Double knitted fabric

A knitted fabric and double-layer technology, applied in the field of double-layer knitted fabrics, can solve technical difficulties, increase the number of bars, increase costs, etc., and achieve the effect of improving the efficiency of the knitting machine, reducing the number of bars, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described based on illustrated examples.

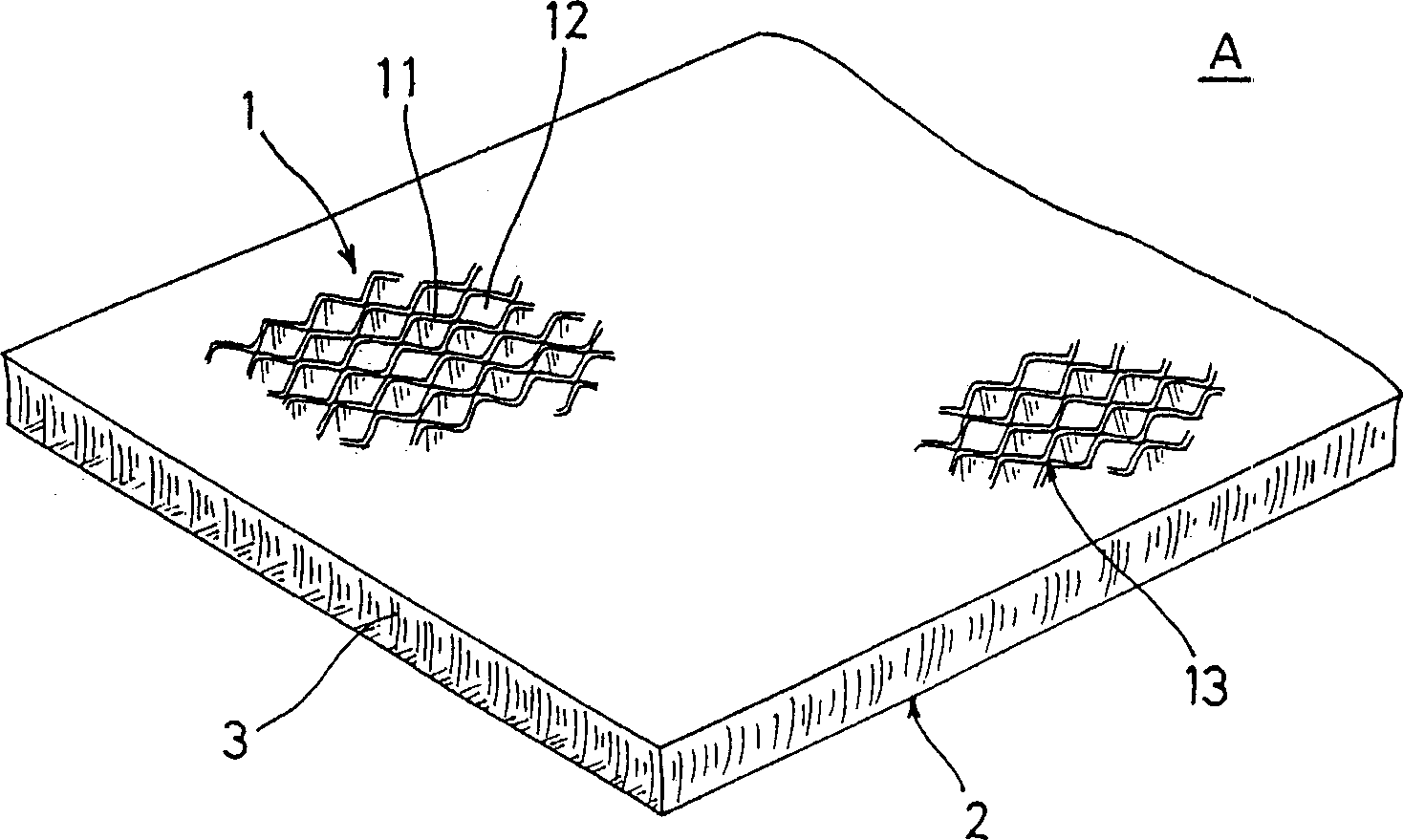

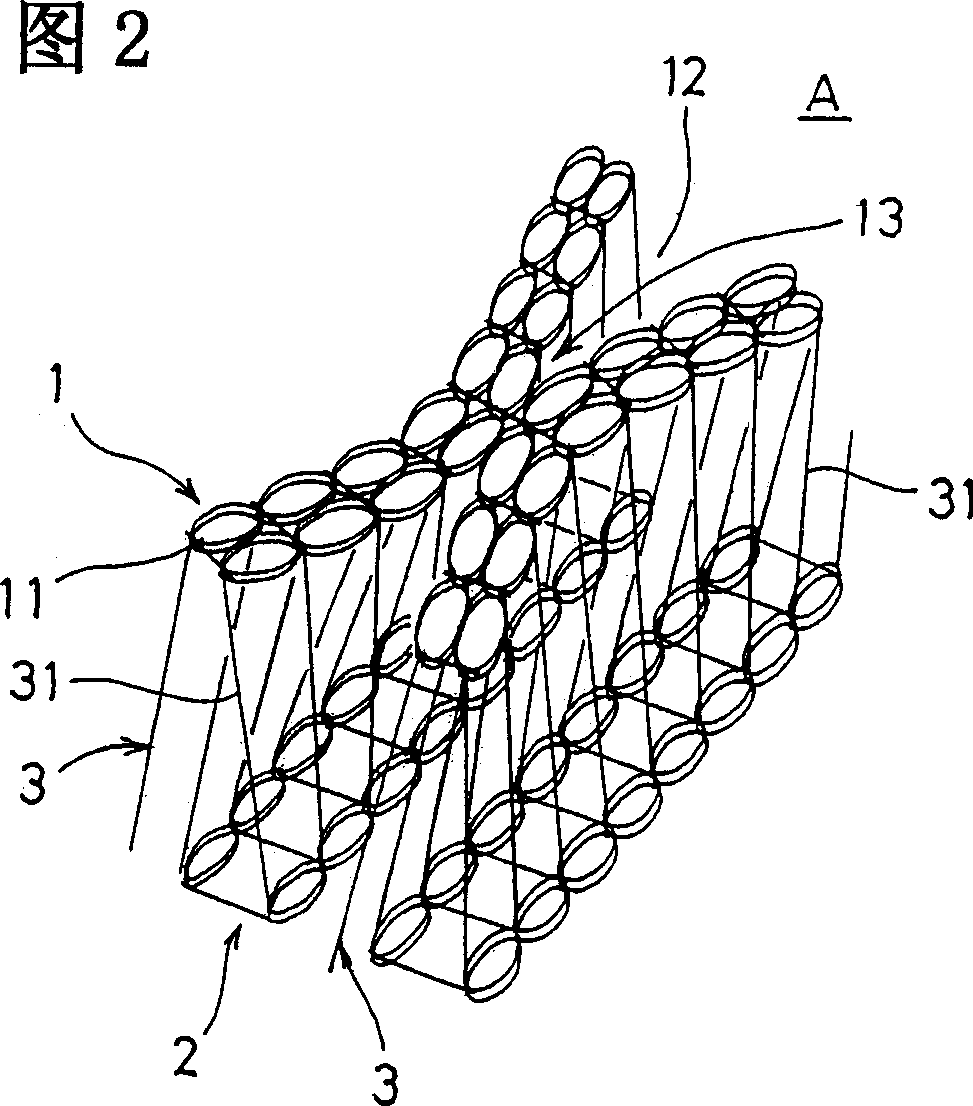

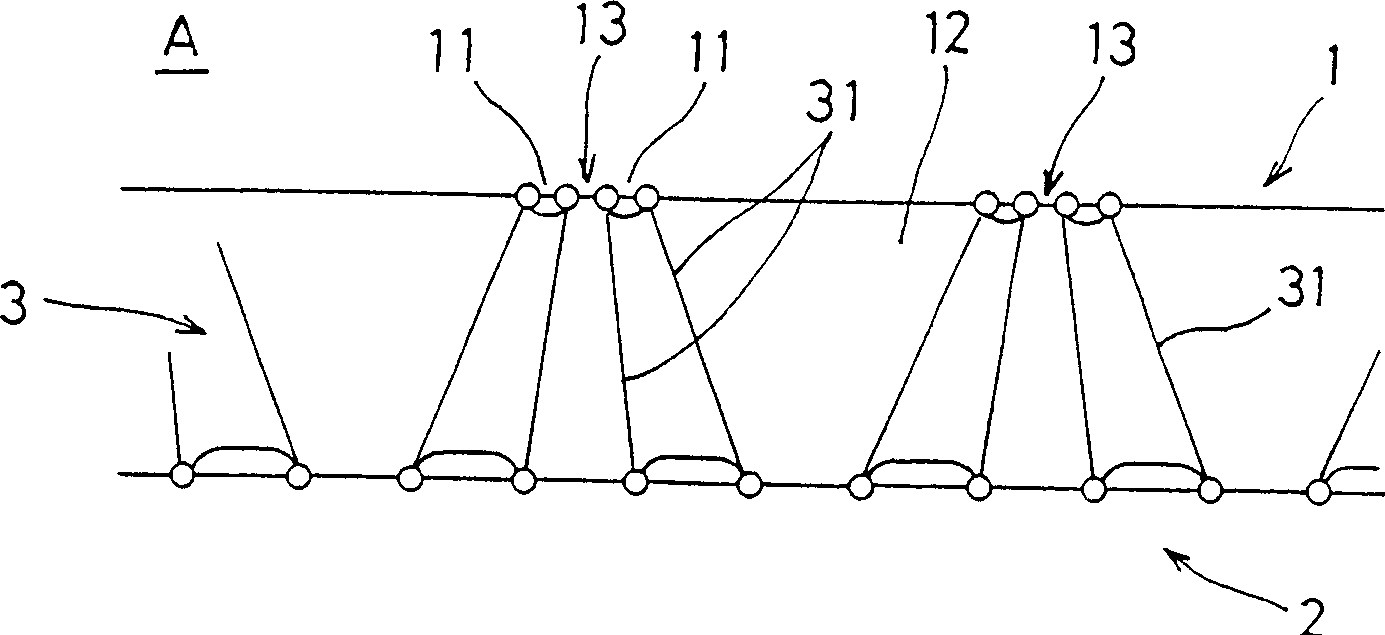

[0070] figure 1 It is a schematic perspective view showing an embodiment of the warp-knitted double-layer knitted fabric of the present invention. Figure 2 is figure 1 A schematic enlarged perspective view of a part of the double-layer knitted fabric of . image 3 yes figure 1 A schematic enlarged cross-sectional view of a portion of a double-ply knitted fabric. Figure 4 It is an enlarged explanatory diagram of the double stitch structure of the connecting yarn. Figure 5 It is a lapping diagram of each bar which shows an example of the above-mentioned knitting structure.

[0071] In the figure, 1 and 2 represent the front and back base materials, and 3 represents the connecting yarn connecting the two base materials 1 and 2 with a predetermined gap. In the two-layer knitted fabric A of this embodiment, one of the front and back sides, for example, the base materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com