Granulation-free ecological plate high-pressure decorative surface material and manufacturing method thereof

A manufacturing method and ecological board technology, applied in the field of building decoration materials, can solve problems such as the impact on the health of operators, serious secondary pollution, and increased energy consumption, and achieve benefits to health, protection of health, and transverse tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

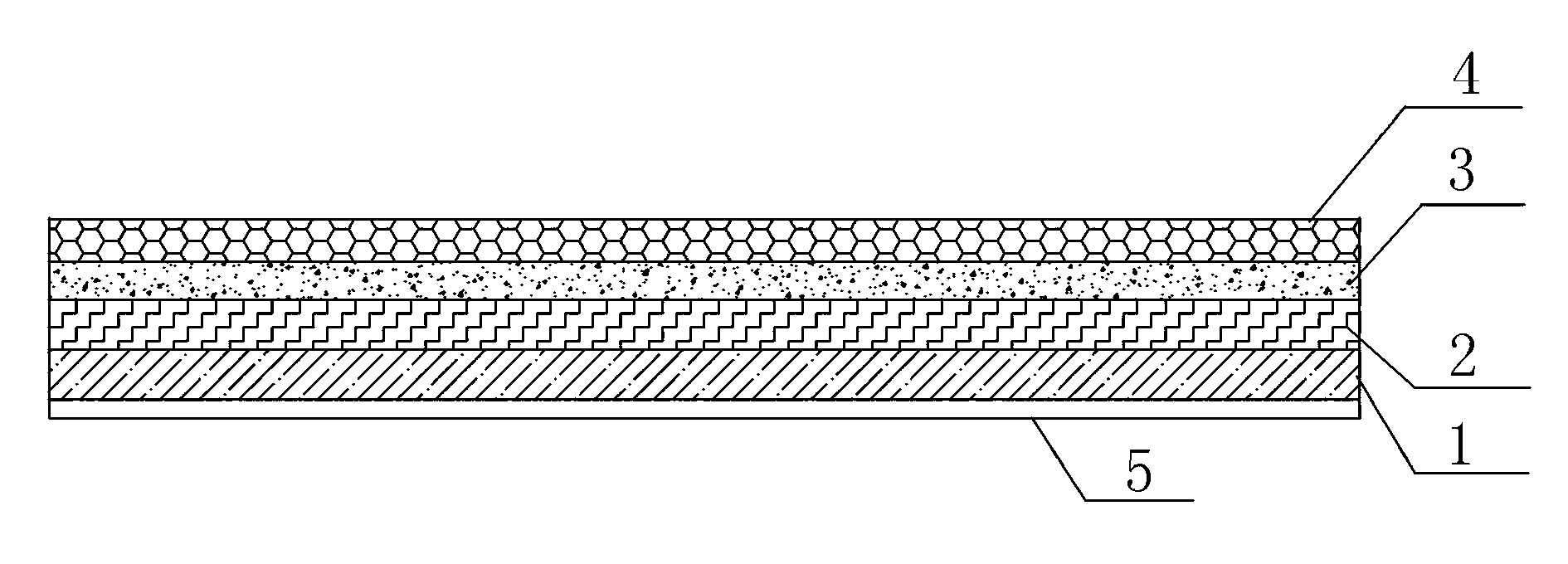

[0073] In this embodiment, the high-pressure decorative surface material of the sand-free ecological board is the bottom paper layer from bottom to top 1 , core paper layer 2 , decorative paper layer 3 and surface paper 4 , the bottom paper layer 1 Back to the core paper layer 2 One side is also coated with a release agent coating 5 .

[0074] In this embodiment, the production method of the high-pressure decorative surface material of the sand-free ecological board, the detailed steps of the production method are as follows:

[0075] a. Preparation of special release agent: mix 40Kg siloxane compound release agent with 960Kg deionized water, add 2Kg dispersant to the stirring tank, stir slowly for 45 minutes, put it in a stainless steel storage tank and let it stand for 7 hours to obtain special release agent;

[0076] b. Preparation of impregnated core paper: Kraft paper with a weight of 120g / ㎡ and a width of 1250mm is impregnated with melamine-modified urea-formaldeh...

Embodiment 2

[0087] In this embodiment, the high-pressure decorative surface material of the sand-free ecological board is the bottom paper layer from bottom to top 1 , core paper layer 2 , decorative paper layer 3 and surface paper 4 , the bottom paper layer 1 Back to the core paper layer 2 One side is also coated with a release agent coating 5 .

[0088] In this embodiment, the production method of the high-pressure decorative surface material of the sand-free ecological board, the detailed steps of the production method are as follows:

[0089] a. Preparation of special release agent: Mix 50Kg silicone compound release agent with 1000Kg deionized water, add 4Kg dispersant Tween 80 to the stirring tank, stir slowly for 60 minutes, put it in a stainless steel storage tank and let it stand for 8 hours , get a special release agent;

[0090] b. Preparation of impregnated core paper: Kraft paper with a weight of 140g / ㎡ and a width of 1330mm is impregnated with melamine-modified urea-f...

Embodiment 3

[0100] In this embodiment, the high-pressure decorative surface material of the sand-free ecological board is the bottom paper layer from bottom to top 1 , core paper layer 2 , decorative paper layer 3 and surface paper 4 , the bottom paper layer 1 Back to the core paper layer 2 One side is also coated with a release agent coating 5 .

[0101] In this embodiment, the production method of the high-pressure decorative surface material of the sand-free ecological board, the detailed steps of the production method are as follows:

[0102] a, the preparation of release agent: 30Kg siloxane compound release agent mixes with 900Kg deionized water and adds 2Kg dispersant Tween 80 in the stirring tank, slowly stirs for 30 minutes and puts it into a stainless steel storage tank to stand for 6 hours, Get a special release agent;

[0103] b. Preparation of impregnated core paper: kraft paper with a weight of 120g / ㎡ and a width of 1250mm is impregnated into phenolic resin after impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Formaldehyde emission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com