Vehicle-body structure of vehicle and manufacturing method of the same

A body and vehicle technology, which is applied to the vehicle body structure and its manufacturing field, can solve the problems that the vehicle cannot be effectively restrained, and achieve the effects of improving rigidity, avoiding the increase of body weight, and suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

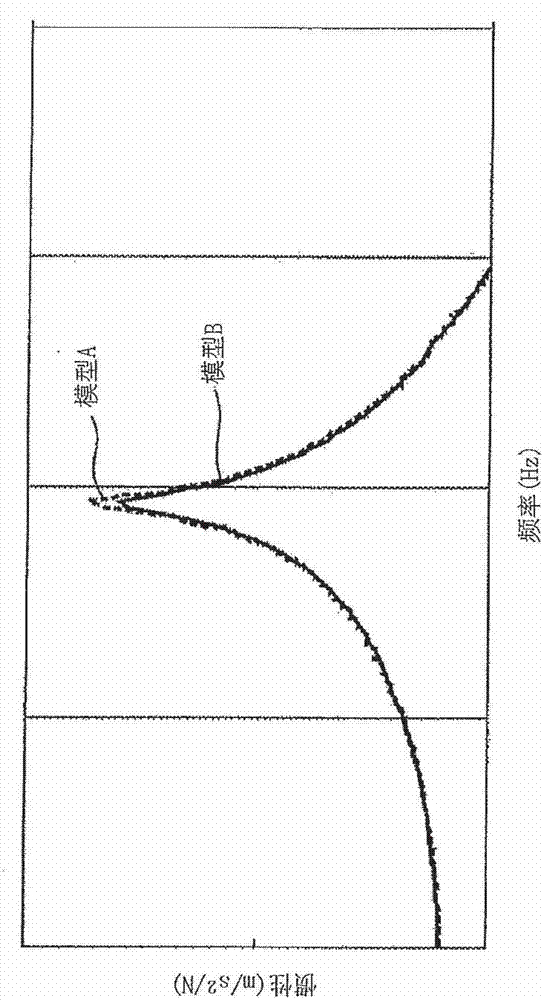

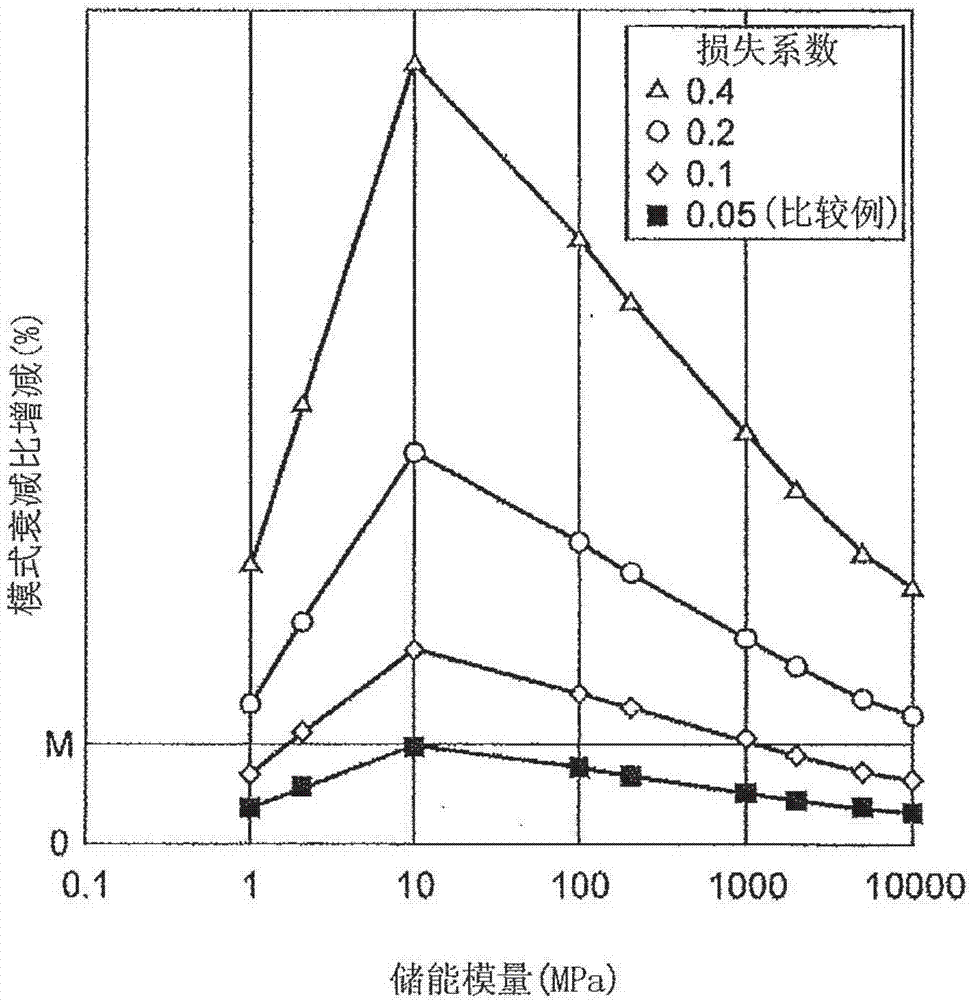

[0040] Before explaining the specific structure in which the present invention is applied to an actual vehicle body, first, the results of a simulation performed on a model with a simplified structure will be described.

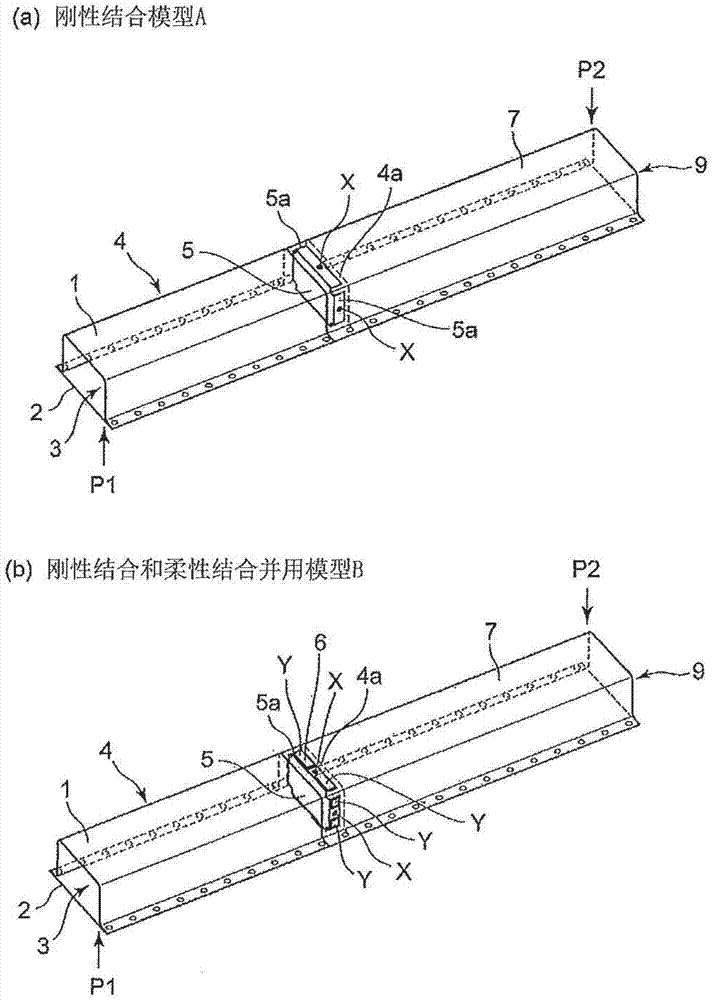

[0041] figure 1 (a) represents the rigid binding model A used for this simulation, figure 1 (b) represents the combination of rigid bonding and flexible bonding Model B. Such as figure 1 As shown in (a) and (b), in any model of rigid bonded model A and rigid bonded and flexible bonded model B, the first part 1, the third part 7, and the plate-shaped cap-shaped section are used. The second member 2 is used as a vehicle body structural member, and the hollow frame 4 extending in the longitudinal direction is formed by joining the second member 2 on one surface of the first member 1 and the third member 7 .

[0042] Both the first member 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com