Coating method and apparatus

a coating method and coating technology, applied in the direction of coatings, instruments, photosensitive materials, etc., can solve the problems of uneven coating, stripe generation in the coating layer, and inability to meet the demand of obtaining a magnetic layer with thin film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

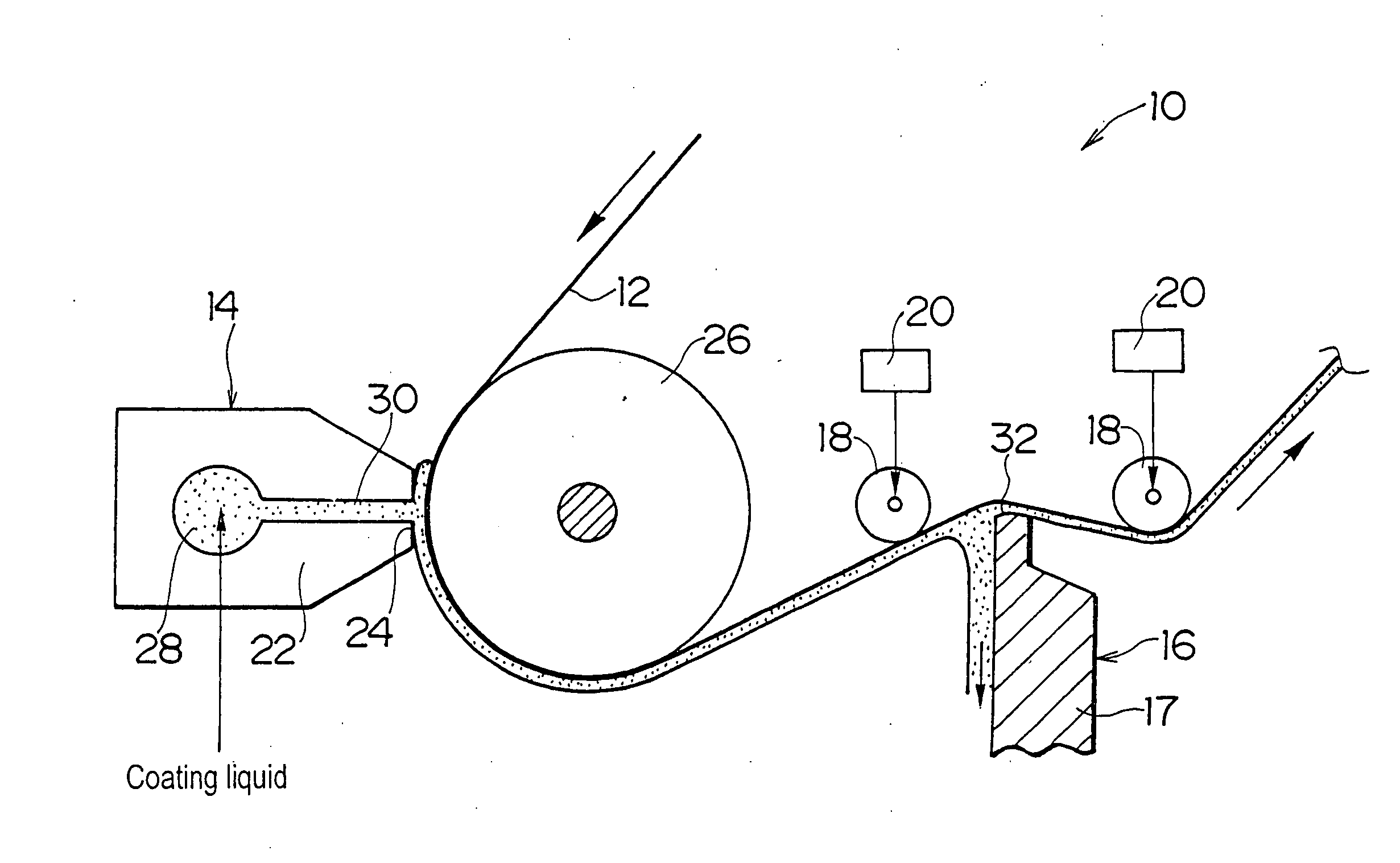

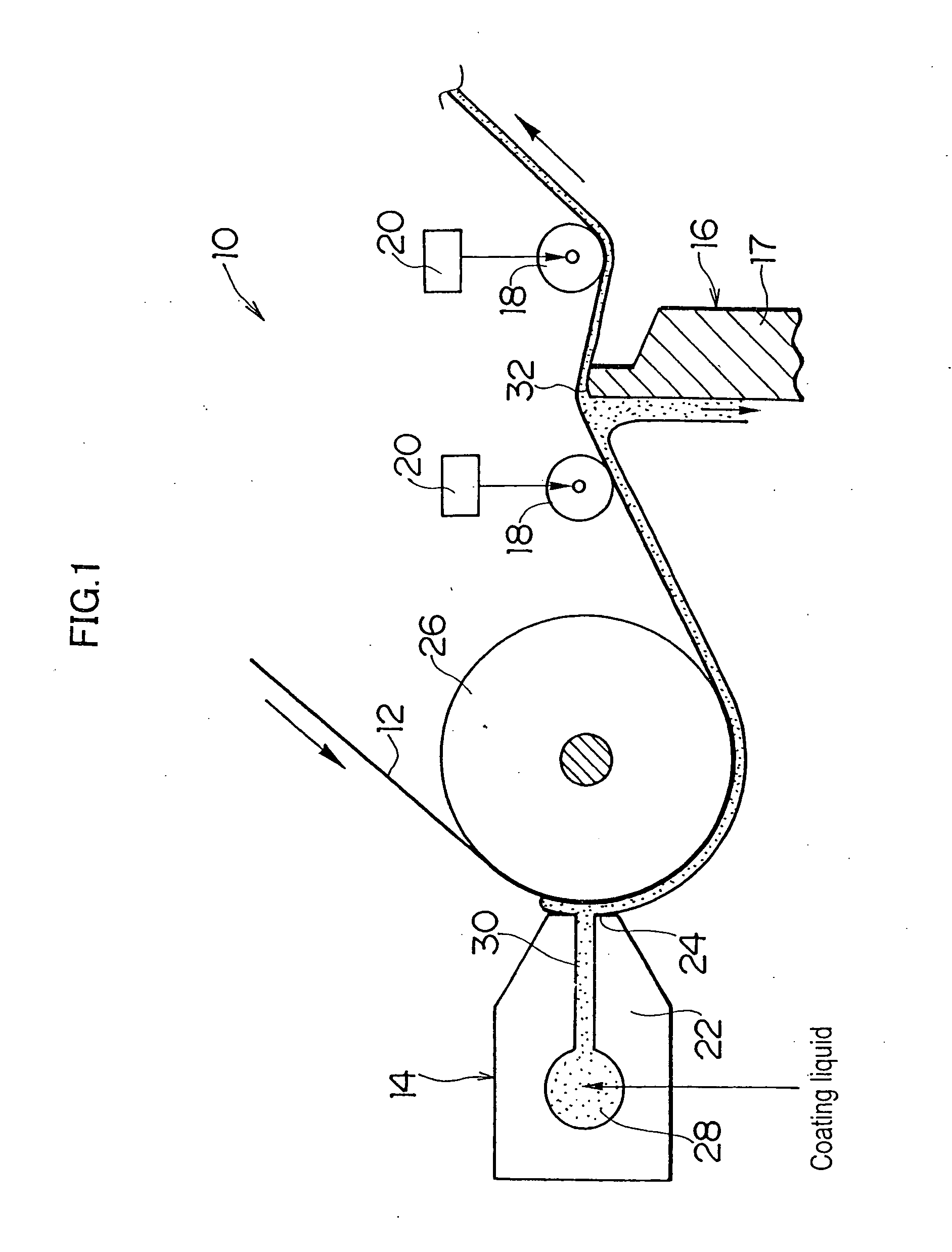

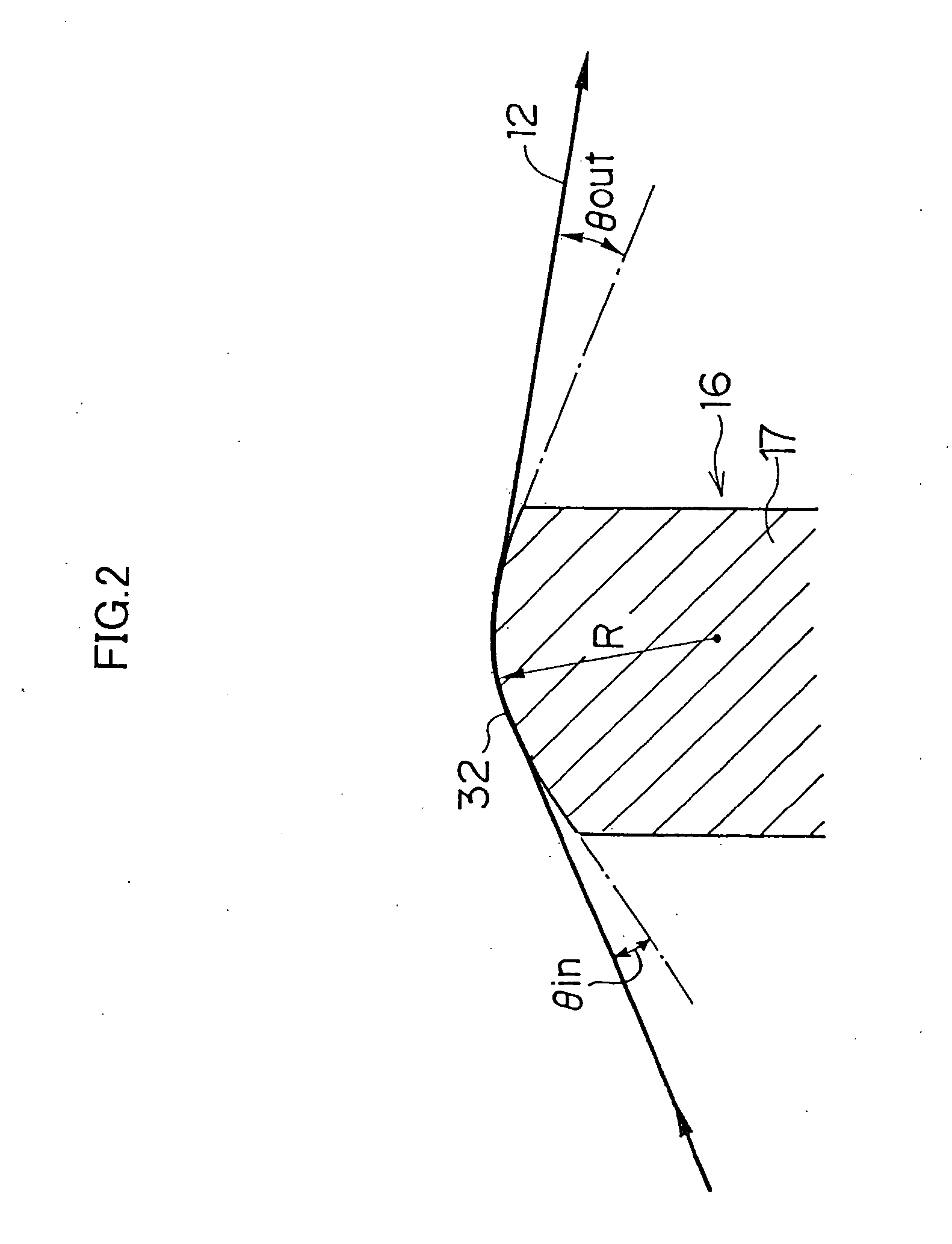

[0094]FIG. 1 is a conceptual drawing showing the entire configuration of a scraping-off type coating apparatus 10 according to the present invention, and FIG. 2 is an enlarged view of an end section of a doctor blade.

[0095] As shown in FIG. 1, the coating apparatus 10 mainly comprises: a precoating apparatus 14 applying coating liquid more excess than the desired coating quantity on a web 12 traveling continuously; a doctor blade 17 as a scraping-off member 16 that scraps off an excess of coating liquid; support rollers 18 and 18 that press the web 12 against the doctor blade 17; and a pressure distribution adjusting device 20 that adjusts the pressure distribution in a web width direction. In addition, though a backed-up extrusion type coating head will be exemplified as the precoating apparatus 14, the present invention is not limited to this. But, with providing each support roller in upstream and downstream sides of the precoating apparatus 14 without using a backup roller 26, ...

embodiment 2

[0119] Next, the second embodiment of the present invention will be described with assigning the same reference numerals to the same members as those in the first embodiment.

[0120] As shown in FIG. 9, a coating apparatus 100 where a coating method of the present invention is applied mainly comprises: a precoating apparatus 14 applying coating liquid excessive than the desired coating quantity on a web 12; a scraping-off member (applicator) 16 that scraps off an excess of the coating liquid excessively applied; support rollers 18 and 18 that gives pressure with pressing the web 12 against the scraping-off member 16; and a pressure distribution adjusting device 121 that adjusts the coating thickness distribution in a web width direction before scraping off the excess of the coating liquid by the scraping-off member 16.

[0121] The coating apparatus 100 is constituted by using the backed-up extrusion type coating head 22 as the precoating apparatus 14, the doctor blade 17 as the scrapi...

embodiment 3

[0149] Next, the third embodiment of the present invention will be described with assigning the same reference numerals to the same members as those in the first and second embodiments.

[0150]FIG. 18 is a conceptual drawing showing the entire configuration of a scraping-off type coating apparatus where a coating method according to the present invention is applied.

[0151] A coating apparatus 200 mainly comprises: a precoating apparatus 14 applying coating liquid excessive than the desired coating quantity on a web 12; a scraping-off member (applicator) 16 that scraps off an excess of the coating liquid excessively applied; support rollers 18 and 18 that gives pressure between the web 12 and the scraping-off member 16; and a variance suppressing device 220 that suppresses a factor of thickness variance so as to obtain a coating layer where the thickness variance in a web traveling direction after the scraping-off.

[0152] The coating apparatus 200 in FIG. 18 is a post-measurement syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com