PVC (polyvinyl chloride) decorative film surface treating agent, PVC decorative film treated with same and preparation method thereof

A technology of surface treatment agent and decorative film, which is applied in special decorative structures, decorative arts, decorative structures, etc. It can solve the problems of unsatisfactory matte effect and non-scratch-resistant handle of PVC decorative films, so as to achieve a smooth surface effect and improve the surface Wetting performance, effect of preventing craters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

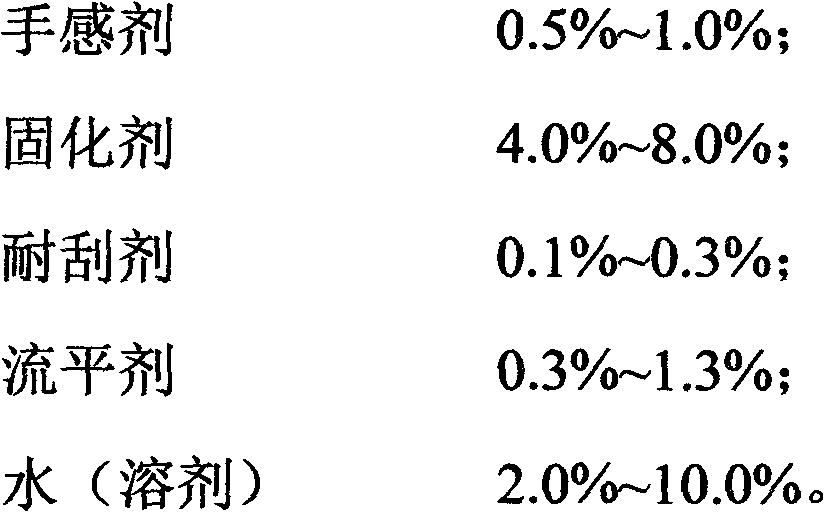

[0017] Embodiment 1: Preparation of PVC decorative film surface treatment agent

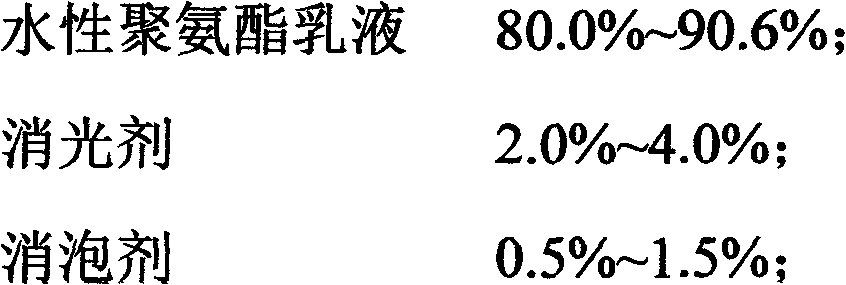

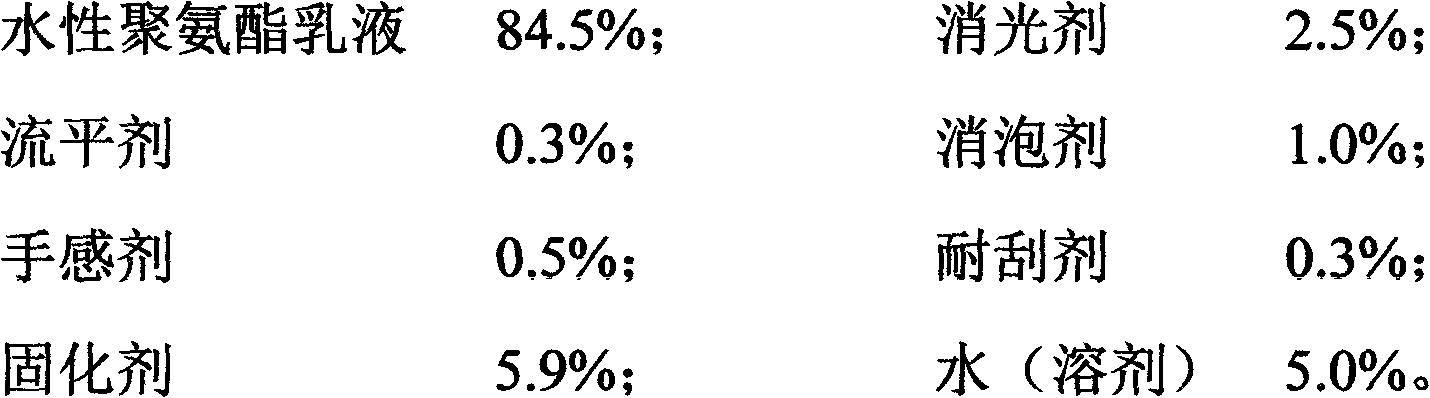

[0018] Each component is weighed according to the following weight percentage:

[0019]

[0020] Wherein, the matting agent is silica matting powder; the hand feeling agent is silicone or acrylic slip agent; the curing agent is aziridine crosslinking agent cross-linked with isophorone diisocyanate The compound of the linking agent, the mass ratio of the aziridine crosslinking agent to the isophorone diisocyanate crosslinking agent is between 1:10 and 1:2; the scratch-resistant agent is silicone oil; the The leveling agent is a polyether modified organosilicon compound; the defoamer is an acrylic modified compound.

[0021] Stir the water-based polyurethane emulsion evenly until no solid phase substance is precipitated at the bottom of the emulsion, then add defoamer, matting agent, hand feeling agent, scratch-resistant agent and leveling agent to the water-based polyurethane emulsion, stir fo...

Embodiment 2

[0022] Example 2: Preparation of ultra-matte scratch-resistant PVC decorative film

[0023] 1) Take two or three kinds of PVC base film, PVC printing middle layer film and PVC matting mask and compound them sequentially to obtain a PVC composite film, and then use a matte wheel to perform preliminary embossing and matting treatment to control the glossiness at 20~ between 60°;

[0024] 2) Using a coating machine, the PVC decorative film surface treatment agent prepared in Example 1 is coated on the surface of the PVC composite film, and the thickness of the coating is adjusted by using the upper rubber roller and the scraper, and the thickness of the coating is controlled at 0.02 ~0.10mm to ensure good toughness and tensile properties of the treated layer;

[0025] 3) Utilize the coater body of furnace to cure and dry the PVC composite film after the surface treatment agent for PVC decorative film is surface-coated, in order to ensure that the surface treatment agent is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com