Moulding, filling and sealing appts. for self-standing bags

A technology of sealing equipment and sealing mechanism, applied in packaging sealing/fastening, transportation and packaging, envelope/bag manufacturing machinery, etc., which can solve problems such as reduced productivity, large installation area, and prolonged sealing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

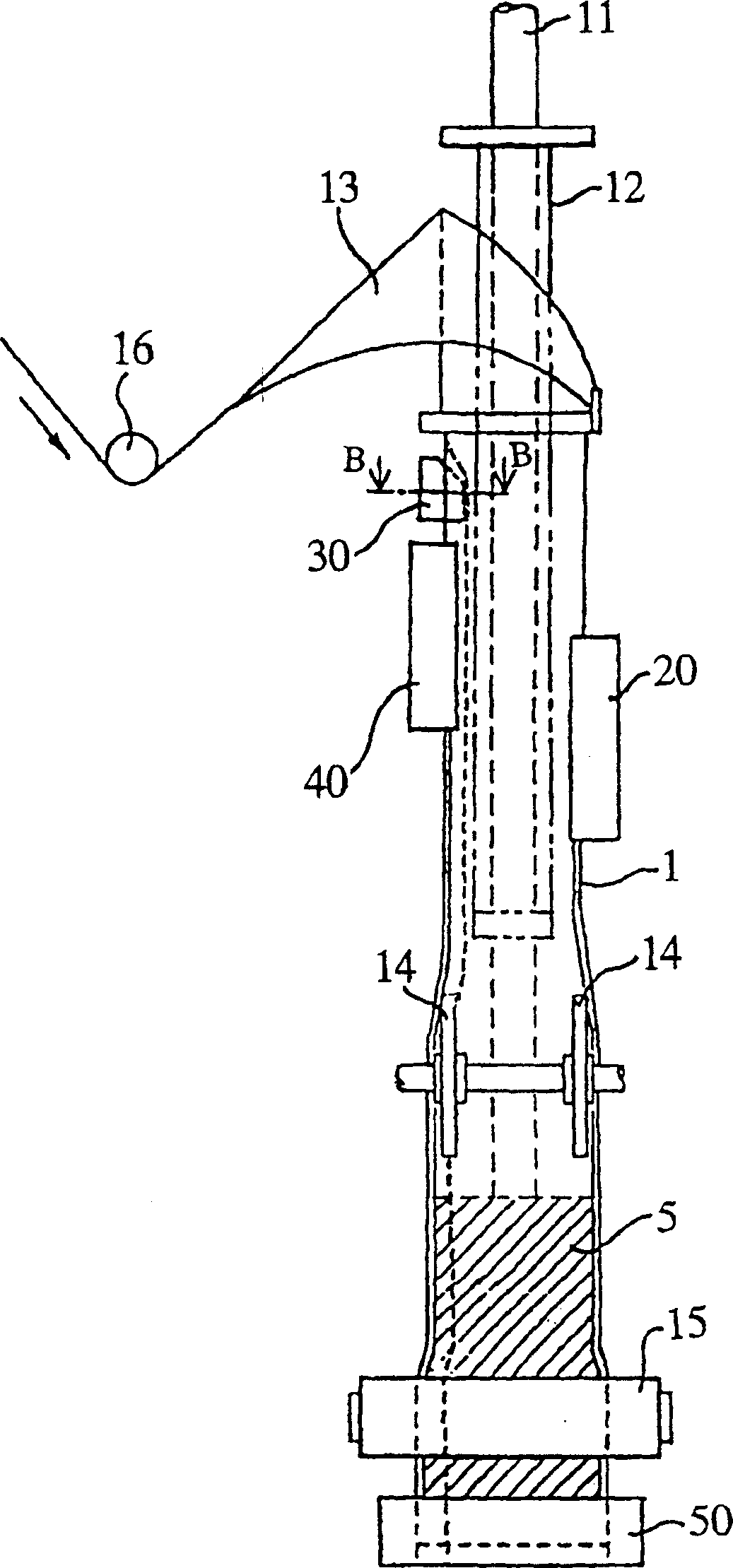

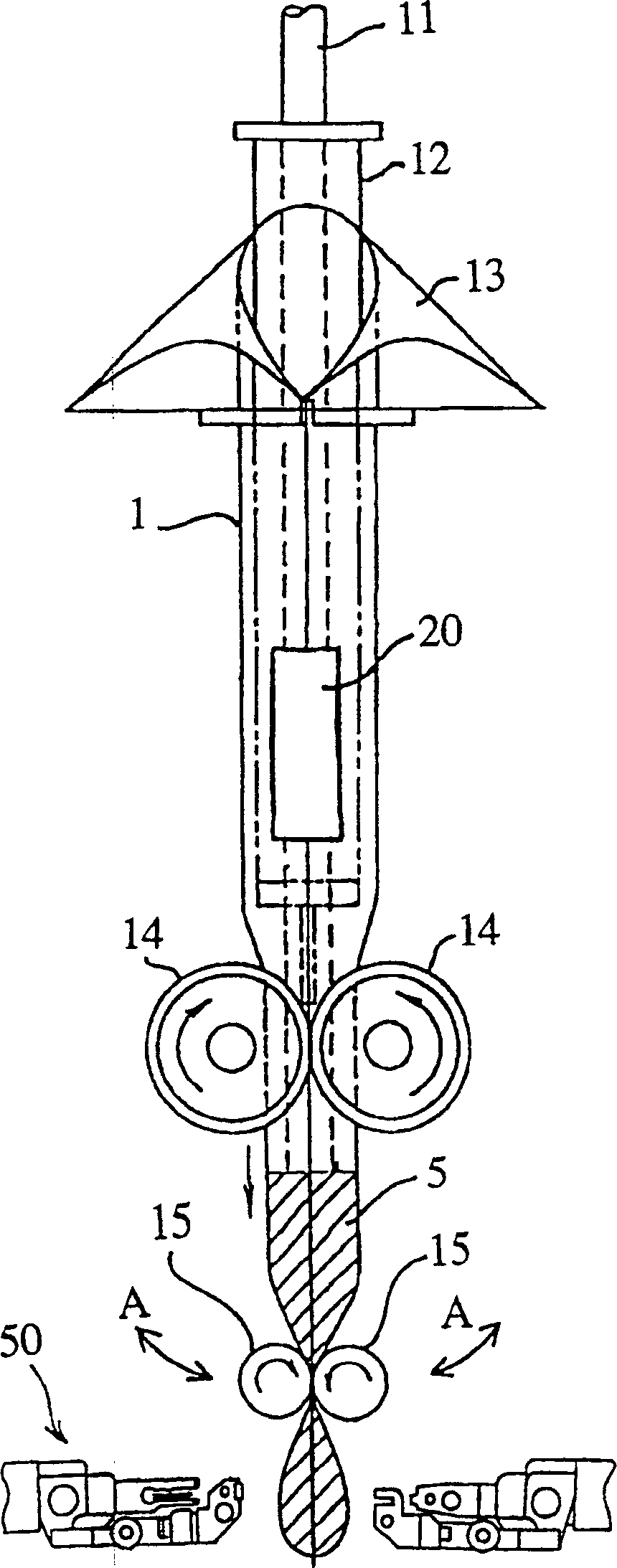

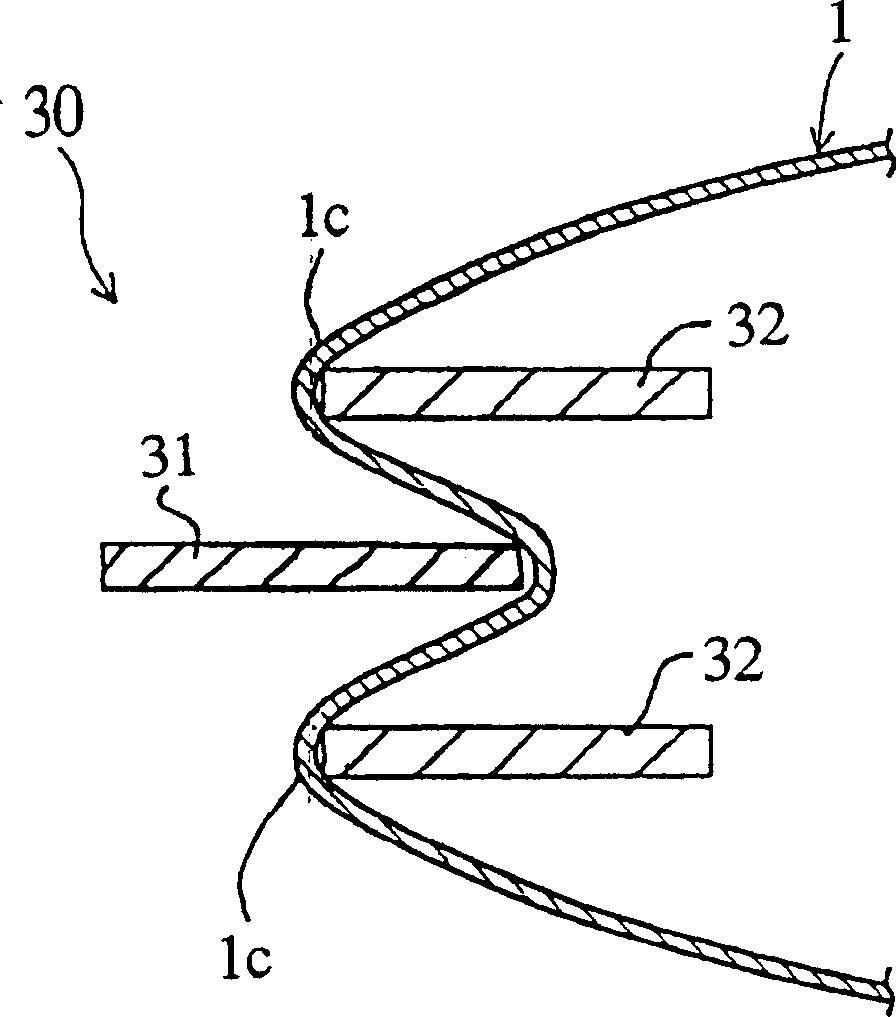

[0053] Now refer to the attached figure 1 and 2 , which represents a form, fill and seal apparatus according to a first preferred embodiment of the present invention. This form, fill and seal equipment is a vertical form, fill and seal equipment, used to manufacture the stand-up pouch 1000 shown in Figure 9, through the injection pipe 11 provided inside the main pipe 12 to fill the liquefied or pasty Material 5 is packed into bag 1000 .

[0054] On the outer periphery of the main pipe 12, there is provided a film forming guide 13 for overlapping both side ends of the sheet film 1 supplied by the tension roll 16 to successively form it into a tubular shape. The film 1 formed into a tubular shape by means of the film forming guide 13 is vertically heat-sealed along the side edges of the overlapping surfaces by the top sealing mechanism 20 provided below the film forming guide 13 . Now, since the top sealing mechanism 20 is similar in structure to a conventional vertical form,...

no. 2 example

[0101] Refer to the attached Figure 12-2 0 describes the second embodiment of the present invention.

[0102] Now refer to the attached figure 2 and 3, which represents a forming, filling and sealing apparatus according to a second embodiment of the present invention. Above the injection pipe 114, a film forming guide 114 is provided for folding both side ends of the film 101 so that they overlap each other, supplied from the film supply roll 113 via a tension roll (not shown) and a guide roll 115. Film 101. Furthermore, a tension mechanism identical to that of the first embodiment is arranged between the film supply roller 13 and the tension roller.

[0103] The film forming guide 111 is arranged obliquely, so that the film 101 can pass on the surface of the guide 111, and it includes a trapezoidal plate whose base is smaller than the top and two film guiding arms 112, and the arms 112 are arranged on the bottom of the trapezoidal plate Nearby, for checking the elongat...

no. 3 example

[0156] The above-mentioned first and second embodiments have shown form, fill and seal equipment for efficiently manufacturing stand-up pouches without introducing any foreign matter according to the operating principle of a vertical form, fill and seal equipment.

[0157] As can be seen from the foregoing embodiments, the stand-up pouch has a thick bottom, and the degree of expansion of the pouch varies with the location. Therefore, when heat sealing the film, there is a tendency to create creases in the film compared to making a pillow-shaped package. When such a wrinkle occurs, it spoils not only the appearance of the package but also good airtightness, and depending on the situation, there is a possibility that the filling material may leak from this portion.

[0158] Therefore, in order to prevent the film from wrinkling, this embodiment provides a filling and packaging equipment, which can better realize heat sealing, and can also take advantage of the advantages of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com