Glass fiber reinforced plastic pipe and manufacturing method thereof

A manufacturing method and technology of FRP, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as troublesome processes, inhalation, and health effects on workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

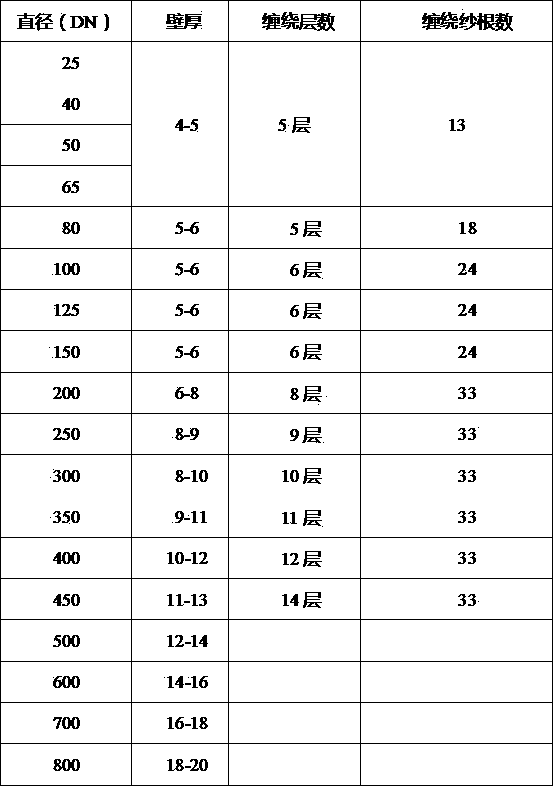

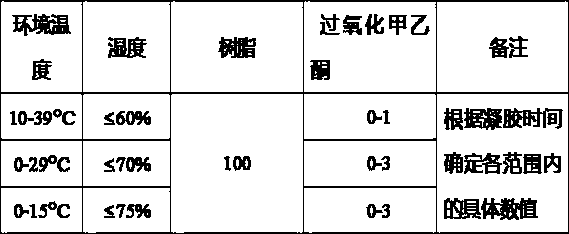

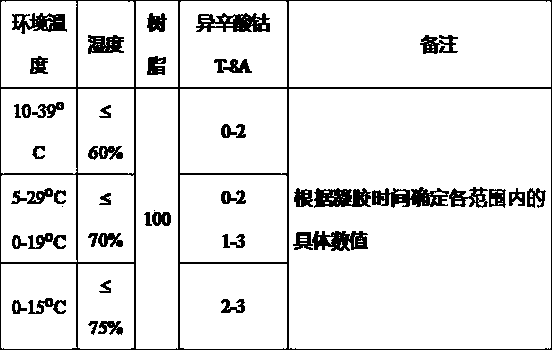

[0029] A kind of FRP pipeline provided by the invention and its manufacturing method, its specific implementation steps are:

[0030] 1. Preparation

[0031] 1.1 Receive corresponding quantity of raw materials according to the requirements of "production plan": FW-H-2028 unsaturated polyester resin (for lining), HR-192N unsaturated polyester resin (for structural layer), methyl ethyl ketone peroxide, isooctanoic acid Cobalt T-8A, flame retardant FR-705U, roving EDR240-T910, alkali-free knitted felt MEK380, grid cloth, surface felt EWR30g-200mm and polyester film.

[0032] 1.2 Before batching, check whether the materials used meet the specified requirements and whether they are within the effective shelf life, whether the color is uniform, and whether there are impurities; fiber materials: roving EDR240-T910, alkali-free knitted felt MEK380, mesh cloth, surface felt EWR30g-200mm Wait for the presence of moisture.

[0033] 1.3 Get the mold with corresponding specifications acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com