Patents

Literature

153results about How to "Physical health hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine product meat sausage and making method thereof

The invention discloses a marine product meat sausage and a making method thereof. The marine product meat sausage is characterized by comprising the following raw materials proportioning by weight: 30-85 portions of marine product, 0-30 portions of edible meat, 10-30 portions of edible water, 1-12 portions of edible vegetable oil, 2-6 portions of soybean protein isolate, 0.5-1.6 portions of saltand 2.0-7.5 portions of starch; the marine product meat sausage is prepared according to the steps of raw material processing, twisting, chopping, stirring, filling, sterilizing and packaging. The invention is prepared by adopting the marine products (scallop muscle, oyster meat, sleeve-fish meat, salmon meat, shrimp meat, trepang, abalone, yellow croaker meat, hairtail meat, fish seeds, ling meat, waste fish meat and the like) or adding the edible meat (chicken, pork, mutton, beef and the like) as the main raw materials, has abundant and balanced nutrition, meets the requirement of a consumeron the marine products and increases the appetite, and the product has strong seafood taste and unique flavor, does not contain nitrite, is beneficial to health, is packaged in vacuum, has unique appearance and is ready to be enjoyed when a bag is opened.

Owner:青岛农博农食品科技有限公司

Water montmorillonite nano composite heat insulating waterproof paint and preparation method thereof

The invention discloses water montmorillonite nano composite heat insulating waterproof paint and a preparation method thereof. The water montmorillonite nano composite heat insulating waterproof paint comprises the following ingredients in percentage by mass: 30 to 35 percent of nano composite emulsion, 10 to 15 percent of polymer emulsion, 10 to 15 percent of rutile-type titanium pigment, 10 to15 percent of organic modified nano montmorillonite, 5 to 10 percent of nano oxide, 0.3 to 0.35 percent of pH adjusting agent, 0.50 to 0.65 percent of film-forming additive, 0.35 to 0.4 percent of elastic foam killer, 0.20 to 0.30 percent of wetting agent, 0.10 to 0.15 percent of dispersion agent, 0.50 to 0.65 percent of anti-freezing agent, 0.10 to 0.15 percent of sterilization antiseptic and 20to 25 percent of water. The water montmorillonite nano composite heat insulating waterproof paint not only has good compatibility, dispersion performance and good stability, but also has good water resistance, heat insulation, environmental protection, outdoor weather resistance and good adhesive attraction and has an antibacterial self-cleaning function.

Owner:CHINA MCC17 GRP

Physical grounding resistance reducing agent

InactiveCN1472750AWill not pollutePhysical health hazardConductive materialElectrical resistance and conductanceSoil resistivity

The agent mainly consists of electrode graphite and cement, which is an ideal conduction material for earthing and has low resistivity for durative action and stability service. It can satisfy earthing protective requirements for various electric or microelectronic equipment with in quite long period under the various environmental conditions.

Owner:成都圣威电气有限公司

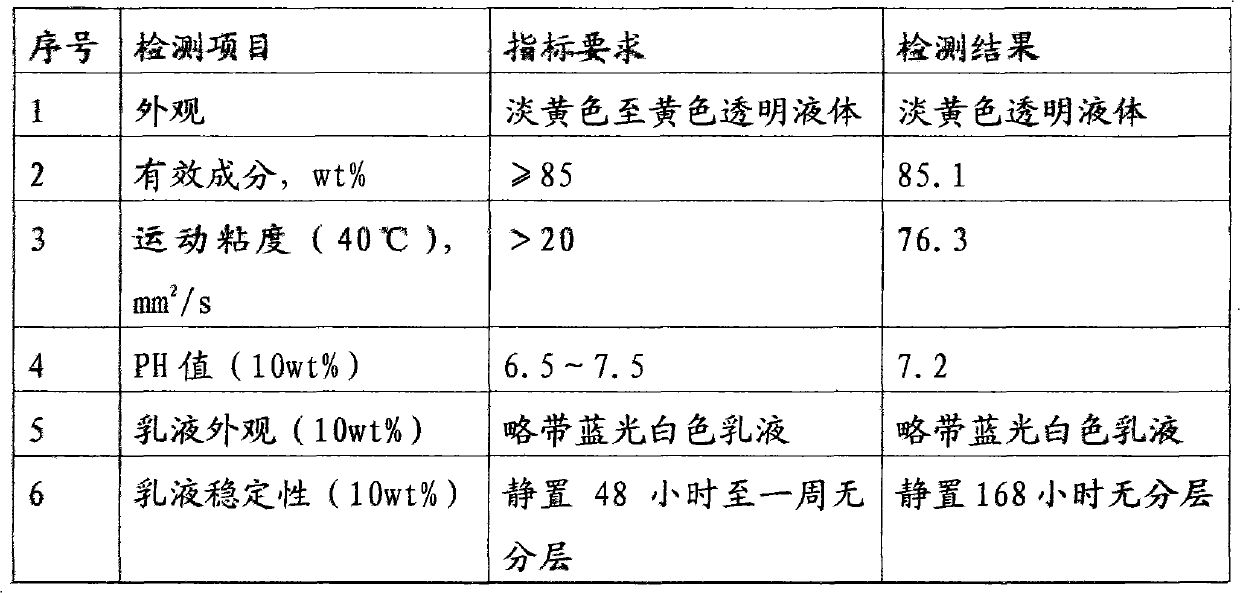

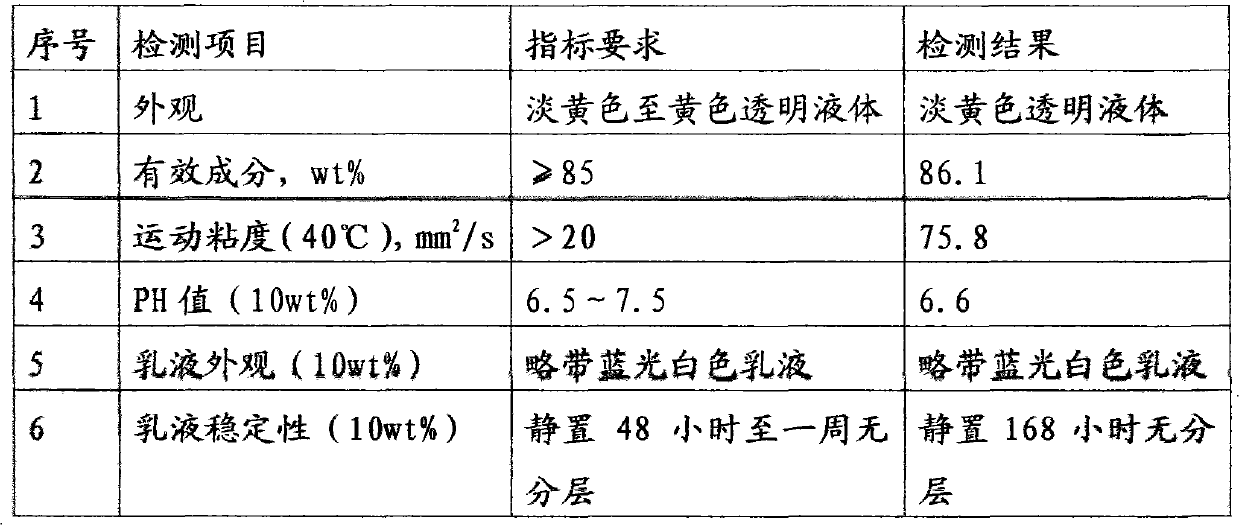

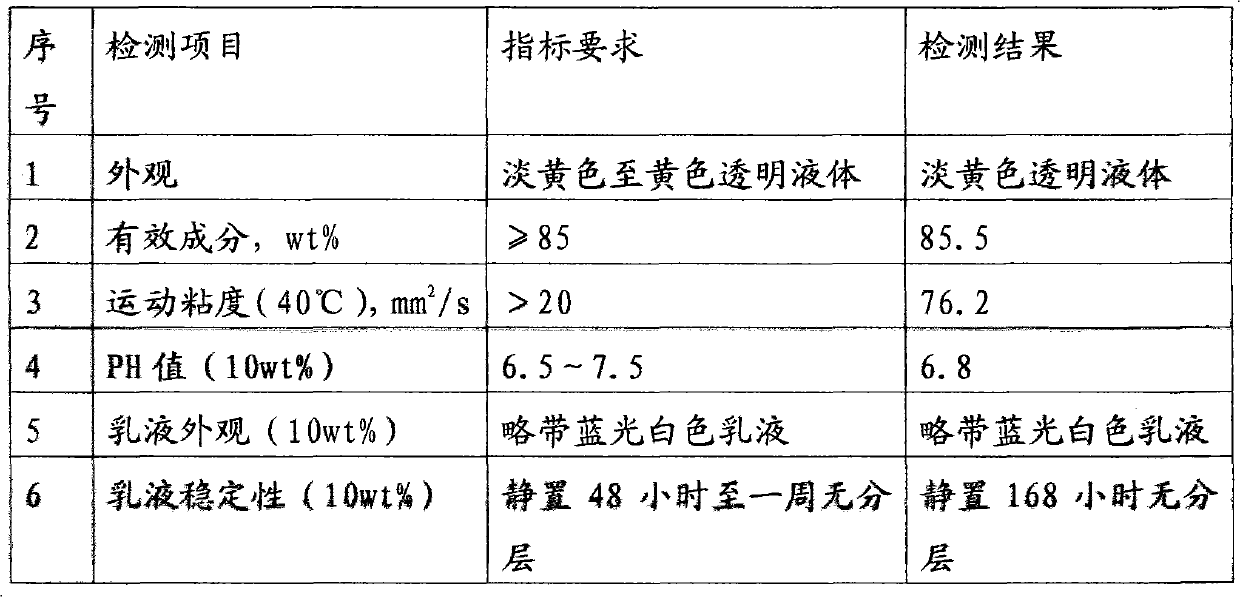

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

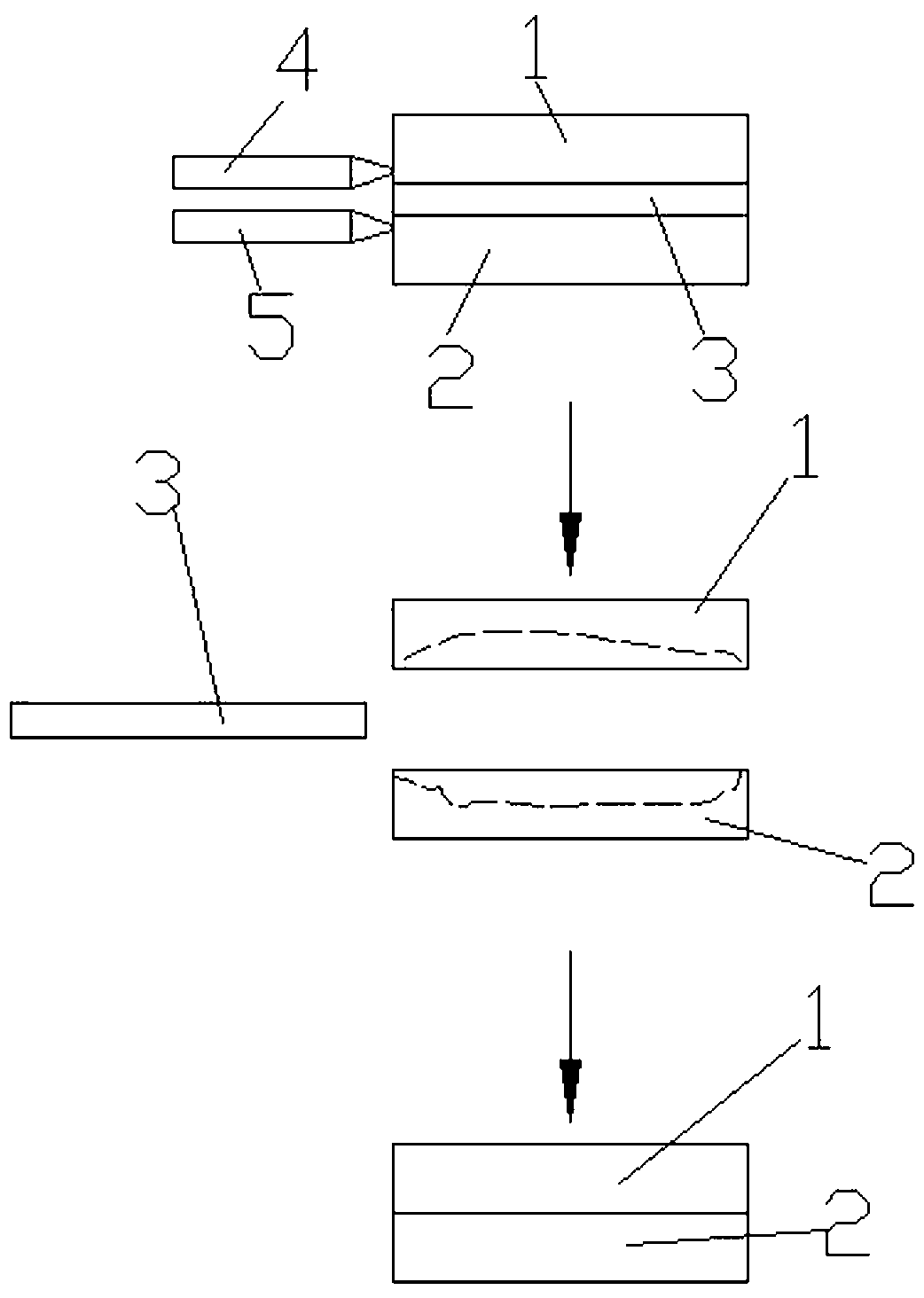

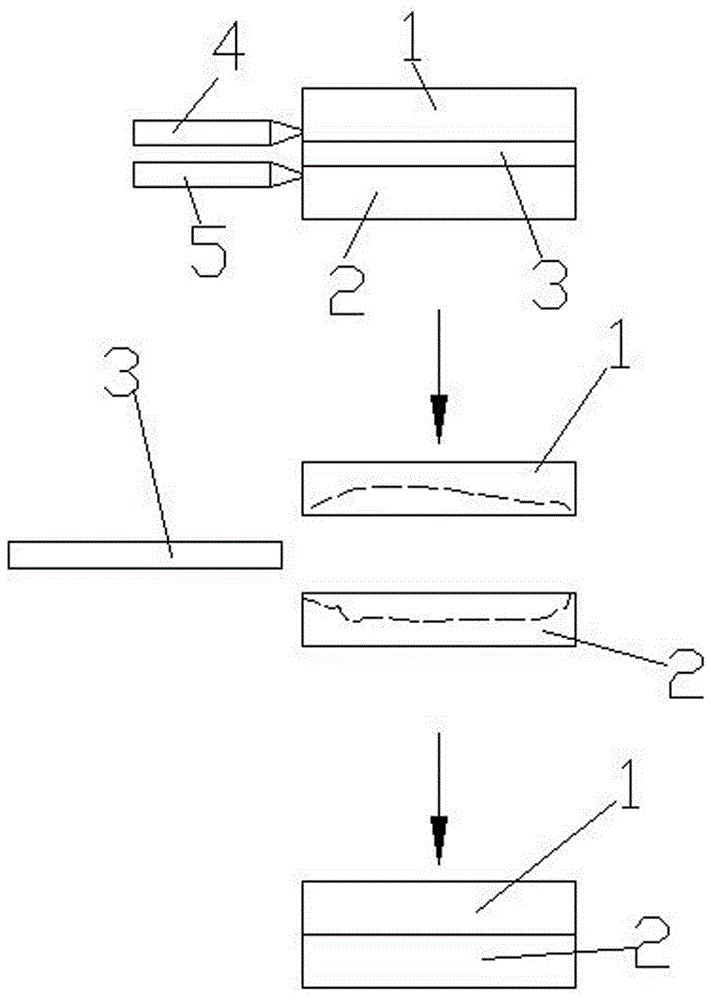

Forming technology and preparation method for double-color and double-hardness sole

ActiveCN103128978AEliminates manual hand gluing stepsSimple processDomestic articlesPlastic injection moldingHardness

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

Water-based lubricant and preparing method of the same based on nanometer tungsten disulfide

The invention discloses a water-based lubricant based on nanometer tungsten disulfide, which comprises the following components and contents, by weight, 1% to 15% of nanometer tungsten disulfide, 1% to 10% of solid lubricant, 0.2% to 3% of antirust agent, 10% to 40% of aqueous stearic acid, 10% to 20% of waterborne zinc stearate, 0.4% to 4% of emulsifying stabilizer, 0.01% to 0.05% of defoaming agent, and 8% to 77% of water. The constituent content of the components sums up to 100%. The preparing method of the water-based lubricant and a usage method thereof are disclosed. The water-based lubricant based on the nanometer tungsten disulfide has the advantages of being good in the lubrication effect of the water-based lubricant, large in elongation coefficient, environment-friendly and unpolluted, and wide in applying scope. In addition, the preparing method of the water-based lubricant and the use method and process steps thereof are simple and fast so as to improve the production efficiency and benefit the environmental protection.

Owner:HENAN HUIER NANO TECH

Preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for pet

ActiveCN102630827AImprove freshnessReduce fishy smellAnimal feeding stuffWorking-up animal fodderRaw meatBiting

The invention relates to the field of pet food, and in particular relates to a preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for a pet. According to the preparation method disclosed by the invention, poultry, livestock meat or bright flesh of fish or fresh skin of animals such as pig, calf and fish is taken as raw material, the raw material is minced and chopped, moulded and frozen and then split, or the raw material is directly split and then frozen, or the raw material is split into the required shape and then frozen, subsequently microwave vacuum dryingis carried out, and sterilizing and packaging are carried out, and thus the edible jerky or calfskin, pigskin and fish skin biting chew for the pet is obtained. The edible jerky or calfskin, pigskin and fish skin biting chew finished product can show primary colour of raw meat, has a strong meat flavour and maintains nutrition of a meat product while a food calling function is realized. The edible jerky or calfskin, pigskin and fish skin biting chew can be taken as a meat snack for the pet and also can be taken as a nutritional supplement for an old-aged dog or little dog after being rewatered and torn up.

Owner:JIANGSU YIHE PET PROD CO LTD

Aqueous zinc stearate dispersion liquid and preparation method thereof

ActiveCN103266534AHigh speed stirringSmall particle sizeNon-fibrous pulp additionCoatingsPreservativeZinc

The invention discloses an aqueous zinc stearate dispersion liquid. The aqueous zinc stearate dispersion liquid is prepared from the following components by weight: 35 to 45% of zinc stearate, 4 to 10% of an emulsifier, 1 to 4% of a dispersant, 0.1 to 0.5% of a defoaming agent, 0.1 to 0.3% of an antiseptic and 40.2 to 59.8% of water, wherein the content of the above-mentioned components sums to 100%. The invention further discloses a preparation method for the aqueous zinc stearate dispersion liquid. The aqueous zinc stearate dispersion liquid provided by the invention has the advantages of a small particle size, high solid content, small viscosity, good stability, no toxicity, environment friendliness and an ideal lubrication effect. The preparation method for the aqueous zinc stearate dispersion liquid is simple, easy to operate and beneficial for industrialized application and enables production cost to be reduced.

Owner:肇庆市至立自动化科技有限公司

Forming technology and preparation method of bicolor sole

The invention relates to the field of soles, and provides a forming technology and preparation method of a bicolor sole which has simple forming technology and high production efficiency. According to the bicolor sole which is produced by utilizing the forming technology, the bicolor sole is free from debonding and delaminating as the shoe undersole and the shoe insole are combined firmly, and the service life is long. The forming technology and preparation method of the bicolor sole, provided by the invention, relates to the following steps of: material preparing-pelleting-injection-forming preparing-injection forming-foaming-punching-milling expanding-oil pressing.

Owner:晋江市五里艇源鞋塑有限公司 +1

Preparation method of flame-retardant magnesium alloy

The invention discloses a preparation method of a flame-retardant magnesium alloy and relates to a magnesium alloy with aluminum as a minor main component. The method comprises the steps of weighing a magnesium ingot, an aluminum ingot, an Mg-Ca master alloy with the calcium content of 20 wt percent and an Mg-Y master alloy with the yttrium content of 25 wt percent as raw materials for feed preparation according to the mass percentage of component elements in the target magnesium alloy, wherein the target magnesium alloy comprises component elements in percentage by weight: 90.7-92.7 percent of Mg, 6.0 percent of Al, 0.3 percent of Mn, 0.5-1.5 percent of Ca and 0.5-1.5 percent of Y, the purity of a magnesium ingot is 99.99 percent, the purity of an aluminum ingot is 99.99 percent, and the purity of a manganese sheet is 99.99 percent; and putting all the raw materials in a gas protection melting furnace, carrying out smelting on the raw materials, then adding a refining agent into the gas protection melting furnace, carrying out refining, pouring the refined raw materials into a cast iron die finally, and carrying out air cooling until room temperature is reached to prepare a flame-retardant magnesium alloy cast ingot of Mg-Al-Mn-Ca-Y. With the adoption of the preparation method, the disadvantages of the flame-retardant magnesium alloy in the prior art that the raw material cost is high, and components contain toxic substances are overcome.

Owner:HEBEI UNIV OF TECH

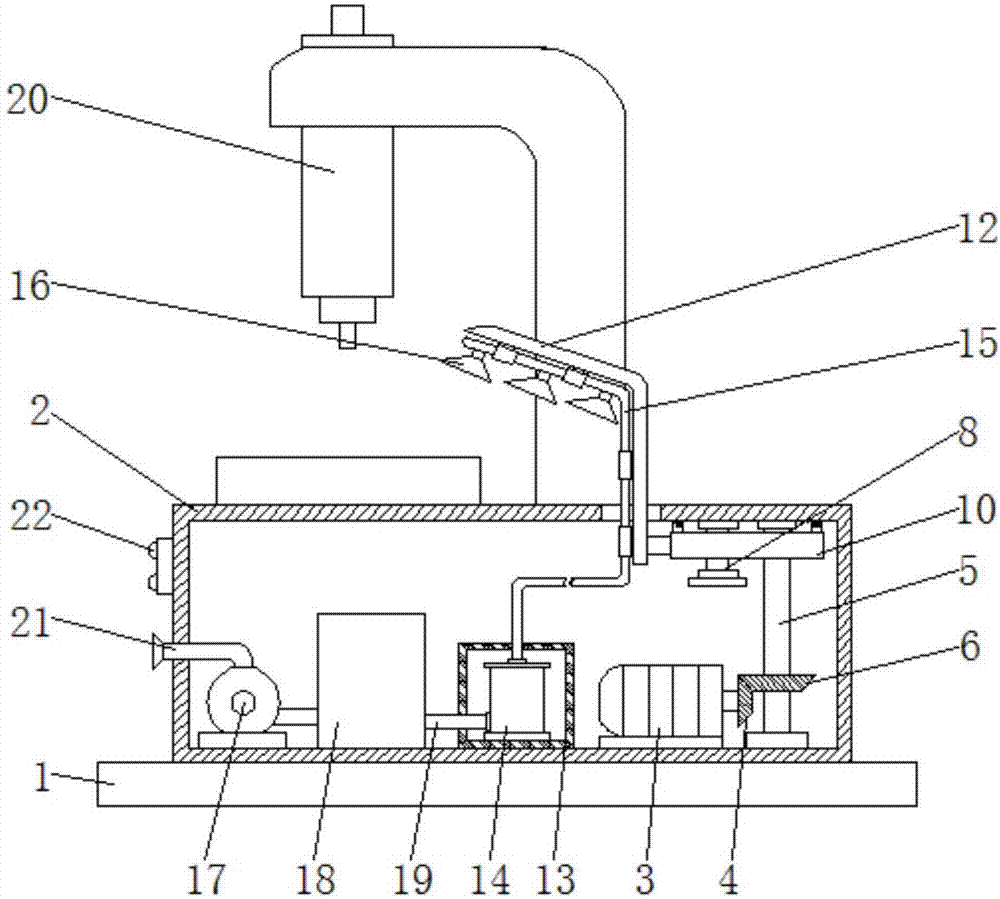

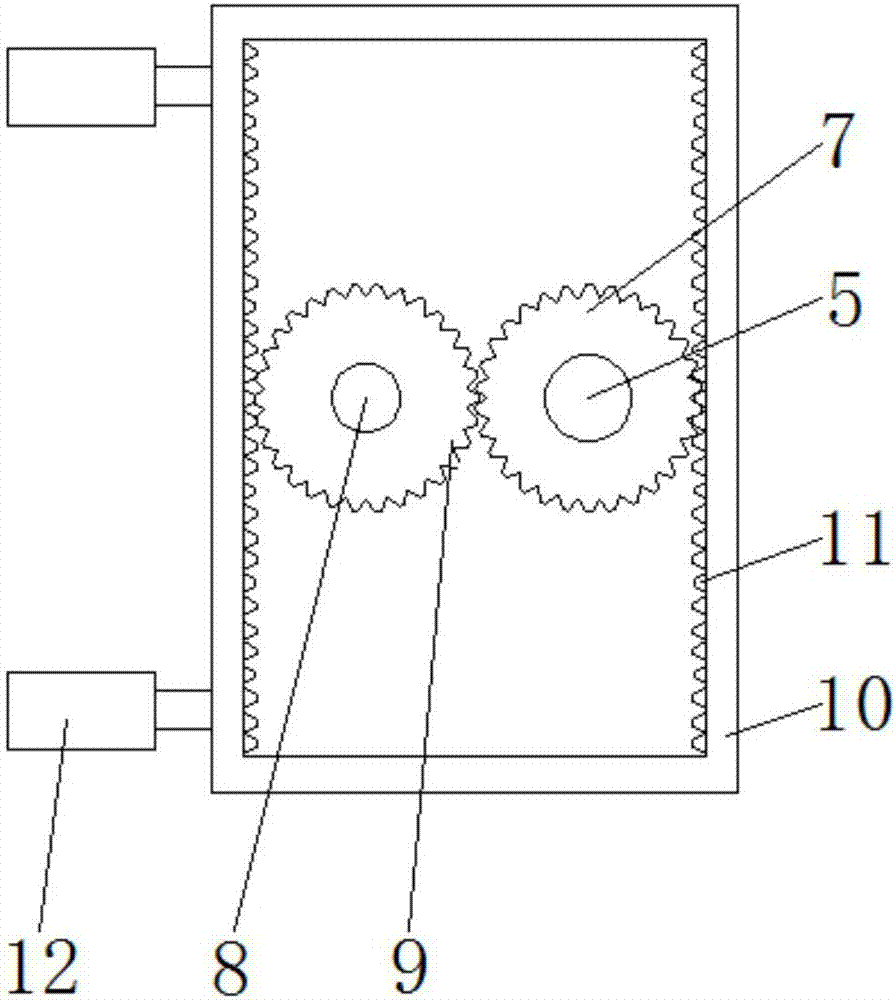

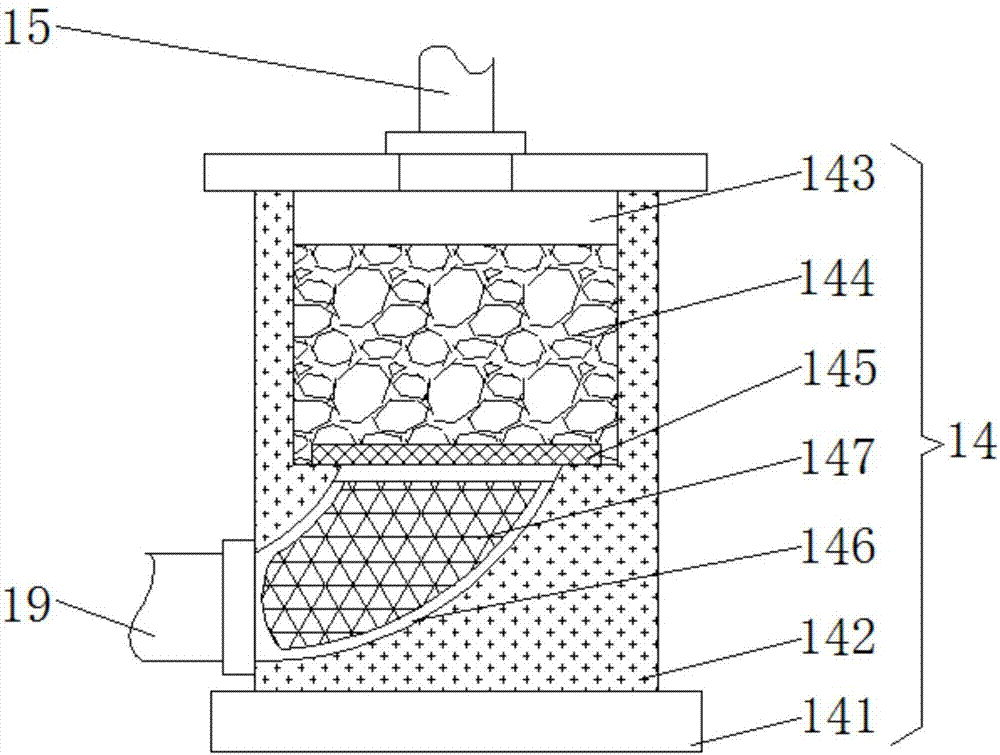

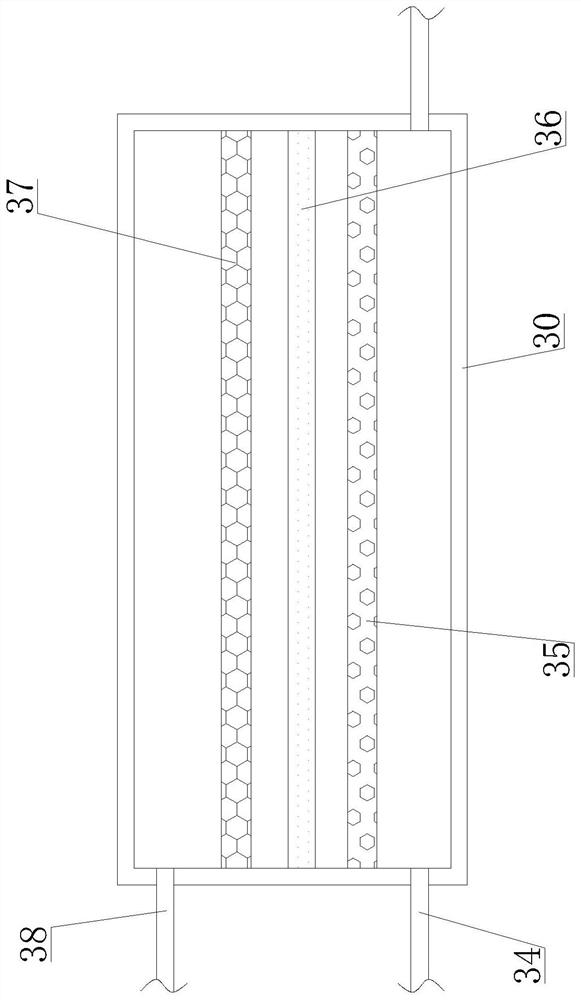

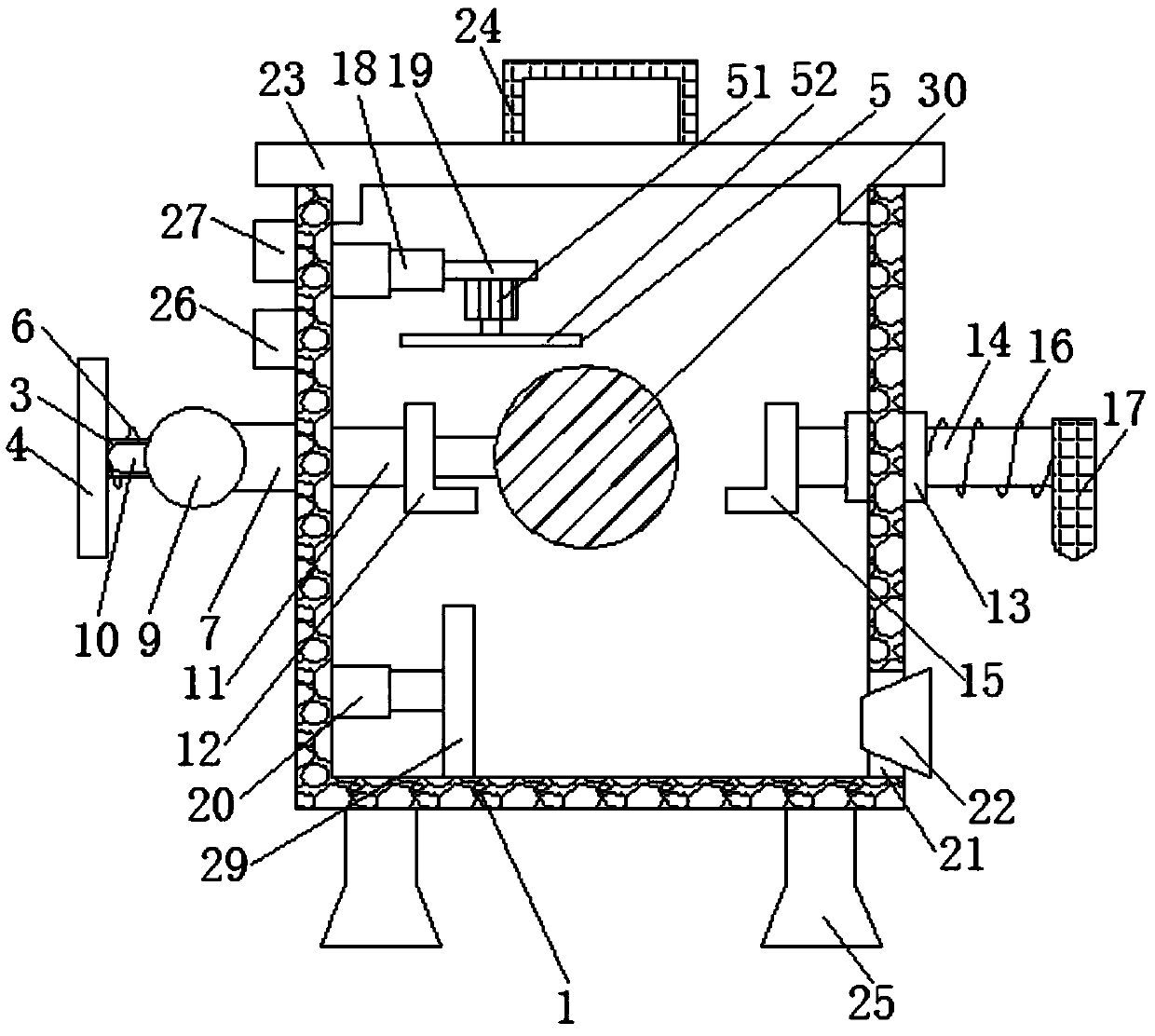

Spot welding machine welding fume purifying device with environment-friendly function

InactiveCN107442917AWith environmental protection functionPromote environmental protectionResistance welding apparatusPhysical healthDrive shaft

The invention discloses a spot welding machine welding fume purifying device with an environment-friendly function and relates to the technical field of spot welding machine purifying equipment. The spot welding machine welding fume purifying device comprises a bottom plate; a case is fixedly connected to the top of the bottom plate; a motor is fixedly connected to the bottom of the inner wall of the case through a connecting block; an output shaft of the motor is sleeved with a first bevel gear; and a transmission shaft is rotatably connected to the position, located on one side of the motor, at the bottom of the inner wall of the case through a bearing seat. According to the spot welding machine welding fume purifying device with the environment-friendly function, the environmental protection property of a spot welding machine is greatly improved, welding fume discharged by the spot welding machine is well collected and purified in a centralized mode, the situations that the welding fume is directly discharged into air and pollutes the environment around the spot welding machine are prevented, and the situation that workers suck the large amount of welding fume, and thus the physical health of the workers is greatly damaged is well avoided, so that normal spot welding work of the workers is guaranteed, and using of people for the spot welding machine is quite facilitated.

Owner:湖州同晟管理咨询有限公司

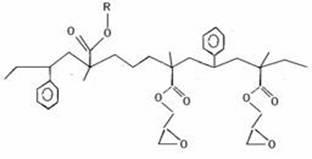

Preparation method of heat-resistant polylactic acid biodegradable material

The invention relates to a method for preparing a polylactic acid biodegradable material by chemical polymerization, which takes lactic acid as a raw material and comprises an esterification dehydration step and a polycondensation step. After the esterification dehydration step is finished and before the polycondensation step is finished, a catalyst, a nucleating agent and a chain extender are added into a reaction kettle, wherein the nucleating agent is a mixed emulsion formed by completely dissolving disodium salicylate solids in a resin emulsion, and the adding quantity of the nucleating agent is 5-25% of the total weight of the heat-resistant polylactic acid; the resin emulsion is an epoxy resin emulsion or a polyurethane resin emulsion or a combination of the epoxy resin emulsion and the polyurethane resin emulsion; and the chain extender is a styrene-acrylic acid copolymer of which the number-average molecular weight is 7500-15000 and the side chain contains 6-7 epoxy groups, and the adding quantity of the chain extender is 0.5-5% of the weight of the heat-resistant polylactic acid. In the method provided by the invention, talcum powder is not used, the production process can be controlled easily, and the prepared polylactic acid biodegradable material has excellent heat resistance and is suitable for industrialized production.

Owner:ZHANGJIAGANG CHAINENG BIOLOGICAL TECH

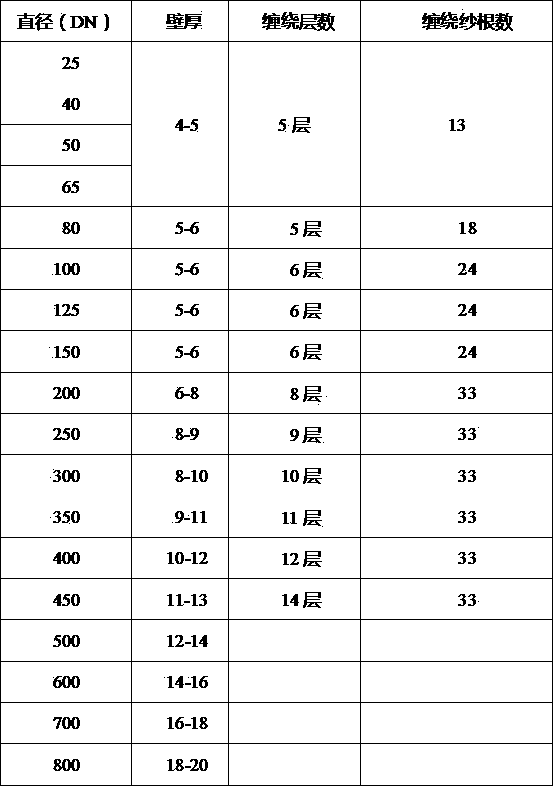

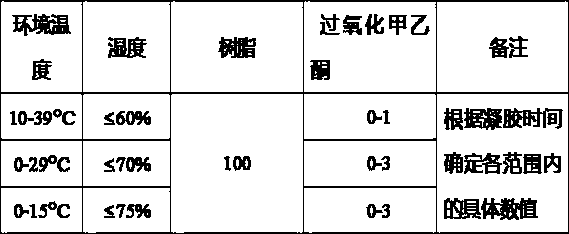

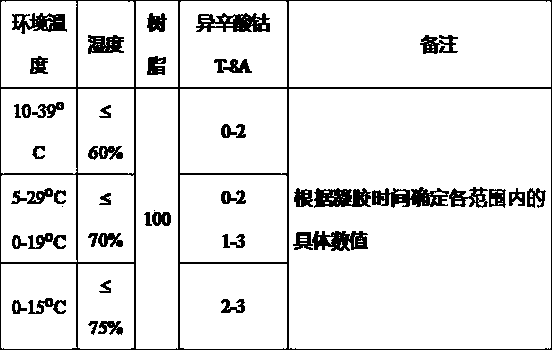

Glass fiber reinforced plastic pipe and manufacturing method thereof

The invention relates to a glass fiber reinforced plastic pipe and a manufacturing method thereof. Materials of the glass fiber reinforced plastic pipe comprise FW-H-2028 unsaturated polyester resin, HR-192-N unsaturated polyester resin, curing agent, accelerant, flame retardant, roving EDR240-T910, a non-alkali knitting mat MEK380, mesh cloth, a surface mat and a polyester thin film. The manufacturing method comprises weighing the two types of adequate unsaturated polyester resin, pouring the unsaturated polyester resin into different mixing buckets respectively and adding into the flame retardant and pigment paste in proportion; measuring the adequate accelerant and adding into the mixing buckets to be uniformly stirred; weighing a certain amount of curing agent to be mixed with the materials and uniformly stirring; manufacturing a lining in a corresponding mould and then manufacturing a structure layer; hoisting the mould to a curing station through a hoisting device to be heated and cured; hoisting the mould to a mould dismounting machine after the curing and performing demoulding through a mould dismounting ring. The production process of the glass fiber reinforced plastic pipe is simple, the materials are environmentally-friendly, and the damage to the physical health of people cannot be produced.

Owner:SUZHOU MUYI SHIPPING EQUIP

Combination cultivation kit of beadroll bacterium, hemophilus and mycoplasma, and uses thereof

InactiveCN101270382APhysical health hazardNo radioactivityMicrobiological testing/measurementMycoplasma cultureOrganism

The invention relates to a combined culture reagent box of Candida Albicans, hemophilic bacteria and mycoplasma and application thereof. The reagent box comprises a culture medium and a CO2 generator. The culture medium comprises culture medium of Candida Albicans, culture medium of hemophilic bacteria and culture medium of mycoplasma. The pH value of the culture medium is 6.3 plus or minus 0.5. The invention is used to detect Candida Albicans, hemophilic bacteria and mycoplasma, also evaluate the microecology of the urogenital tract of male and female, diagnose the infection of Candida Albicans, hemophilic bacteria and mycoplasma, and evaluate the curative effect of the bacteria. Compared with the prior art, the combined culture reagent box of Candida Albicans, hemophilic bacteria and mycoplasma of the invention has the advantages of the simple operation, the reliable method, the stable characteristics, and easily observing and judging the results, provides a diagnostic tool with more scientific, more convenient, more humanized and more accurate, is favorable for biological or medical practice and commercialized transportation and has the good social and economic efficiency.

Owner:叶鹰

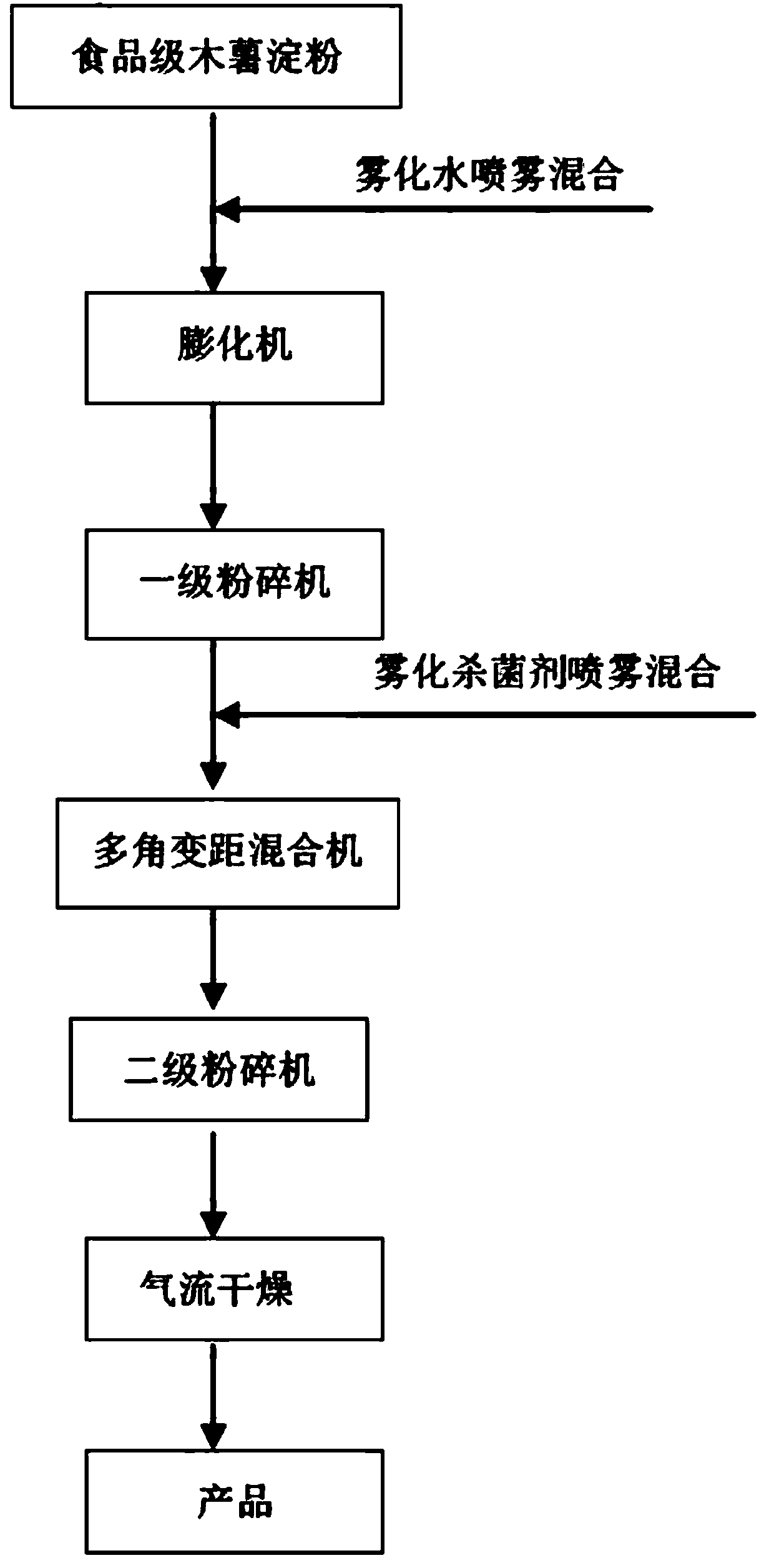

Pre-gelatinized starch and preparation method thereof

InactiveCN103739721AFeed water content is lowReduce energy consumptionTemperature resistanceSaline water

The invention provides pre-gelatinized starch and a preparation method thereof. The pre-gelatinized starch comprises the following components in percentage by weight: 87.00-99% of pre-gelatinized tapioca starch, 0.1-1% of 2-methyl-4-isothiazolin-3-one (MI), 0.1-1% of 5-chloro-2-methyl-4-isothiazolin-3-one (CMI) and the balance of water. The product provided by the invention has the characteristic of perfect liquidity like fine sand, and the characteristic is very convenient to use on the site; although as a powdery product, the product does not generate dust and avoids harm to the physical health of workers on the site; after being added into water or slurry, the product can be automatically and uniformly dispersed and quickly dissolved, and the phenomenon of caking or fish eyes is avoided even without stirring; the requirement on the water loss of 4% salt water and saturated salt water slurry at normal temperature is met; the temperature resistance is good, and the acceptable temperature can reach 120 DEG C in 4% NaCl and saturated salt water slurry; and the product is not a toxic substance and does not have oxidability, corrosivity and radioactivity.

Owner:KAIPING LIANJI CHEM

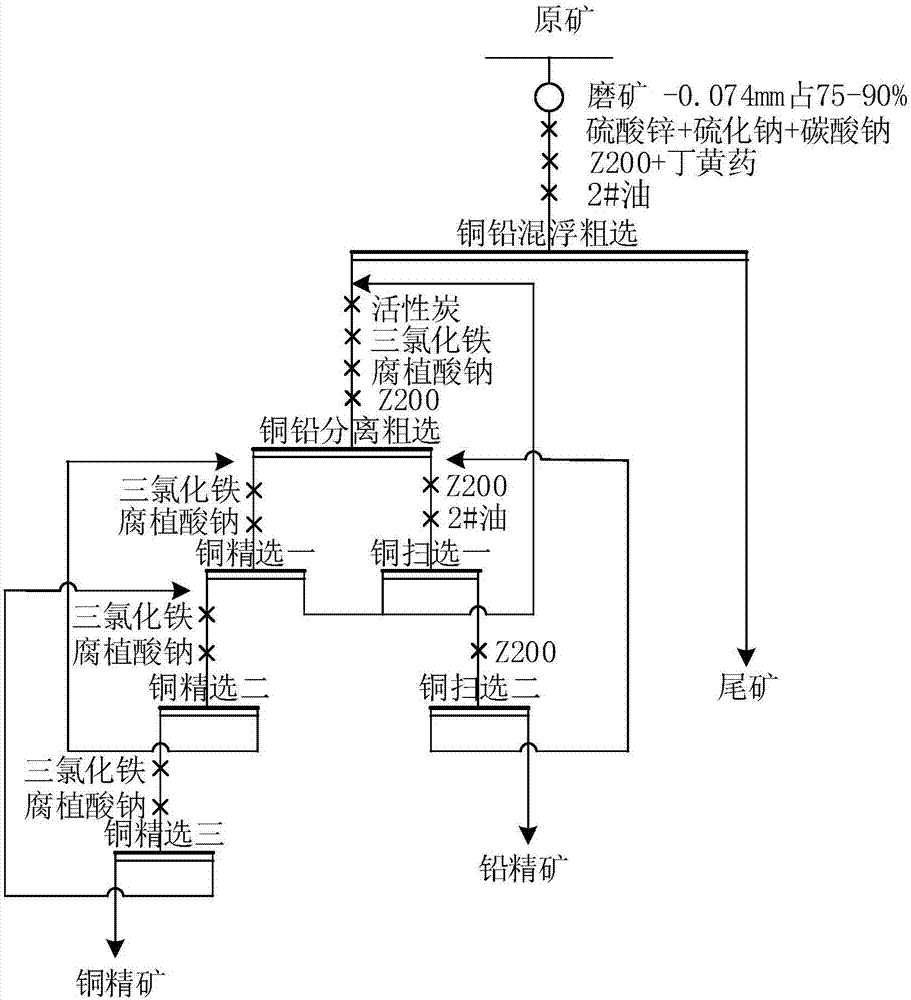

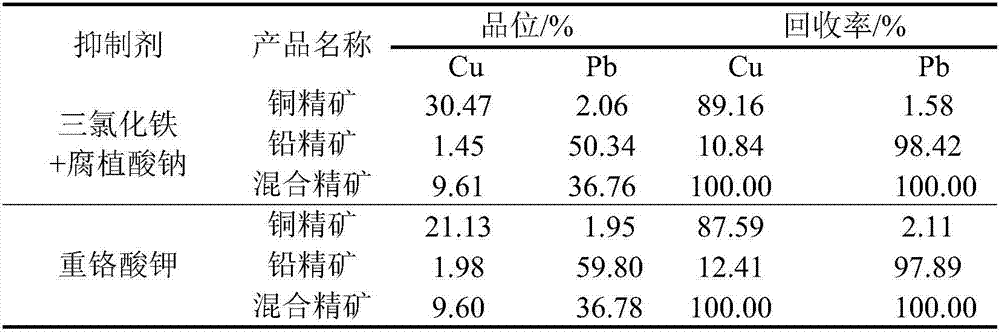

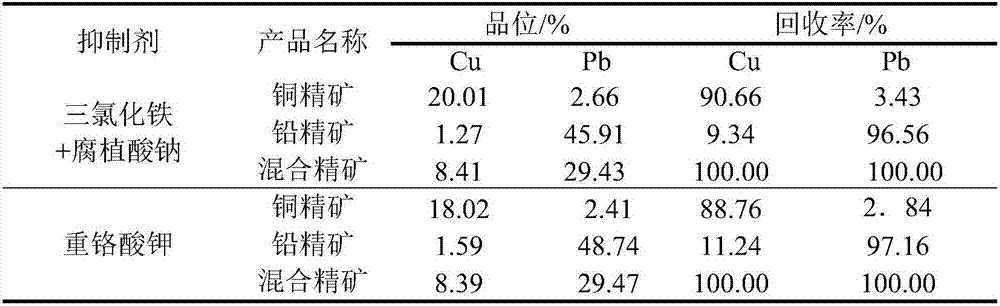

Inhibitor for copper lead sulphide minerals and method for conducting flotation separation with inhibitor

ActiveCN107350087AReduce the impactAchieve the purpose of separationFlotationEnvironmental resistanceMineral flotation

The invention discloses a novel combined inhibitor for copper lead sulphide mineral flotation separation. The inhibitor is formed by mixing a ferric chloride solution with the mass concentration being 1%-3% and a humic acid substance solution with the mass concentration being 8%-10%, and the mass proportion of the ferric chloride (FeCl3) solution and the humic acid substance solution is 1:(6-10). A flotation separation method for copper lead sulphide minerals is provided. The method comprises the following steps that 1, raw ore is subjected to ore grinding; 2, copper and lead mixed flotation is conducted on ground ore; 3, flotation separation is conducted, wherein copper and lead mixed rough concentrate is subjected to reagent removal, the inhibitor composed of the ferric chloride (FeCl3) solution and the humic acid substance solution is added, a collecting agent and a foaming agent are added, and copper concentrate and lead concentrate are obtained through roughing, concentration and scavenging. The inhibitor is applied to copper lead sulphide mineral separation, the copper and lead proportion in the concentrated ore can be lowered, and the grade of the concentrated ore is improved; the advantages that the mineral recovery rate is high, the economical and environmentally friendly properties are achieved, and beneficiation wastewater is easy to process are achieved.

Owner:CENT SOUTH UNIV

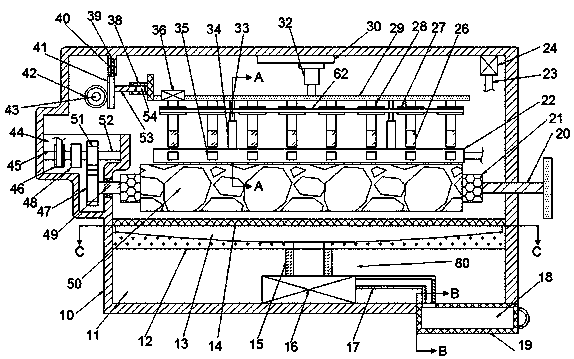

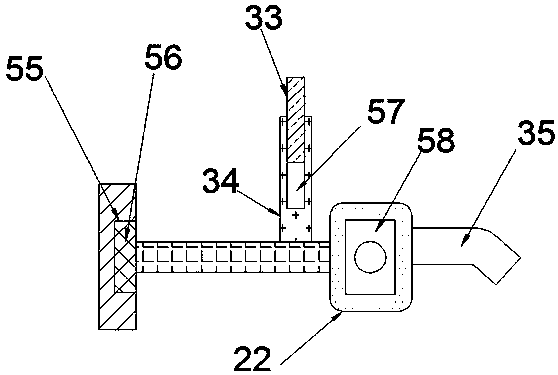

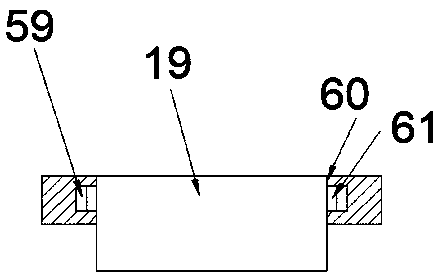

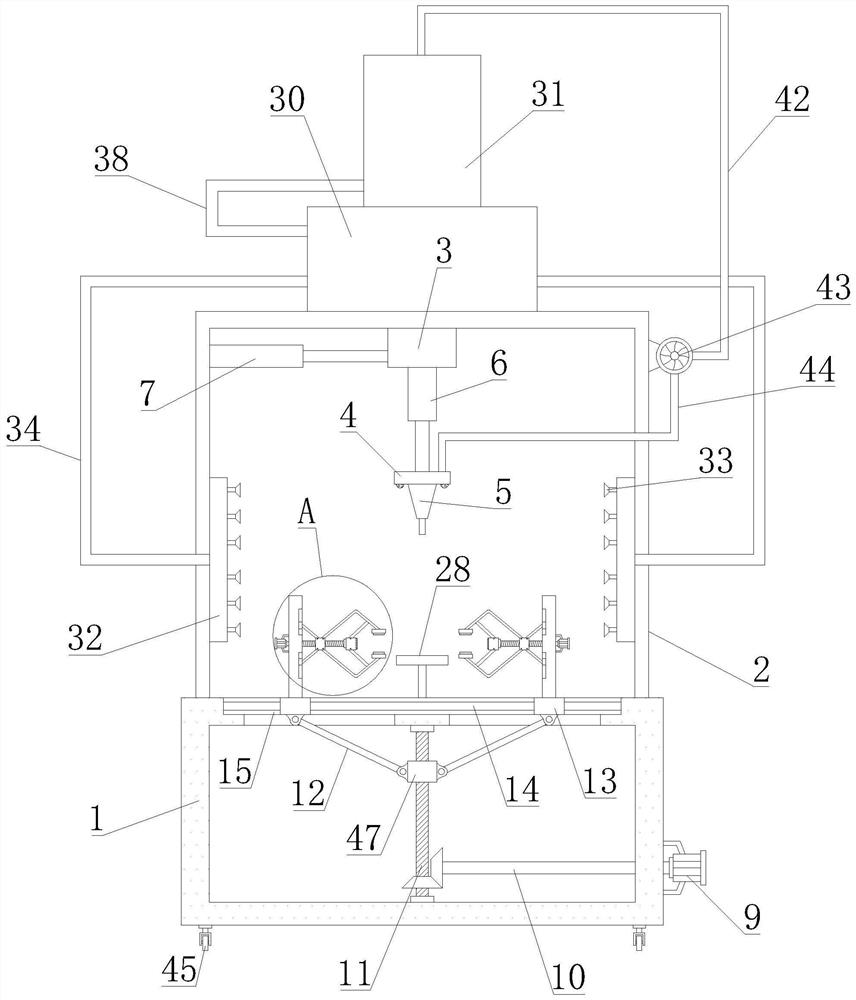

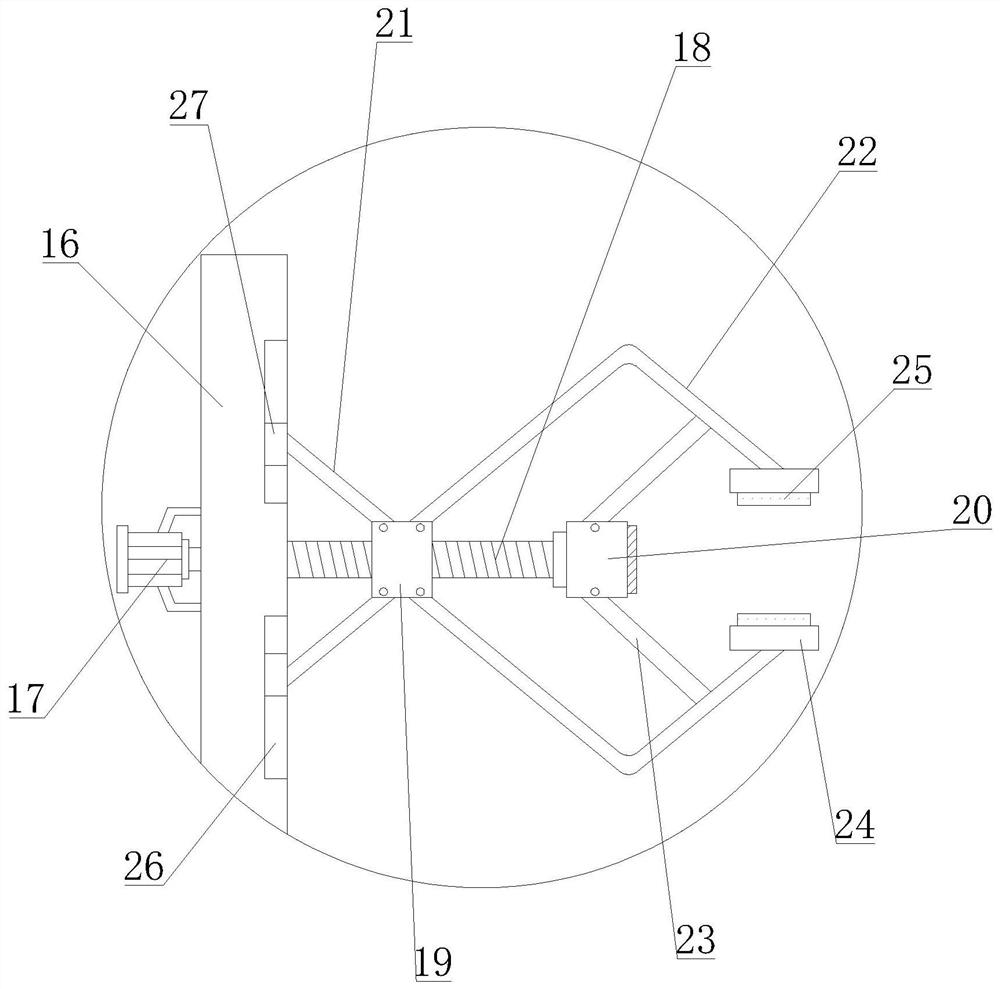

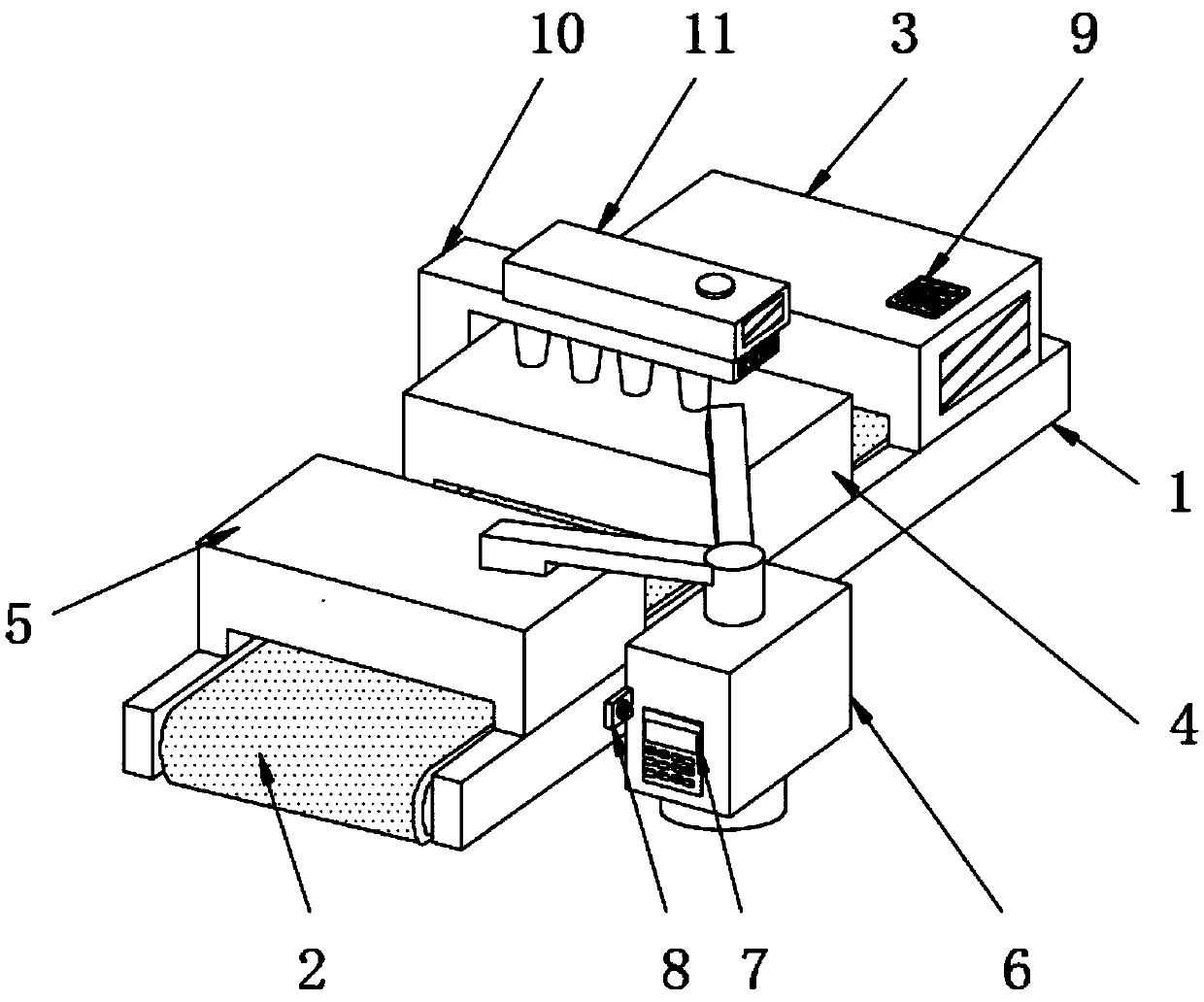

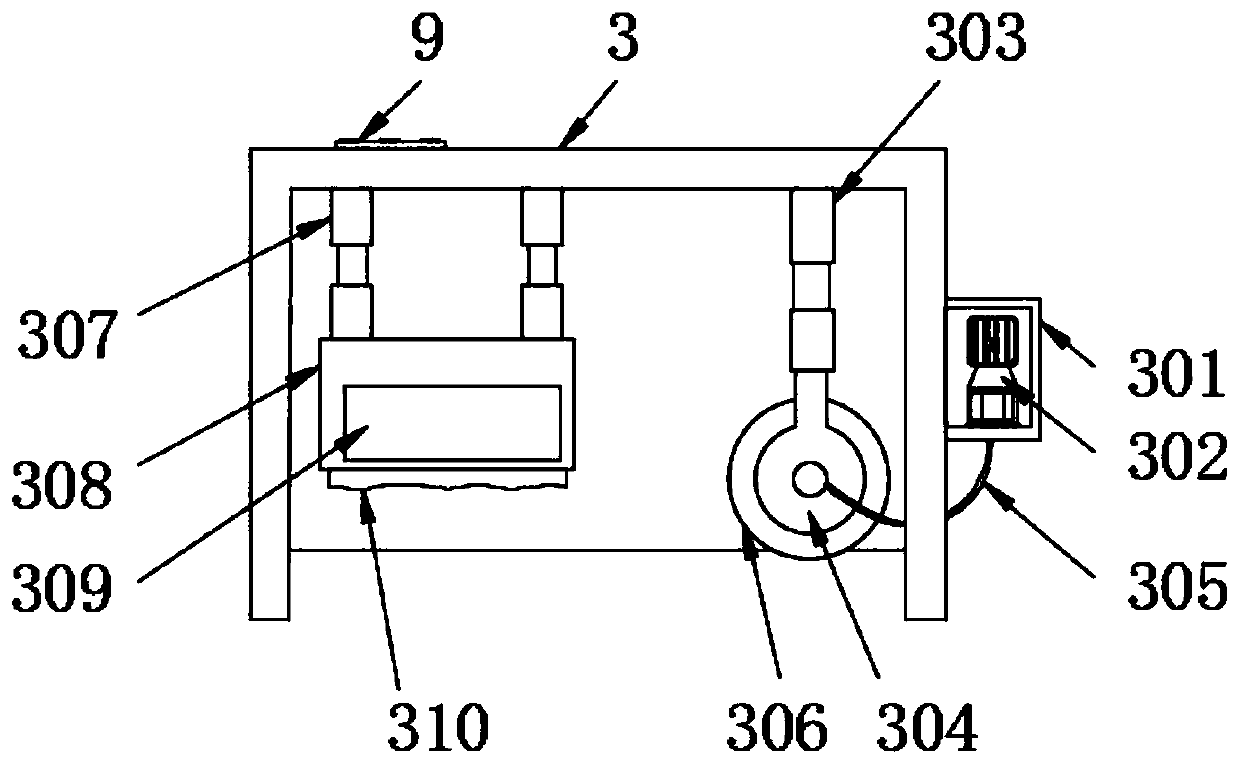

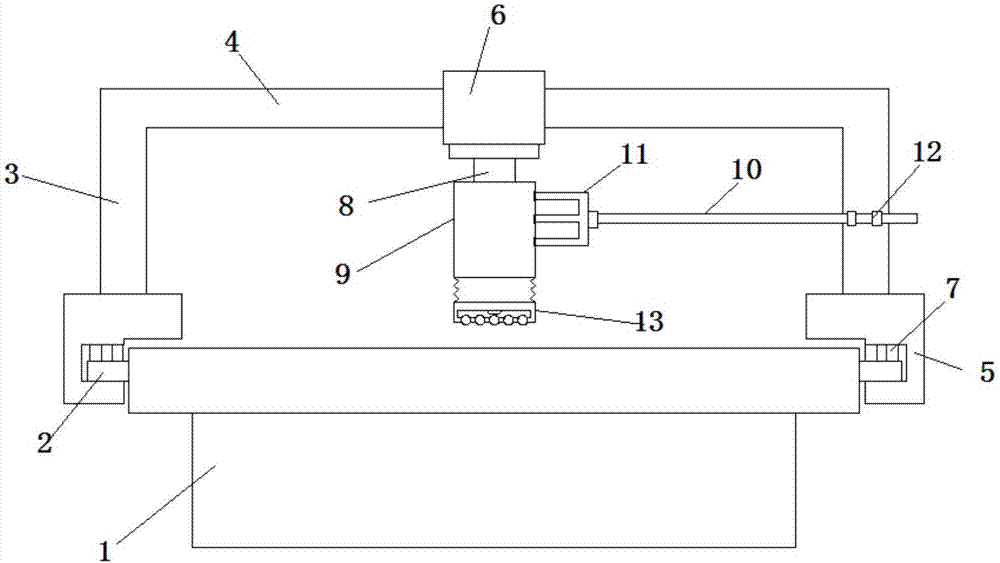

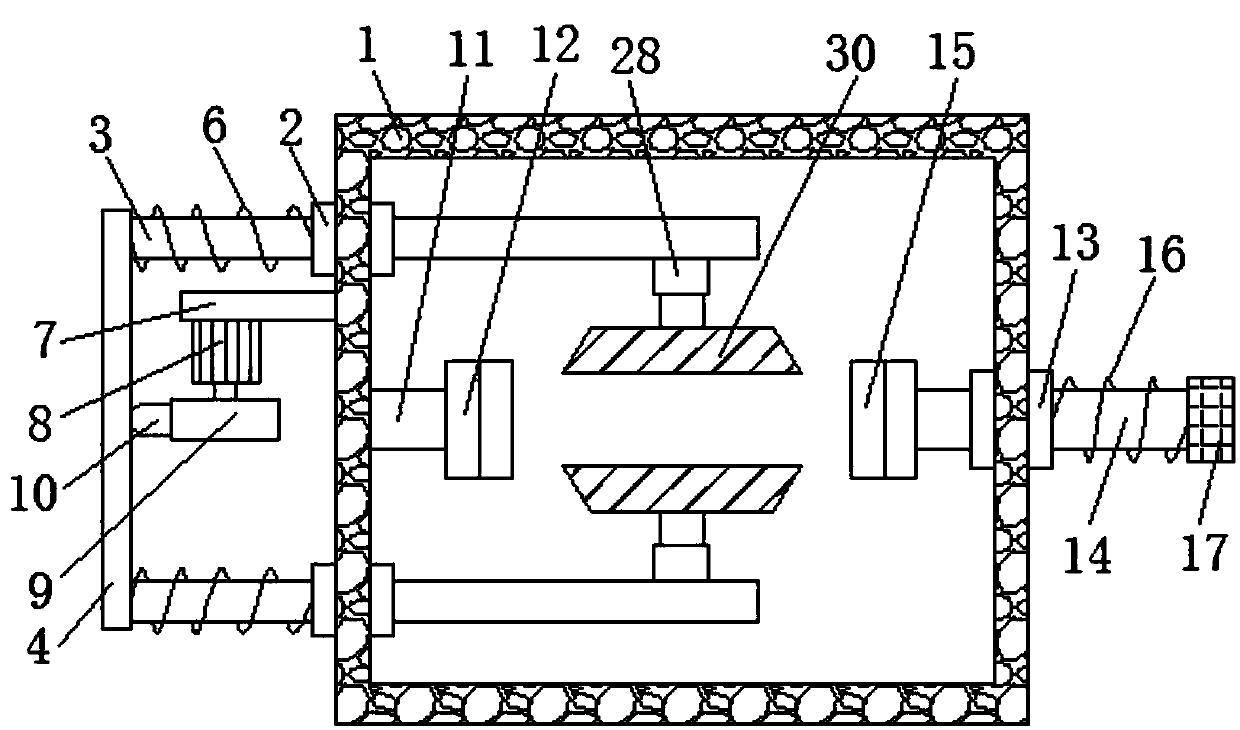

Auxiliary device used in basswood agaric culture

InactiveCN110476722APhysical health hazardImprove efficiencyCultivating equipmentsMushroom cultivationAgaricEngineering

The invention discloses an auxiliary device used in basswood agaric culture. The auxiliary device comprises a work box and a work cavity in the work box, clamping blocks are bilaterally symmetricallyarranged in the work cavity, the right clamping block can move left and right, basswood is put between the left clamping block and the right clamping block, and under the action of the clamping blocks, the basswood is clamped. The clamping blocks can drive the basswood to rotate, after the basswood is put at a specified position, the auxiliary device can drill a row of holes in the basswood at thesame time, and the efficiency is improved; by arranging a dust collection mechanism, wood chips and dust generated in the drilling process are sucked, the harm, caused when wood chips and dust are dispersed into air, to the body health of an operator is prevented, and the collected wood chips and dust can be reused, and the income is increased.

Owner:TIANJIN YUANBAI DAILY NECESSITIES CO LTD

Laser cutting machine with automatic positioning function

InactiveCN112872616AReduce distanceAchieve positioningDispersed particle filtrationWelding/cutting auxillary devicesFlue gasAir pump

The invention relates to a laser cutting machine with an automatic positioning function. The laser cutting machine with the automatic positioning function comprises a fixing box, a protective box, a purifying box and a cooling box; the protective box is arranged on the fixing box; a gas distributing disc is arranged at the bottom of a Z-axis telescopic rod, and a laser cutting head is arranged on the gas distributing disc; gas collecting cases are arranged in the protective box, flue gas sucking covers are arranged on the gas collecting cases, and first connection pipes communicate with the gas collecting cases and the purifying box; a first connection case and a second connection case are arranged in the cooling box, and the second connection case is located over the first connection case; a second connection pipe communicates with the purifying box and the first connection case, and a heat-dissipating pipe communicates with the first connection case and the second connection case; a gas return pipe and an exhausting hose are arranged on a gas pump, and the gas return pipe communicates with the second connection case; and gas spraying heads are arranged at the bottom of the gas distributing disc, and the exhausting hose communicates with the gas distributing disc. According to the laser cutting machine with the automatic positioning function, not only can products be effectively fixed, but also flue gas generated in cutting processes can be purified, and product cuts can be cooled, so that functions are diverse, and the laser cutting machine with the automatic positioning function has an excellent use effect.

Owner:张荷友

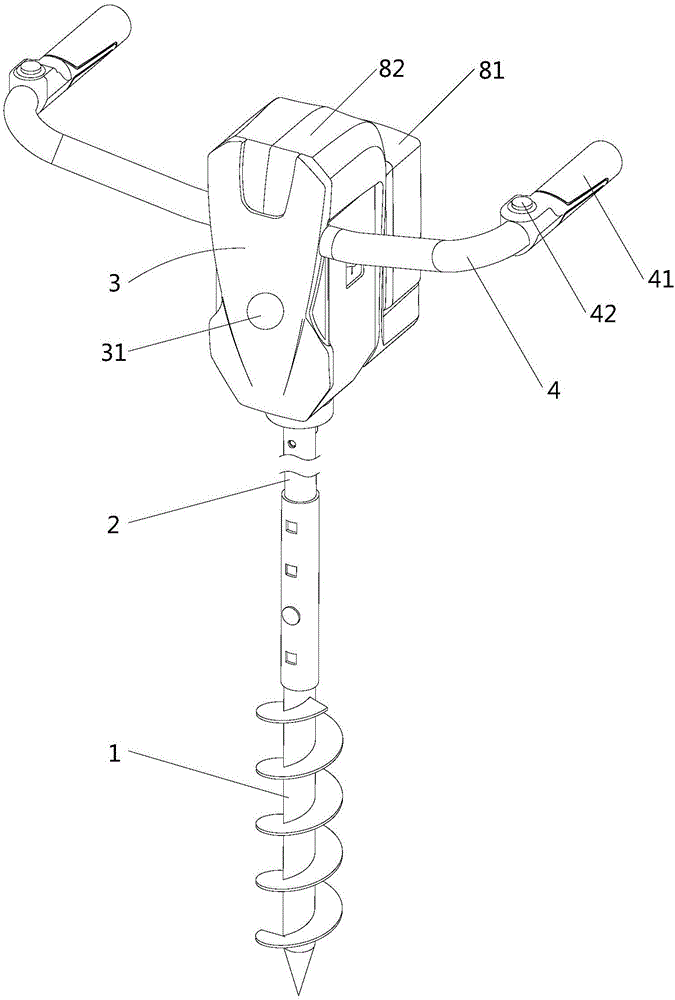

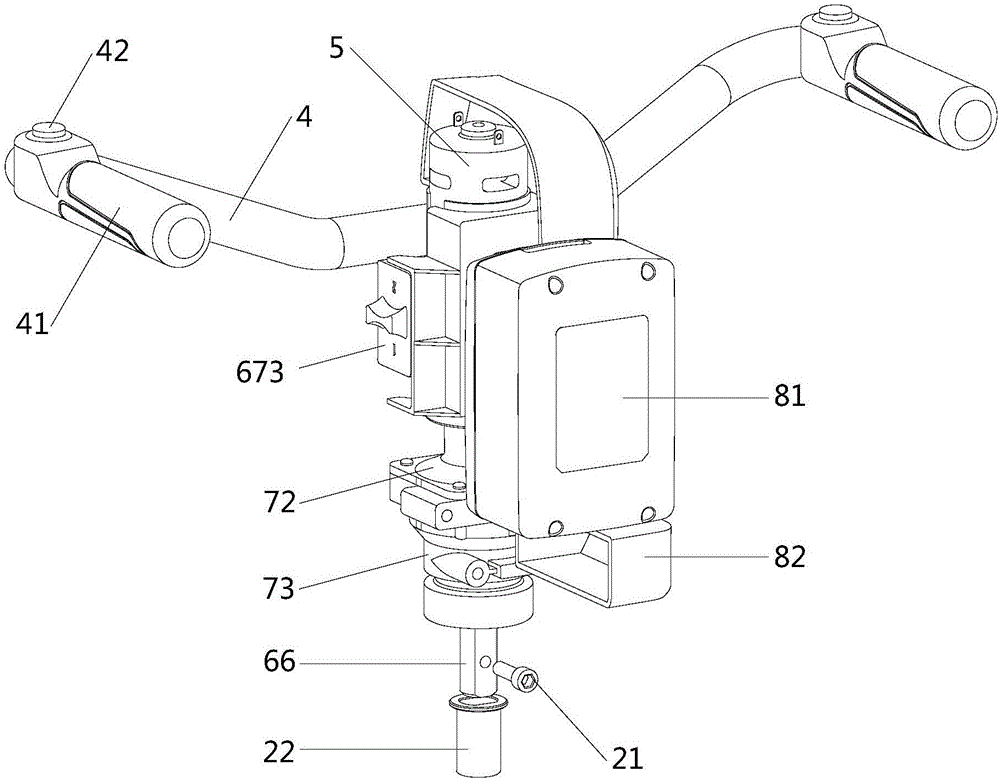

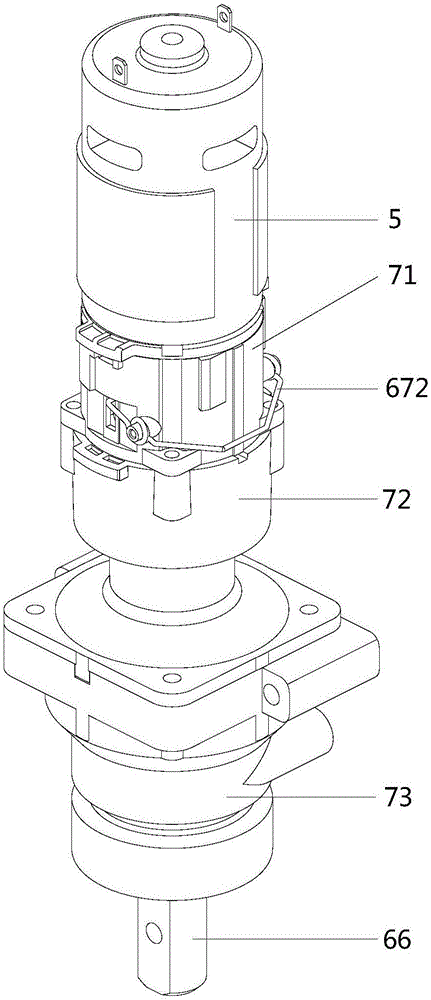

Hand-held drill

ActiveCN106639862AImprove versatilityAvoid Damaged SituationsConstructionsLighting elementsHand heldEngineering

The invention discloses a hand-held drill. The hand-held drill belongs to the technical field of the garden machine. The drill comprises a drill bit and a working head, wherein the drill bit comprises a shell, a hand shank placed on the shell, a generator and a transmission gear both located inside the shell. The transmission gear comprises an output shaft which is connected with the working head. The generator drives the working head to rotate through the transmission gear which comprises a speed controller for adjusting the speed of the output shaft. The prepared product is an improvement in respect of the transmission gear. More Assembly for regulating speed is added. The speed of the output shaft is thus changed. The speed of the working head is adjusted because of the change. It is important to note that the speed of the working head can be changed according to the specific work, which, in turn, improves the commonality of the hand-held drill. Besides, the reform in the speed of the working head may prevent the working head or the generator or the transmission gear from damage, prolonging the life of each component.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

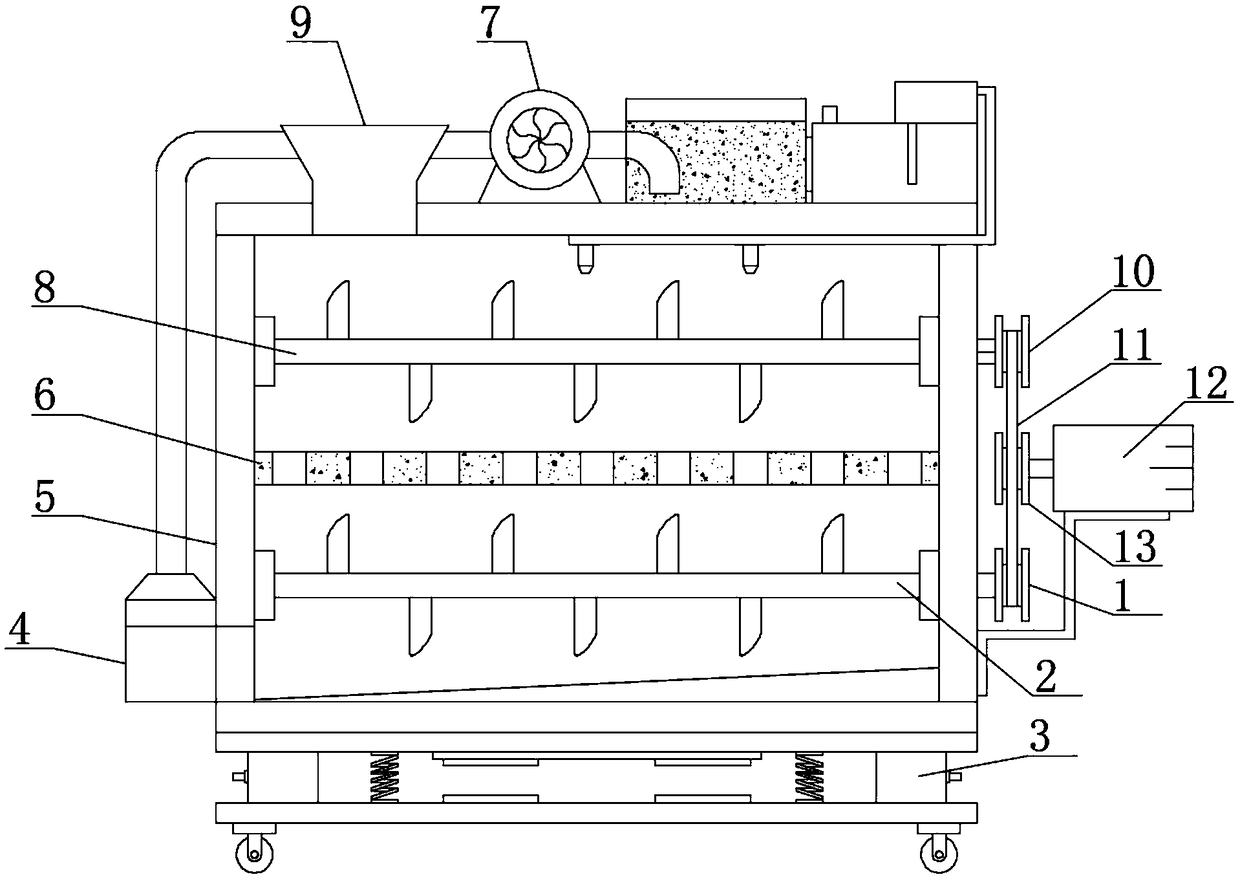

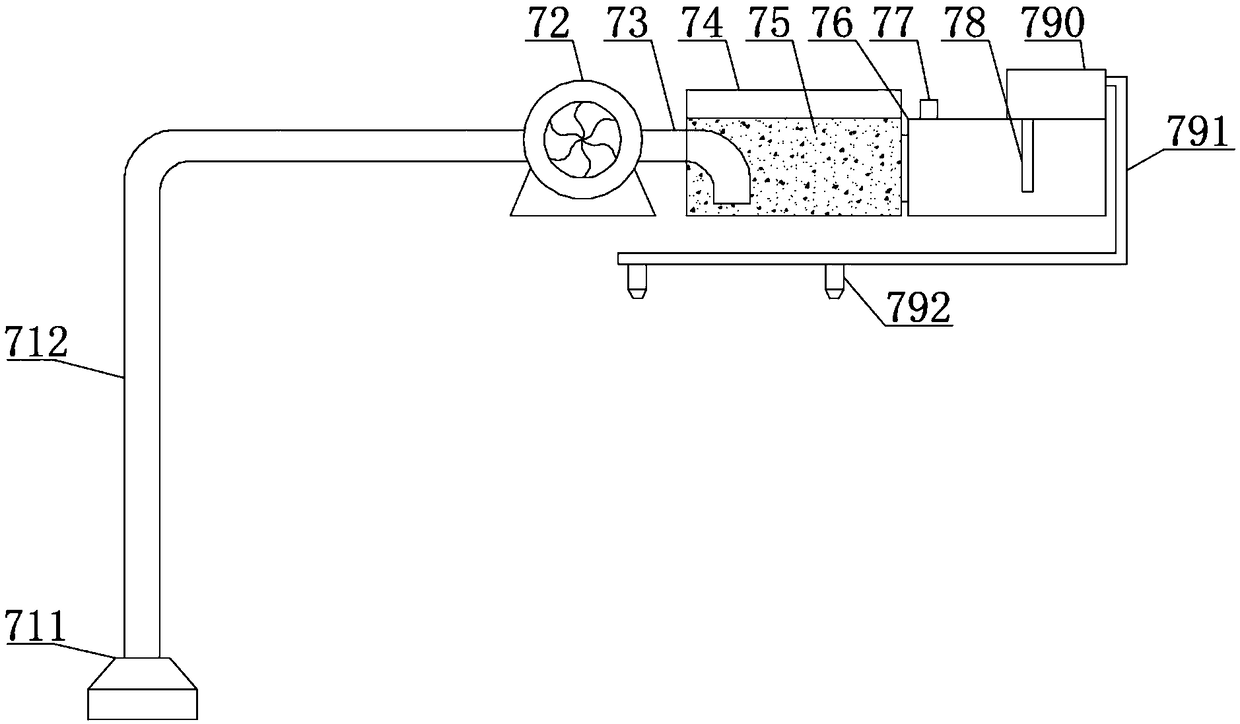

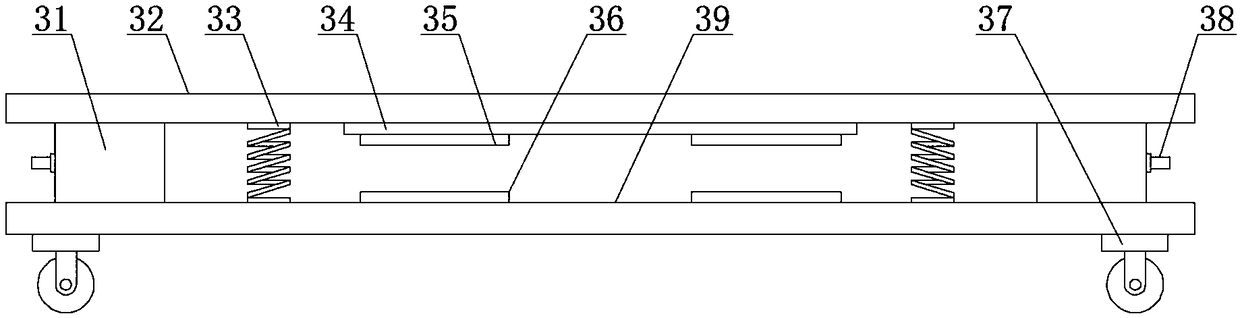

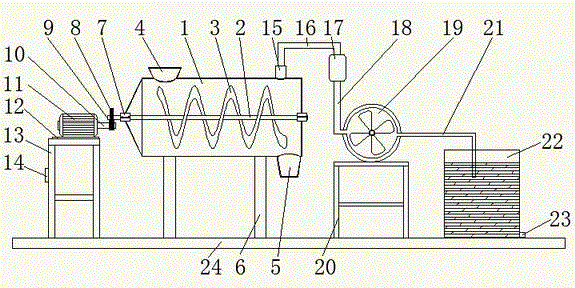

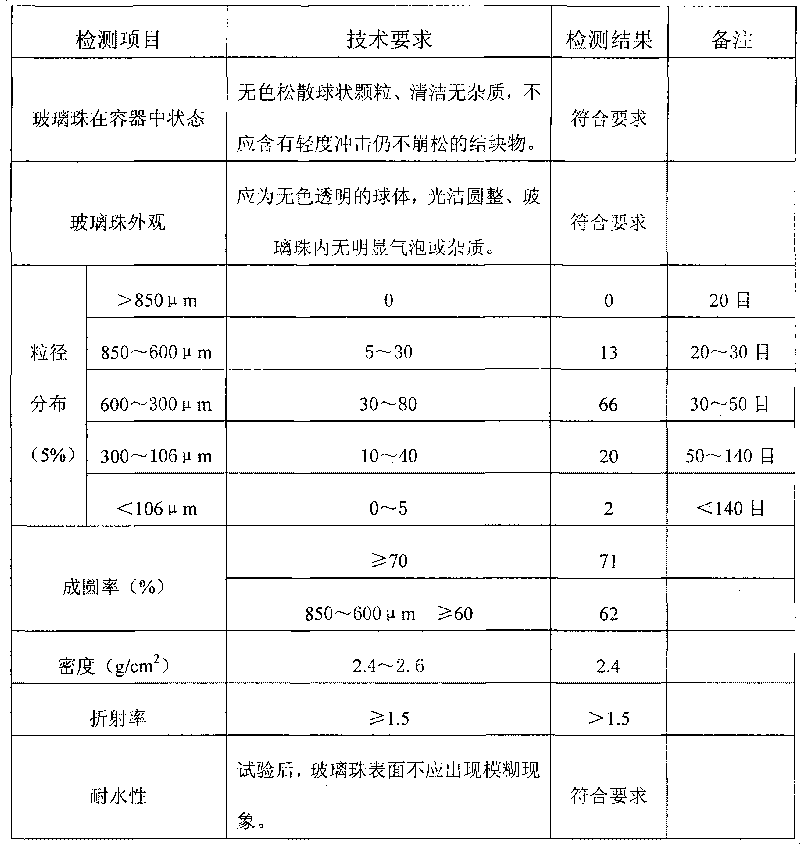

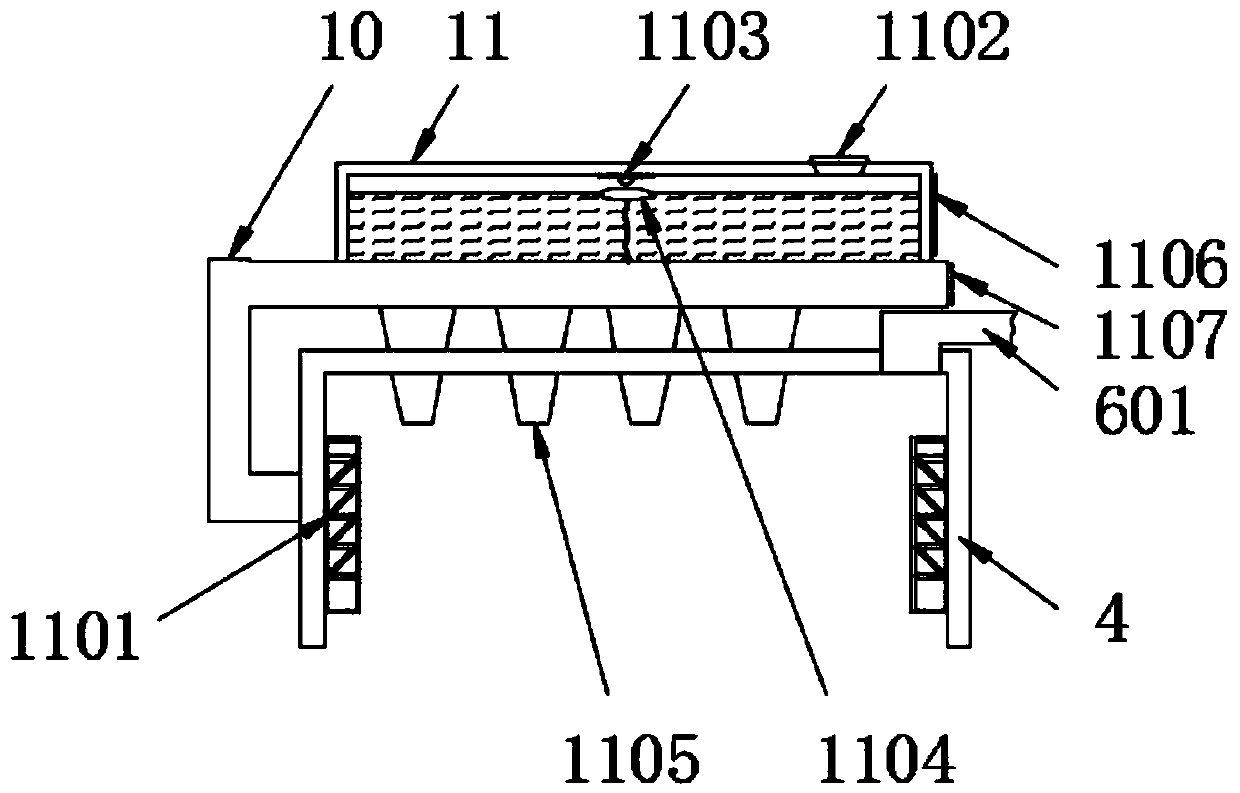

Straw smashing device with dust removal function

InactiveCN109302900AReduce generationAvoid driftingUsing liquid separation agentCuttersSprayerEngineering

The invention discloses a straw smashing device with a dust removal function. The straw smashing device comprises a shock absorption mechanism, a machine housing and a dust removal mechanism, whereina feeding hopper is welded to one end of the upper surface of the machine housing, a filter plate is arranged in the machine housing, a second smashing shaft is arranged above the filter plate, and one end of the second smashing shaft is provided with a second driven gear. A first smashing shaft is arranged below the filter plate, one end of the first smashing shaft is provided with a first drivengear, and a motor is arranged on one side of the first driven gear. The straw smashing device is provided with the dust removal mechanism, a user can use a sprayer in the dust removal mechanism to spray water, so that straw is wetted with the water sprayed through the sprayer, and then less dust is generated when the straw is smashed. The user can use a blower to blow the dust drifting from the straw smashing device into a purifying box, so that the dust is adsorbed by water in the purifying box, and then it is avoided that a lot of dust drifts out in the using process of the straw smashing device.

Owner:孟桂臣

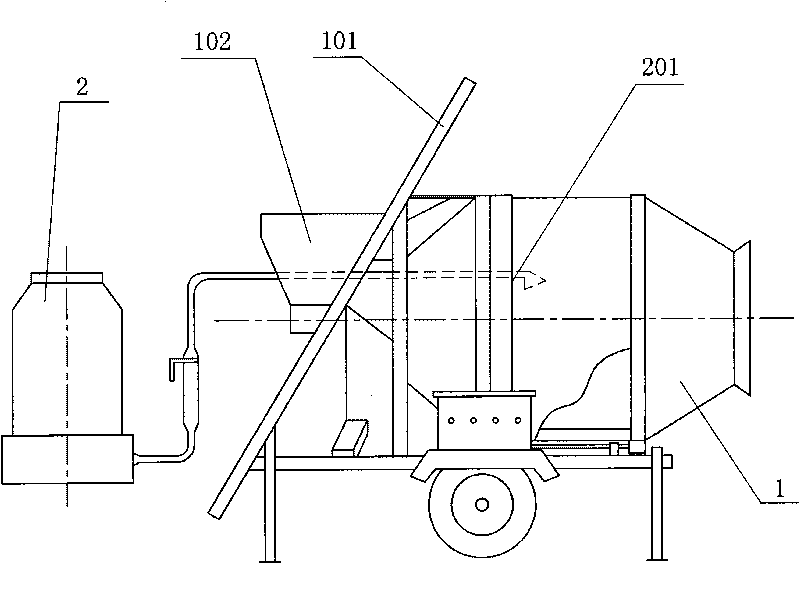

Dust-free mixer

InactiveCN106799178AAvoid harmProtect the environment and personal health and safetyCombination devicesRotary stirring mixersEngineeringWater tanks

The invention discloses a dust-free mixer. The dust-free mixer comprises a mixing box, an exhaust hole is formed in the right side of the top of the mixing box, a first exhaust pipe is connected at the top end of the exhaust hole, a filter device is fixedly connected at the other end of the first exhaust pipe, a filter screen is arranged in an inner cavity of the filter device, a bin door is arranged on the right side of the filter device, a second exhaust pipe is fixedly connected at the bottom of the filter device, a fan is fixedly connected at one end of the second exhaust pipe, and a third exhaust pipe is fixedly connected on the right side of the fan. According to the invention, the exhaust hole, the first exhaust pipe, the filter device, the fan, the second exhaust pipe and a water tank are arranged, so that the first exhaust pipe and the second exhaust pipe discharge dust generated during the use of the mixer into the water tank under the action of the fan through the exhaust hole to be collected so as to avoid environment pollution and harm to physical health of an operator to achieve the purpose of protecting the environment and the health and safety of a human body.

Owner:WUXI AOYUTE NEW TECH DEV

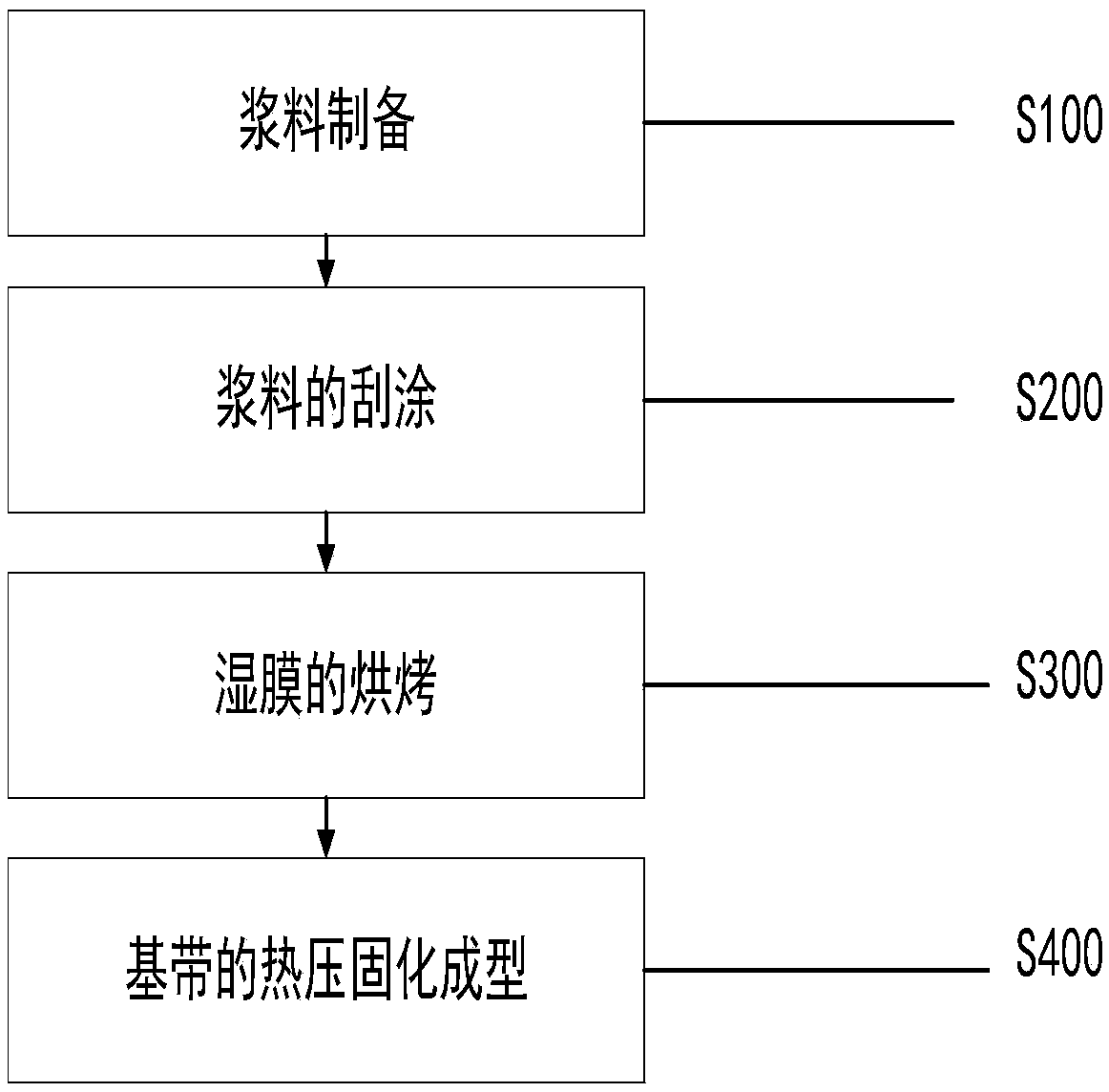

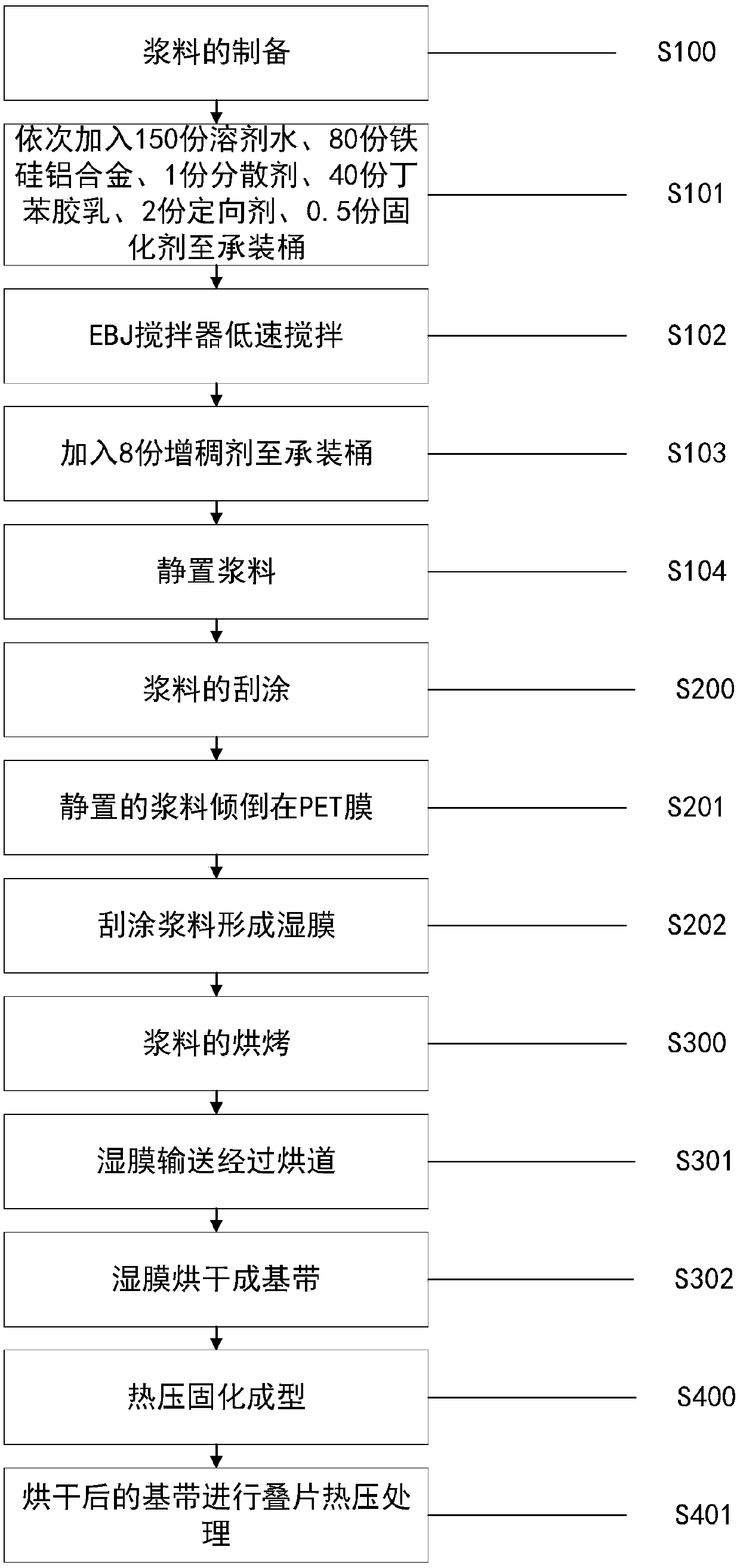

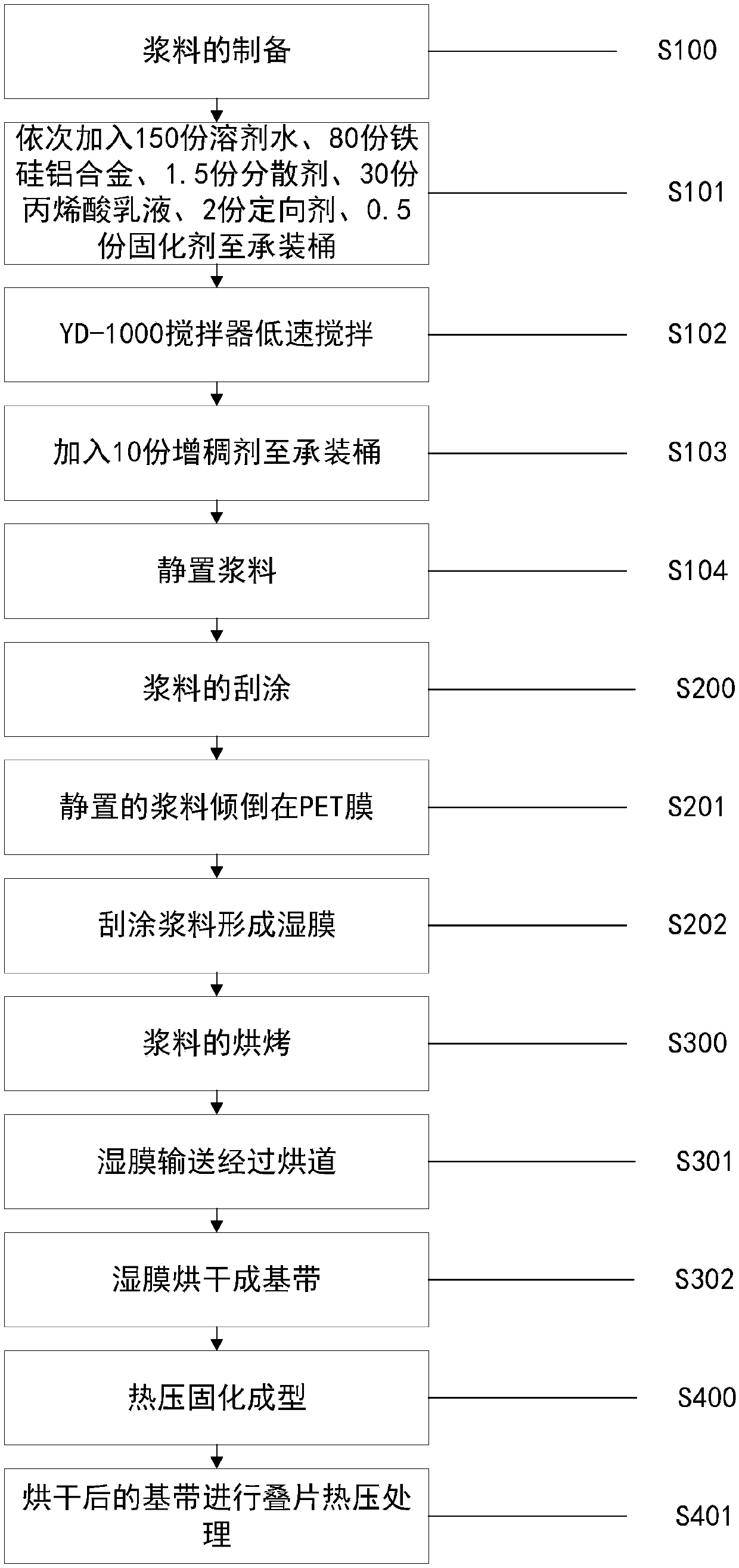

Tape-casting wave absorbing material and preparing method and preparing device thereof

InactiveCN109627529AThe preparation process is environmentally friendlyNo pollution in the processPhysical well beingSolvent

The invention discloses a tape-casting wave absorbing material. The tape-casting wave absorbing material is prepared from, by mass, 150-250 parts of solvent water, 1-2.5 parts of a dispersing agent, 80 parts of a wave absorbing agent, 20-40 parts of a binder, 2-3 parts of a directional agent, 0.5 part of a curing agent and 8-12 parts of a thickening agent. According to the tape-casting wave absorbing material, the purposes that when the wave absorbing material is manufactured, the manufacturing process is environmentally friendly and causes no pollution, the body health of a production workeris not harmed, and the production cost is lowered are achieved.

Owner:重庆市鸿富诚电子新材料有限公司

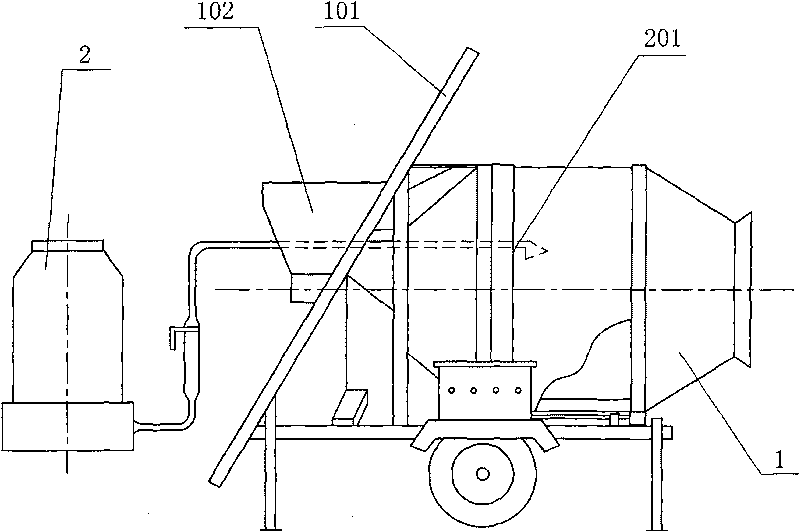

Technology for processing cold coated reflective glass beads

The invention discloses technology for processing cold coated reflective glass beads, which comprises the steps of: dumping qualified glass beads with the diameter between 0.05 and 1.00mm into a feeding funnel of a drum mixer; preparing a medicament, namely taking a silane coupling agent or mixed methyl silicone oil and sodium silicate or mixed thinner and methyl silicone oil as the medicament; adding the medicament, spraying the medicament and stirring the glass beads, namely loading the medicament into a high-pressure sprayer according to the proportion of adding 400 to 600g of the medicament into each ton of glass beads, arranging a nozzle of the high-pressure sprayer above the inside of the drum mixer, downward directly spraying the medicament to the surfaces of the glass beads to form moistureproof protective films, and stirring the glass beads at the same time, wherein the stirring time is between 8 and 10 minutes; and packaging and performing random inspection, namely using packaging bags lined with plastic inner films for packaging, placing the product for 3 days, then performing random inspection, and sending the product into a warehouse after the product is qualified through random inspection. The technology has the advantages that the technology has high production efficiency, raw material conservation, energy conservation, low production cost, good coating effect and strong adhesive power, has no harm to the health of workers, meets requirement of environmental protection, and can be used for pavement markings and various reflective materials and decorative materials.

Owner:张万春

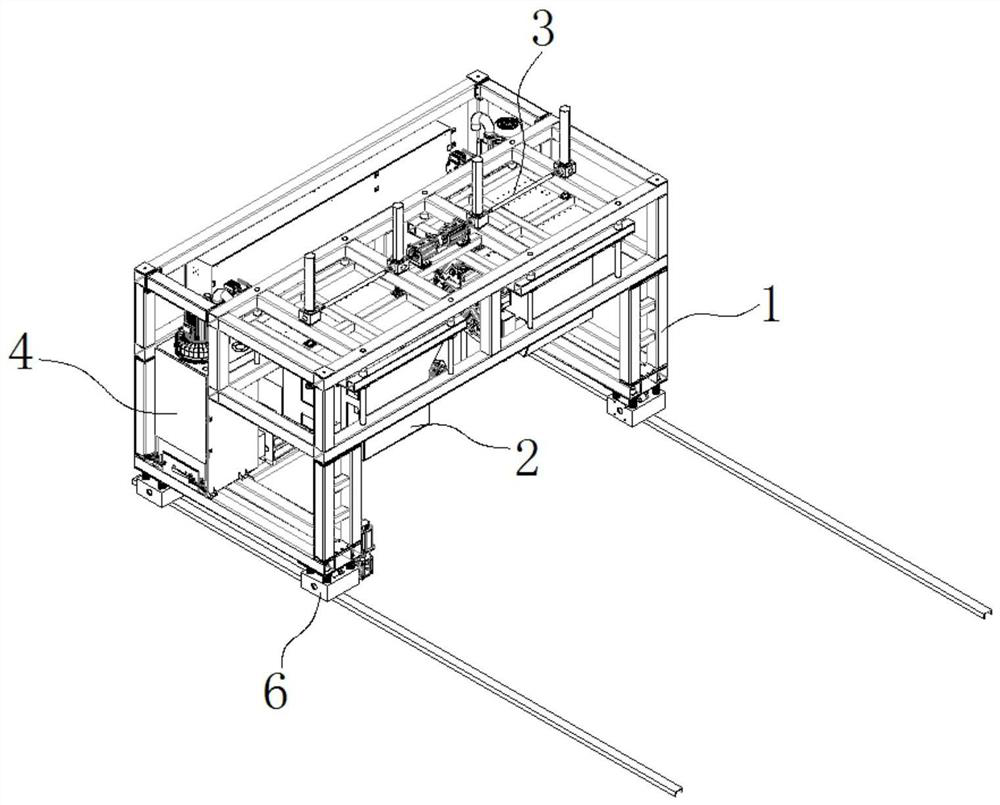

Wind power blade main beam trimming method

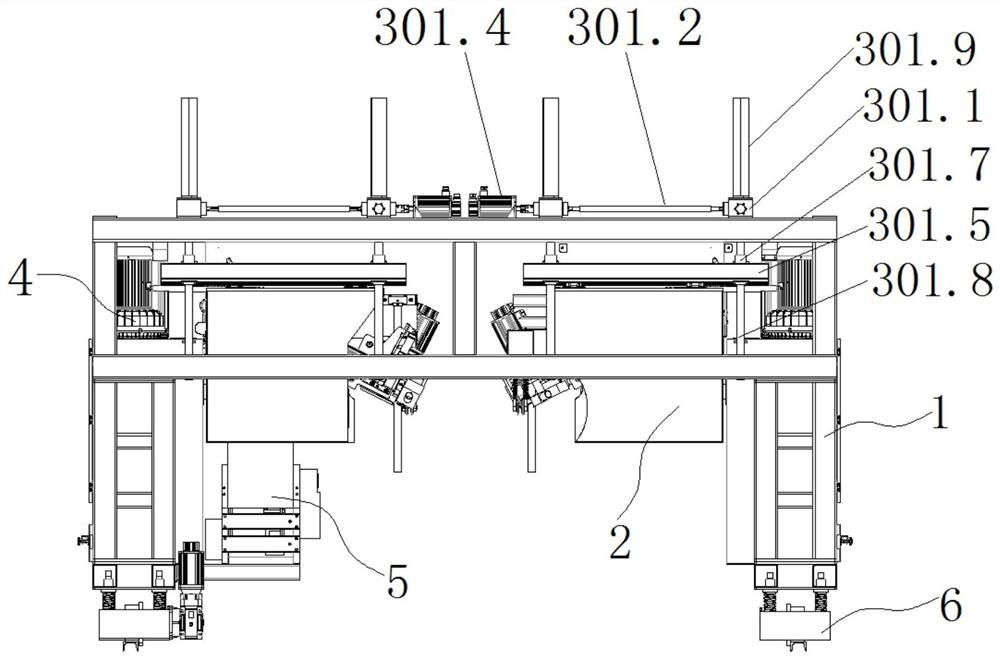

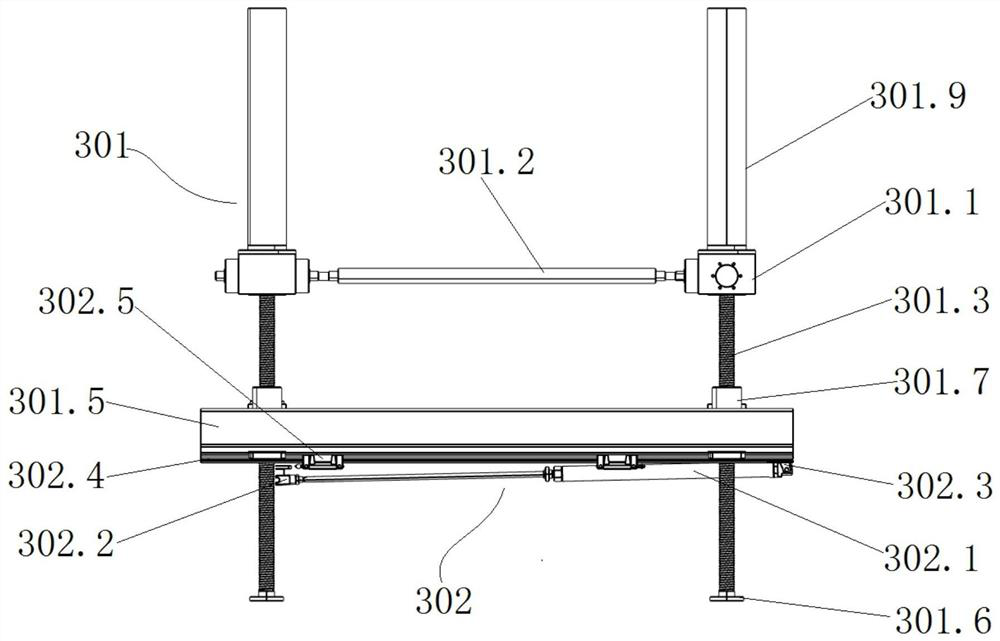

ActiveCN112248322AImprove processing efficiencyImprove cutting accuracyEdge grinding machinesGrinding drivesPolishingStructural engineering

The invention discloses a wind power blade main beam trimming method. The wind power blade main beam trimming method adopts wind power blade main beam automatic trimming equipment for trimming, the equipment comprises a travelling frame, a left cutting and polishing unit and a right cutting and polishing unit are arranged on the travelling frame, the cutting and polishing units are driven by lifting and transverse moving units to lift and transversely move, the cutting and polishing units comprise cutting mechanisms and polishing mechanisms which are arranged front and back, the cutting mechanisms comprise cutting mechanism racks, cutting angle adjusting assemblies and cutting assemblies are arranged in the cutting mechanism racks, the cutting angle adjusting assemblies are used for adjusting the cutting angles of the cutting assemblies during operation, the polishing mechanisms comprise polishing mechanism racks, polishing angle adjusting assemblies and polishing assemblies are arranged in the polishing mechanism racks, and the polishing angle adjusting assemblies are used for adjusting the polishing angles of the polishing assemblies during operation. According to the wind powerblade main beam trimming method, redundant sharp corners and burrs on the side edge of the blade main beam can be automatically cut and polished, and the method is high in machining precision and machining efficiency.

Owner:江阴市科诚技术有限公司

Making method of novel puffed pet snack food

InactiveCN104982653AWithout prejudice to reservationWith bactericidal functionAnimal feeding stuffSnack foodMicrowave technology

The invention relates to a making method of novel puffed pet snack food. The making method of the novel puffed pet snack food comprises the steps that fresh hide of pigs, cattle, fishes and the like are used as raw materials, the raw materials are pre-boiled to remove odor and oil, the raw materials are cut into pieces and dices and then placed in a high-temperature kneading machine to be decocted and kneaded, and meanwhile the needed fresh meat paste, natural gourmet powder and related nutrient matter are added; the decocted hide paste is placed in a mold to be formed and cooled, and then slicing and drying are conducted; puffing is conducted through a creative microwave technology, and after sterilization and packaging, the high-protein low-fat puffed snack food for pets is obtained. The finally obtained product has thick meat fragrance, is easy to digest and absorb, maintains the nutrient of fresh hide collagen type food, has the health-care function on the skin and hair of the pets and can be used as meat type snack food and a nutritional supplement for the pets.

Owner:高鸿立 +1

Quantity-controllable type glass surface mirror back paint spraying device

InactiveCN110548632AKeep clean and tidyPreventing Problems That Affect Paint QualityElectrostatic cleaningCleaning using toolsAir filterFixed frame

The invention discloses a quantity-controllable type glass surface mirror back paint spraying device. The quantity-controllable type glass surface mirror back paint spraying device comprises a fixingframe. A conveying belt is installed on one side of the fixing frame. A cleaning box is fixedly installed on the upper surface of the fixing frame, a paint spraying box is fixedly installed on the side, close to the cleaning box, of the upper surface of the fixing frame, and an air drying box is fixedly installed on the side, close to the paint spraying box, of the upper surface of the fixing frame. An air filtering box is arranged on one side of the fixing frame, and a filtering box control panel is installed on the front surface of the air filtering box. According to the quantity-controllable type glass surface mirror back paint spraying device, by means of the cleaning box, the cleaning operation can be conducted before the paint spraying operation of a glass mirror is conducted. In addition, two-stage cleaning is set in the cleaning box, and the remaining dust can be further absorbed by static electricity after the glass mirror is roughly cleaned by a cleaning roller. By means of an infrared sensor and a suspension ring, height information of paint materials in a paint material barrel can be displayed on a displayer, and workers conduct material control for different glass mirrors advantageously.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

A molding process of two-color double-hardness sole

ActiveCN103128978BEliminates manual hand gluing stepsSimple processDomestic articlesCross-linkPlastic injection molding

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

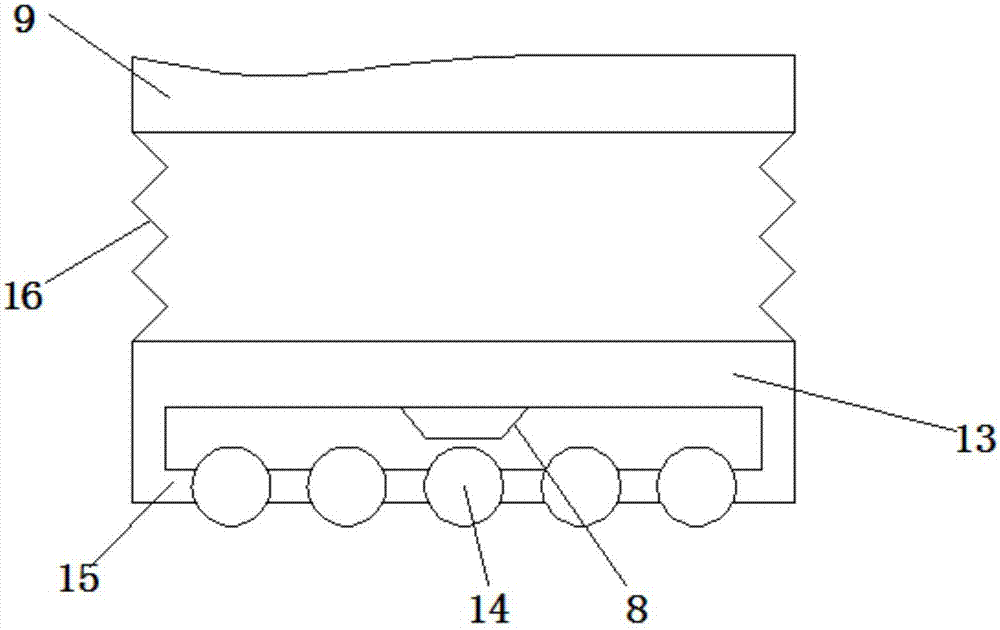

Plasma cutting device with protective cover

InactiveCN107498161AAvoid stimulationPhysical health hazardWelding/cutting auxillary devicesAuxillary welding devicesPhysical healthEngineering

The invention relates to the field of plasma cutting technology, in particular to a plasma cutting device with a protective cover, which includes a workbench, a pair of first guide rails are installed on the side wall of the workbench, and slides are installed on the first guide rails. The inner wall of the chute is provided with rollers, the rollers are connected to the external motor through the transmission gear, the upper end of the chute is vertically provided with a bracket, and the end of the bracket away from the chute is fixedly connected with a horizontal second guide rail, the second guide rail is slidingly provided with a cutting machine, the cutting head of the cutting machine is sleeved with a sleeve, the outer wall of the sleeve is inserted with a plurality of connecting pipes, and the connecting pipes are connected with the negative pressure Pipe connection, the plasma cutting device with a protective cover avoids excessive cutting fume gathering in the processing workshop and causing harm to the health of operators, and can block the arc light generated during cutting, avoiding arc light irritating human eyes, maintenance the health of operators.

Owner:湖北敏丰机电设备有限公司

Dust clearing device convenient to use for computer circuit board

InactiveCN109865681AEasy to useConvenience to workCleaning using toolsCleaning using gasesReciprocating motionHand held

The invention discloses a dust clearing device convenient to use for a computer circuit board, The dust clearing device convenient to use for the computer circuit board comprises a shell, the left side face of the shell is connected with two first sliding sleeves in a clamped mode, the inner surfaces of the two first sliding sleeves both sleeve first sliding rods correspondingly, the left ends ofthe two first sliding rods are fixedly connected with the same pressing plate, the outer surfaces of the first sliding rods are sleeved with first springs, and the two ends of the first springs are fixedly connected with the right side surface of the pressing plate and the left side surfaces of the first sliding sleeves correspondingly. The dust clearing device convenient to use for the computer circuit board is provided, so that two soft brushes can do reciprocating motion left and right on the front side and the back side of the circuit board correspondingly to remove dust on the surface ofthe circuit board, the dust on the surface of the circuit board can be cleared without using hand-held soft brushes by workers, so that the physical strength of the workers is saved; and meanwhile, the harm to the body health of the workers, caused by the fact that the workers inhale the dust into respiratory tracts is avoided as well, and then convenience is brought to the work of the workers.

Owner:SHAANXI ZHONGXING LANTU EDUCATION TECH CO LTD

Thermally-conductive rubber material and preparation method thereof as well as thermally-conductive rubber sheet

ActiveCN108164992AGuaranteed cleanlinessPhysical health hazardHeat-exchange elementsRubber materialPolymer science

The invention provides a thermally-conductive rubber material and a preparation method thereof as well as a thermally-conductive rubber sheet, relates to the technical field of thermally-conductive materials. The thermally-conductive rubber material is prepared from the following raw materials in percentage by mass: 7 to 50 percent of polyurethane resin, 40 to 92 percent of thermally-conductive powder and 1 to 30 percent of a flame retardant. The technical problem that the thermally-conductive rubber material with no odor, no oil leakage and long-term low-temperature resistance does not appearin the current market is alleviated, and the polyurethane resin, the thermally-conductive powder and the flame retardant are synergistically matched; the prepared thermally-conductive rubber materialhas the advantages of high thermal conductivity, low heat resistance and good thermal conductivity; in addition, oil leakage is avoided, so that the surface cleanness of the rubber material is kept;meanwhile, technical effects of good flame-retardant effects, no possibility of producing irritating smell and avoiding hidden danger to the health of personnel are realized.

Owner:KUSN ZHONGDI MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com