SF6 and SF6 mixed gas density relay verifying unit

A calibration device and mixed gas technology are applied in the calibration field of SF6 electrical products to overcome errors, improve calibration accuracy, and facilitate the inflation system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

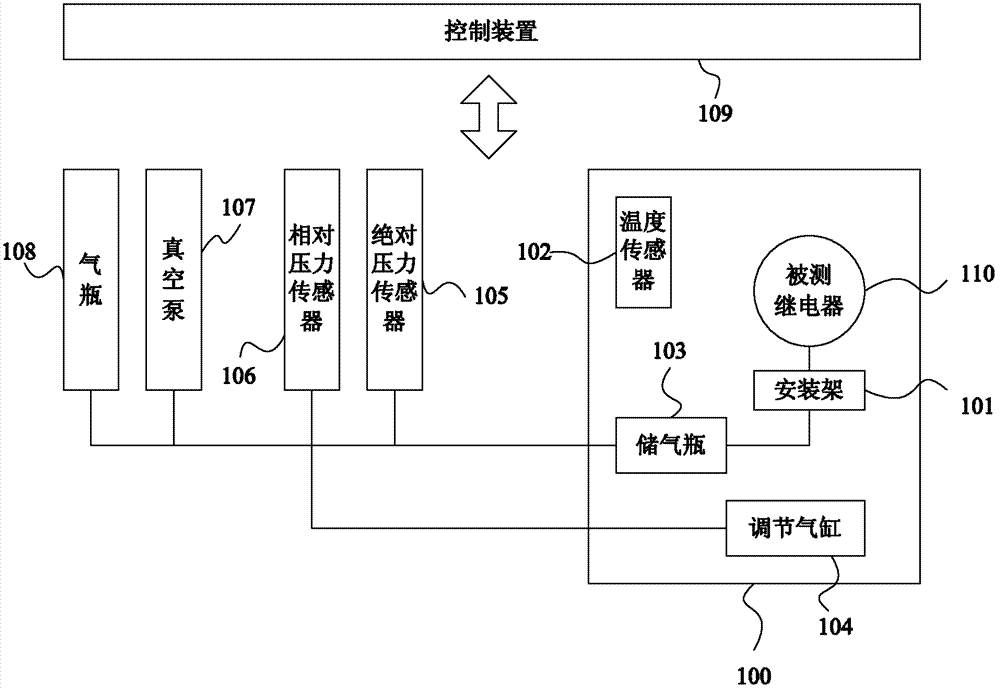

[0022] Such as figure 1 As shown, the SF of this example 6 The gas density relay calibration device includes: a high and low temperature constant temperature box 100, which is used to provide a high temperature constant temperature or a low temperature constant temperature to the test environment in the box; SF 6 Gas density relay; temperature sensor 102, installed in the high and low temperature thermostat 100, used to detect the temperature data of the test environment in the cabinet; regulating cylinder 104, arranged in the high and low temperature thermostat 100, through the gas pipeline and the relay mounting frame to be tested 101 phase connection for regulation to SF 6 SF provided by gas relay 6 gas pressure; SF 6 The gas storage bottle 103 is arranged in the high and low temperature thermostat 100, and is connected with the measured relay installation frame 101 through the gas pipeline, and is used for storing SF 6 Gas; the absolute pressure sensor 105 is connecte...

Embodiment 2

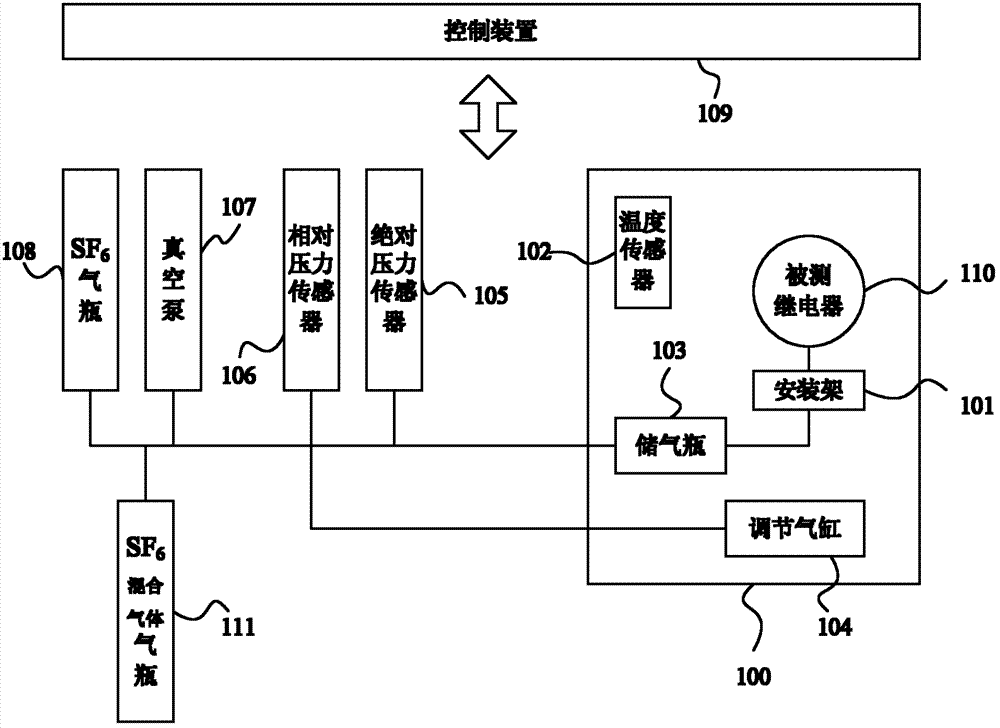

[0040] Such as image 3 As shown, the SF of this example 6 The mixed gas density relay calibration device includes: a high and low temperature constant temperature box 100, which is used to provide a high temperature constant temperature or a low temperature constant temperature to the test environment in the box; a measured relay mounting frame 101, which is set in the high and low temperature constant temperature box SF 6 Mixed gas density relay; temperature sensor 102, installed in the high and low temperature thermostat 100, used to detect the temperature data of the test environment in the cabinet; regulating cylinder 104, arranged in the high and low temperature thermostat 100, installed with the relay under test through the gas pipeline frame, used to adjust the pressure of the SF6 mixed gas provided to the SF6 mixed gas relay; the SF6 mixed gas gas cylinder 103 is arranged in the high and low temperature thermostat 100, and is connected with the measured relay mountin...

Embodiment 3

[0060] Such as image 3 As shown, the SF of this example 6 and SF 6 The mixed gas density relay calibration device includes: a high and low temperature constant temperature box 100, which is used to provide a high temperature constant temperature or a low temperature constant temperature to the test environment in the box; a measured relay mounting frame 101, which is set in the high and low temperature constant temperature box SF 6 Gas Density Relay or SF 6 Mixed gas density relay; temperature sensor 102, installed in the high and low temperature thermostat 100, used to detect the temperature data of the test environment in the cabinet; regulating cylinder 104, arranged in the high and low temperature thermostat 100, installed with the relay under test through the gas pipeline frame 101 for adjusting the SF provided to the relay under test 110 6 gas or SF 6 Pressure of mixed gas; SF 6 and SF 6 The mixed gas storage bottle 103 is arranged in the high and low temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com