Device for producing wire rope

A technology for cables and equipment, applied in the field of cable manufacturing devices, can solve problems such as filler distortion, and achieve the effect of increasing the speed of cable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

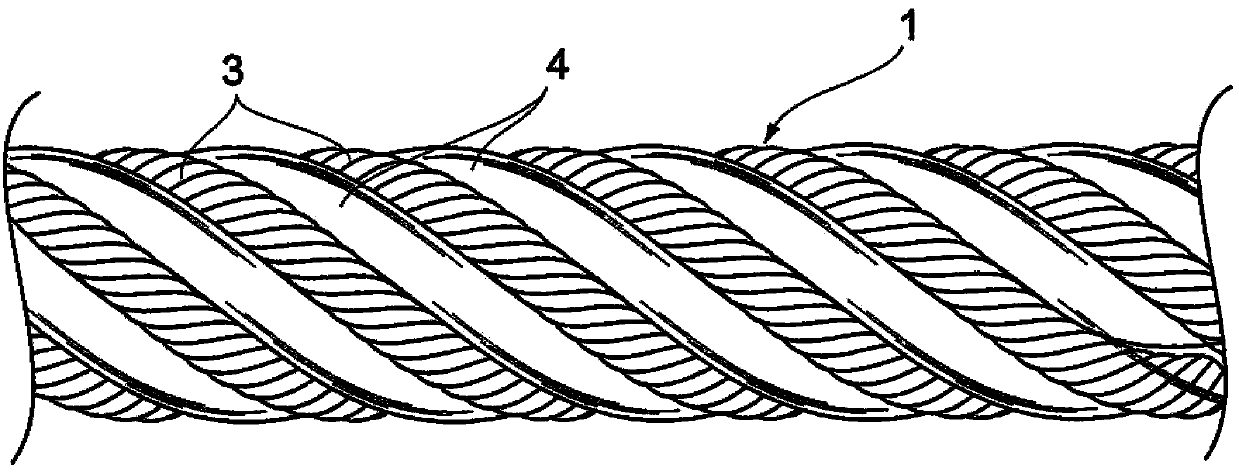

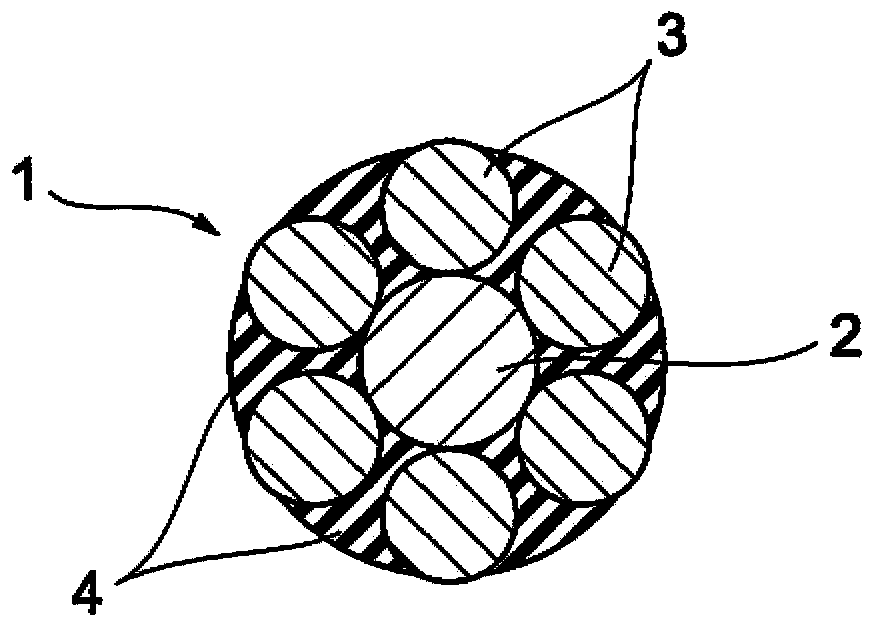

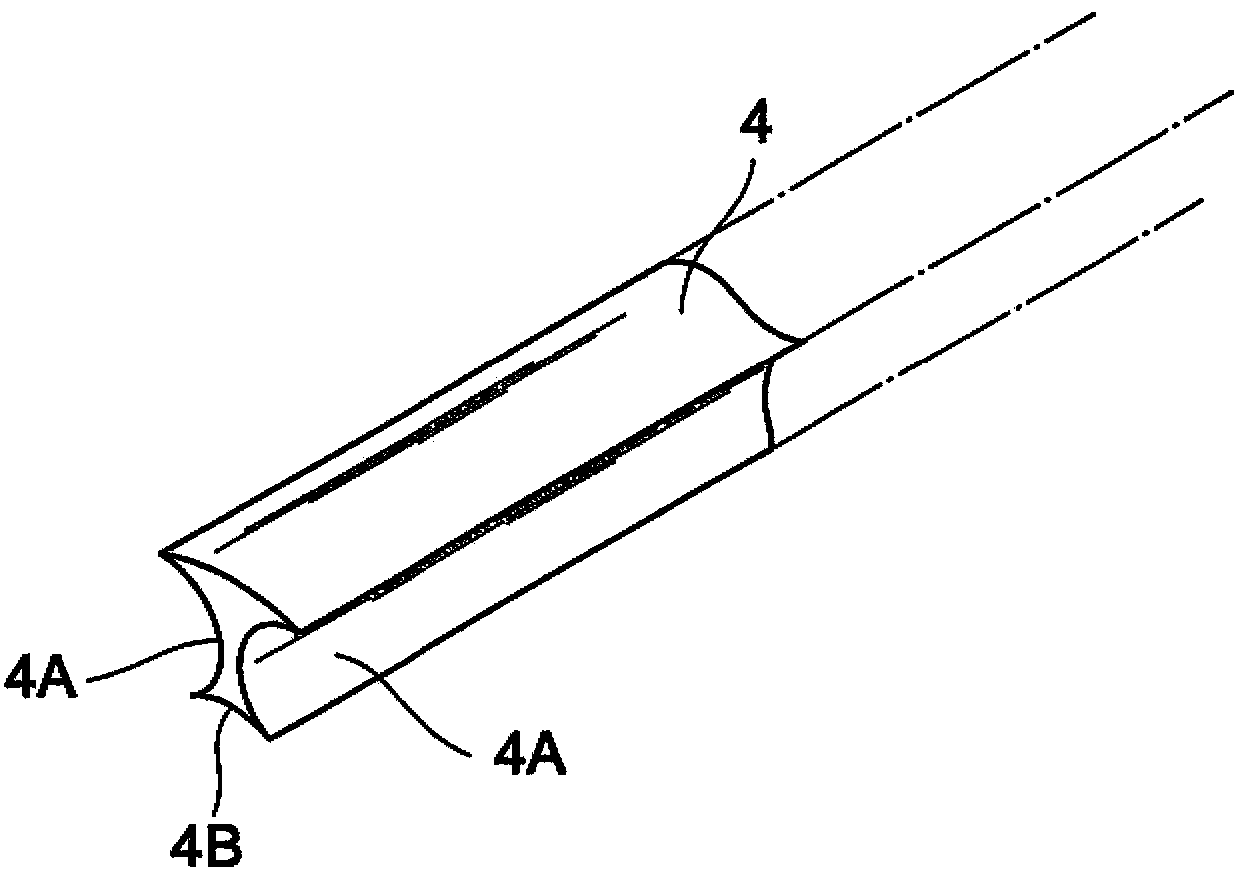

[0021] Figure 1A is the front view of cable 1, Figure 1B is a cross-sectional view of cable 1, and Figure 1C is a partially enlarged perspective view of the filler 4 contained in the cable 1 . exist Figure 1B In the sectional view of , a plurality of steel wires (wire elements) constituting each side strand 3 are not shown.

[0022] The cable 1 comprises a centrally arranged cable core 2 and is formed by laying six side strands 3 around the cable core 2, wherein each strand has a plurality of flat steel wires and the six side strands 3 lay six fillers 4 between them. The packing 4 is formed in a straight shape from a flexible material such as rubber or synthetic resin. see Figure 1B and 1C , each filler 4 has in its cross section a relatively deep recessed portion 4A formed on each side and a relatively shallow recessed portion 4B formed on the bottom. The upper side (convex part) of each filler 4 is exposed to the outside of the cable 1 . The side strands 3 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com