Inhibitor for copper lead sulphide minerals and method for conducting flotation separation with inhibitor

A mineral flotation and separation method technology, applied in flotation, solid separation, etc., can solve problems such as poor suppression effect, incomplete separation effect of copper and lead, and large environmental hazards, so as to promote clean production and reduce processing costs and treatment difficulty, and the effect of improving the comprehensive recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

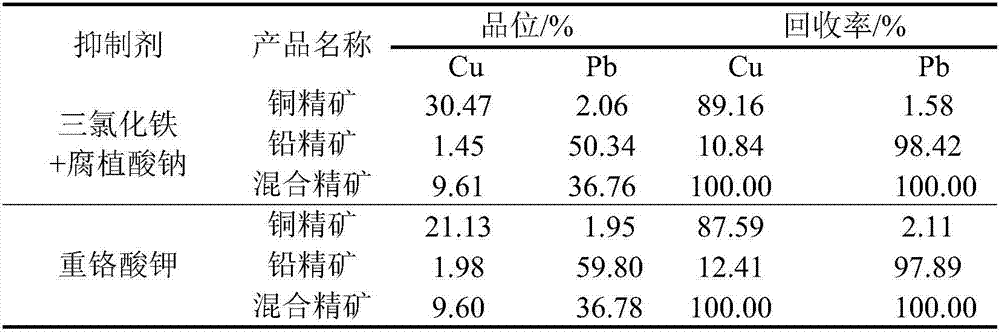

Embodiment 1

[0043] In a copper-lead-zinc complex polymetallic sulfide mine in Hunan, the copper content in the ore is 0.34%, and the lead content is

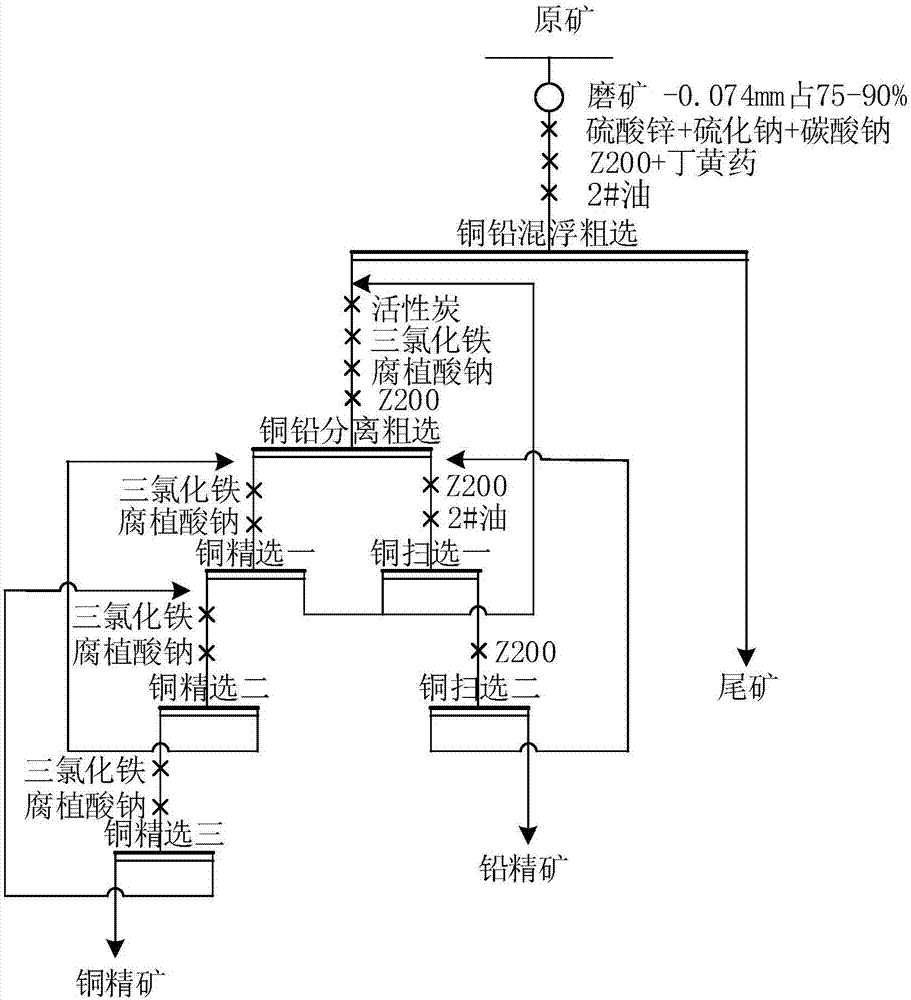

[0044] 1.23%, the grade of raw ore is low, and different minerals are metasomatically symbiotic and wrapped with each other, and the particle size of useful minerals is not uniform, and some are fine-grained. Phase analysis shows that the copper and lead in the raw ore are mainly in the form of It exists in the form of chalcopyrite, chalcocite, bornite, lead sulfide and other sulfide ores. The gangue minerals are mainly quartz, and there are a small amount of chlorite and calcite. According to the process mineralogy characteristics of the ore, the process of copper-lead mixed flotation to obtain mixed concentrate and then copper-lead separation process is used to recover the valuable metals. The specific process is as follows: figure 1 shown, including the following steps:

[0045] (1) Grinding the raw ore, after grinding, the fineness to ...

Embodiment 2

[0058] The content of copper in a raw ore in Anhui is 0.51%, and the content of lead is 0.96%. The process of three fines and two sweeps is separated, and the specific process is as follows figure 1 shown, including the following steps:

[0059] (1) Grinding the raw ore, after grinding, the fineness to -0.074mm accounts for 86.5%;

[0060] (2) Carry out copper-lead mixed flotation by grinding, the medicament system adopted is: butyl xanthate 20g / t, Z200 35g / t as collector; 2# oil 20g / t as foaming agent; zinc sulfate 500g / t, sodium sulfide 180g / t and sodium carbonate 550g / t as inhibitors;

[0061] (3) Add 1000g / t of activated carbon to the copper-lead mixed coarse concentrate and stir for 8min; add 100g / t of ferric chloride solution and stir for 3min; add 800g / t of sodium humate and stir for 5min; add 50g / t of thiocarbamate t is used as a collector, stirring for 3 minutes to carry out copper and lead separation roughing operation;

[0062] (4) Carry out 3 times of benefici...

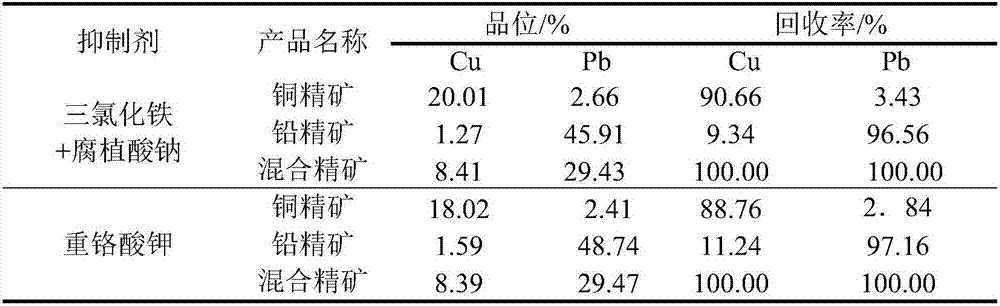

Embodiment 3

[0072] The copper content in a raw ore in Guizhou is 0.78%, and the lead content is 1.42%. The process of three fines and two sweeps is separated, and the specific process is as follows figure 1 shown, including the following steps:

[0073] (1) Grinding the raw ore, after grinding, the fineness to -0.074mm accounts for 82.5%;

[0074] (2) Carry out copper-lead mixed flotation by grinding, the medicament system adopted is: butyl xanthate 20g / t, Z200 35g / t as collector; 2# oil 20g / t as foaming agent; zinc sulfate 500g / t, sodium sulfide 180g / t and sodium carbonate 550g / t as inhibitors;

[0075] (3) Add 800g / t of activated carbon to the copper-lead mixed coarse concentrate and stir for 6min; add 75g / t of ferric chloride solution and stir for 3min; add 600g / t of sodium humate and stir for 5min; add 30g / t of thiocarbamate t is used as a collector, stirring for 3 minutes to carry out copper and lead separation roughing operation;

[0076] (4) Carry out 3 times of beneficiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com