Cable heating aluminum-wood floor heating system and paving method thereof

A technology for floor heating and aluminum wood, which is applied to the cable heating aluminum wood floor heating system and its paving field, can solve the problems of reducing the heat dissipation performance of the circulating water pipe, the poor heat conduction capacity of the solid wood layer, and the trivial and complicated installation process, and achieves safety and reliability. Durable, avoid serious waste, small cutting allowance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

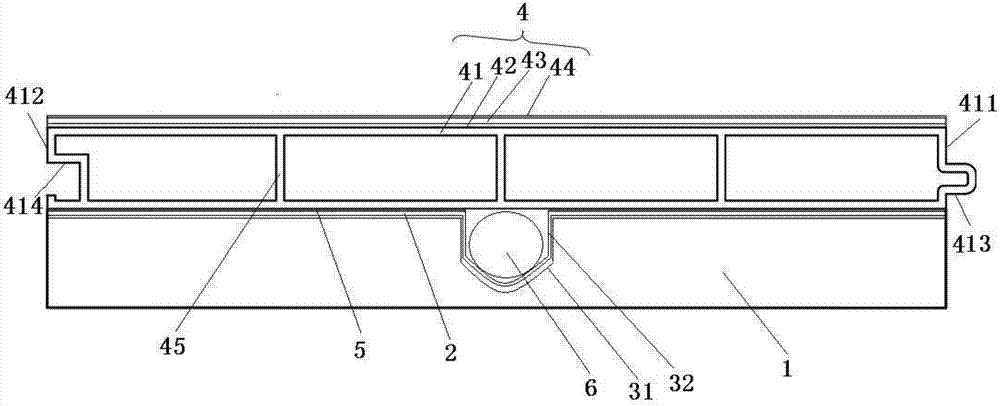

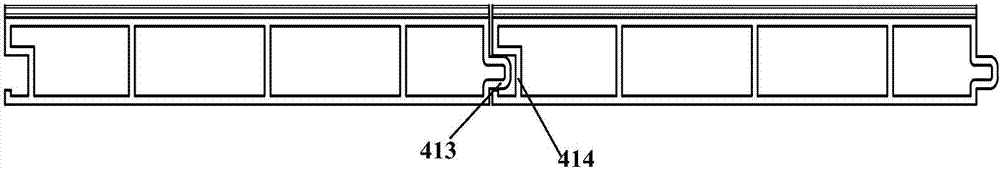

[0044] Please refer to the attached Figure 1-4 , the invention discloses a cable heating aluminum-wood floor heating system, comprising: a thermal insulation board 1, a reflective film 2, a heating cable 6 and an aluminum-wood composite floor 4; A heat insulation board groove 31 with a linear or arc-shaped track is provided, and a reflective film groove 32 with a linear or arc-shaped track is arranged on the reflective film 2, and the heat preservation plate groove 31 matches the reflective film groove 32 ; The heating cable 6 is located in the reflective film groove 32; the aluminum-wood composite floor 4 is laid on the top of the reflective film 2;

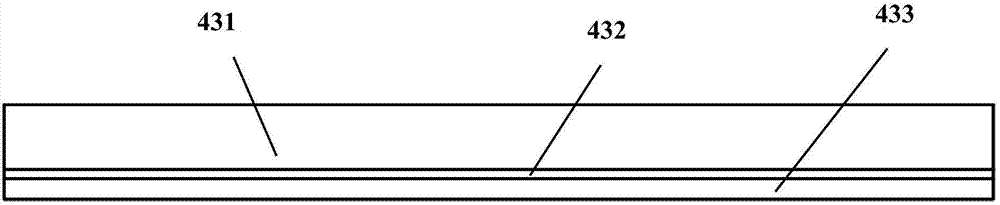

[0045] The aluminum-wood composite floor 4 includes an aluminum alloy substrate 41, a PUR adhesive layer 42 and a solid wood board 43. The PUR adhesive layer 42 and the solid wood board 43 are sequentially laid on the top of the aluminum alloy substrate 41, and the solid wood board 43 and the aluminum alloy substrate 41 pass th...

Embodiment 2

[0058] Please refer to the attached Figure 1-4 , the invention discloses a cable-heated aluminum-wood floor heating system, comprising: a thermal insulation board 1, a reflective film 2, a waterproof film 5, a heating cable 6, and an aluminum-wood composite floor 4; wherein, the reflective film 2 is laid on the thermal insulation board 1, The insulation board 1 is provided with a linear or arc-shaped insulation board groove 31, and the reflection film 2 is provided with a linear or arc-shaped reflection film groove 32, and the insulation board groove 31 is connected with the reflection film groove. The grooves 32 are matched and matched; the heating cable 6 is located in the groove 32 of the reflective film; the waterproof film 5 is laid on the top of the reflective film 2, and the setting of the waterproof film 5 not only prevents the moisture in the ground from causing harm to the floor, but also can keep enough water in the ground. moisture to ensure the heat conduction ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com