Production method of polymer film and production apparatus of the same

A polymer film and manufacturing method technology, applied to flat products, other household appliances, coatings, etc., can solve problems such as difficulty in applying voltage, poor smoothness of cast film, damage to electrodes, etc., to achieve less defects and better smoothness , high-speed and stable manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

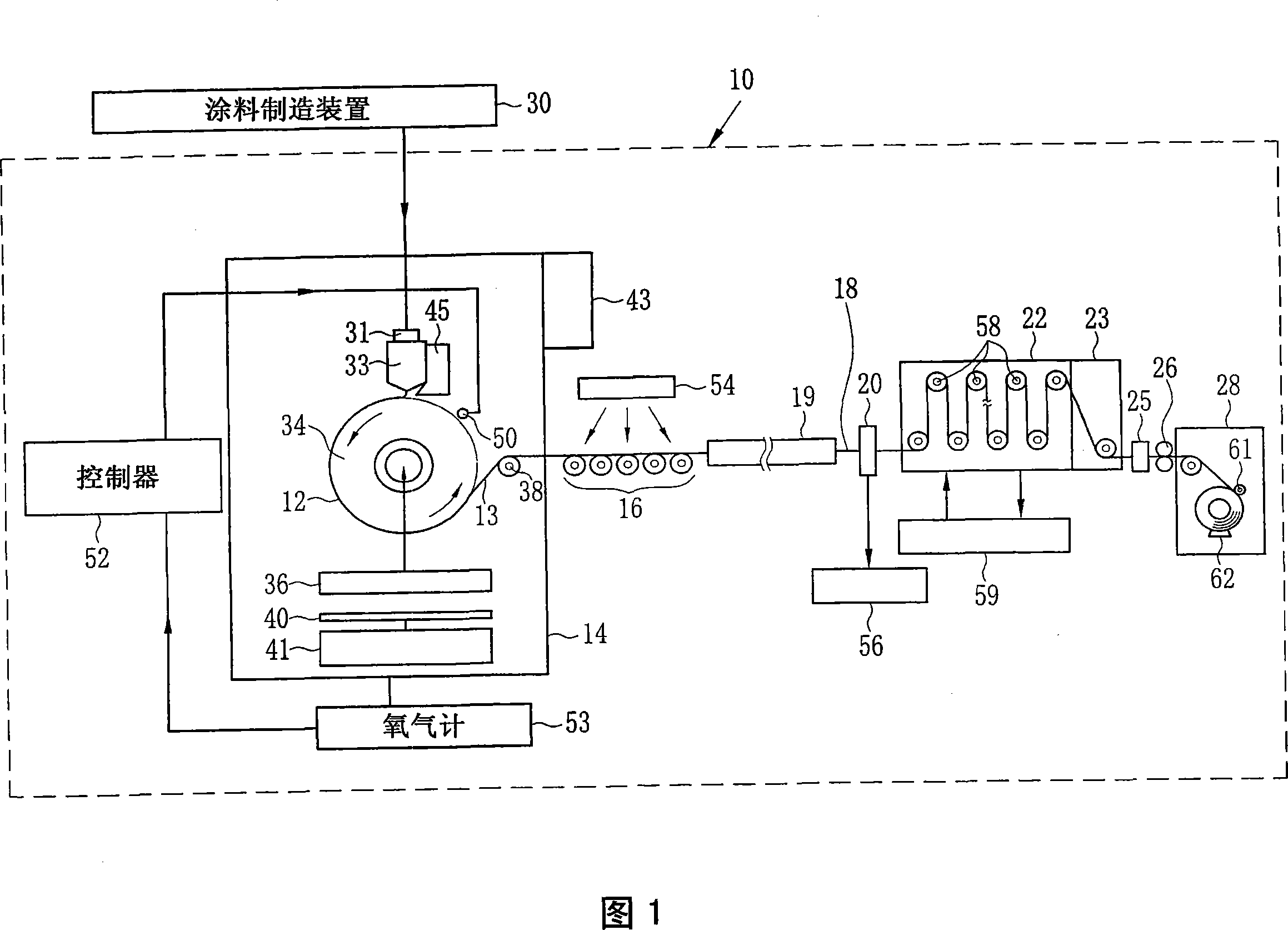

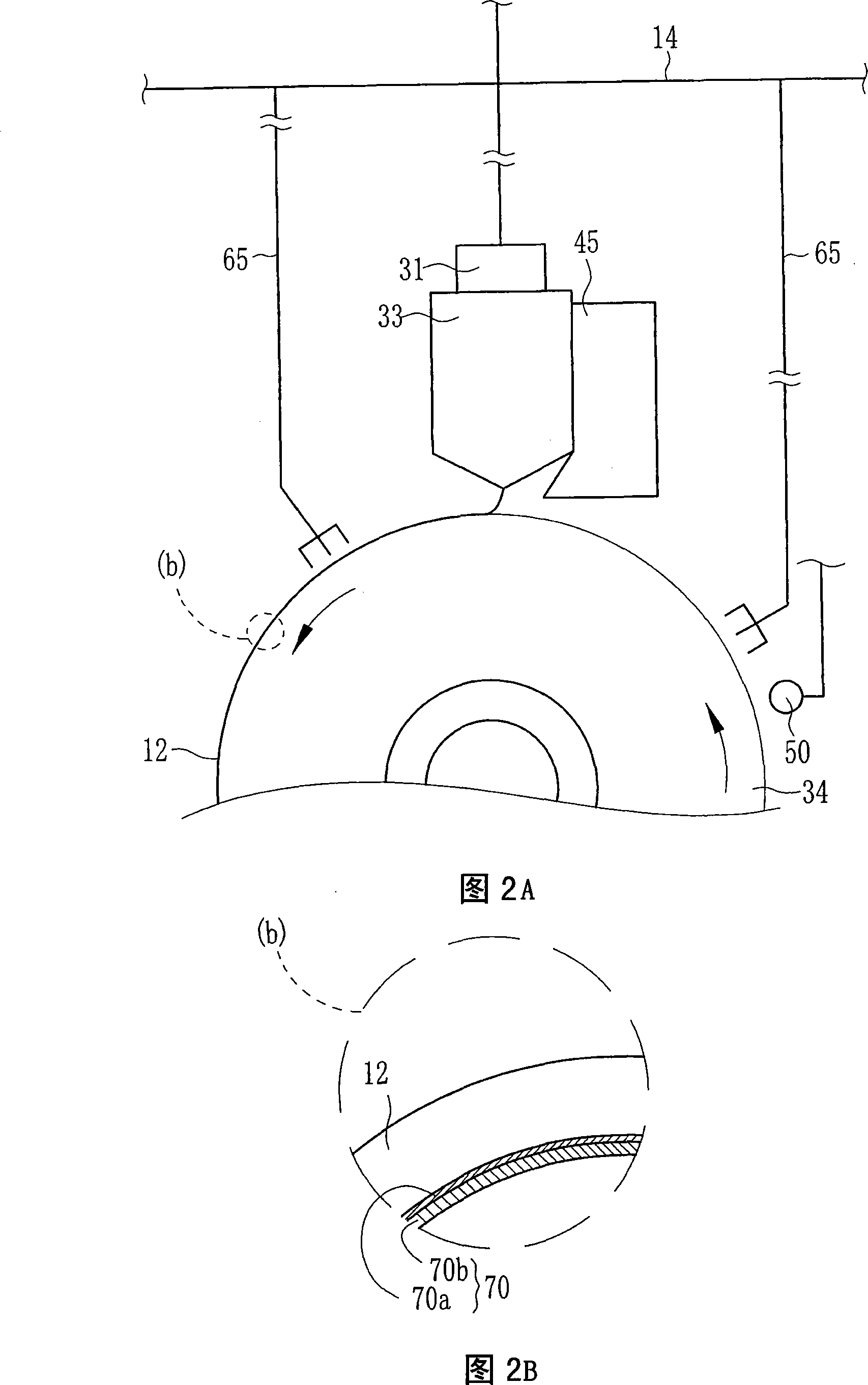

[0080] A film manufacturing apparatus 10 as shown in FIG. 1 is used to produce a film 18 . After a sufficient amount of dope is supplied from the dope manufacturing apparatus 30 to the casting die 33 through the supply block 31, the dope is discharged from the discharge port of the casting die 33 to the continuously rotating casting drum 34 as shown in FIG. 2A. At this time, the pressure in the suction chamber 45 is set to 600 Pa to reduce the pressure in the upstream region of the flow path. The discharge amount of the paint was adjusted so that the thickness of the film 18 after drying was 80 μm.

[0081] The casting drum 34 is made of stainless steel and the frequency of rotation can be controlled by a driver (not shown). A heat transfer medium for cooling was supplied from a heat transfer medium feeder 36 to the casting drum 34 so that the surface temperature of the casting drum 34 became -10°C. As shown in FIG. 2A , before casting the dope, a DC high voltage is applied ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com