Manufacturing method and system of radio frequency self-adhesive label

A manufacturing method and label technology, applied in semiconductor/solid-state device manufacturing, record carriers used by machines, instruments, etc., can solve the problems of complex radio frequency self-adhesive label manufacturing process, poor adaptability to durable environment, and high manufacturing cost. Achieve the effects of reducing the number of rewinding and unwinding, low dependence, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the present invention will be described in detail with reference to the drawings.

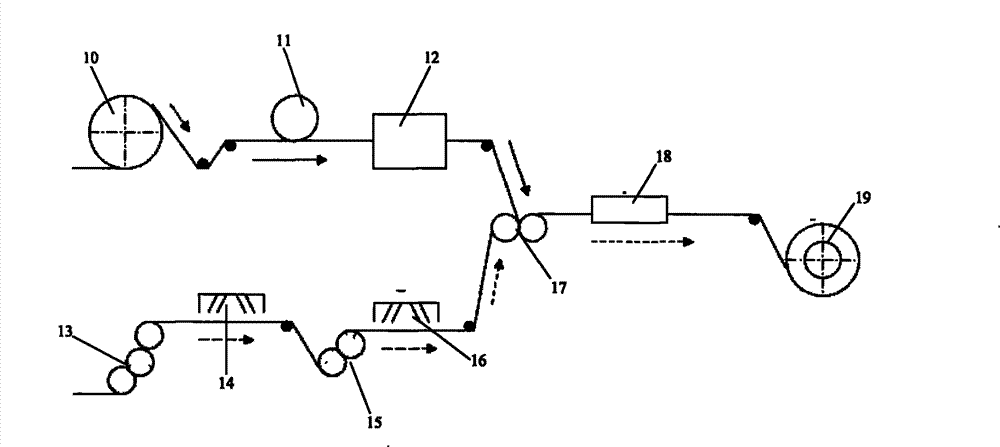

[0050] See figure 2 , Which is a schematic structural diagram of the radio frequency adhesive label manufacturing system of the present invention. The system includes a printer 10, a chip mounting device 11, a testing device 12, a silicone oil coating head 13, a UV curing lamp with a nitrogen protection device 14, and a hot melt Glue coating head 15, UV lamp 16, composite equipment 17, die cutting equipment 18 and winding equipment 19, printing machine 10, chip mounting equipment 11, testing equipment 12, composite equipment 17, die cutting equipment 18 and winding equipment 19 The silicone oil coating head 13, the ultraviolet curing lamp 14 with nitrogen protection device, the hot melt adhesive coating head 15 and the ultraviolet lamp 16 are connected in sequence, and the ultraviolet lamp 16 is connected to the composite equipment 17.

[0051] In this example, the printing mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com