Winding apparatus

A device, wire technology, used in the field of effectively winding coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

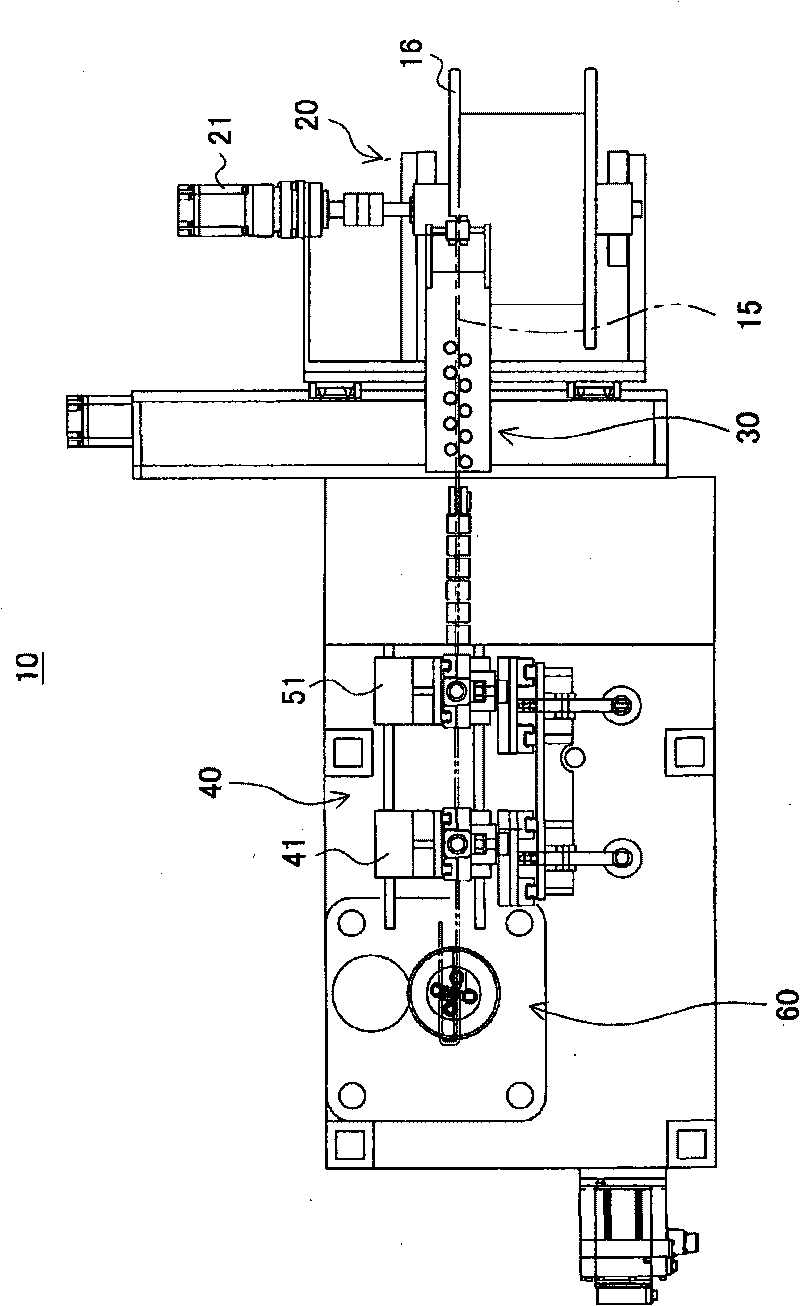

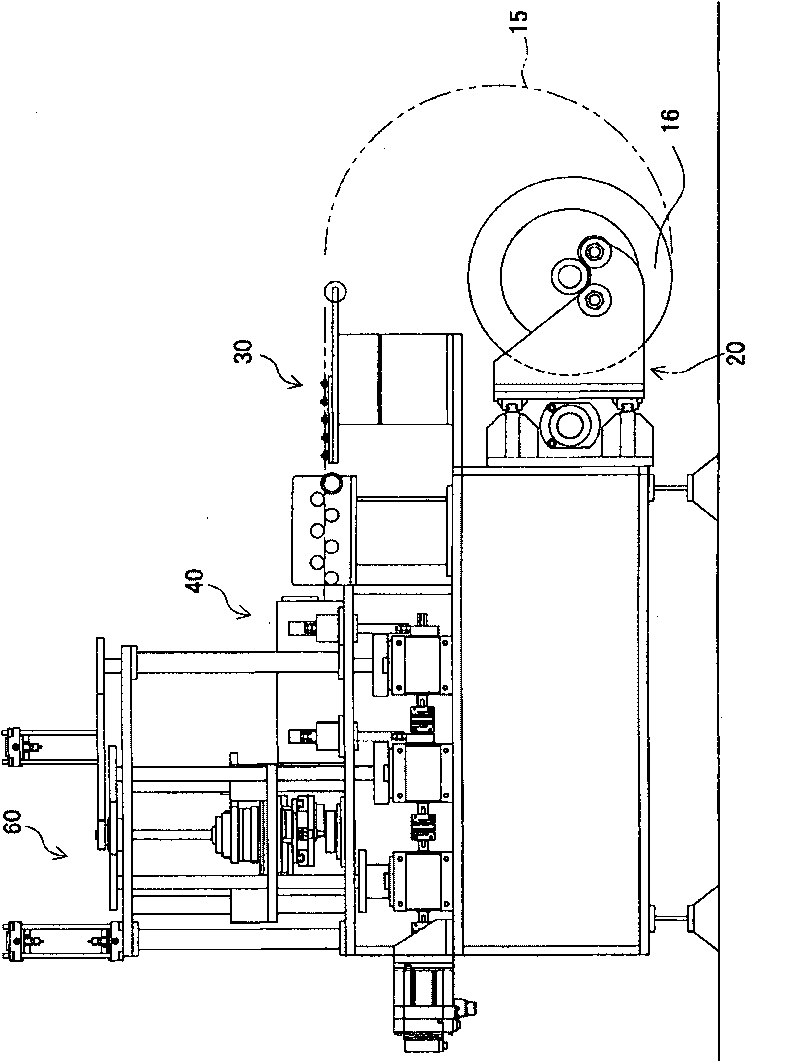

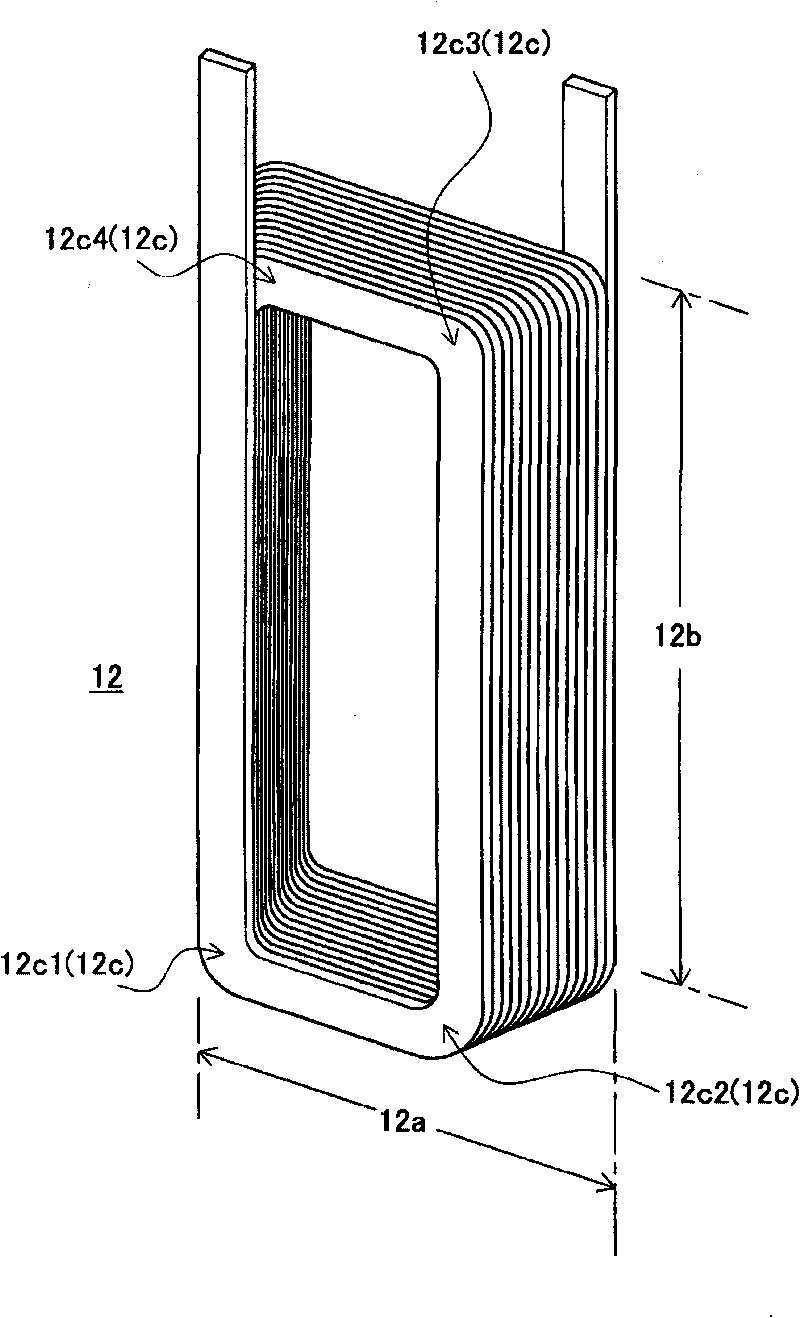

[0077] figure 1 is a plan view of the sidewinding apparatus 10 of the first embodiment. figure 2 is a side view of edgewise winding device 10 . image 3 is a perspective view of the coil 12 . exist figure 1 and figure 2 In , device 10 is partially omitted in terms of scale.

[0078] The edgewinding device 10 includes an uncoiler 20 , a straightening system 30 , a feeding system 40 and a bending system 60 . This apparatus 10 is configured to perform edgewise bending of a flat wire 15 , which is a conductor having a rectangular cross-section, to manufacture the coil 12 . Coil 12 is image 3 The coil is shown as being wound rectangularly, and includes a short side portion 12a and a long side portion 12b. These short side portions 12a and long side portions 12b correspond to non-curved portions existing between the curved portions 12c.

[0079] Each long side portion 12b has a length several times longer than each short side portion 12a. The bent portions 12c exist at f...

no. 1 example

[0160] The first embodiment providing the above configuration and operation specifically has the following advantages.

[0161] First, the coil 12 can be wound at high speed.

[0162] The edge bending apparatus 10 is configured to manufacture a coil 12 made by winding a flat wire 15 into a non-circular form by edge bending so that the coil 12 includes a plurality of bent portions 12c having equal bending angles, each existing in a bend Short side portion 12a and long side curved portion 12b between portions 12c. The apparatus 10 includes a holding shaft 67 to be brought into contact with the inner peripheral surface 15a of the flat wire 15 and to clamp the bent portion 12c of the flat wire 15 in the thickness direction of the flat wire 15, and a rotary table 75. The peripheral surface 15 a will form the inner periphery of the finished coil 12 . The apparatus 10 also includes a bending jig 77 to be brought into contact with the outer peripheral surface 15 b of the flat wire 1...

no. 2 example

[0173] The second embodiment is capable of performing the same operations as the first embodiment, except in the manner of power transmission. Configurations different from those of the first embodiment will be described below. Components or parts with the same symbols as those of the first embodiment have the same functions as those of the first embodiment. Figure 30 is a plan view of the edge-bending device 10 in the second embodiment. Figure 30 corresponds to figure 1 . Figure 31 is a side view of device 10 and corresponds to figure 2 .

[0174] The second embodiment is very different from the first embodiment in the way of power transmission. In the first embodiment, power transmission is performed through the roller gear 90 . On the other hand, in the second embodiment, power transmission is performed by the Malter mechanism to cause intermittent operation. Thus, the uncoiler 20 and straightening system 30 are substantially the same as the first embodiment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com