Ultraviolet light cured silk screen snowflake printing ink and preparation method thereof

A snowflake ink and ultraviolet light technology, applied in the field of printing, can solve the problems of difficult VOC control requirements of cigarette packs, large ink smell, air pollution and other problems, and achieve the effect of unique appearance, small taste and smooth hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

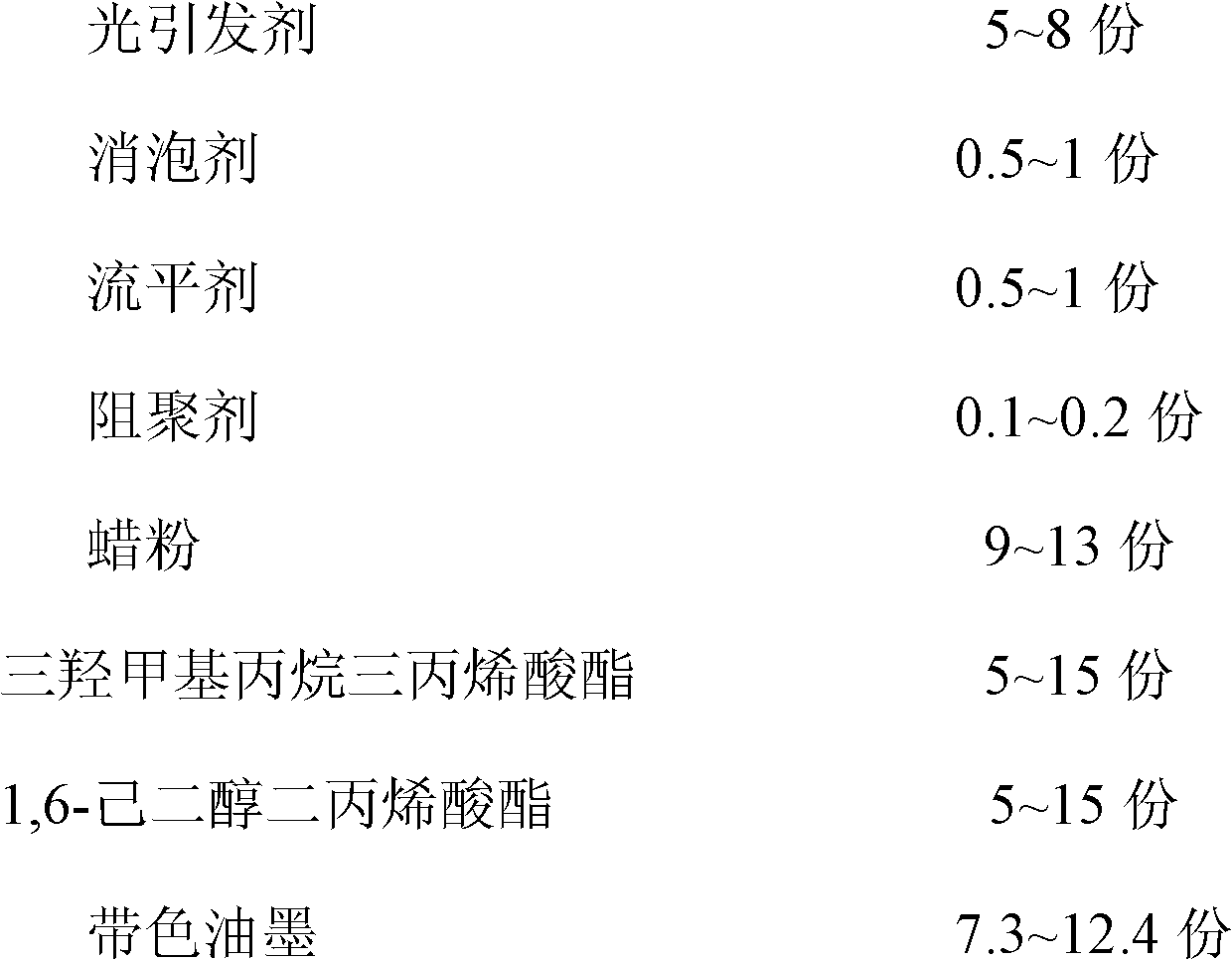

[0023] Embodiment 1: a kind of UV curing screen printing snowflake ink, is characterized in that, is made up of following raw materials in parts by weight:

[0024]

[0025]

[0026] A kind of method that adopts above-mentioned formula to produce ultraviolet curing silk screen printing snowflake ink, comprises stainless stirring container, disc type stirrer, it is characterized in that following the steps of operation:

[0027] (1) Prepare materials according to the parts by weight of the above components;

[0028] (2) Select a certain volume of stainless steel stirring container according to the amount of ink to be configured, and add 90% of trimethylolpropane triacrylate (SR351NS) and 90% of 1,6-hexanediol diacrylate Esters (SR238NS) and all BYK307 leveling agents, DF258 defoamers, hydroquinone (produced by Taicang Xincheng Chemical Co., Ltd.) and 2,4-diethylthioxanthone (JRCure DETX Tianjin Jiuri Chemical Co., Ltd. Co., Ltd.), using a disc stirrer to pre-disperse at ...

Embodiment 2

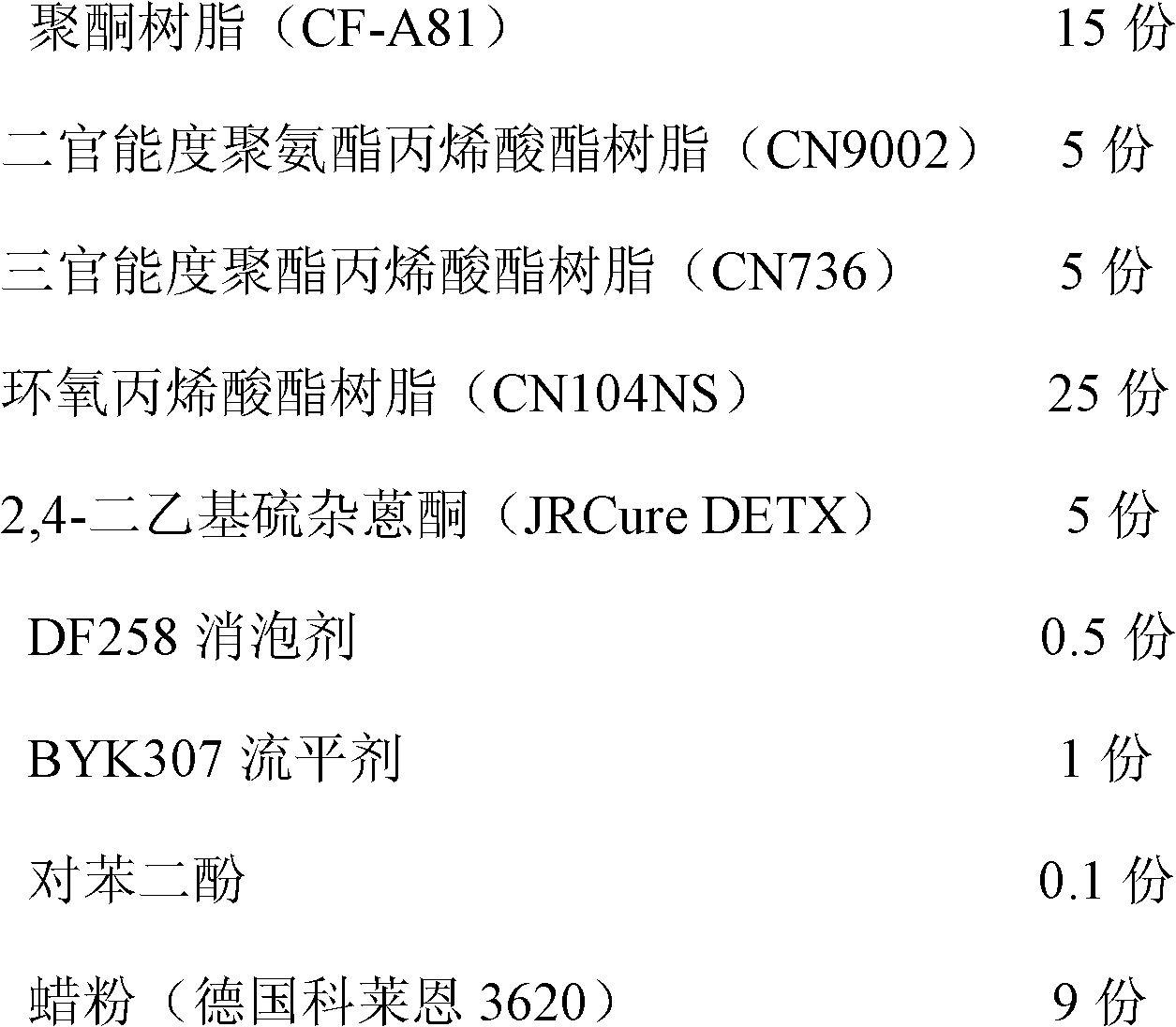

[0032] Embodiment 2: a kind of UV curing screen printing snowflake ink, is characterized in that, is made up of following raw materials in parts by weight:

[0033]

[0034] A kind of method that adopts above-mentioned formula to produce ultraviolet curing silk screen printing snowflake ink, comprises stainless stirring container, disc type stirrer, it is characterized in that following the steps of operation:

[0035] (1) Prepare materials according to the parts by weight of the above components;

[0036] (2) Select a certain volume of stainless steel stirring container according to the amount of ink to be configured, and add 90% of trimethylolpropane triacrylate (SR351NS) and 90% of 1,6-hexanediol diacrylate Ester (SR238NS) and all BYK307 leveling agent, DF258 defoamer, hydroquinone (produced by Taicang Xincheng Chemical Co., Ltd.) and 2,4-diethylthioxanthone (JRCureDETX Tianjin Jiuri Chemical Co., Ltd. Produced by the company), using a disc agitator to pre-disperse for ...

Embodiment 3

[0041] A kind of ultraviolet curing screen printing snowflake ink, is characterized in that, is made up of following raw materials in parts by weight:

[0042]

[0043]

[0044] A kind of method that adopts above-mentioned formula to produce ultraviolet curing silk screen printing snowflake ink, comprises stainless stirring container, disc type stirrer, it is characterized in that following the steps of operation:

[0045] (1) Prepare materials according to the parts by weight of the above components;

[0046](2) Select a certain volume of stainless steel stirring container according to the amount of ink to be configured, and add 90% of trimethylolpropane triacrylate (SR351NS) and 90% of 1,6-hexanediol diacrylate Esters (SR238NS) and all BYK307 leveling agents, DF258 defoamers, hydroquinone (produced by Taicang Xincheng Chemical Co., Ltd.) and 2-isopropylthioxanthone (produced by ITX Tianjin Jiuri Chemical Co., Ltd. ), using a disc agitator to pre-disperse for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com