Tape-casting wave absorbing material and preparing method and preparing device thereof

A wave-absorbing material and tape casting technology, applied in the field of electromagnetic protection, can solve problems such as environmental pollution, high cost, and endangering the health of production workers, and achieve the effects of avoiding harm and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

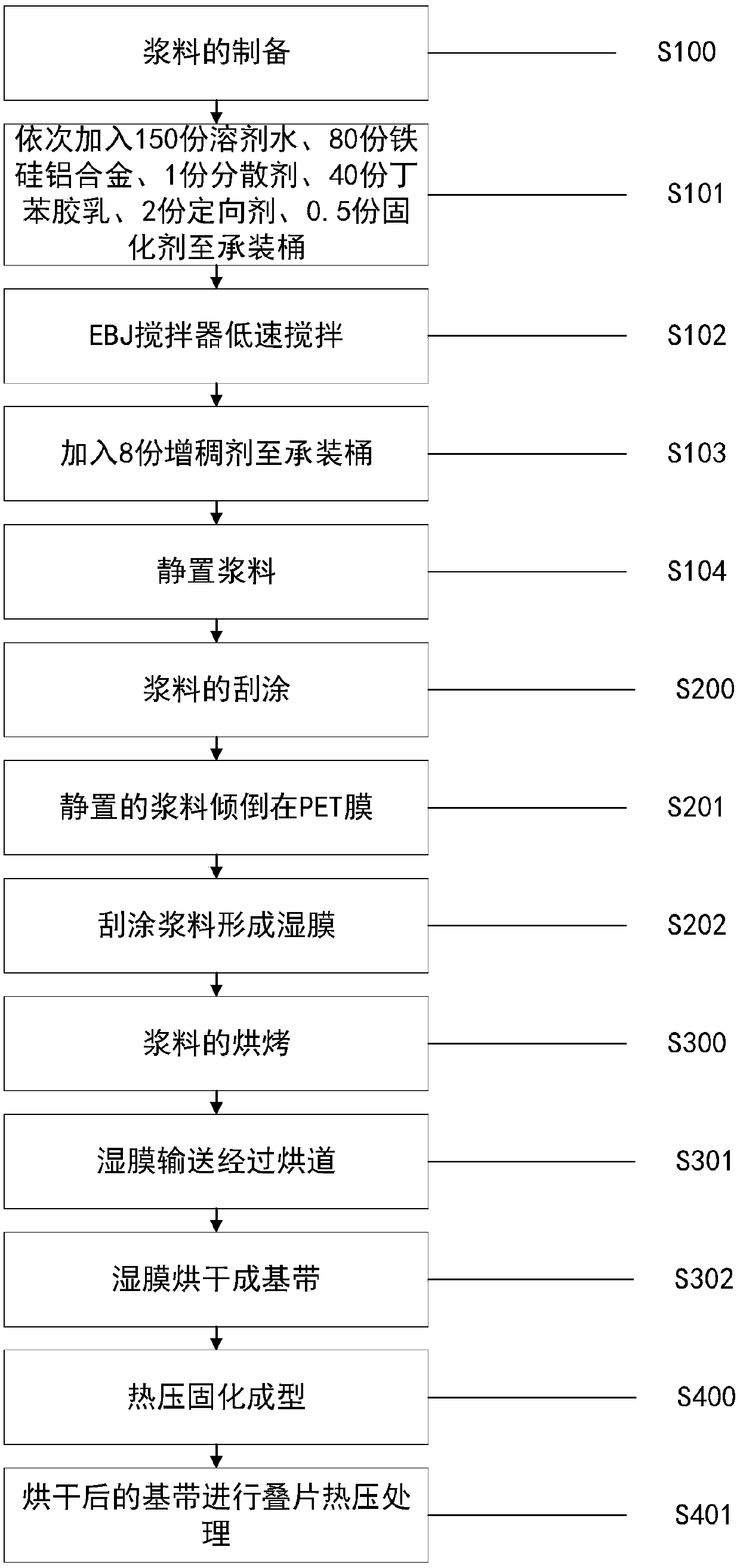

Embodiment 1

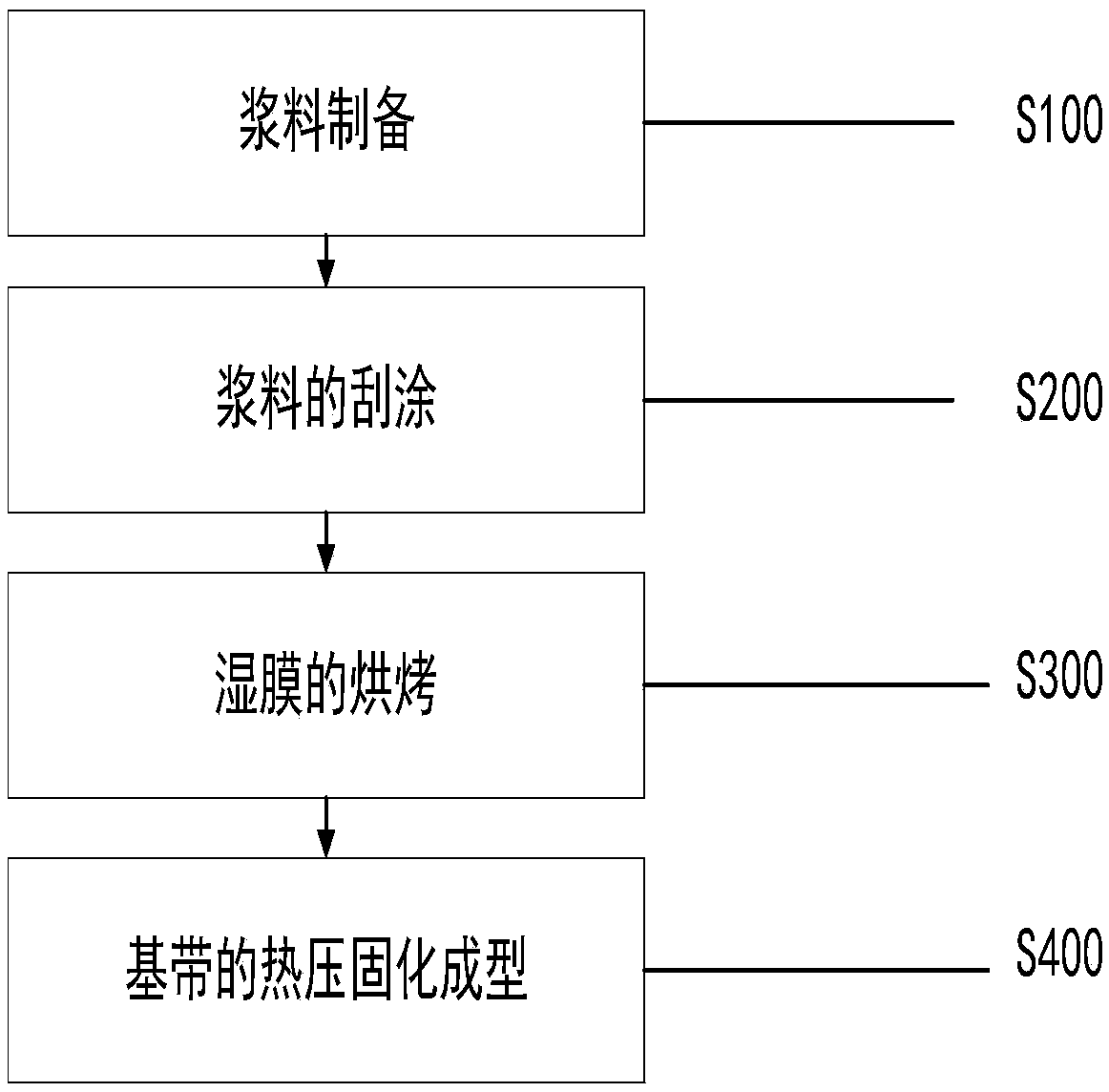

[0038] A method for preparing an extended wave-absorbing material, comprising the following steps:

[0039] S100: preparation of slurry, the specific operation steps are as follows:

[0040] S101: sequentially add 150 parts of solvent water, 80 parts of sendust, 1 part of dispersant, 40 parts of styrene-butadiene latex, 2 parts of directional agent, and 0.5 part of curing agent into the container 10;

[0041] First, 150 parts of solvent water, 80 parts of sendust, 1 part of dispersant, 40 parts of styrene-butadiene latex, 2 parts of directional agent, and 0.5 part of curing agent are weighed respectively by a weighing device and added to the container 10, wherein The sheet diameter of the sendust is 30um and the thickness is 0.5um. Since the selection and dosage of the dispersant play a decisive role in the stability of the slurry, the dispersant can use polyacrylic acid amine salts, polyacrylic acid sodium salts, high One or more combinations of polymer dispersants. The amou...

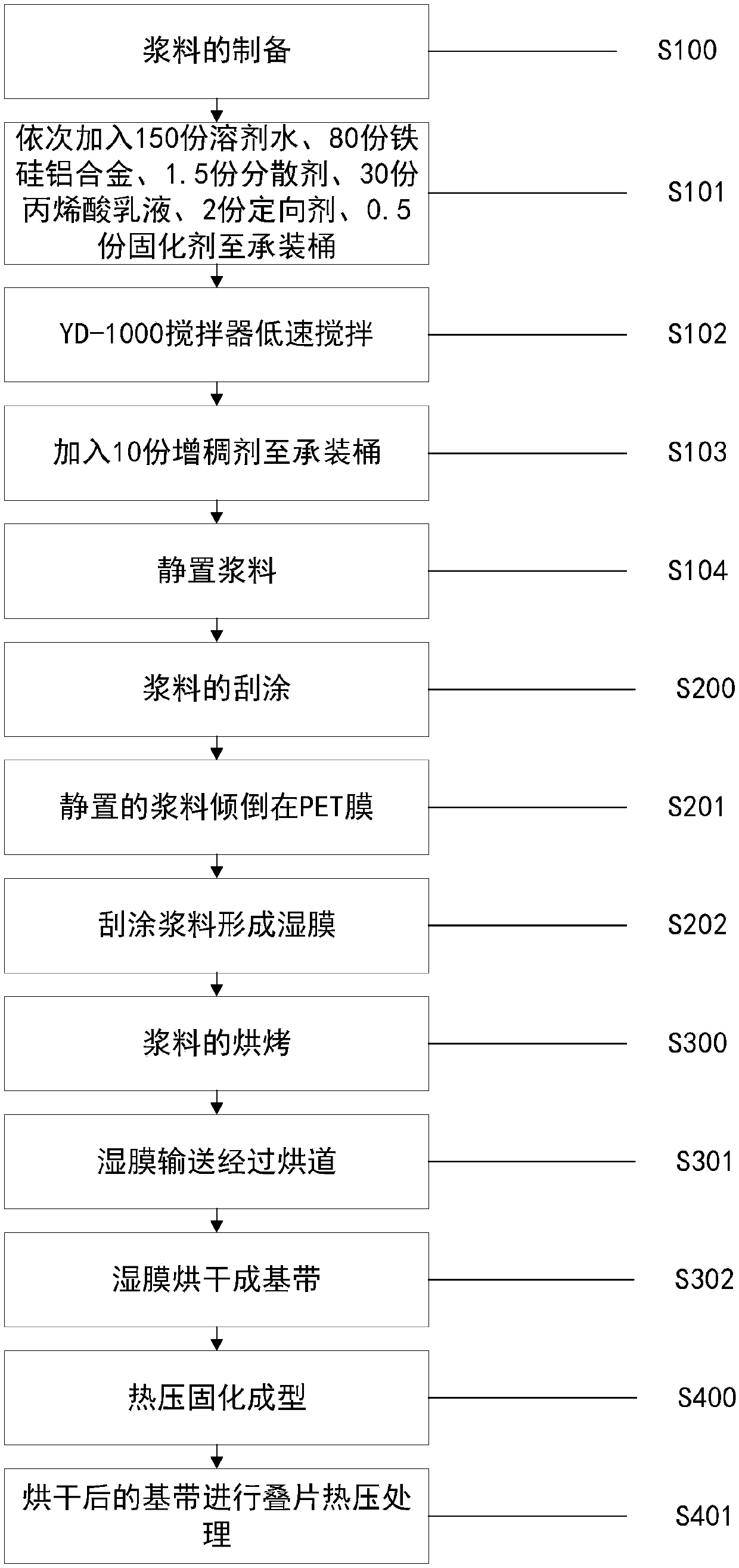

Embodiment 2

[0062] A method for preparing an extended wave-absorbing material, comprising the following steps:

[0063] S100: preparation of slurry, the specific operation steps are as follows:

[0064] S101: sequentially add 150 parts of solvent water, 80 parts of sendust, 1.5 parts of dispersant, 30 parts of acrylic emulsion, 2 parts of directional agent, and 0.5 part of curing agent into the container 10;

[0065] First, 150 parts of solvent water, 80 parts of sendust, 1.5 parts of dispersant, 30 parts of acrylic emulsion, 2 parts of directional agent, and 0.5 part of curing agent are weighed respectively by a weighing device and added to the container 10, wherein iron The sheet diameter of silicon aluminum alloy is 30um and the thickness is 0.5um. Since the selection and amount of dispersant play a decisive role in the stability of the slurry, the dispersant can use polyacrylic acid amine salt, polyacrylic acid sodium salt, high polymer One or more combinations of dispersants. The am...

Embodiment 3

[0086] A method for preparing an extended wave-absorbing material, comprising the following steps:

[0087] S100: preparation of slurry, the specific operation steps are as follows:

[0088] S101: sequentially add 200 parts of solvent water, 80 parts of sendust, 2 parts of dispersant, 25 parts of acrylic emulsion, 3 parts of directional agent, and 0.5 part of curing agent into the container 10;

[0089] Firstly, 200 parts of solvent water, 80 parts of sendust, 2 parts of dispersant, 25 parts of acrylic emulsion, 3 parts of directional agent, and 0.5 part of curing agent are weighed respectively by a weighing device and added to the container 10, wherein iron The sheet diameter of silicon aluminum alloy is 120um and the thickness is 3um. Since the selection and dosage of the dispersant play a decisive role in the stability of the slurry, the dispersant can use polyacrylic acid amine salt, polyacrylic acid sodium salt, polymer One or more combinations of similar dispersants. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com