Propping device of overlong rotary handle

A technology of pushing up and turning the handle, applied in the direction of lifting device, etc., can solve the problems of poor adaptability and single function of the pushing device, and achieve the effect of compact structure, powerful function and beautiful structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

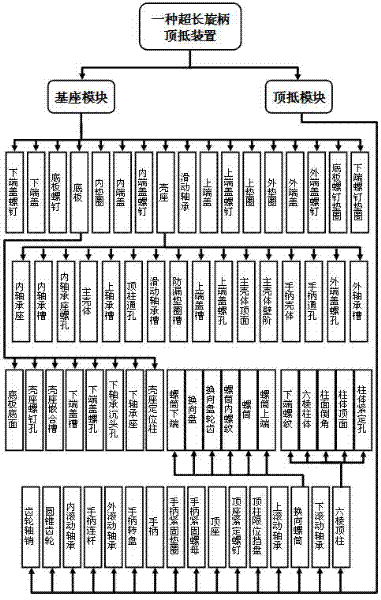

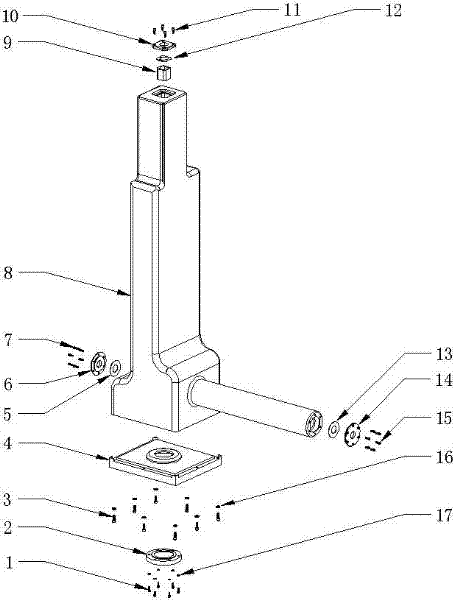

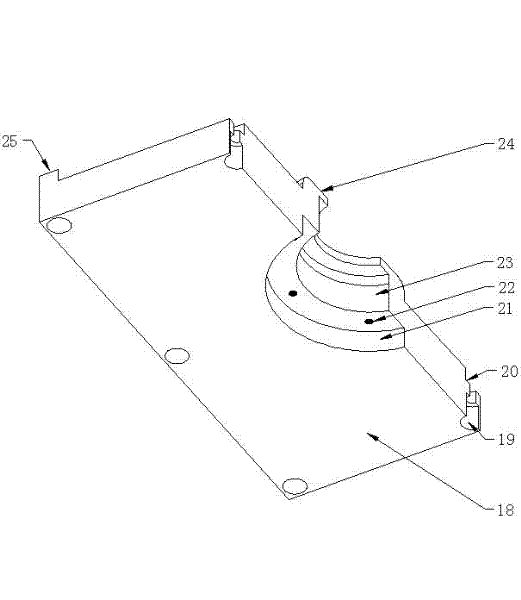

[0031] As a technical scheme of product structure, the present invention can make the product concretely implemented through the organic combination of corresponding parts. The organizational structure of the product of an embodiment of the present invention is as figure 1 shown.

[0032] figure 1 Among them, the product of the present invention is composed of a base and abutting two modules, wherein the base module consists of lower end cover screws, lower end cover, bottom plate screws, bottom plate, inner gasket, inner end cover, inner end cover screws, shell seat, Sliding bearings, upper end caps, upper end cap screws, upper washers, outer washers, outer end caps, outer end cap screws, bottom plate screw washers, and lower end screw washers are composed of seventeen parts; the jacking module consists of hexagonal jacking columns, Lower rolling bearing, reversing screw barrel, upper rolling bearing, top column limit stopper, top seat, handle fastening nut, handle fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com