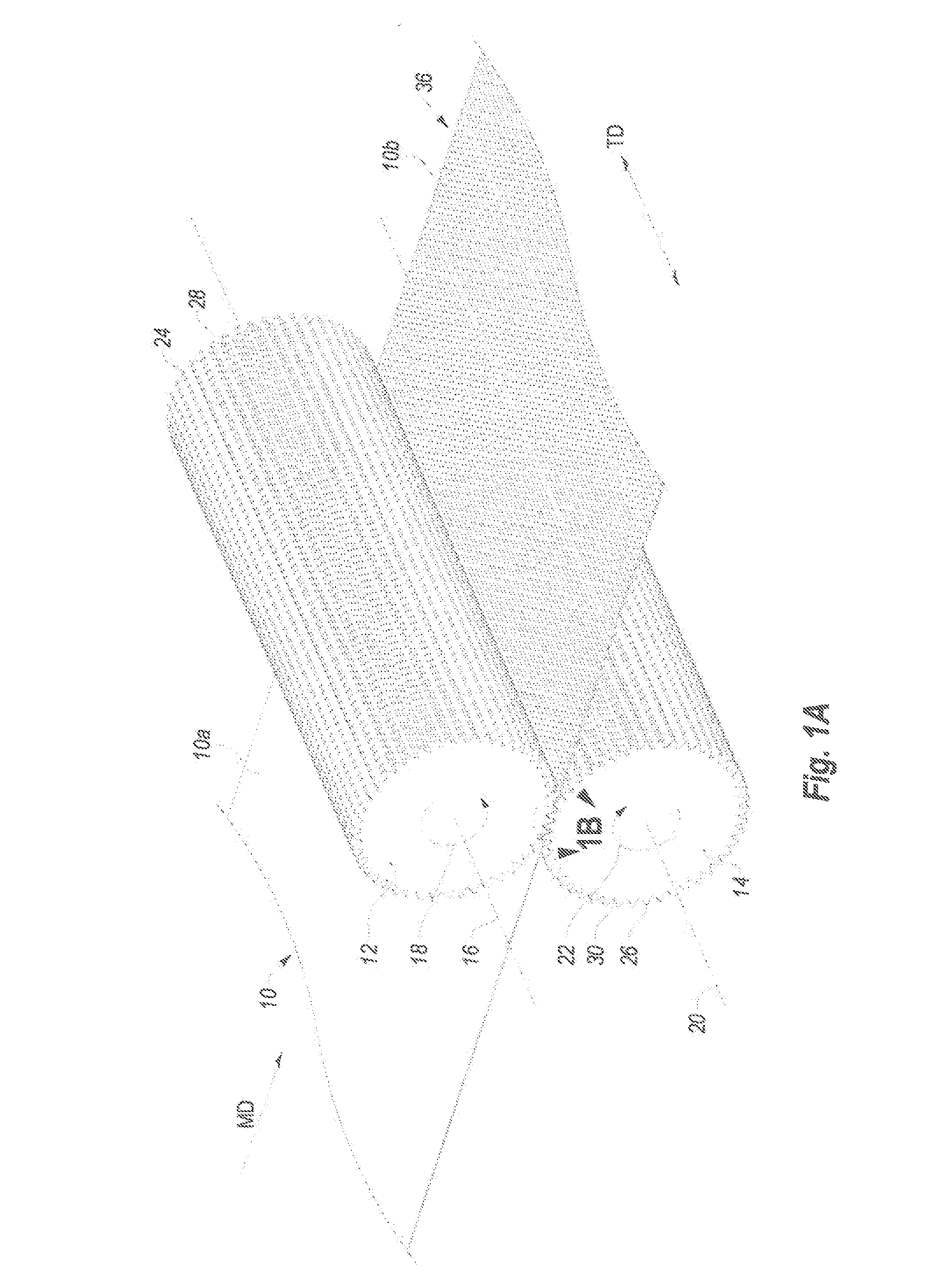

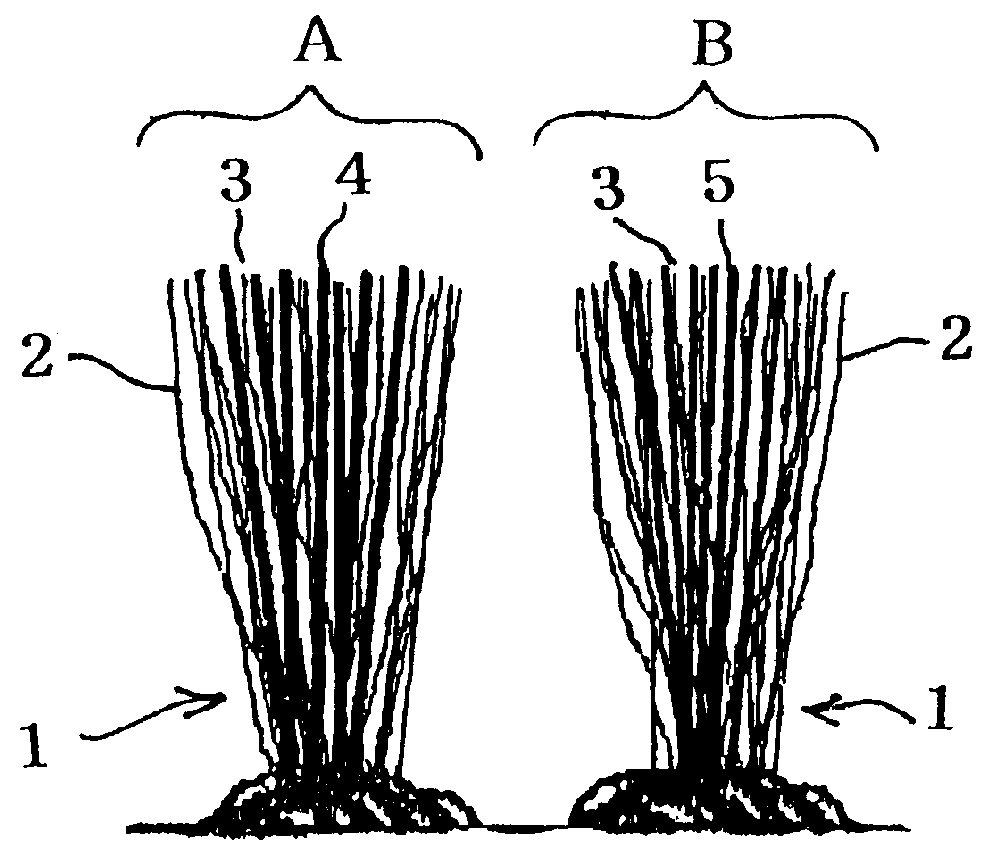

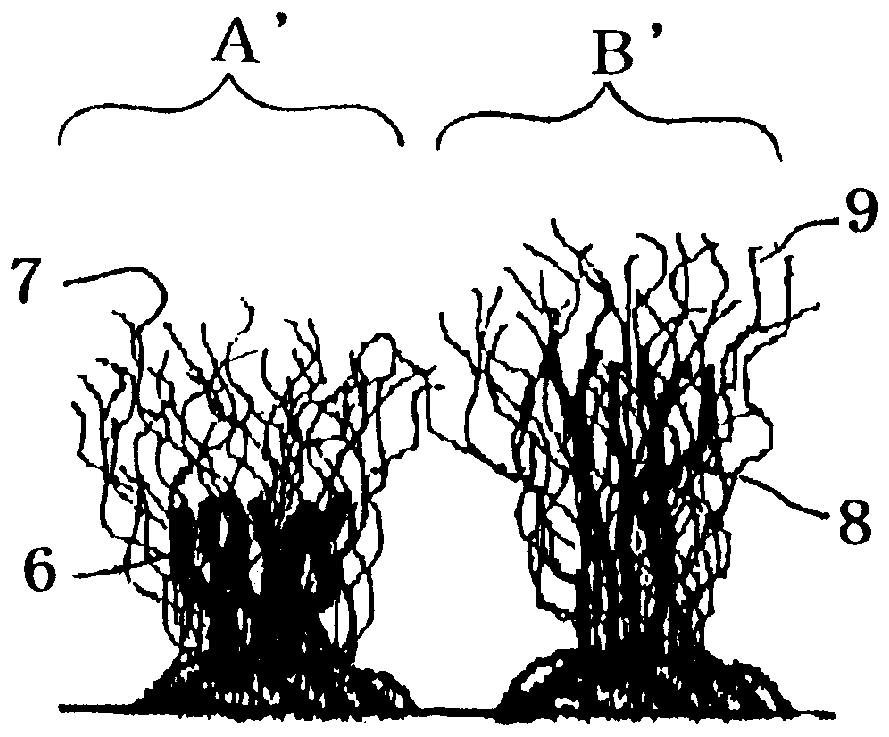

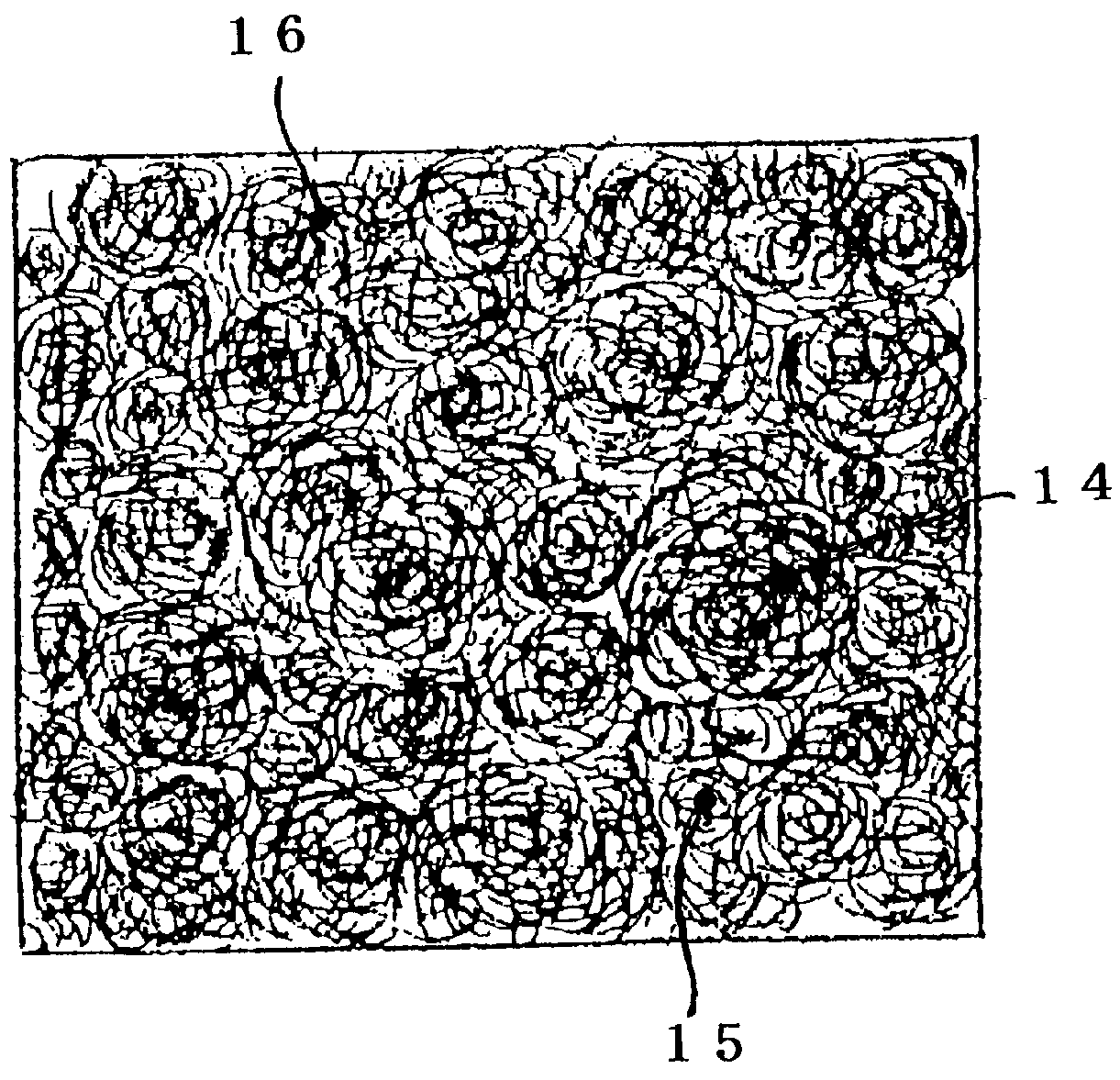

High and-low piles-revealing cut pile fabric cut pile fabric, having rugged surface with snarled piles and process for producing same

InactiveUS6076242AUnique surface appearanceRough surfaceWeft knittingPattern makingEngineeringHeat treated

PCT No. PCT / JP97 / 04581 Sec. 371 Date Aug. 13, 1998 Sec. 102(e) Date Aug. 13, 1998 PCT Filed Dec. 12, 1997 PCT Pub. No. WO98 / 26119 PCT Pub. Date Jun. 18, 1998A cut pile fabric with substantially vertically standing tufts made of a synthetic multifilament yarn which is an intermingled yarn comprised of (a) a crimped multifilament yarn and (b) a non-crimped highly heat-shrinkable multifilament yarn having a heat shrinkage larger than that of the crimped multifilament yarn (a), and having thick portions and thin portions, alternately occurring along the length of each constituting filament of the yarn (b), said thick portions having a heat shrinkage larger than that of said thin portions. When heat-treated, the cut pile fabric provides a high-and-low cut pile fabric having a unique appearance. Especially when tip portions of cut piles of the crimped multifilament yarn (a) are entangled with each other, a cut pile fabric having a rugged surface with lumps of snarled piles is obtained.

Owner:TEIJIN LTD

Synthetic method of titanium dioxide self-assembled particles

The invention discloses a synthetic method of titanium dioxide self-assembled particles. According to the synthetic method, water is taken as a solvent, TiCl4 or an organic alkanol titanium oxide is taken as a titanium oxide precursor, an alkylammonium hydroxide is added as a protective agent, and cauliflower-shaped and rod-shaped titanium dioxide nanoparticles are synthesized via hydrothermal method. The synthetic method is simple; synthetic conditions are not strict; operation is simple; the prepared titanium dioxide nanoparticles possess cauliflower-shaped or rod-shaped appearance, and a structure which is formed via self-assembly of titanium dioxide nanowires along an axial direction. The synthesized titanium dioxide possesses relatively high photocatalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

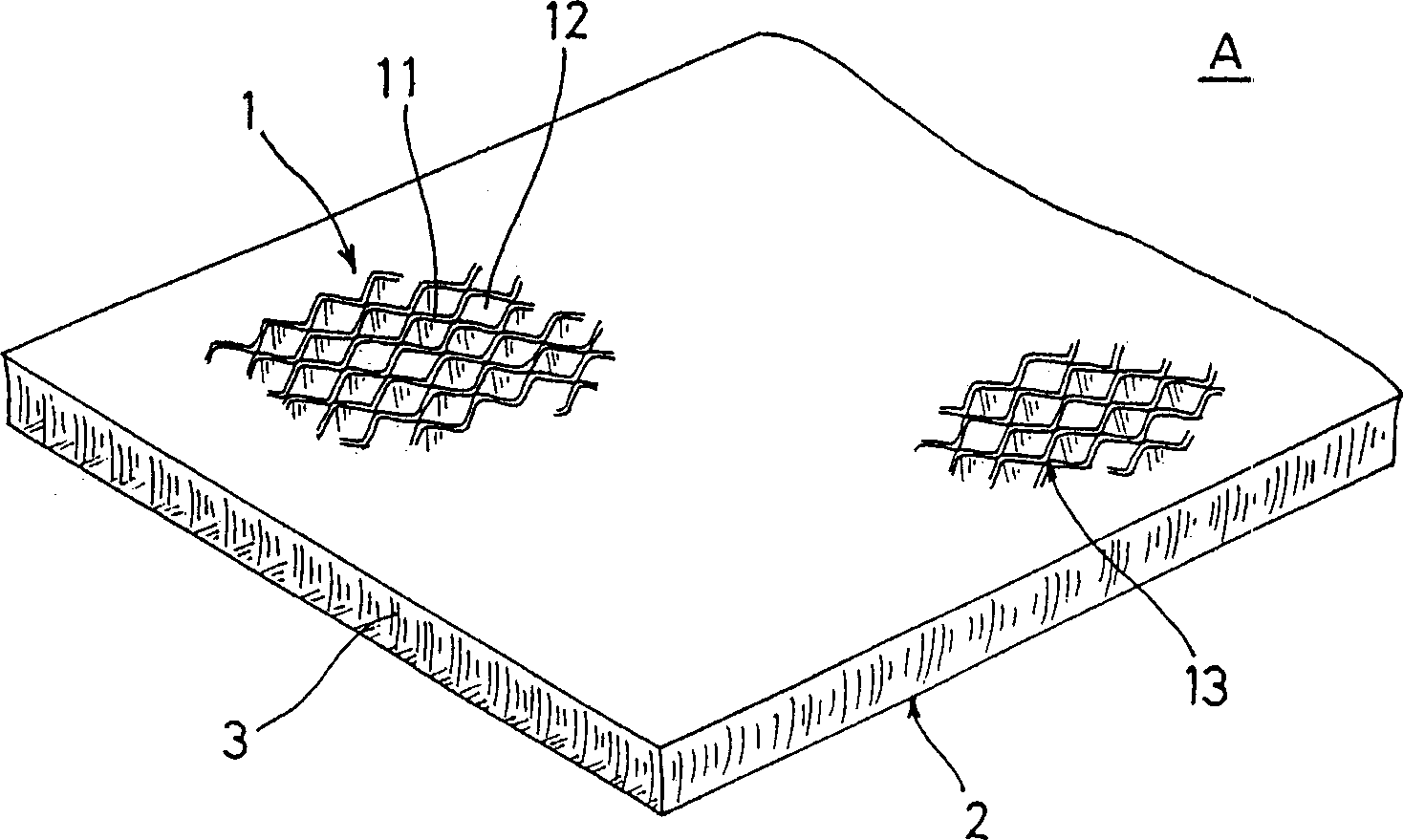

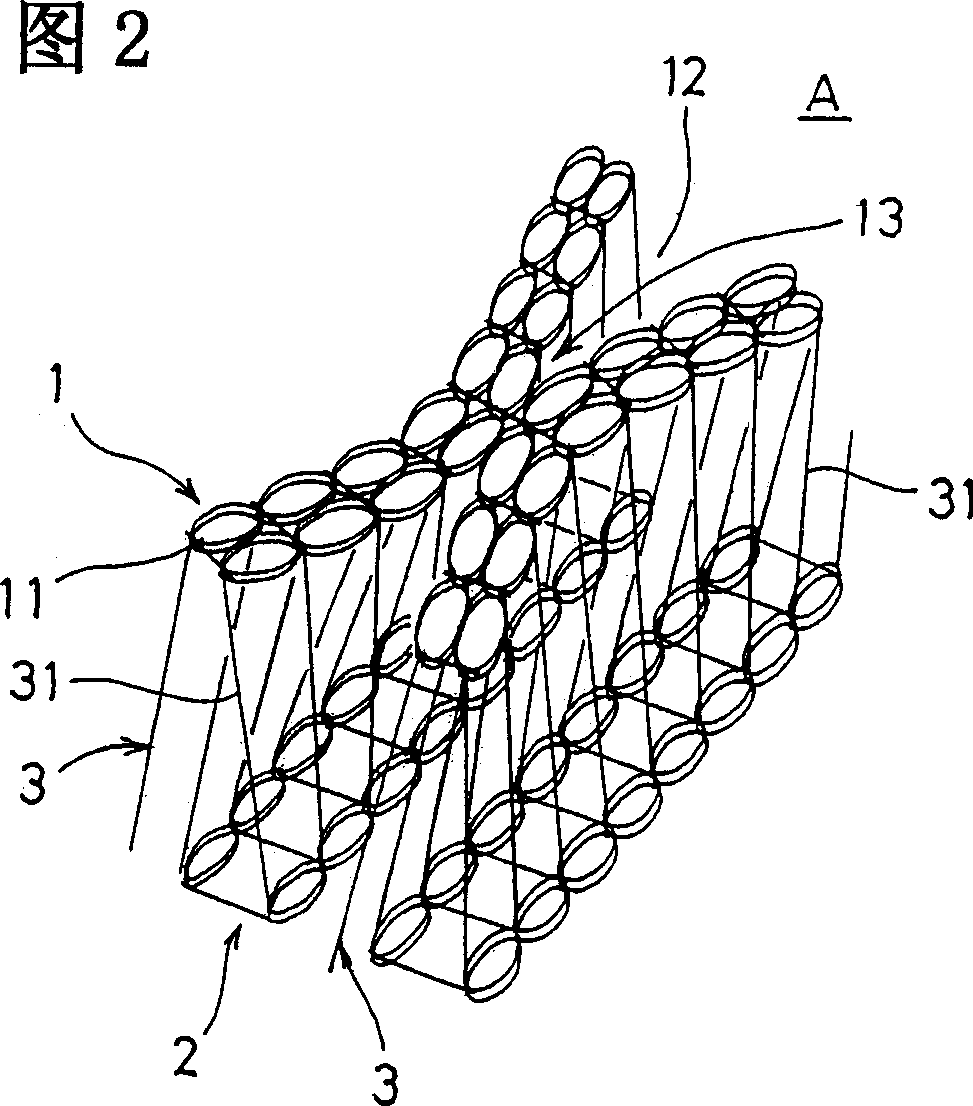

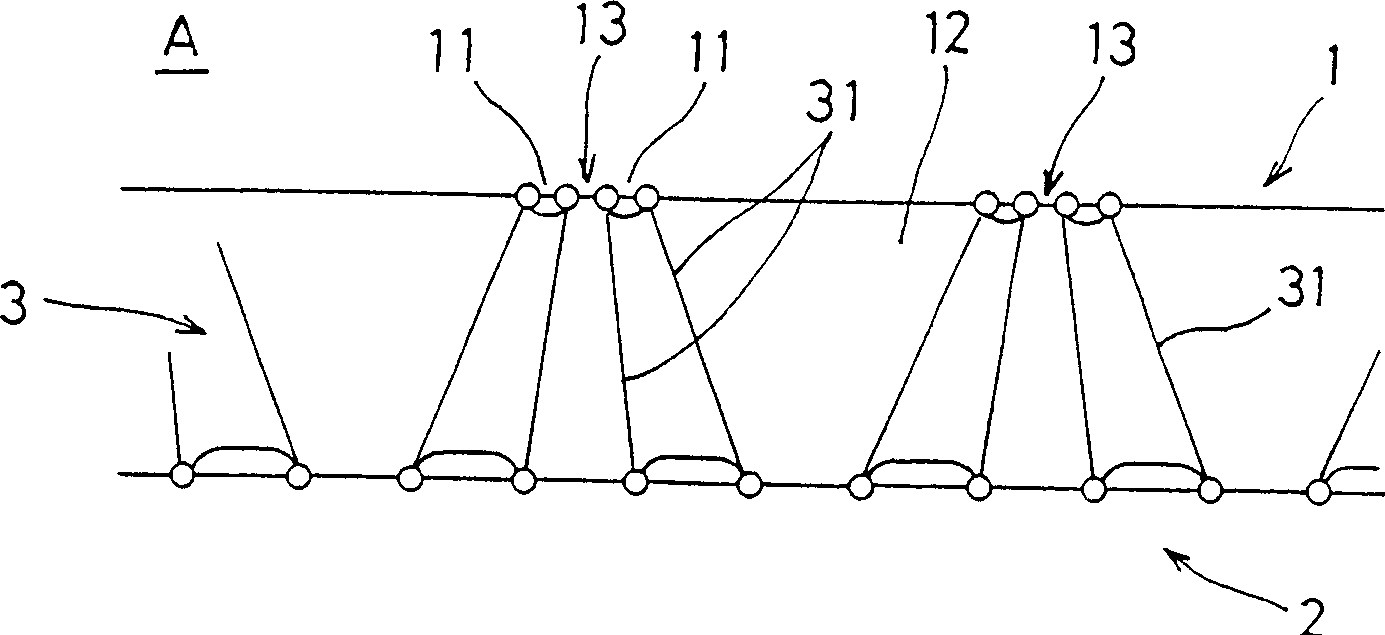

Double knitted fabric

InactiveCN1404539AGood touchImprove appearance qualityOrnamental textile articlesWarp knittingEngineeringLinearity

The invention is aimed to provide a three-dimensional marquisette-like knitted fabric that is good in air retainability, air and water conductibility, light transmittance, as well as dimensional stability and shape retainability in the knitting and knitting-width directions, and in linearity; and has unevenness and slippage preventing property on its surface, thus being suitable in various uses. To this end, a three-dimensional marquisette-like structure is made as follows. A double-web knitted fabric is made by warp knitting, and is preferably comprised of the front and back mesh webs (1, 2) and connecting yarns (3) passed between the mesh webs alternately. At least one of the mesh webs (1, 2) has a marquisette-like construction formed by the rows of chain stitches (11, 21) and inlay yarn (5). In addition, connecting yarns (3) for connecting the mesh webs (1, 2) is shifted knitting-width-wise by at least one wale to be passed as slanted at every required course position corresponding to the marquisette-like construction of at least one of the mesh webs.

Owner:ASAHI DOKEN

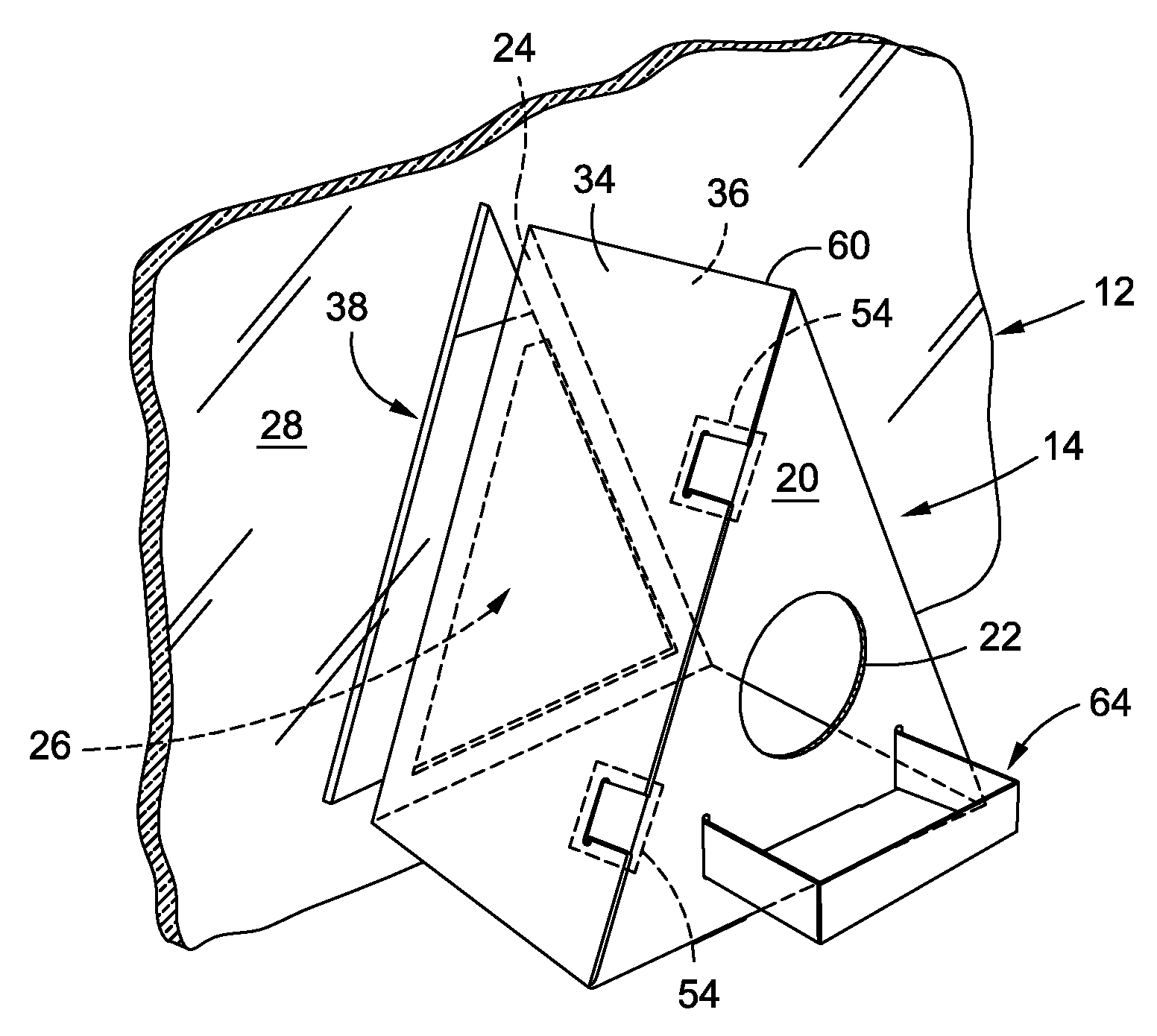

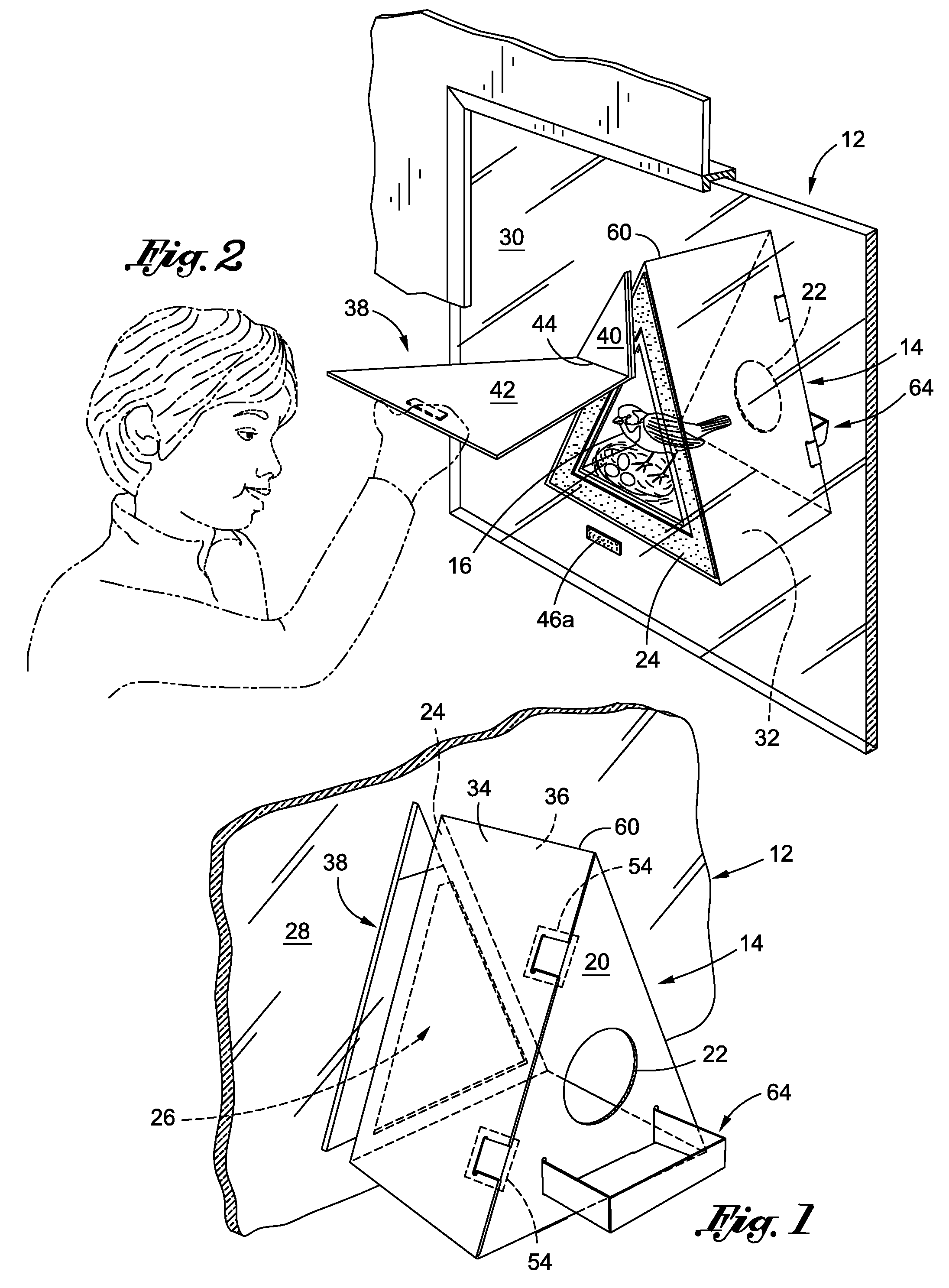

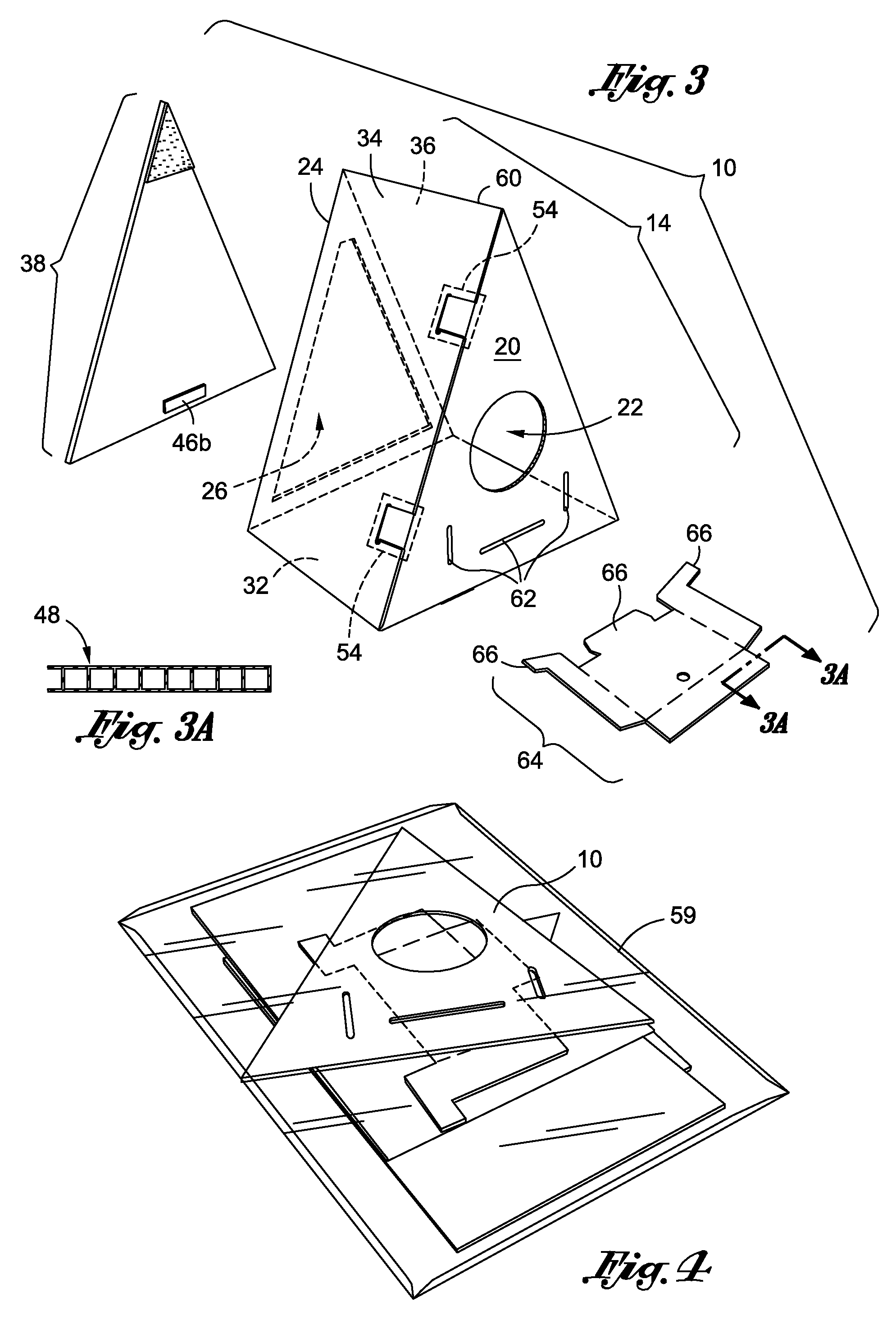

Window Bird House

InactiveUS20100175630A1Conveniently attach to windowEasy to assembleBird housingsEngineeringPlastic film

A window bird house is advantageously configured for easy transport and storage, and is a low cost alternative to prior art bird houses. The window bird house includes a housing having a plurality of walls and a floor which are collapsible upon each other for compact transport and storage. One of the walls includes a viewing opening for observing birds in the housing. Additionally, the rear wall may be removably secured to a first side of a window so that inside of the housing is visible from a second side of the window. Also, one of the walls includes an opening for ingress and egress of birds. A cover may be attached to the second side of the window for selecting covering the viewing opening thereby mitigating disruptions to the birds. The window bird house may be fabricated from die cut corrugated plastic sheet.

Owner:STETABON MICHAEL A

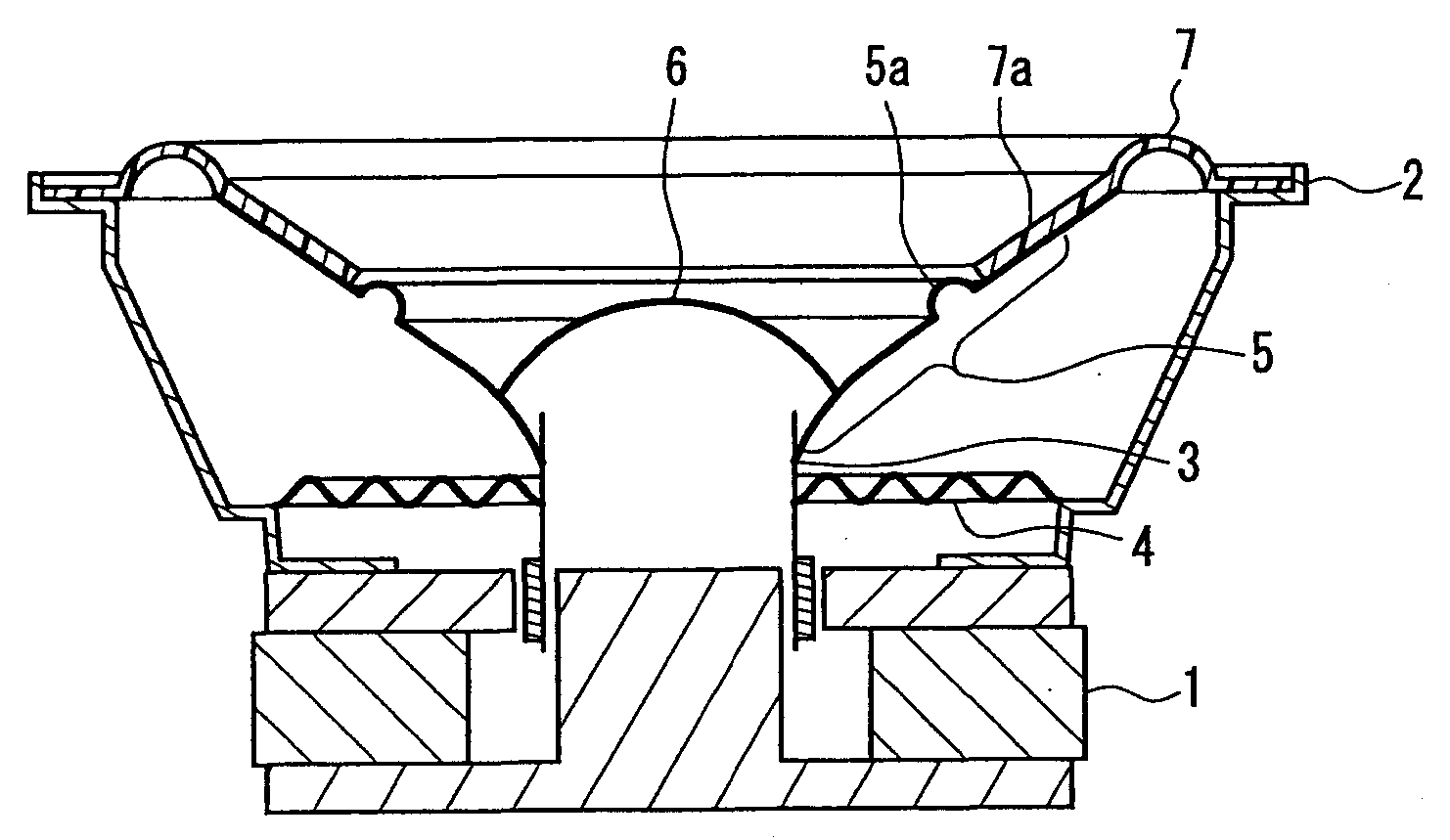

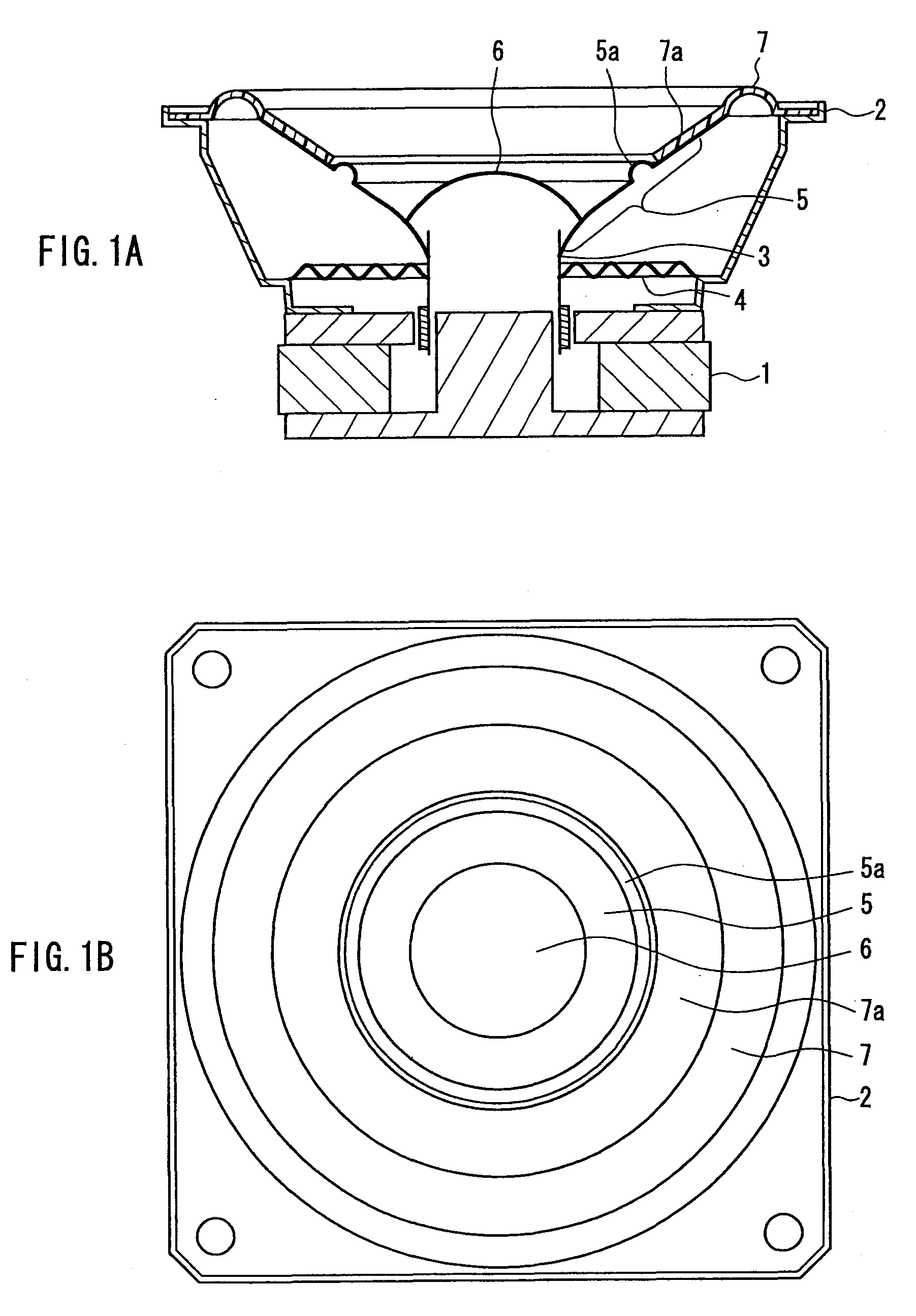

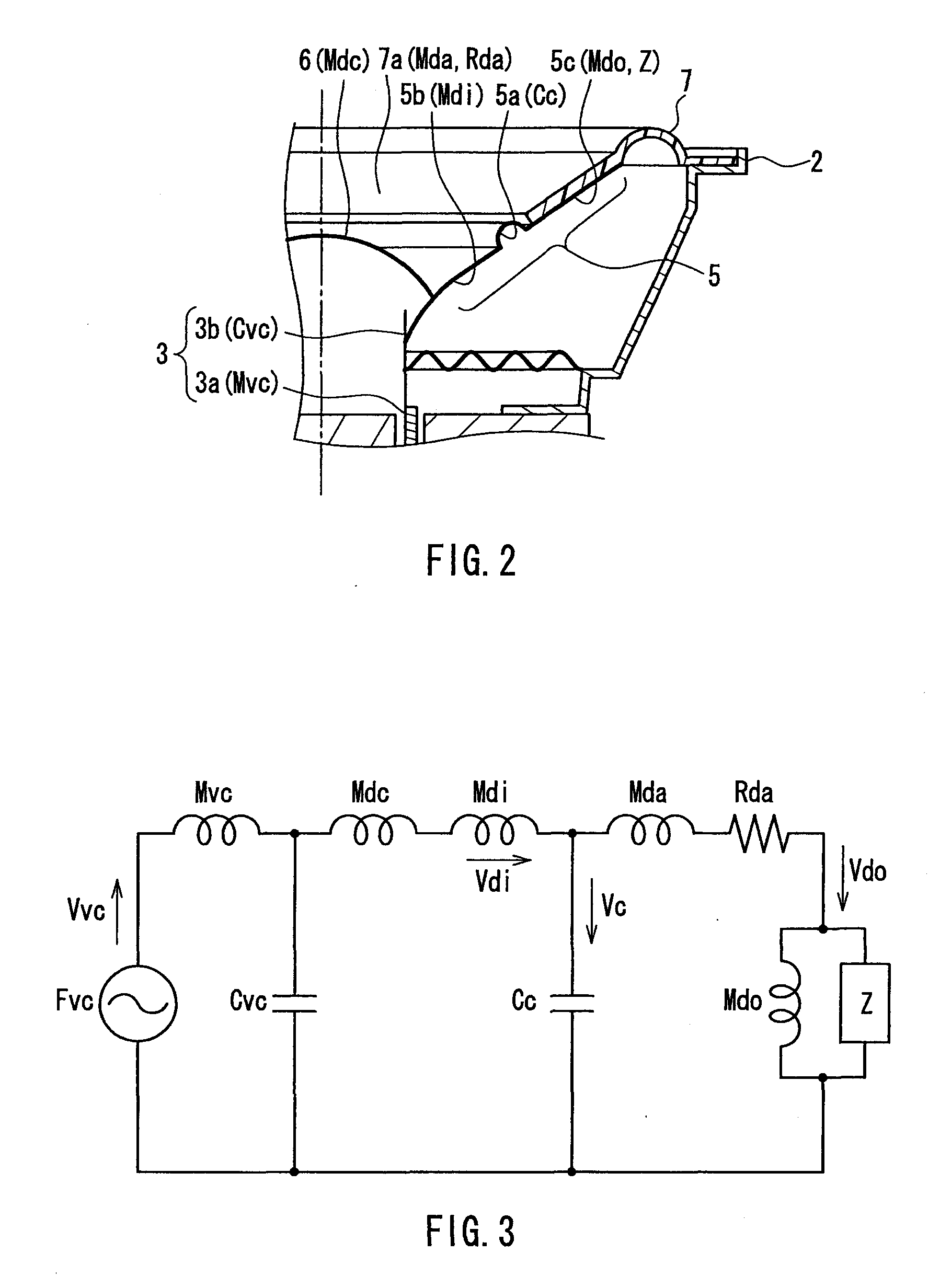

Speaker

InactiveUS20080159583A1Add additional massIncreased mechanical resistanceNon-planar diaphragms/conesDiaphragm dampingResonanceEngineering

A speaker of the present invention includes the following: a diaphragm that includes an inner periphery coupled to a voice coil, and a corrugation provided at the intermediate position between the inner periphery and an outer periphery; a speaker edge for supporting the outer periphery of the diaphragm; and a damping member attached to an outer peripheral part of the diaphragm outside the vicinity of an outer periphery of the corrugation. The effective vibration area of an inner peripheral part of the diaphragm inside an inner periphery of the corrugation is substantially half or less of the total effective vibration area. The damping member is configured as a damping portion by extending an overlap portion of the speaker edge overlapping with the diaphragm to the vicinity of the outer periphery of the corrugation. This configuration can suppress the vibration transmission at high frequencies to the outer peripheral part of the diaphragm outside the corrugation, allows only the inner peripheral part of the diaphragm inside the corrugation to mainly vibrate at high frequencies, and also can suppress a resonance in the outer peripheral part of the diaphragm outside the corrugation. Thus, the speaker can have both an excellent high frequency response and an excellent mid-high frequency response.

Owner:PANASONIC CORP

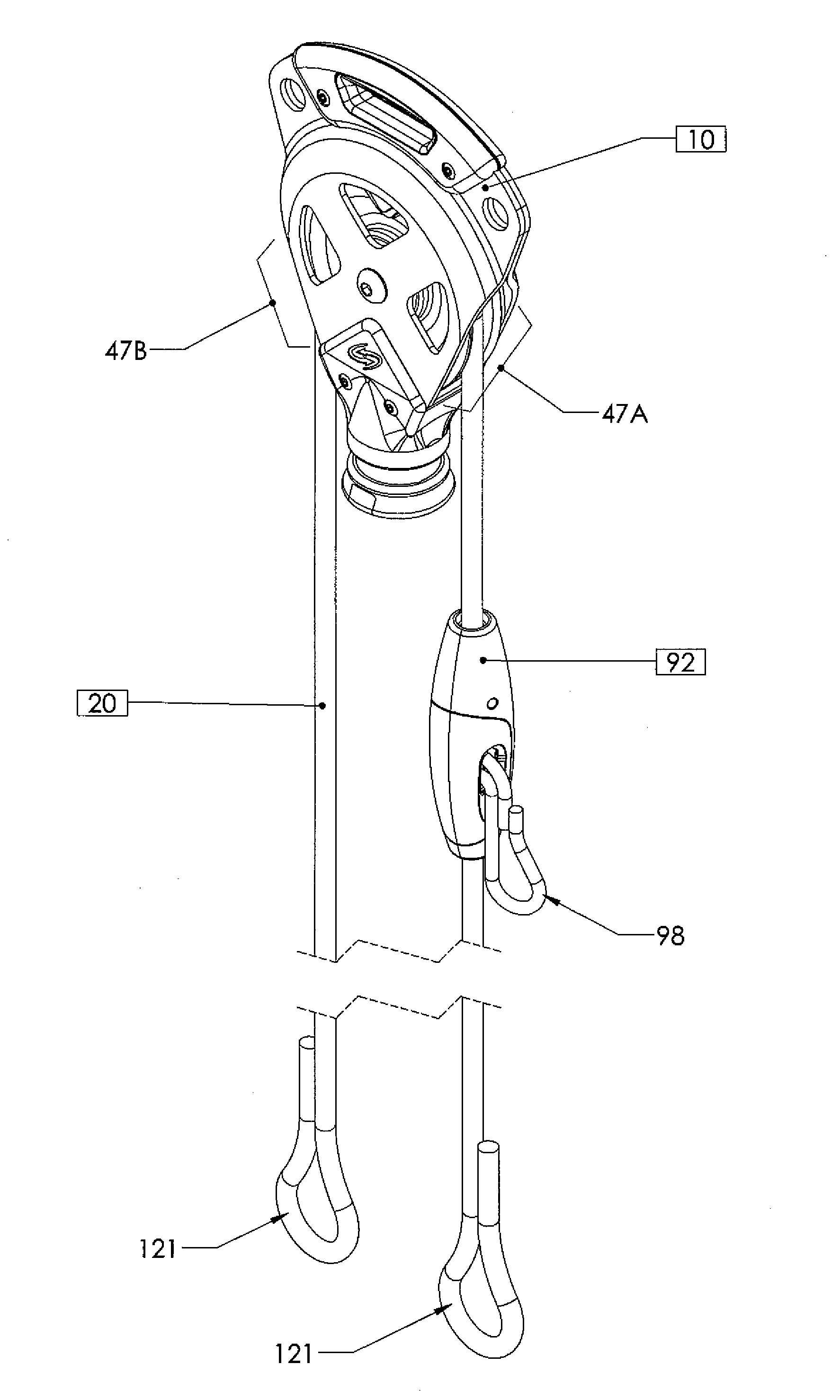

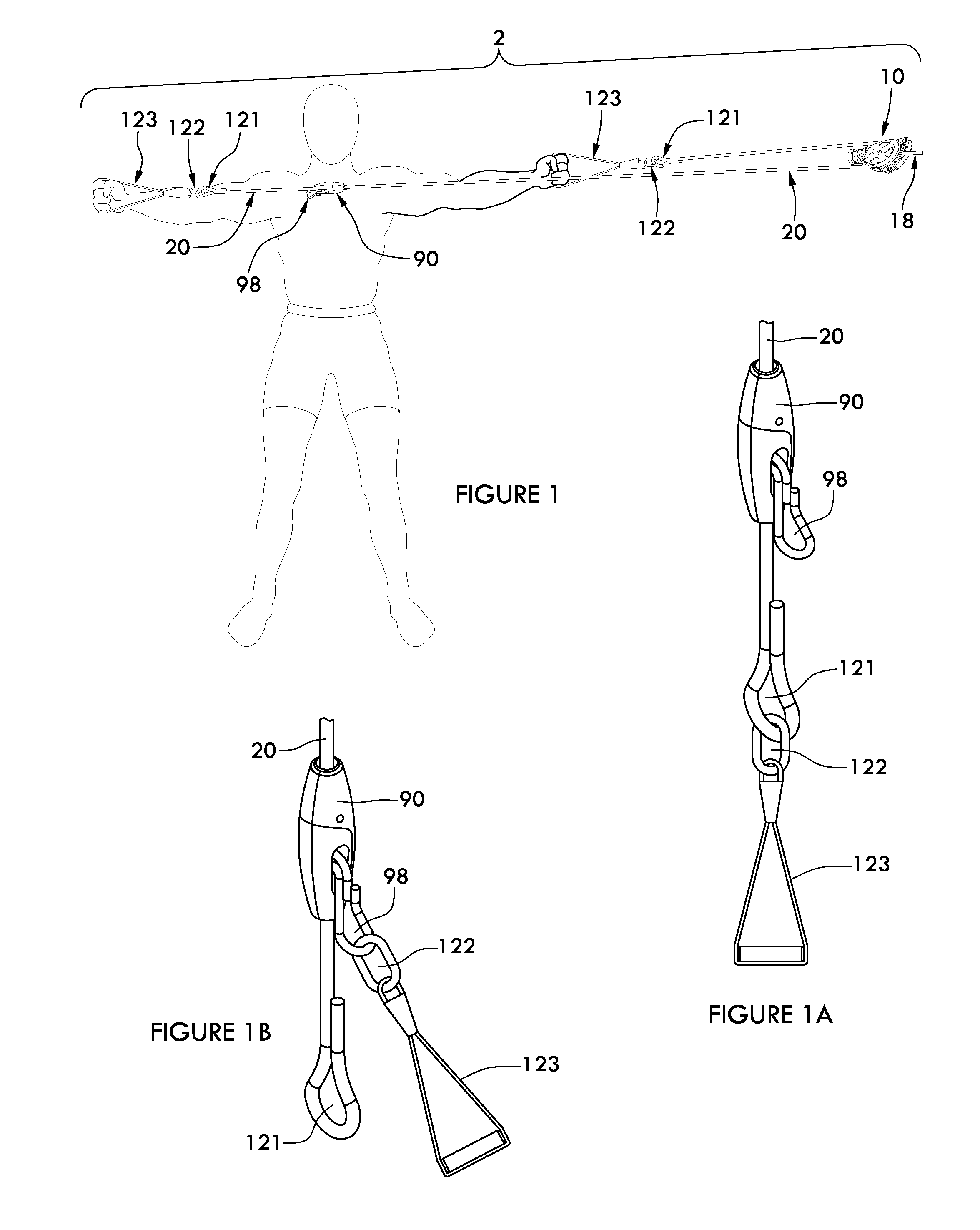

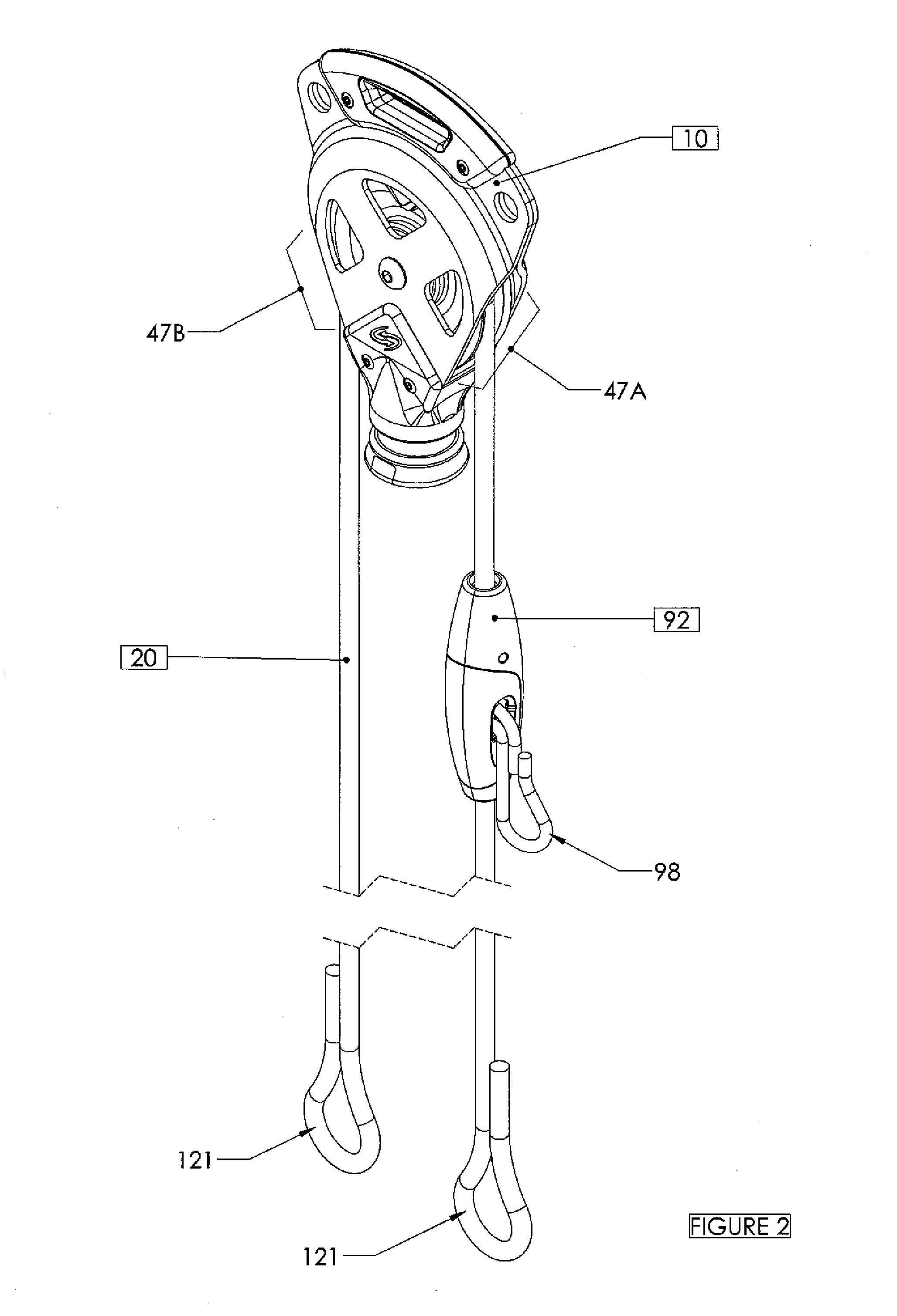

Physical Fitness Training System

ActiveUS20160287922A1Easy to engagePrevent movementDumb-bellsFrictional force resistorsEngineeringPhysical fitness

A pulley training system including a pulley wheel and a pulley housing, configured to receive a cord over the pulley wheel, and including one or more support attachment points. A radial pulley lock for use with a training pulley system. A sliding knot enclosure for use with a training pulley system. A training pulley system adapted for use with one or more of a variety of types of pulley cords, and with rope adjuster mechanisms to operate with such types of pulley cords.

Owner:MAD DOGG ATHLETICS

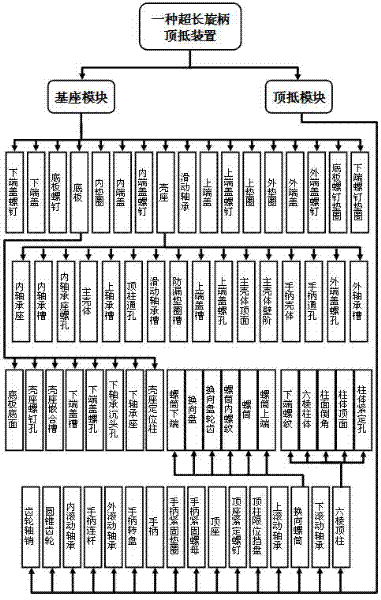

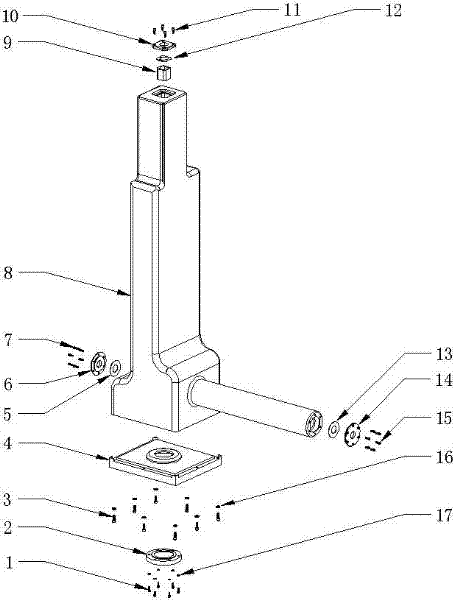

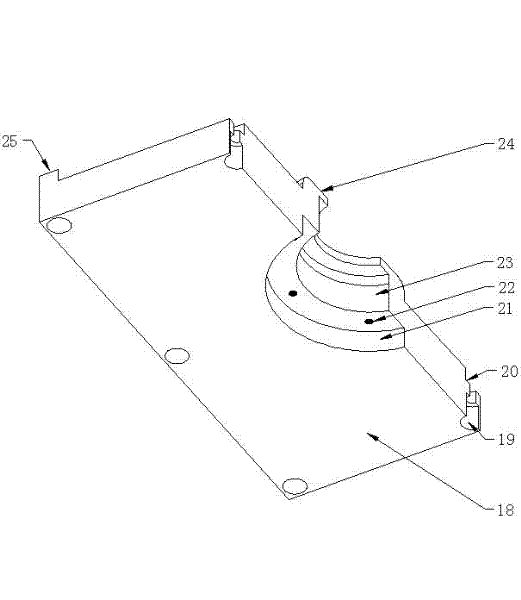

Propping device of overlong rotary handle

The invention relates to a propping device, in particular to a proper comprising an overlong rotary handle and an overlong main body shell and having a special application function. The propping device consists of a base module and a propping module, and specifically comprises 33 components of a lower end cover, a bottom plate, an inner gasket, an inner end cover, a shell seat, a sliding bearing, an upper end cover, an outer gasket, an outer end cover, a bottom plate bolt gasket, a six-arris top column, a lower rolling bearing, a reversing screw tube, an upper rolling bearing, a top column limiting retaining disc, a top seat, a handle fastening nut, a handle, a handle turntable, an outer rolling bearing, a handle connecting rod, an inner rolling bearing, a bevel gear, a gear shaft pin and the like. The propping device overcomes the defects of more optional equipment, large occupied space, narrow adaptation range and the like in the conventional well-known propping device, and has the characteristics of simple and strong structure, convenience for use, overlong stroke, wide adaptability and the like; moreover, the propping device disclosed by the invention is simply implemented and easily manufactured, is attractive, decent, solid and durable, and has a wide market space and a high economic added value.

Owner:钟明华

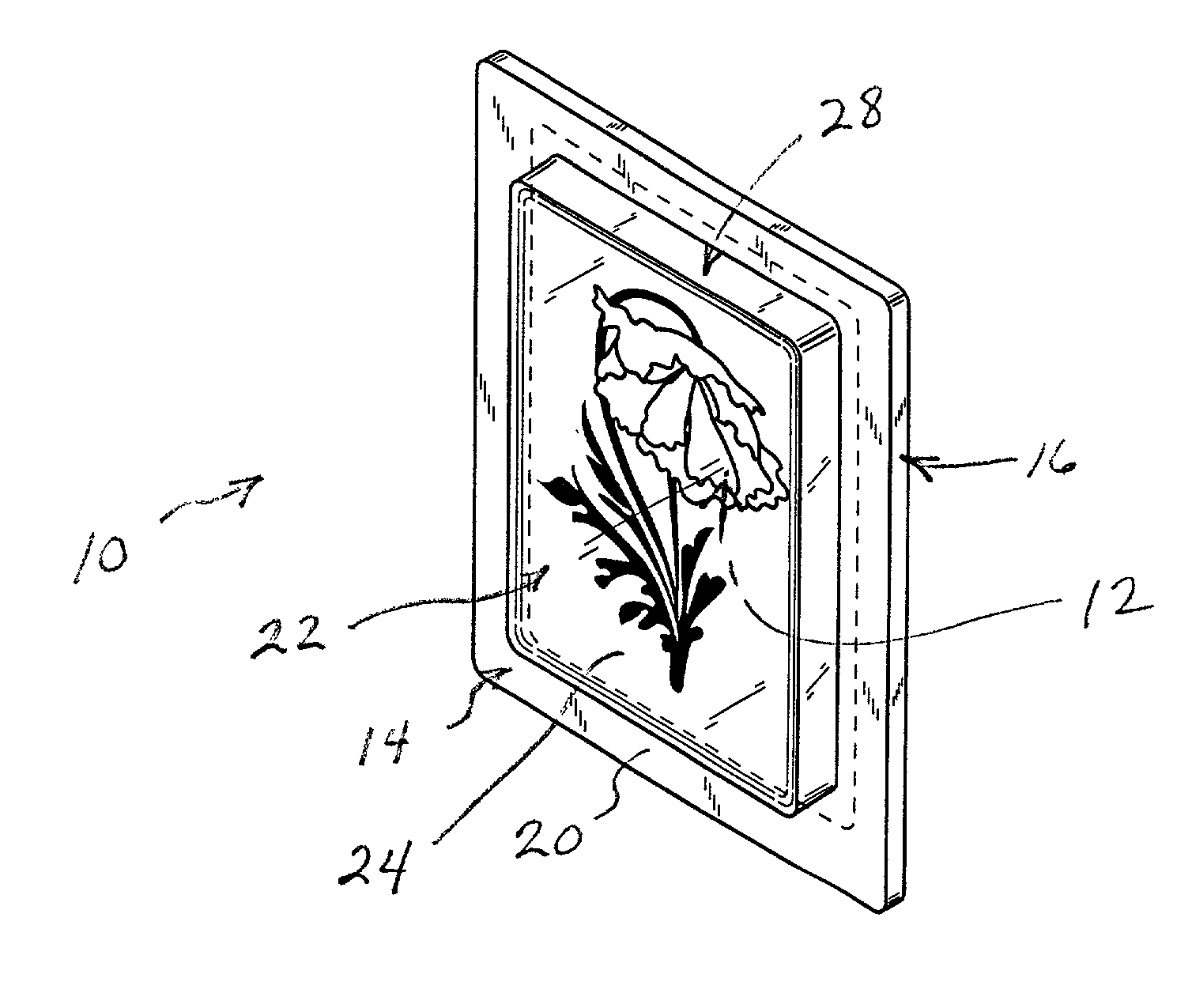

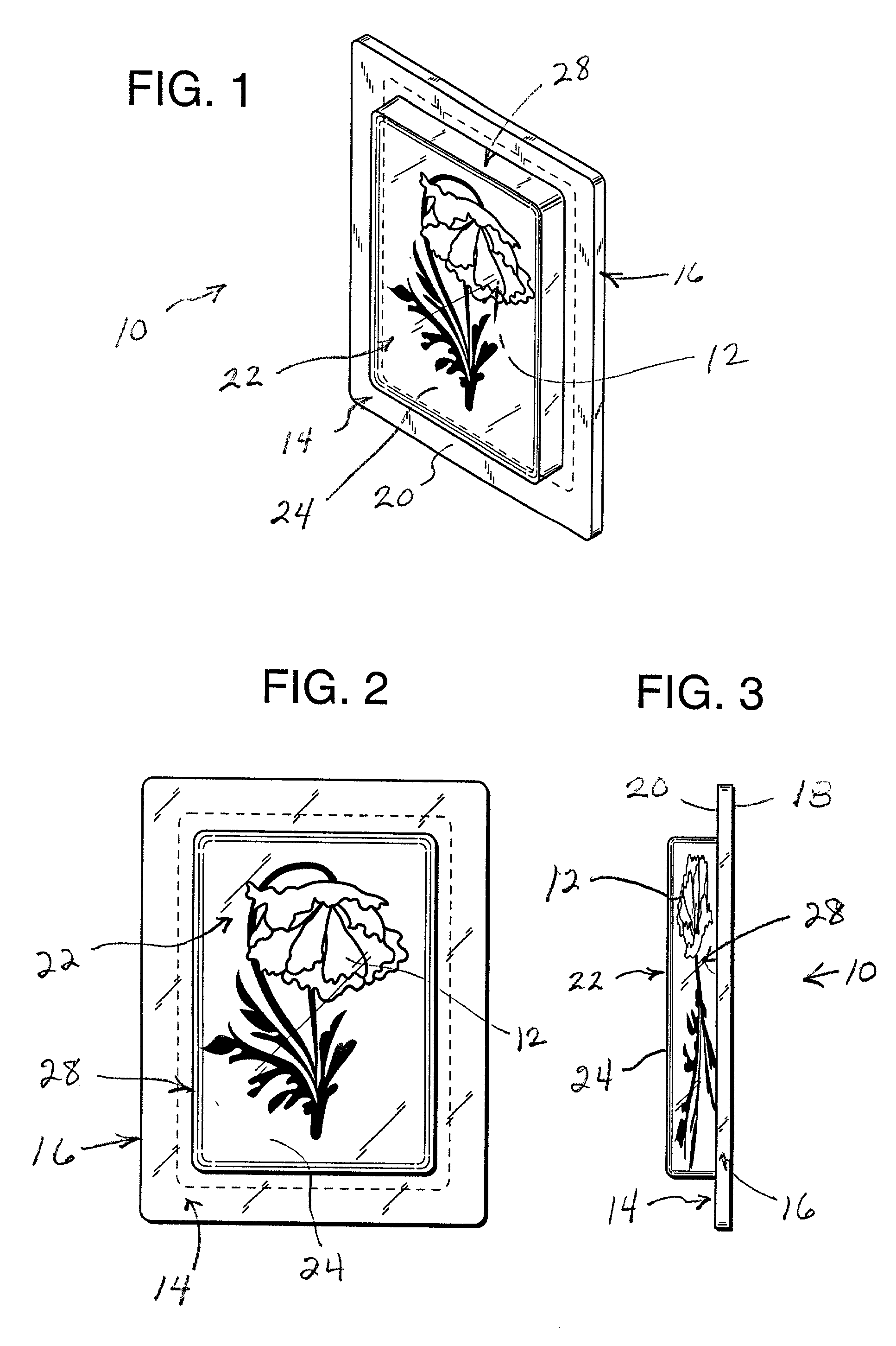

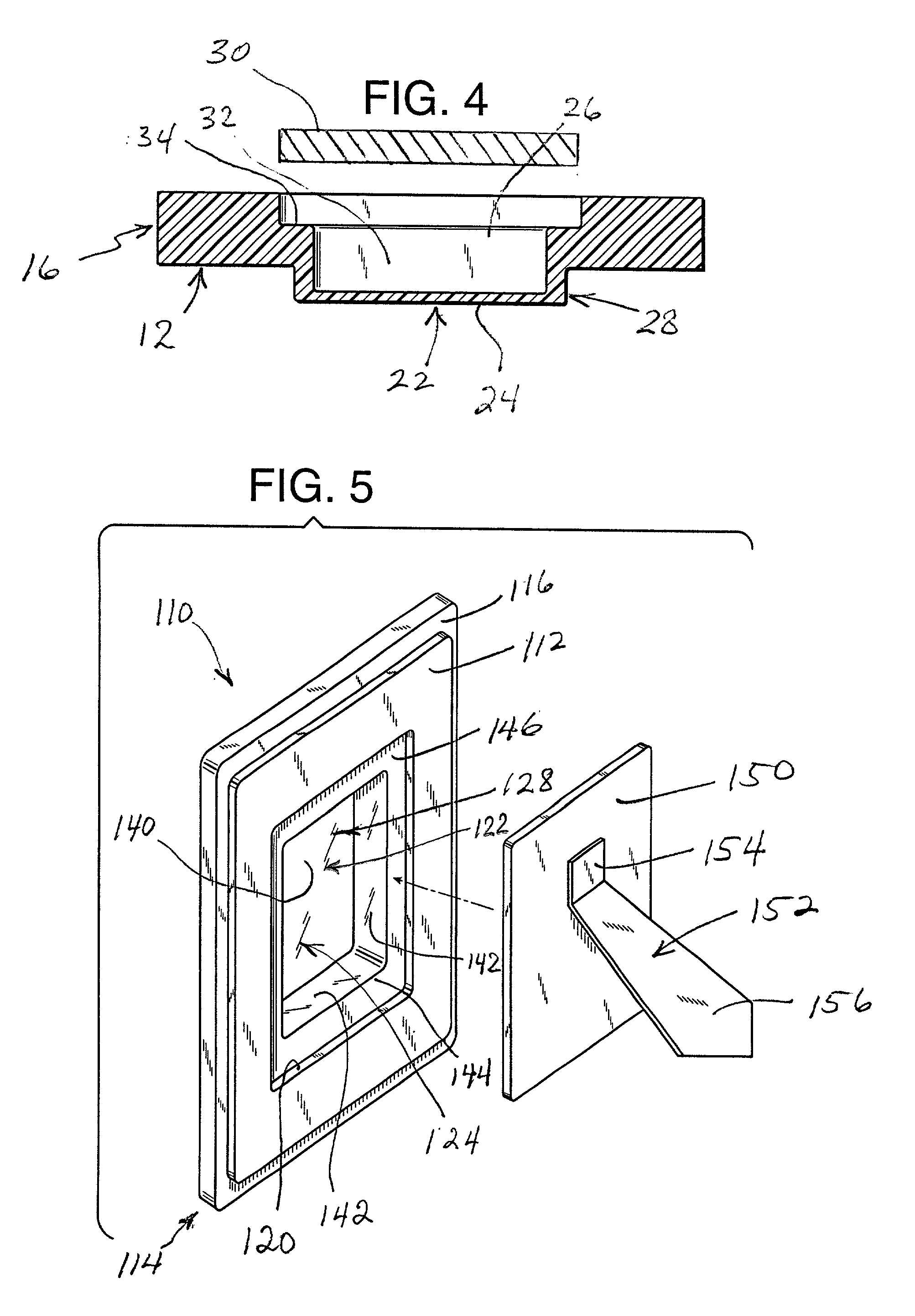

Shallow box display frame

InactiveUS20020108287A1Improve economyUnique appearancePicture framesFlat article dispensingEngineeringClosed cavity

Owner:TRAN LAM H

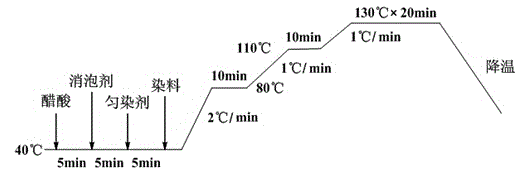

Production process of laser-carving double-faced super-flexible short flosses

ActiveCN104372560AIncrease widthPrevent lodgingPattern makingHeating/cooling textile fabricsFiberProduction rate

The invention discloses a production process of laser-carving double-faced super-flexible short flosses. The production process comprises the following steps: preparing a gray fabric; pre-setting; galling and combing on the front face; carrying out laser-carving; galling on the back face; setting; dyeing; carrying out water washing and softening; drying; combing on front and back faces and ironing and shearing; and setting a finished product. By virtue of a laser-carving method. An instantaneous high temperature of over 1000 DEG C is generated by using laser to melt polyester fibers, so that a concave-convex three-dimensional pattern is generated on the front face of the super-flexible floss and the floss on the front face is pulled to the back to form the super-flexible flosses with concave-convex three-dimensional patterns on two faces. The production process disclosed by the invention can be used for solving the problem that the quality in the large-scale production process is hard to control. And the ratio of top quality goods is improved from 80% to over 94% and the problem of determining the optimal process parameters of laser-carving is solved, so that the carving depth can be well controlled, and the problem that the back is non-uniformly galled is solved; the processing steps are shortened, the production rate is improved and the cost is lowered; the environmental pollution is reduced and the sewage treatment cost is lowered.

Owner:IANGSU COLLEGE OF ENG & TECH

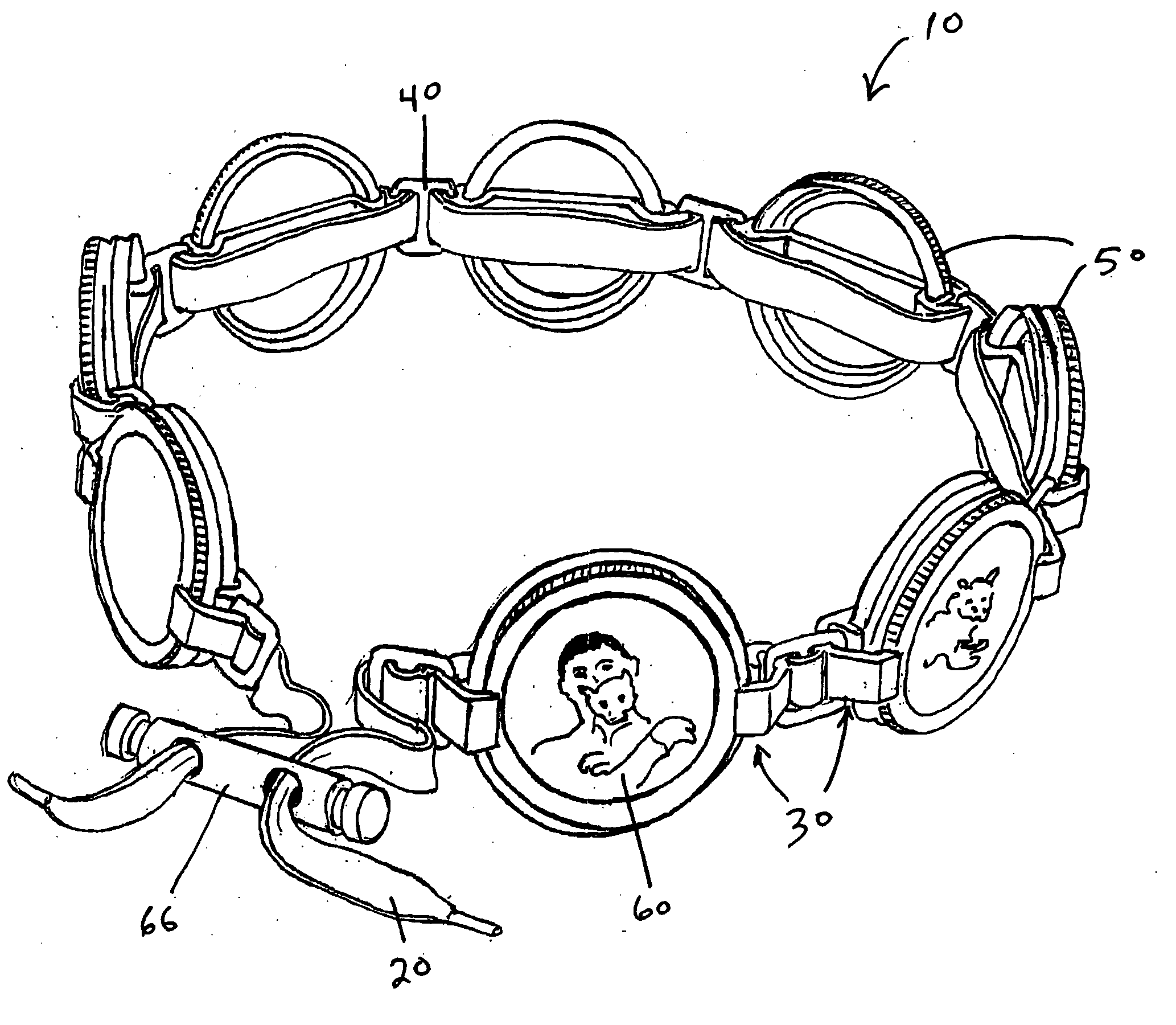

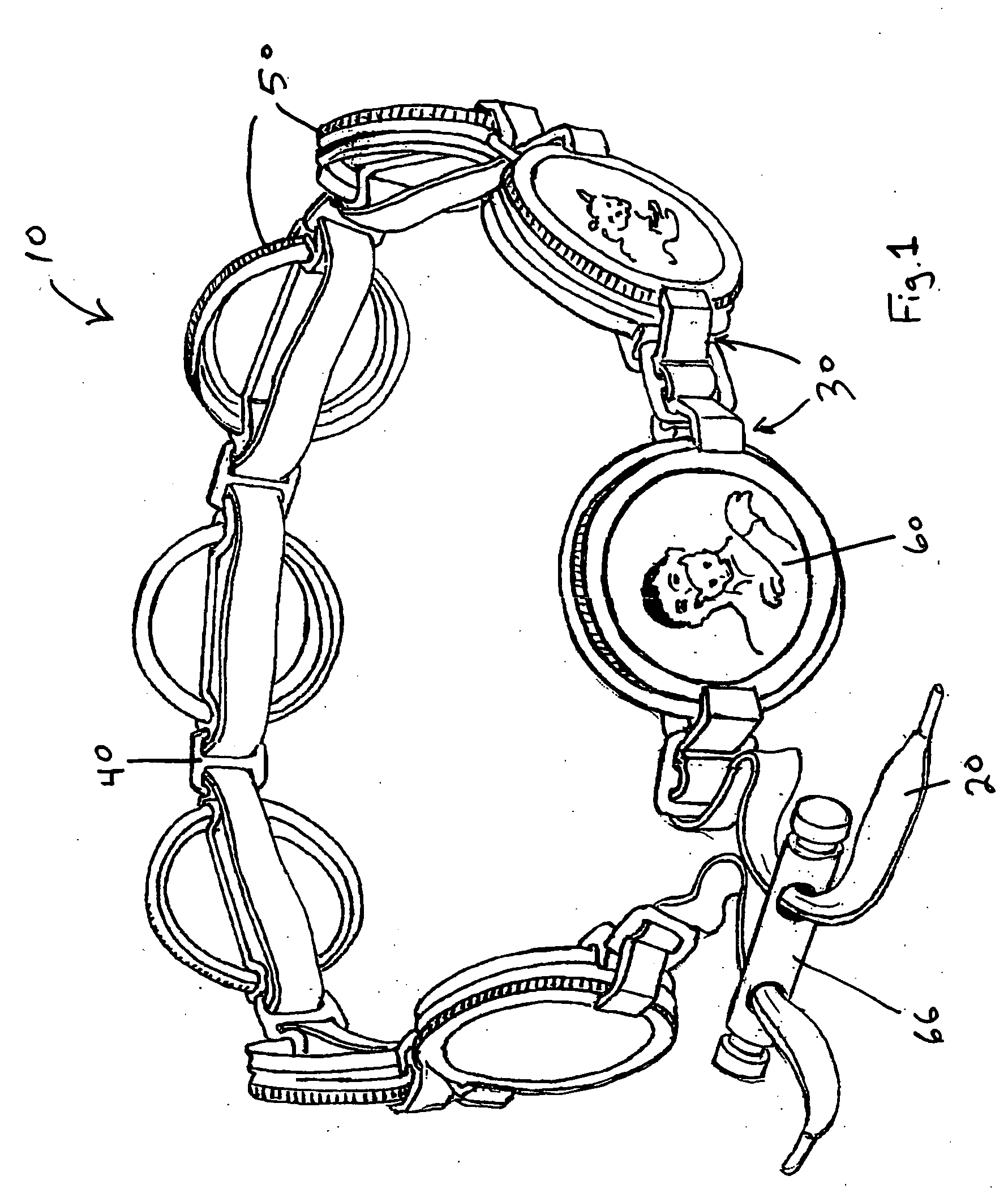

Canning screw band charm clip and assembly

InactiveUS20050150035A1Unique appearanceUniformity in useSnap fastenersShoulder strapEngineeringLink relation

Owner:MARKS ROBERT D

Double-dosage-form moisturizing essence and preparation method thereof

ActiveCN110787093AImprove stabilityImprove permeabilityCosmetic preparationsToilet preparationsPolyolSurfactin

The present invention discloses a double-dosage-form moisturizing essence. The double-dosage-form moisturizing essence comprises oil gel and hydrogel. The oil gel and the hydrogel are mixed accordingto a preset ratio when in use; the oil gel comprises the following components in parts by weight: 0.1-6 parts of an active ingredient, 15-35 parts of polyol, 0.1-1 part of sodium surfactin, 10-70 parts of oil and 1-10 parts of water. The double-dosage-form essence is mixed according to the preset ratio when in the use, and the oil gel and the hydrogel have a transparent appearance and good stability. The present invention also discloses a preparation method of the double-dosage-form essence, the oil gel and the hydrogel are prepared separately, a D-phase emulsification method is used to prepare the oil gel, and an emulsifier is low in use amount and can emulsify oil phase with high oil content.

Owner:GUANGZHOU BIOHOPE CO LTD

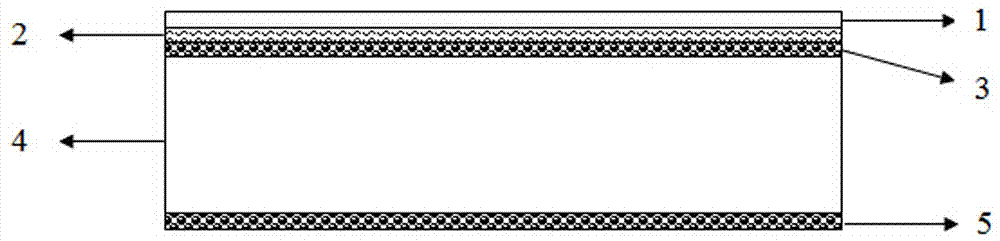

Composite board and preparation method thereof

PendingCN107571577AStrong impact resistanceHigh mechanical strengthLamination ancillary operationsSynthetic resin layered productsSurface layerAdhesive

The invention discloses a composite board, comprising a composite layer, an upper adhesive layer and a lower adhesive layer respectively bonded with the upper and lower surfaces of the composite layerto form an integral body with the composite layer, and a functional surface layer bonded with the upper surface of the upper adhesive layer to form an integral body with the upper adhesive layer. According to the invention, the upper adhesive layer and the lower adhesive layer respectively cover the upper and lower surfaces of the composite layer, and the functional surface layer is laminated with the upper surface of the upper adhesive layer via a film spraying method, so the prepared composite board has excellent impact resistance and the advantages of high mechanical strength, ageing resistance, scratch resistance, etc.; meanwhile, the functional surface layer endows the composite board with unique appearance and functionality; moreover, since one part of the upper adhesive layer is embedded into the upper surface of the composite layer and another part of the upper adhesive layer is embedded into the lower surface of the functional surface layer, such mechanical bonding can improve peeling strength between the functional surface layer and the composite layer; and the lower adhesive layer may be embedded into the lower surface of the composite layer so as to realize bonding between the composite board and other materials.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

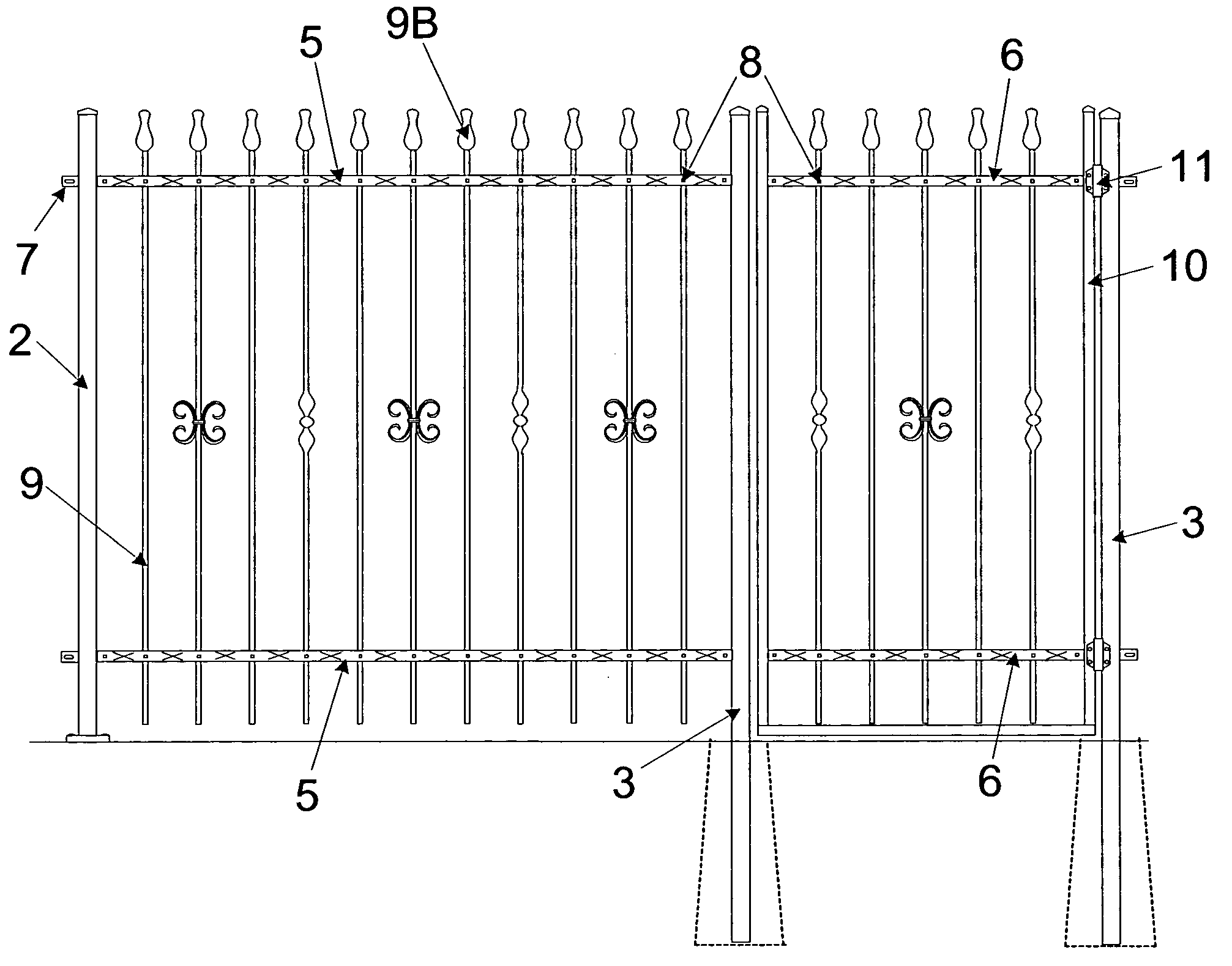

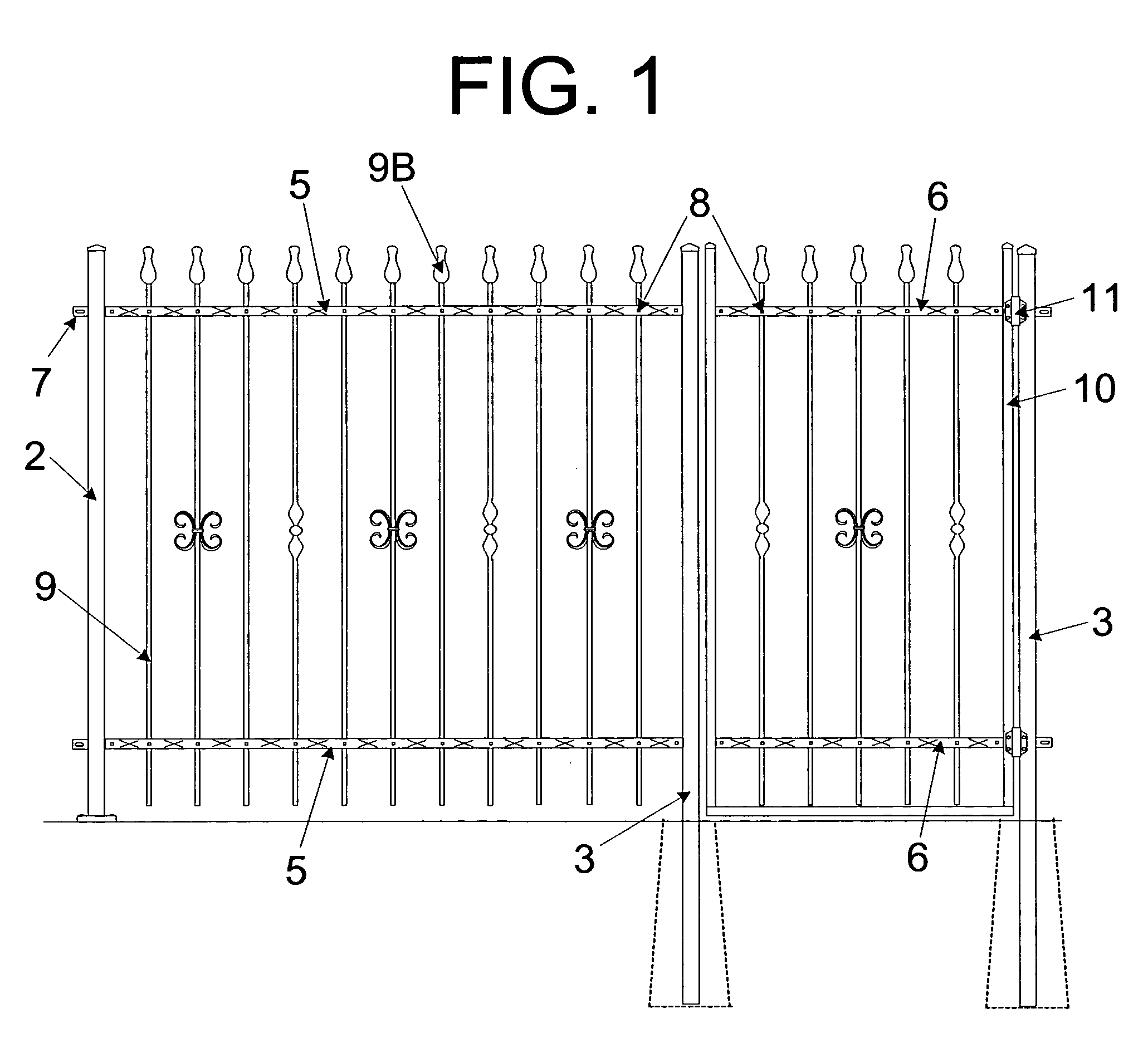

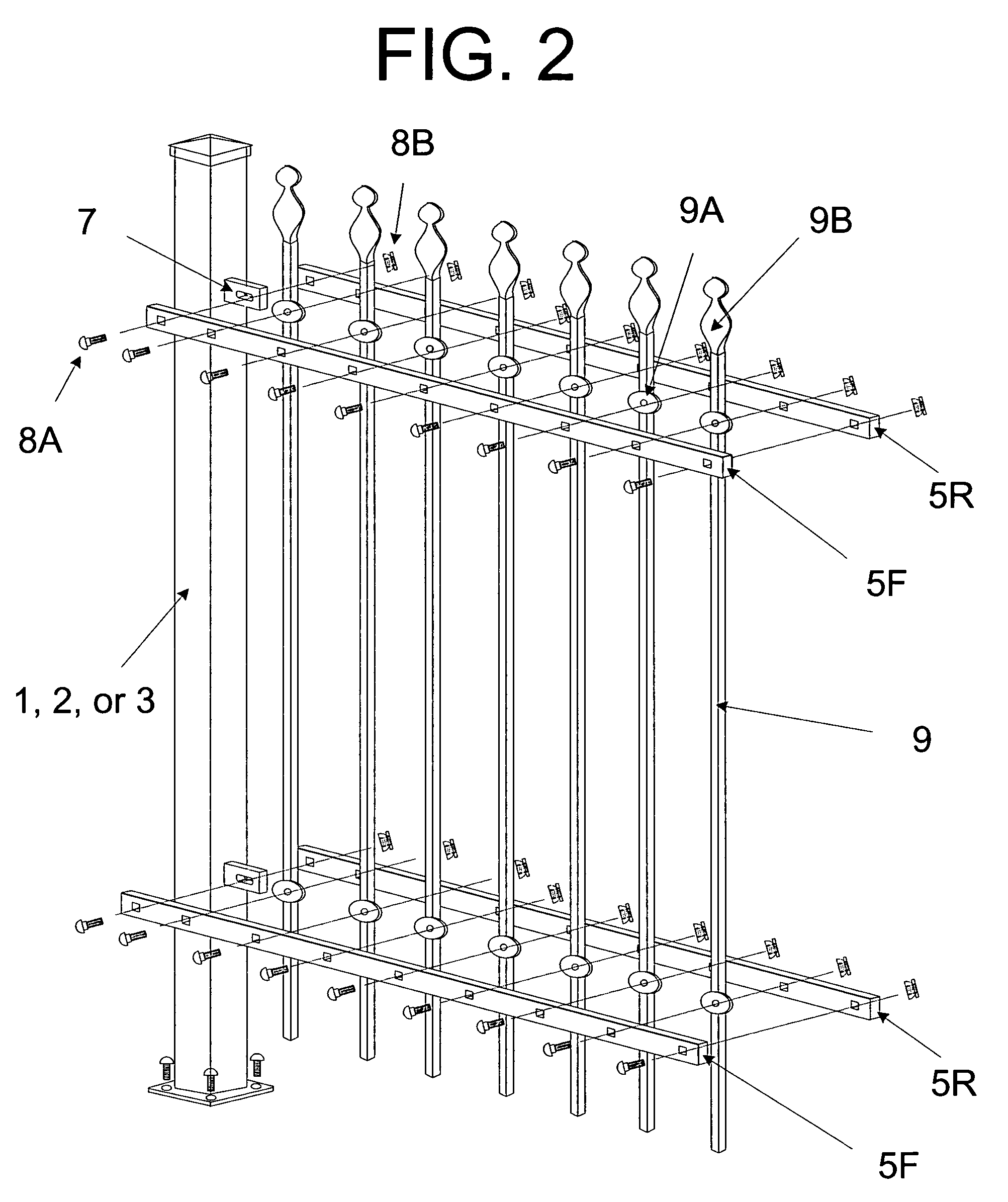

Modular railing, fence, gate, and security bars

InactiveUS20050236611A1Easy to prefabUnique ornamental appearanceBalustradesFencingSkill setsEngineering

The present invention includes modular fence, gate, railing, and security bar systems that can be easily prefabricated of a minimal number of parts, assembled at the installation site without the need for specialized skills or tools, and having a semi-customizable ornamental appearance that can be changed subsequent to the initial installation. A method of connecting the components by aligning holes formed in the rails with similar holes formed in pickets, balusters, and tabs; inserting a connecting bolt through the holes; and fastening nuts to the bolts is claimed. To add strength to the systems' connections, the pickets and / or balusters are formed to have flattened parts with a hole centered therein; the flattened part formed to fit between two rails. Another unique feature is the detachable head on the nut used to secure the connections. Once the head is detached, the connecting bolt and nut remaining have the appearance of a rivet.

Owner:VEREIDE DONALD W +1

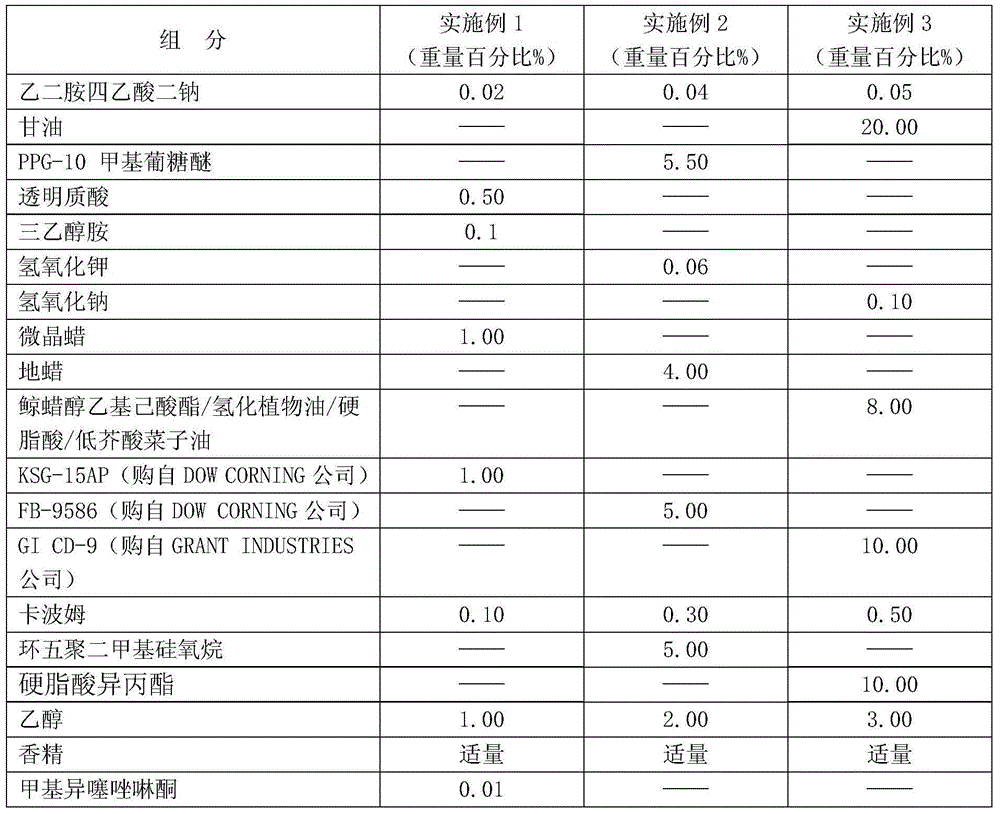

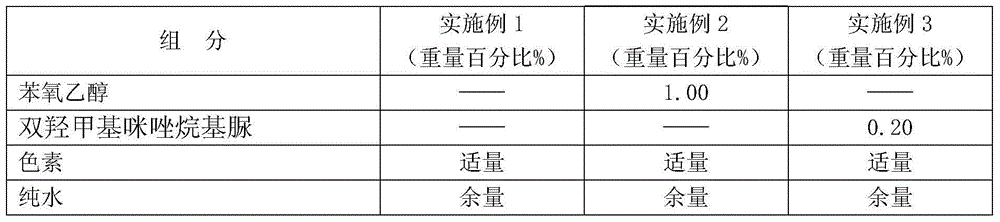

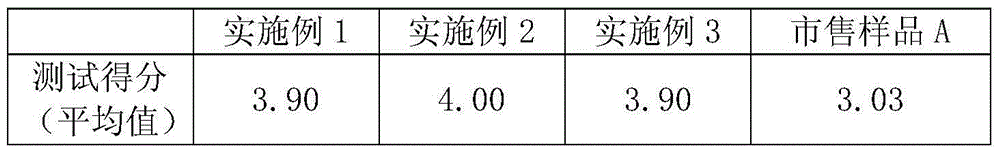

Vanishingmoisturizing cream with high moisturizing property and preparation method of vanishingmoisturizing cream

InactiveCN104473792AUnique appearanceUnique skin feelCosmetic preparationsToilet preparationsEmulsionPreservative

The invention provides vanishingmoisturizing cream which comprises components in percentage by weight as follows: 0.02%-0.05% of ethylene diaminetetraacetic acid sodium, 0.50%-20.00% of a moisturizing agent, 1.00%-8.00% of an emulsion stabilizer, 1.00%-10.00% of a skin conditioning agent, 0%-10.00% of an emollient, 0.10%-0.50% of a thickening agent, 1.00%-3.00% of ethanol, an appropriate quantity of a neutralizer, an appropriate quantity of essence, 0.01%-1.00% of a preservative, an appropriate quantity of pigment and the balance of pure water. The vanishingmoisturizing cream has transparent appearance, special skin feeling and good moisturizing property.

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com