Method and apparatus for producing fiber-fabric material

A technology of fiber structure and fiber fabric, which can be applied in the direction of fabric, fiber treatment, deburring device, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

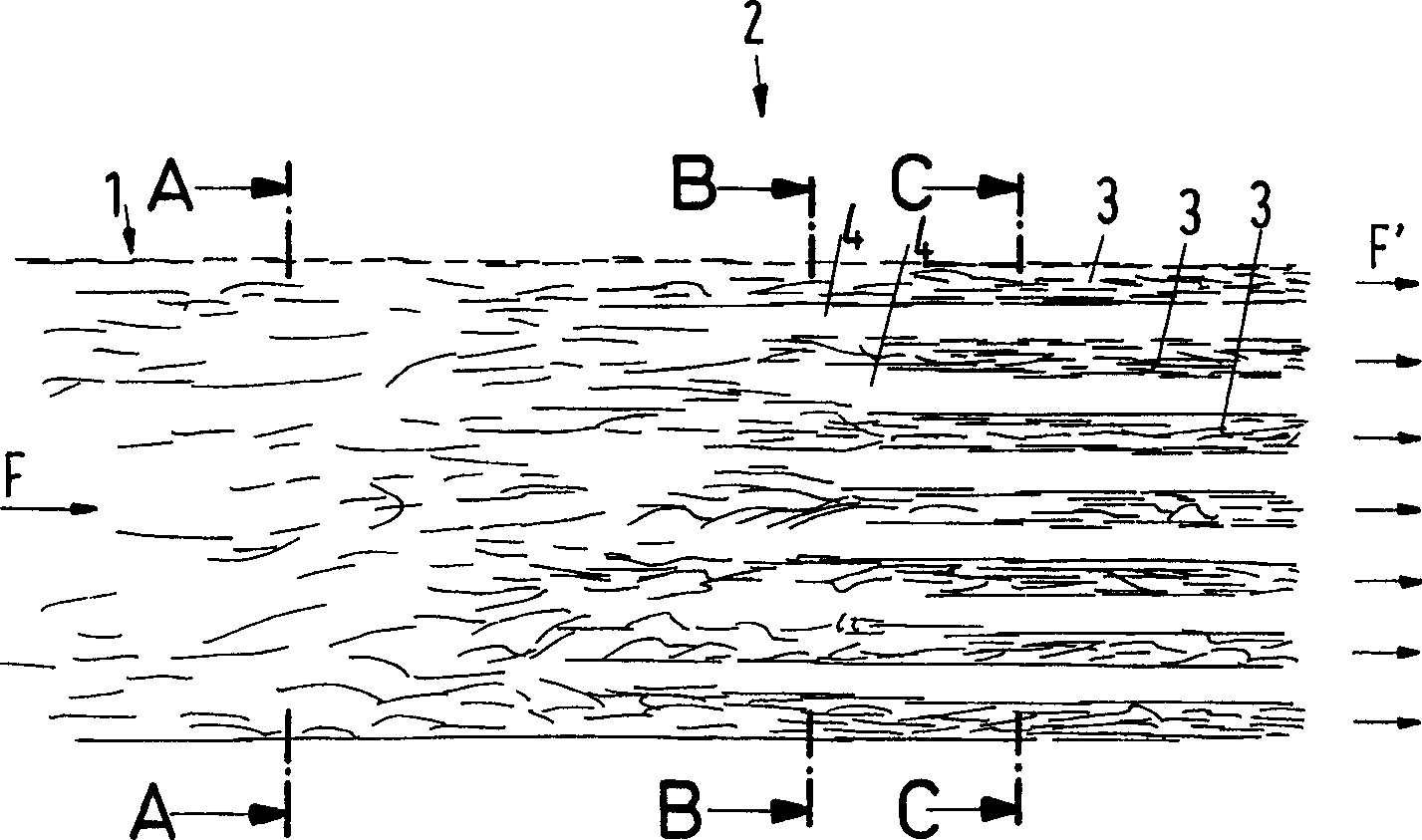

[0030] figure 1 A preferred embodiment of the method of the invention for producing a fibrous textile weave from spinning staple fiber material suitable for producing a flat textile weave in a manner known per se in the textile field, such as making spun yarns, is represented.

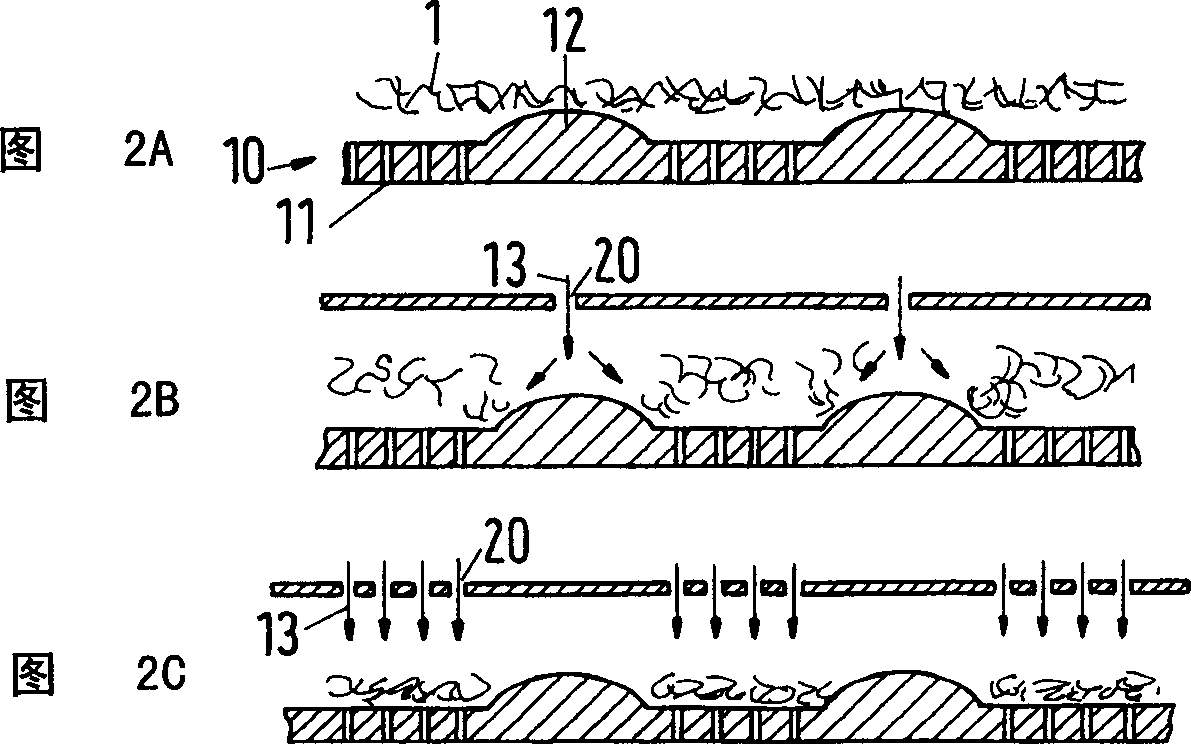

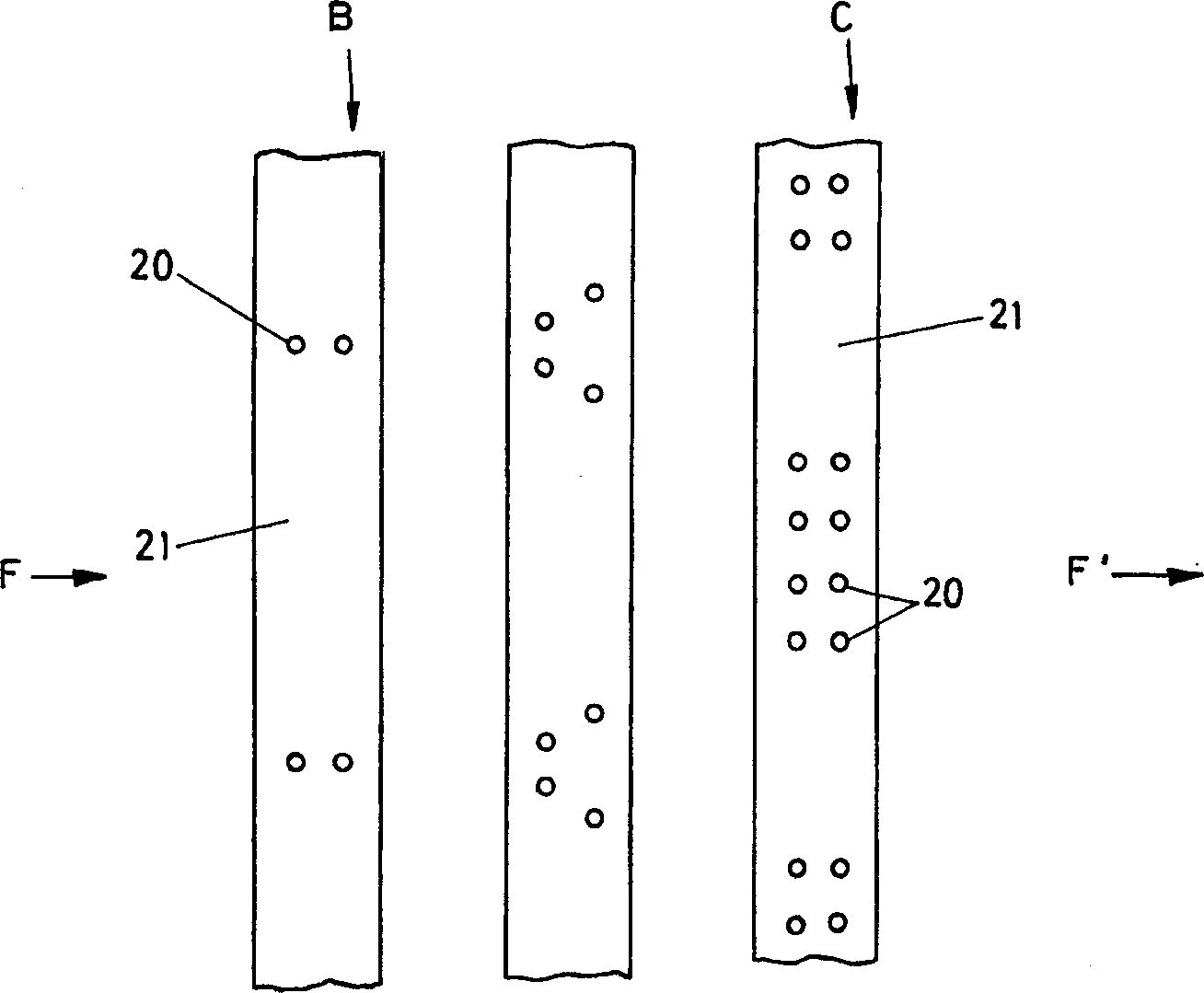

[0031] In the conveying direction F, the approximately continuous nonwoven 1 is fed to the processing zone and passed through the processing zone 2 . During the transport through the processing zone 2, a processing template is positioned on one side of the nonwoven 1 and fine jets such as water, saturated steam or air impinge on the nonwoven 1 from the other side (the jet and the processing template are in contact with each other) figure 1 not shown). Owing to the action of the jet stream and the processing template, in the conveying direction F, strip-shaped sparse areas 4 and a plurality of parallel strips 3 alternating therewith are obtained in the nonwoven. After the processing station 2, the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com