Matte release agent for release materials

一种离型材料、离型剂的技术,应用在纸涂料、没有颜料涂层、纤维原料处理等方向,能够解决破坏贴膜纯净、一致性、静电过大、火灾等问题,达到提高防静电效果、提高耐刮性能、提高防静电性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

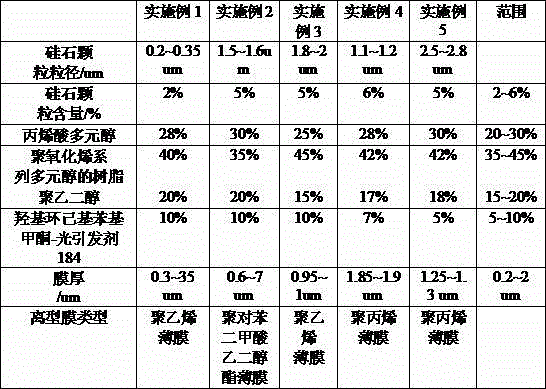

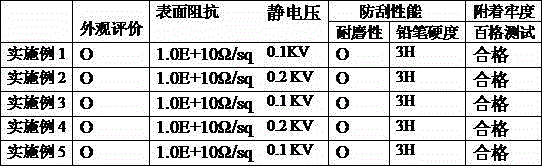

[0022] Examples 1 to 5: A matte release agent for release materials. The matte release agent 1 is located between the release film 2 and the release agent layer 3. The matte release agent has the following quality Percentage component composition:

[0023] Silica particles 2~6%,

[0024] 20-30% acrylic polyol with an average molecular weight of 500-2000,

[0025] Resin of polyoxyalkylene series polyol with an average molecular weight of 200-2500, 35-45%,

[0026] Polyethylene glycol 15~20%,

[0027] 1-hydroxycyclohexyl phenyl ketone-photoinitiator 184 5~10%;

[0028] The particle size of the silica particles is a particle size distribution measured by a laser diffraction and scattering method. The particle size has a peak in the range of 0.1-2um and 1.5-5um, and the average particle diameter is 4um or less.

[0029] The aforementioned release agent layer 2 is silicone oil.

[0030] The aforementioned release film 2 is a polyethylene terephthalate film, a polypropylene film, a polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com