Quantity-controllable type glass surface mirror back paint spraying device

A technology of glass surface and spraying device, which is applied in the direction of spraying device, spray booth, cleaning by electrostatic method, etc. It can solve the problems that cannot remove the fine dust on the surface of the glass mirror, reduce the quality of glass mirror painting, and endanger the staff, so as to prevent Health hazards, good working environment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

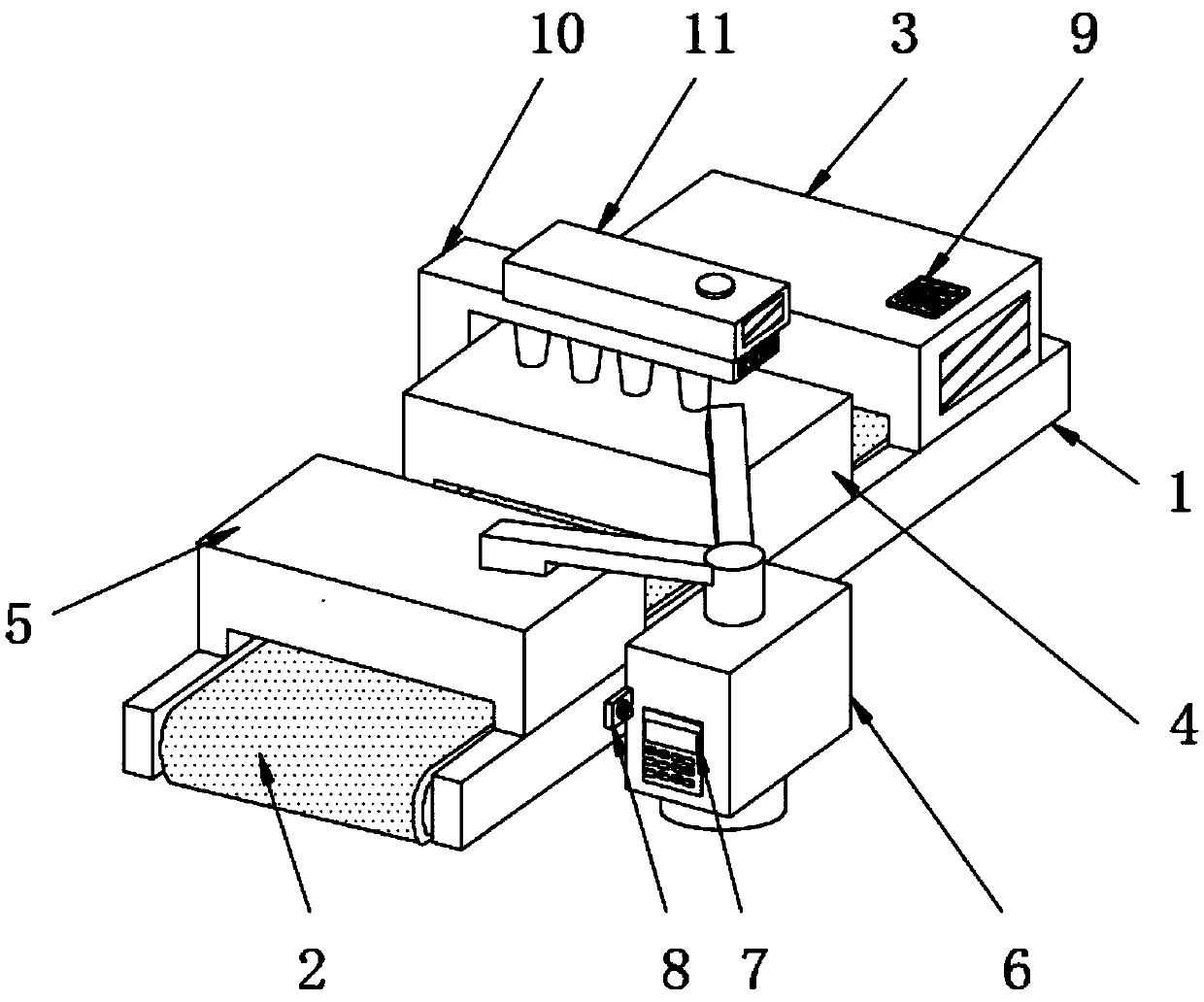

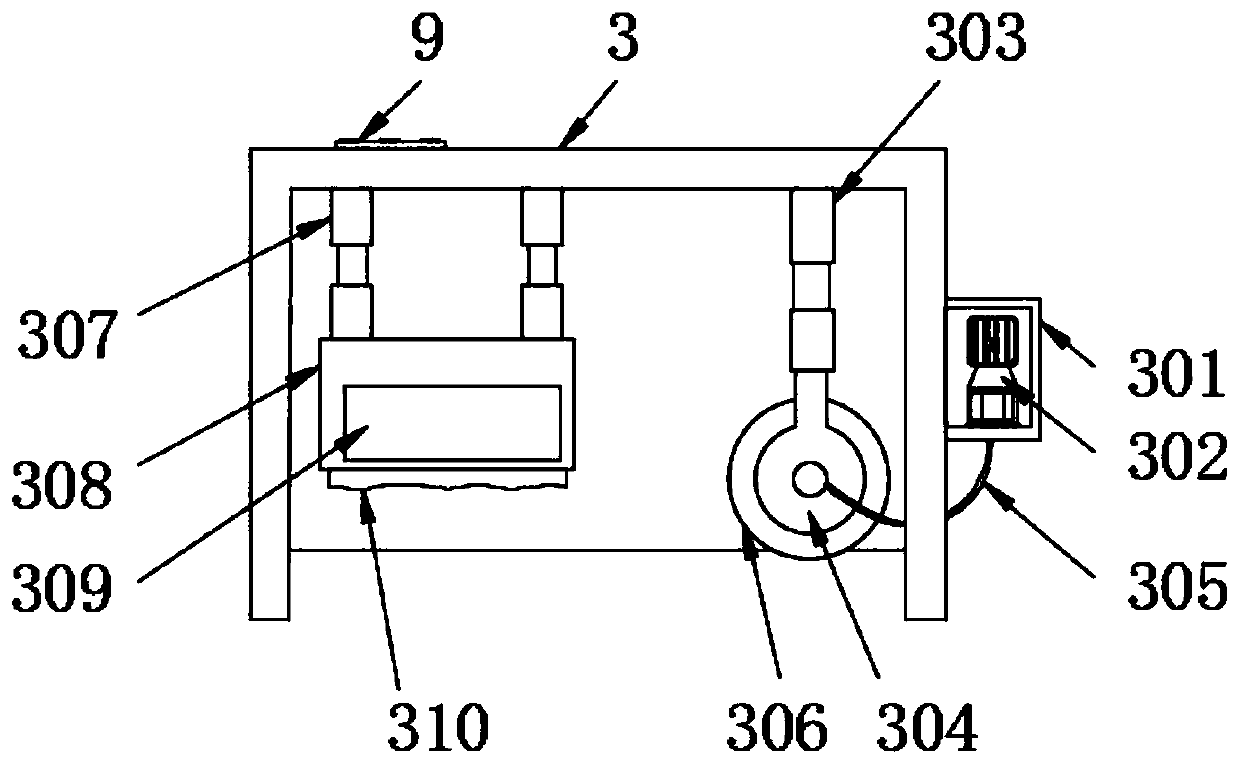

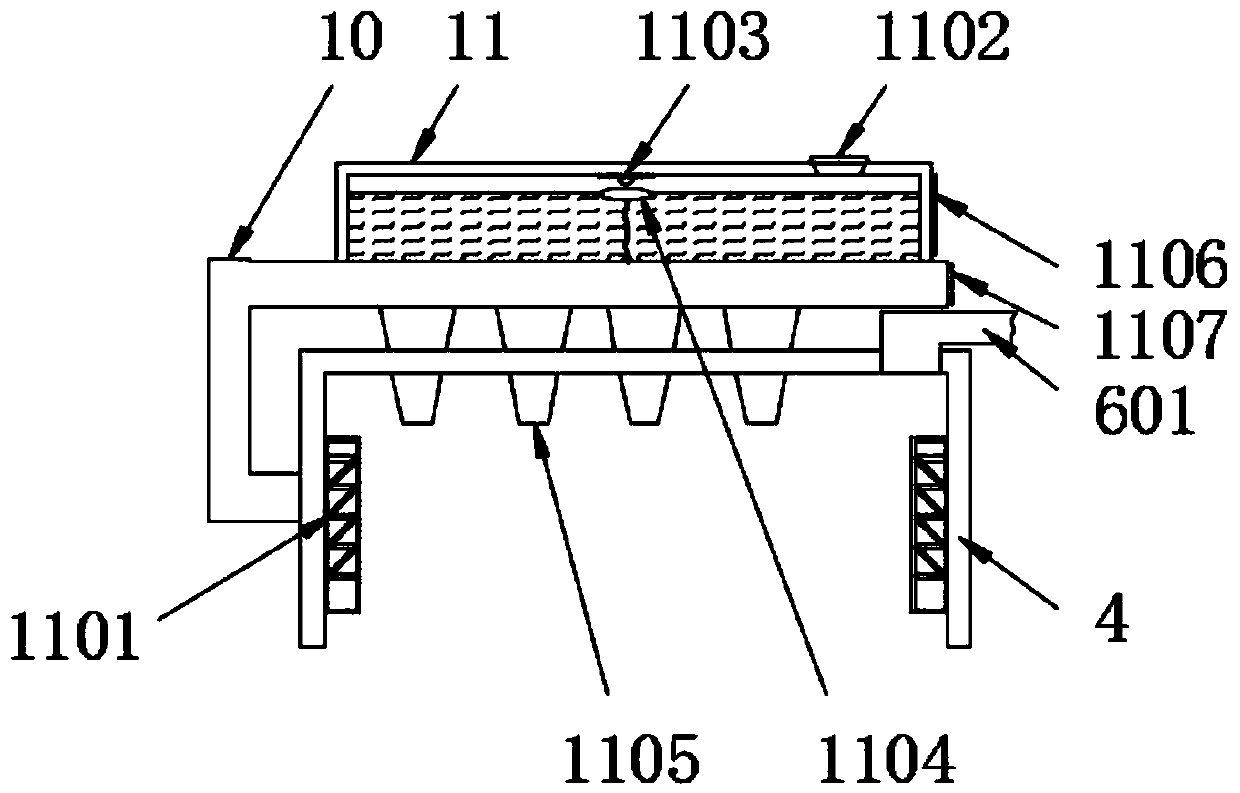

[0029] see Figure 1~5 , in an embodiment of the present invention, a controllable glass surface mirror back paint spraying device includes a fixed frame 1, a conveyor belt 2 is installed on one side of the fixed frame 1, and a cleaning box 3 is fixedly installed on the upper surface of the fixed frame 1 , the upper surface of the fixed frame 1 is fixedly installed with a paint spray box 4 near the side of the cleaning box 3, and the upper surface of the fixed frame 1 is fixed with an air-drying box 5 near the side of the paint spray box 4, and one side of the fixed frame 1 is provided with Air filter box 6, filter box control board 7 is installed on the front surface of air filter box 6, and both sides of air filter box 6 are all fixedly installed with bolt plate 8, fixed frame 1 and air filter box 6 are fixedly installed by bolt plate 8 One side of the paint spray box 4 is fixedly equipped with a connecting rod 10, and a paint box 11 is installed on the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com