Ferroferric oxide porous ball having micro-nano structure, and preparation method of ferroferric oxide porous ball

A technology of ferric tetroxide and micro-nano structure, applied in the direction of iron oxide/iron hydroxide, ferrous oxide, nanotechnology, etc., can solve the problems of dangerous flammable gas, difficult control, troublesome preparation process, etc. , to achieve the effect of low reaction temperature, prevention of agglomeration and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

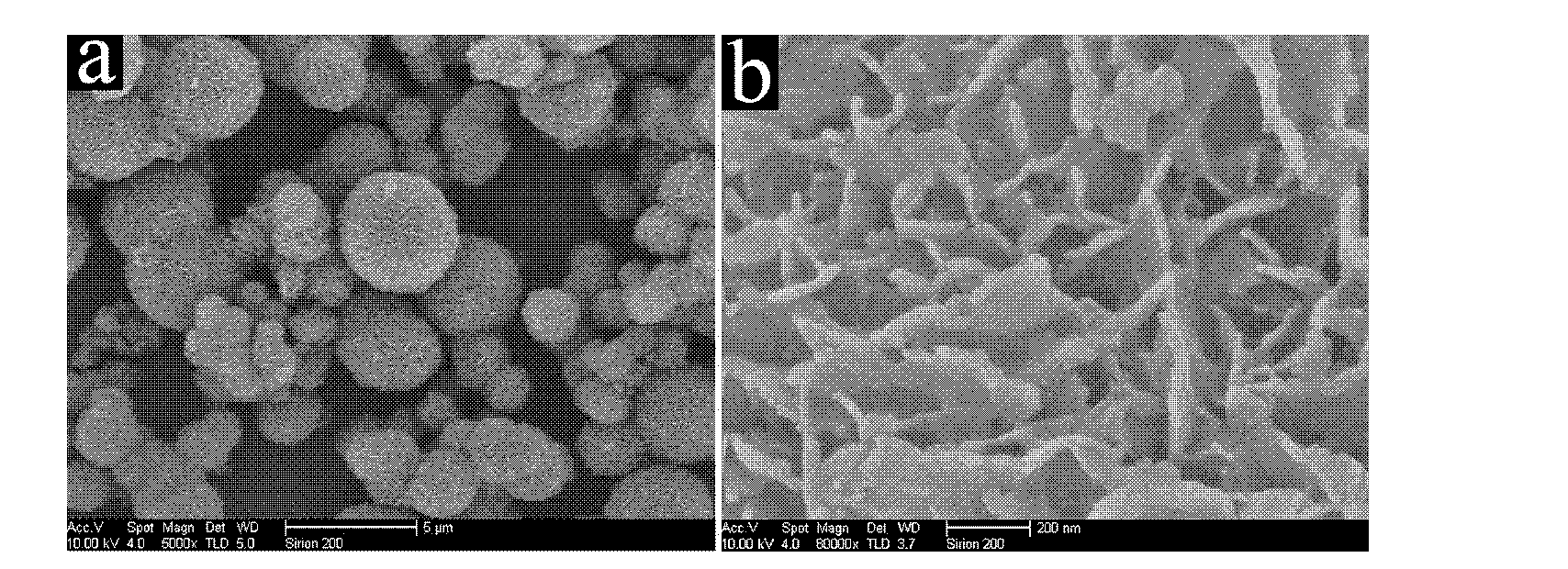

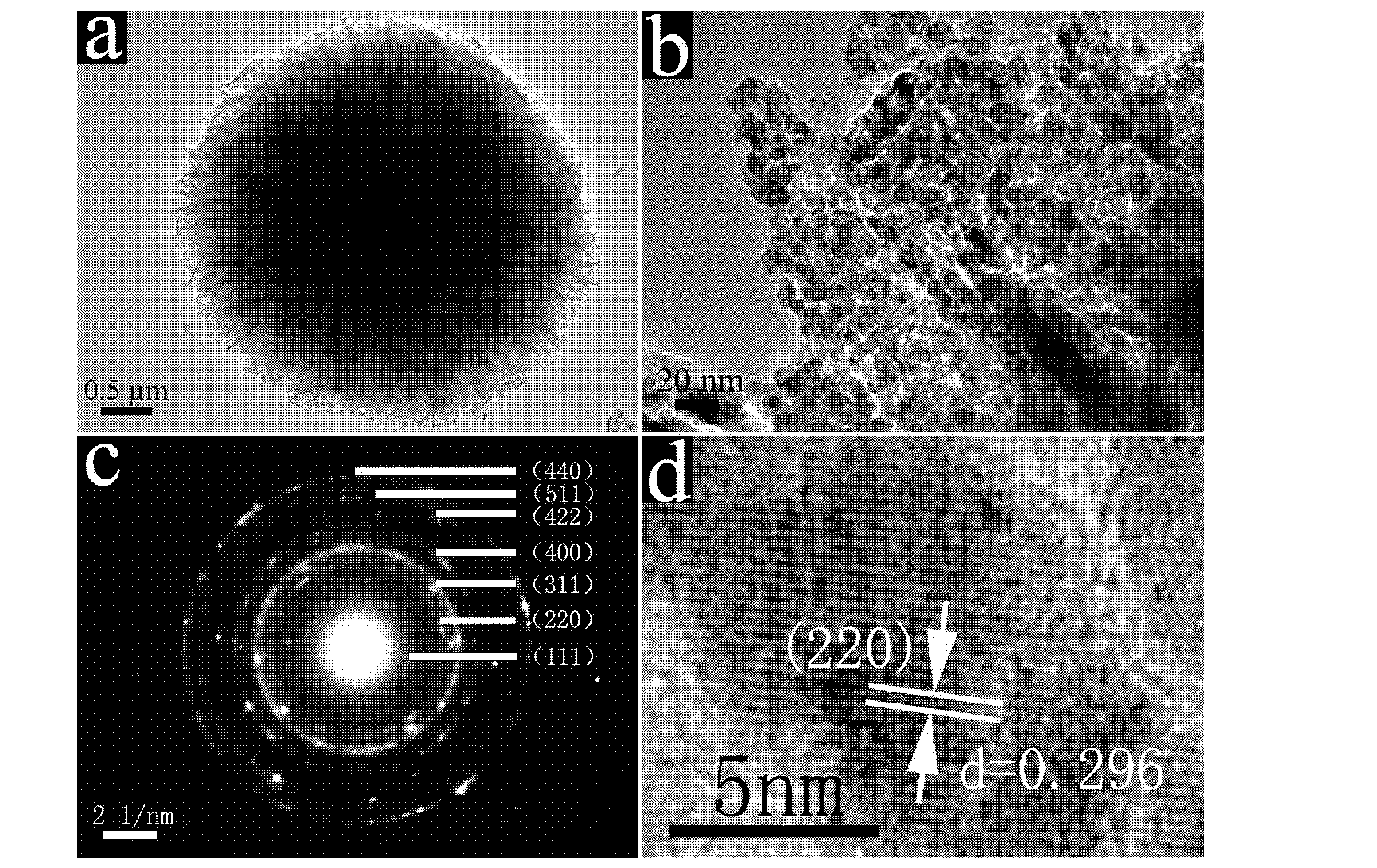

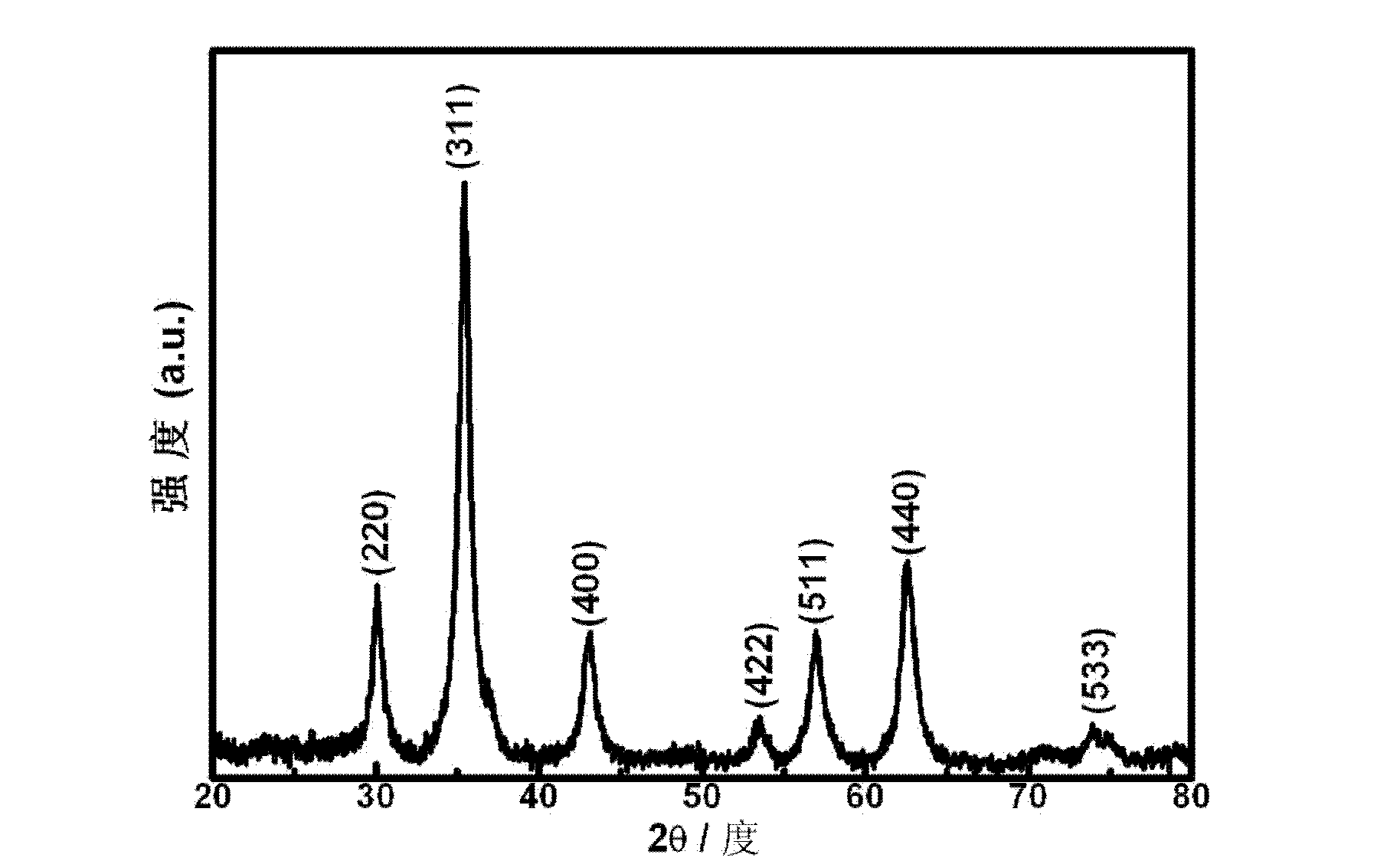

[0033] Embodiment: Micro-nano structured iron ferric oxide porous ball is composed of iron ferric oxide, the porous iron ferric oxide ball is spherical, and the spherical iron ferric oxide is composed of nano-sheet structure, the nano-sheet structure There are nanometer mesopores between them, and the nanosheet structure has a porous structure;

[0034] The micro-nano structured ferric oxide porous ball has a ball diameter of 500-8000nm and a specific surface area of 100-140m 2 / g; the pore diameter of the nano-mesopore is 10-100nm.

[0035] The preparation method of micro-nano structure iron ferric oxide porous ball comprises the following steps:

[0036] (1) First, 4 mmol of ferric chloride hexahydrate, 4 mmol of ascorbic acid and 10 mmol of urea were dissolved in 40 mL of deionized water, and stirred with a magnetic stirrer to obtain a lavender solution;

[0037] (2) Add the uniformly stirred lavender solution into a 70mL polytetrafluoroethylene autoclave, then put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com