Quick liquid film forming agent capable of preventing pine wilt disease spreading

A film-forming agent and liquid technology, applied in the field of pine wood nematode disease control, can solve the problems of heavy bagging and other problems, and achieve the effects of preventing the spread of pine wood nematode disease, good lethal effect, and difficult toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

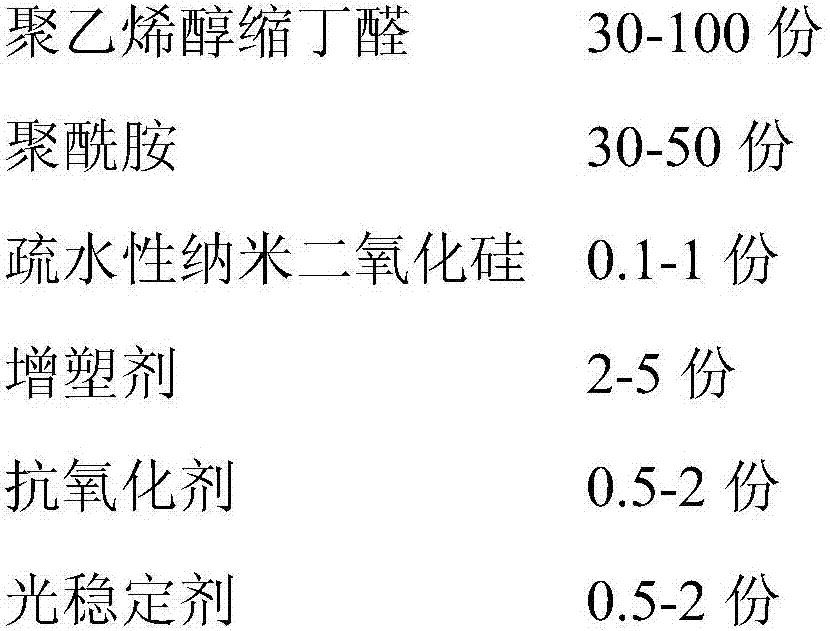

[0030] The preparation of embodiment 1 liquid film-forming agent

[0031] The first step of solvent preparation: n-butanol and ethyl acetate are mixed at a volume ratio of 1:1 to prepare a solvent.

[0032] In the second step, take 30 parts of polyvinyl butyral and 30 parts of polyamide, and mix them evenly.

[0033] The third step is to take the prepared solvent, put it in a closed container, slowly add the above mixture under stirring, and vibrate on a shaker after sealing until it is completely dissolved. After it is completely dissolved, add 2 parts of dioctyl phthalate, 0.5 part of BHT, 0.1 part of hydrophobic nano-silica, 0.5 part of light stabilizer 770, and 1 part of alcohol-soluble nigrosine into the solution, stir to dissolve, and add to prepare The solvent makes the total amount 1000ml.

[0034] The fourth step is to quantitatively seal the solution and pack it according to the requirements.

Embodiment 2

[0035] The preparation of embodiment 2 liquid film-forming agent

[0036] The first step of solvent preparation: n-butanol and ethyl acetate are mixed at a volume ratio of 1:1 to prepare a solvent.

[0037]The second step is to take 100 parts of polyvinyl butyral and 40 parts of polyamide, and mix them evenly.

[0038] The third step is to take the prepared solvent, put it in a closed container, slowly add the above mixture under stirring, and vibrate on a shaker after sealing until it is completely dissolved. After it is completely dissolved, add 5 parts of dioctyl phthalate, 1 part of BHT, 0.5 parts of hydrophobic nano-silica, 1 part of light stabilizer 770, and 1 part of alcohol-soluble nigrosine into the solution, stir to dissolve, and add to prepare The solvent makes the total amount 1000ml.

[0039] The fourth step is to quantitatively seal the solution and pack it according to the requirements.

Embodiment 3

[0040] The preparation of embodiment 3 liquid film-forming agent

[0041] The first step of solvent preparation: n-butanol and ethyl acetate are mixed at a volume ratio of 1:1 to prepare a solvent.

[0042] In the second step, take 100 parts of polyvinyl butyral and 50 parts of polyamide, and mix them evenly.

[0043] The third step is to take the prepared solvent, put it in a closed container, slowly add the above mixture under stirring, and vibrate on a shaker after sealing until it is completely dissolved. After being completely dissolved, add 5 parts of dioctyl phthalate, 2 parts of butylated hydroxyanisole, 0.5 parts of hydrophobic nano silicon dioxide, 2 parts of light stabilizer 770, 10 parts of alcohol-soluble nigrosine into the solution, and stir Dissolve, add the prepared solvent to make the total amount 1000ml.

[0044] The fourth step is to quantitatively seal the solution and pack it according to the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com