Hygienic tissue paper product and manufacturing method thereof

A manufacturing method and technology of tissue paper, applied in the direction of tissue paper/absorbent paper, papermaking, special paper, etc., can solve the problems of easy failure, polluted equipment, and unpopular pattern printing, and achieve the effect of improving attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

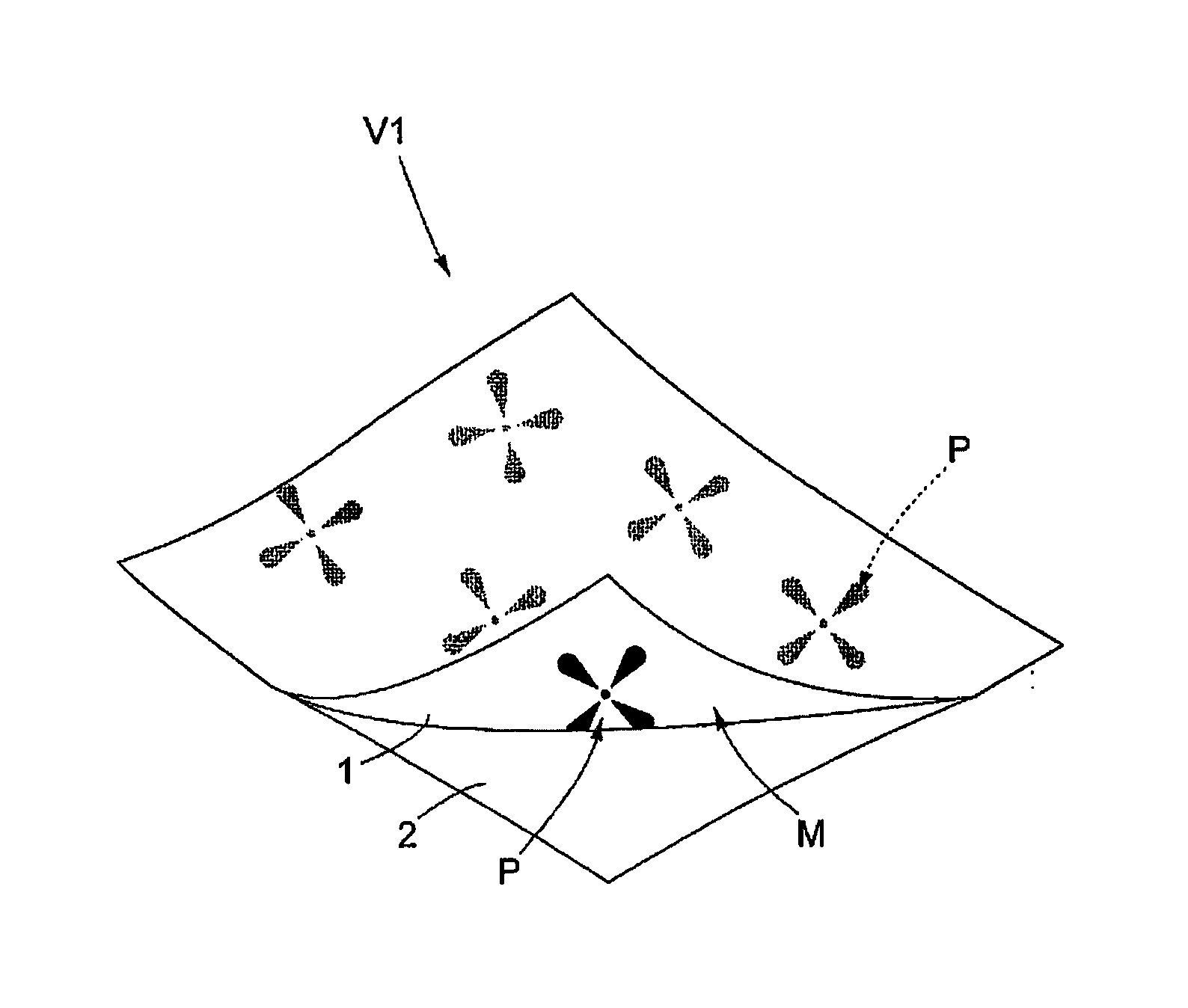

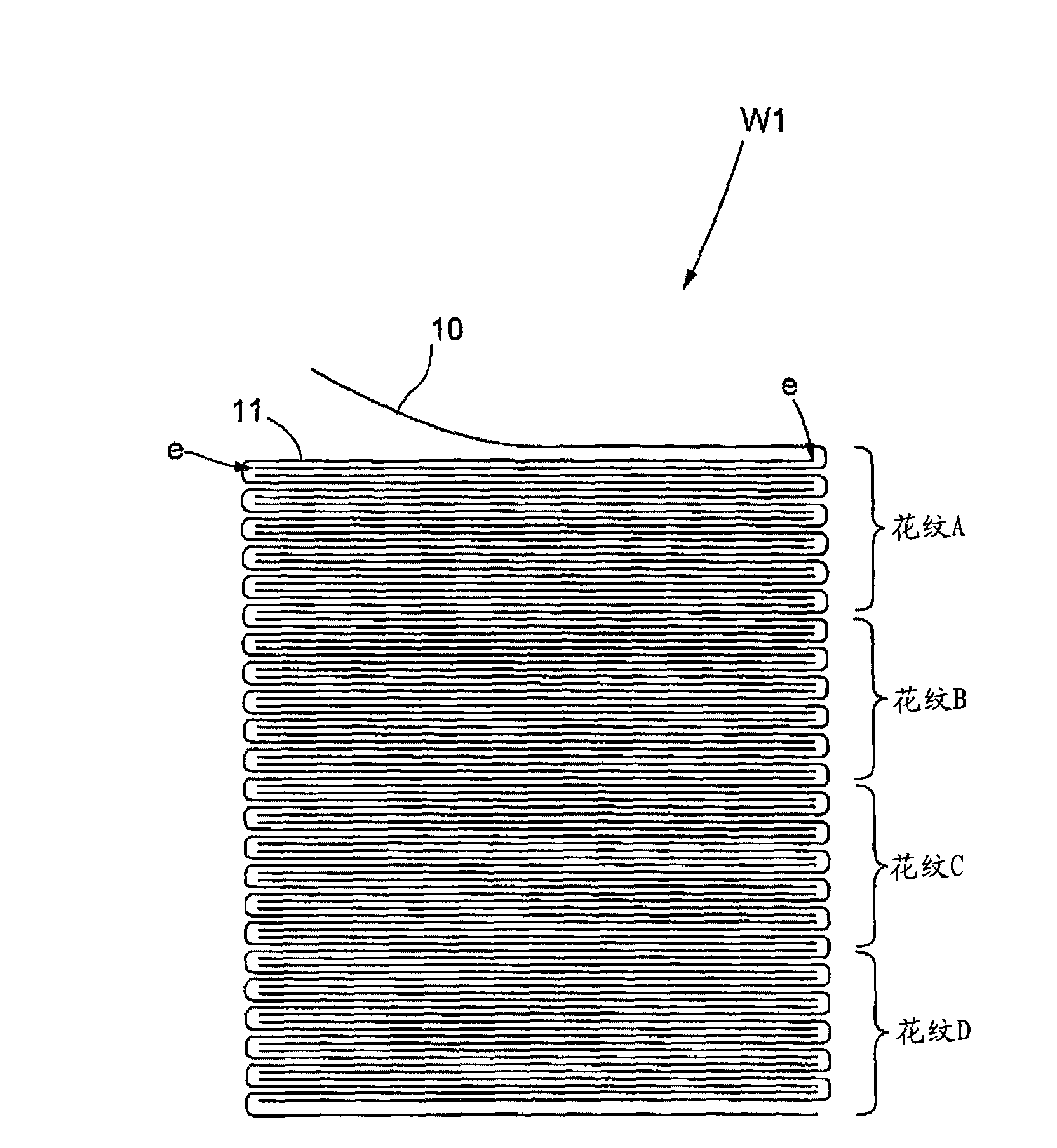

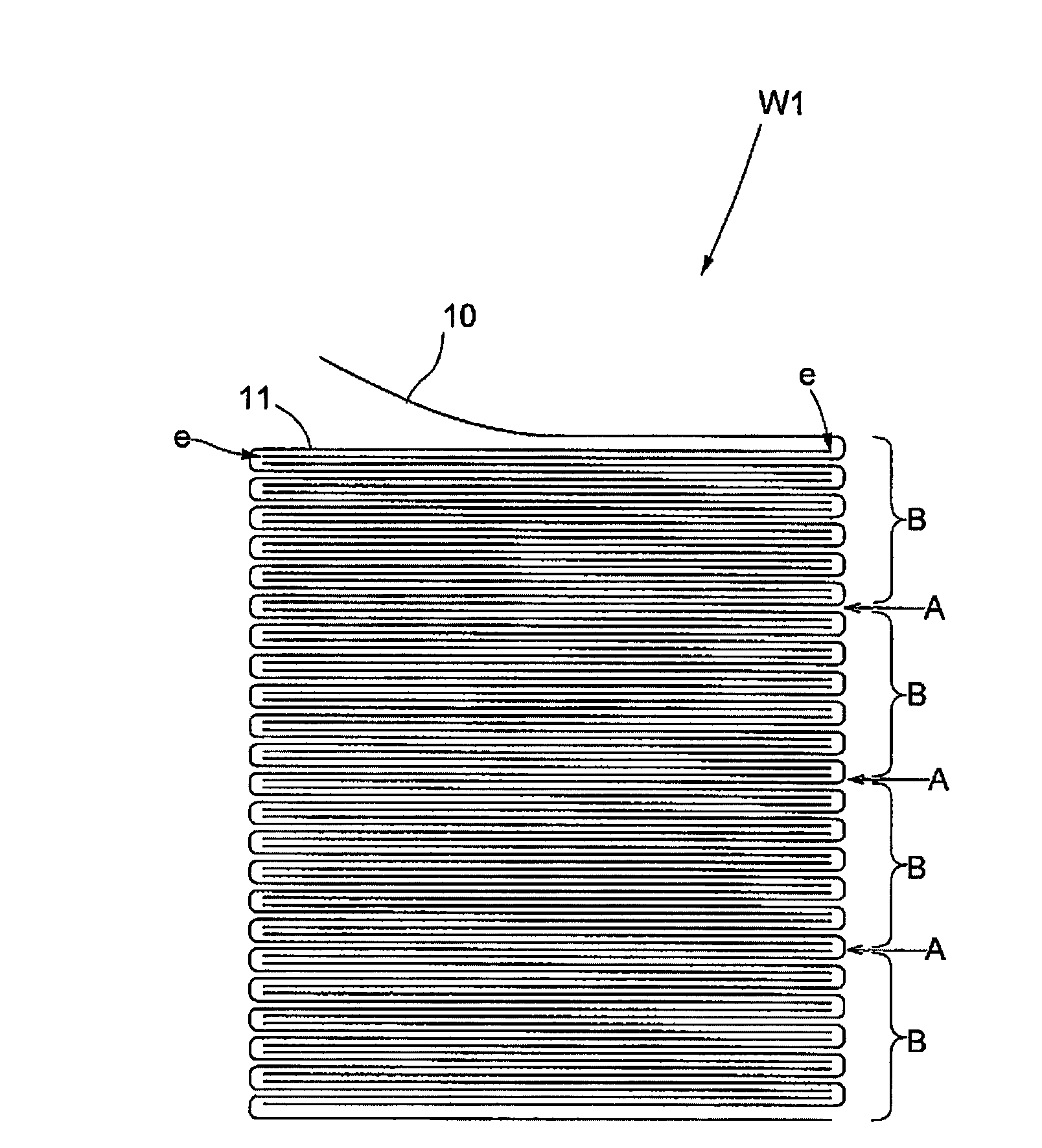

[0221] Here, as can also be seen from the description of the interfolder M, the structure of the bundle W1 shown in the above-mentioned [Structural Example 1 of the Bundle of Sanitary Tissue Papers] and [Example 2 of the Structural Example of the Bundle of Hygienic Tissue Papers] of the present invention is obtained by The manner in which the secondary base paper roll is attached to each base paper roll support part 71, 71 in the above-mentioned interfolder M is determined.

[0222] That is, when forming the sanitary tissue paper bundle W1 in which all the tissue papers have patterns, the printed secondary base paper rolls 45' on which the patterns P are printed are mounted on all the base paper roll support parts 71 in the interfolder. When the bundle of sanitary thin paper sheets sandwiching the non-printing is properly formed, the non-printing secondary base paper roll is mounted on an appropriate base paper roll support portion.

[0223] Furthermore, when forming a sanitar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com