Compact pressing method using continuous press and device for actualizing the method

A technology for pressed products and presses, applied in the field of equipment for implementing the method, can solve the problems of slab obstruction, steel strip wear, and inability to achieve, and achieve the effects of high-quality manufacturing and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

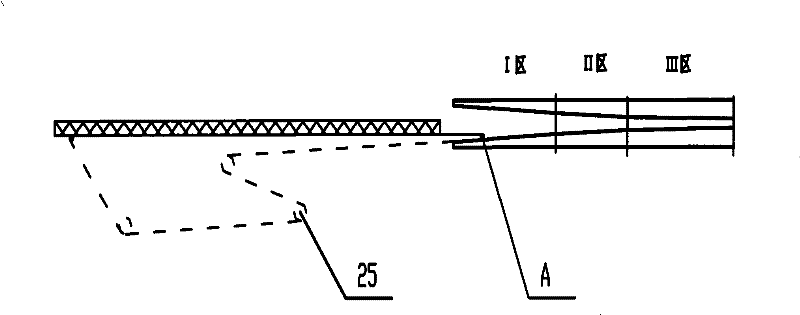

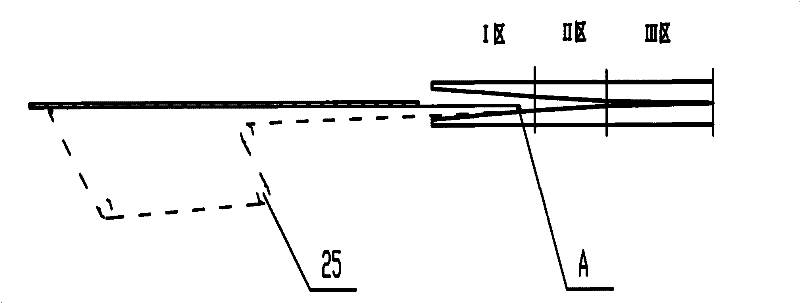

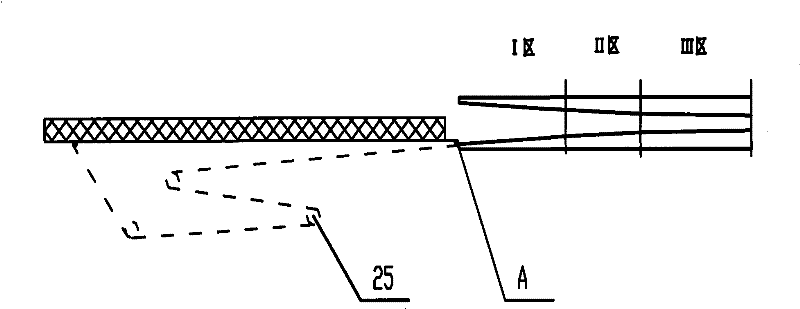

[0030] The following will be based on Figures 1 to 3 A specific example is shown to further illustrate the method according to the present invention.

[0031] Figures 1 to 3 Schematically shows the front end of the conveyor 24 relative to the press inlet ( Figure 4 The location of the area indicated by E in ). In these views, the conveyor 24 is simplified as a conveyor belt shown in dashed lines. The belt is supported by rollers and the position of the roller closest to the press inlet (E) is movable.

[0032] Such as figure 1 As shown, the three zones I, II, III together form the feed inlet (E) of the press.

[0033] figure 1 Indicates the situation when pressing a medium-thick slab. At this time, the front end of the conveyor 24 abuts against point A of the feed inlet (E). This A point is exactly the starting point of conveyer 24 front ends when pressing medium-thick slab.

[0034] Similarly, figure 2 and 3 Respectively represent the situation of pressing thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com