Patents

Literature

37results about How to "High localization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

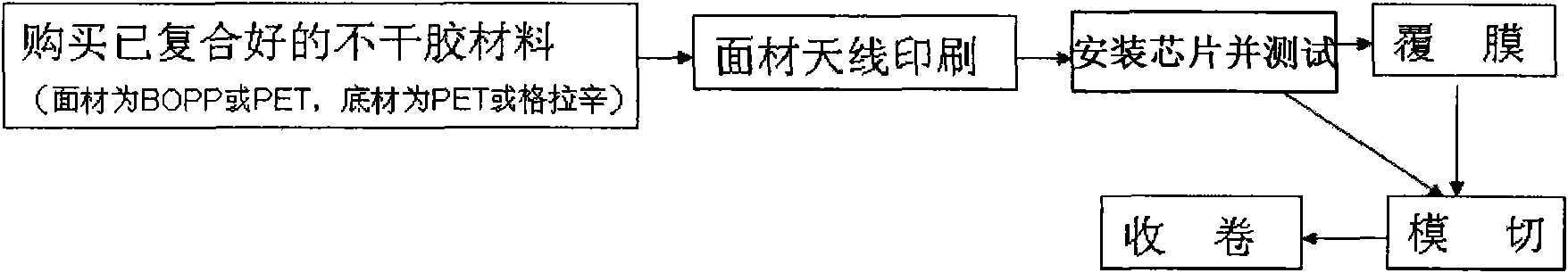

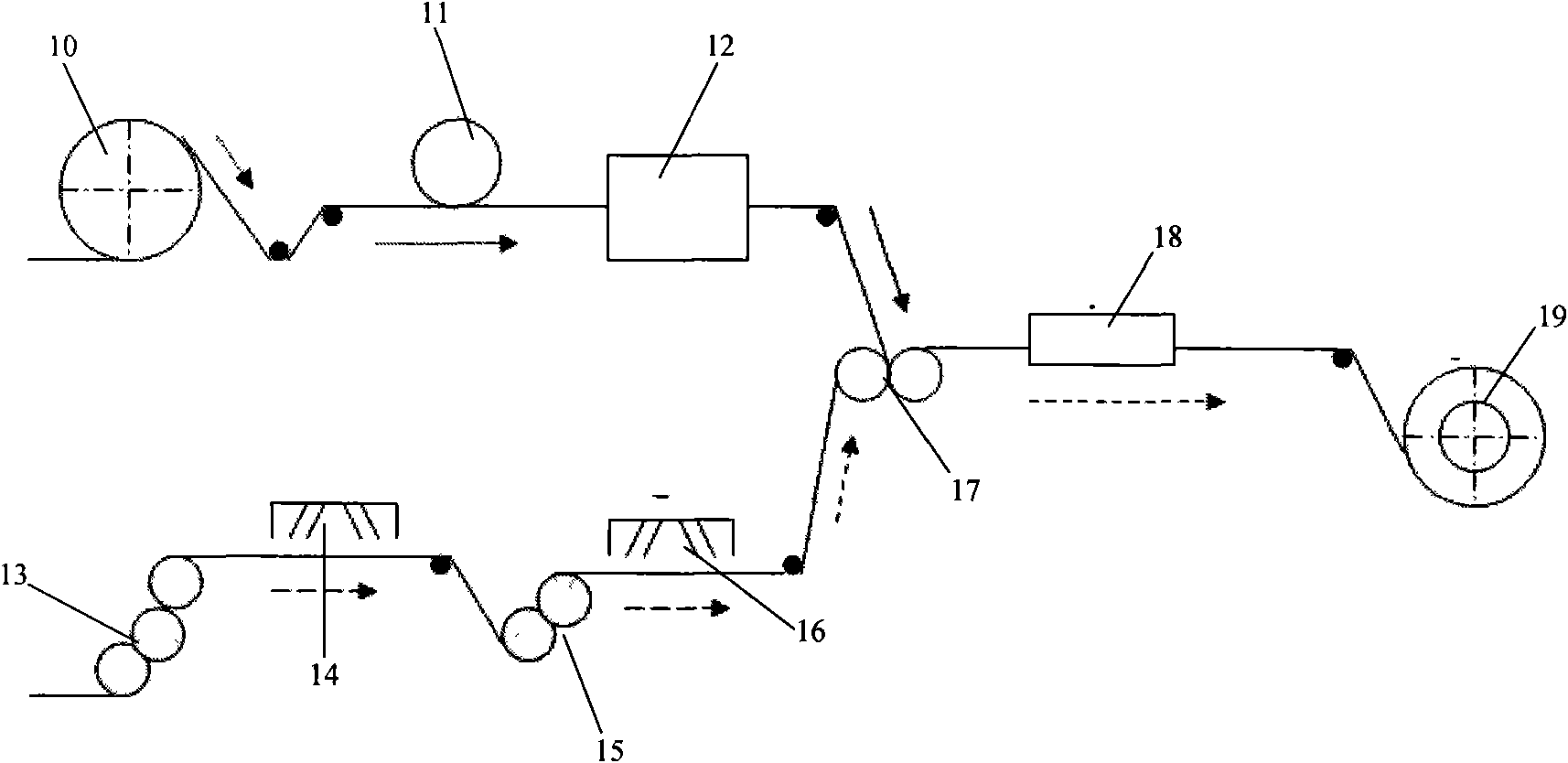

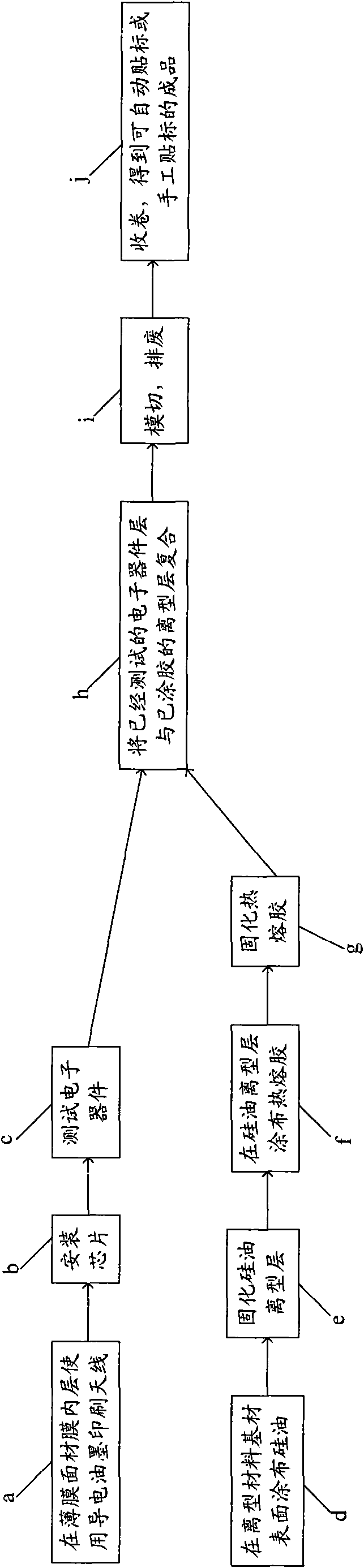

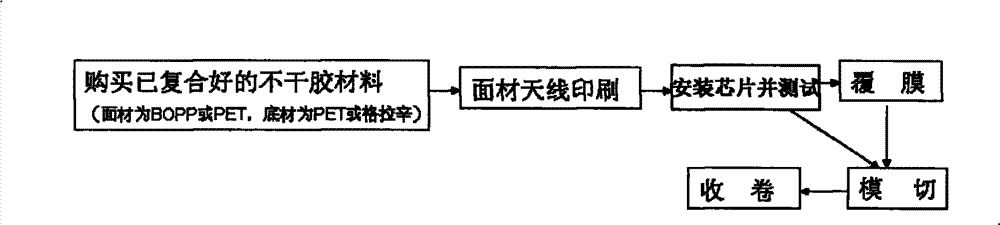

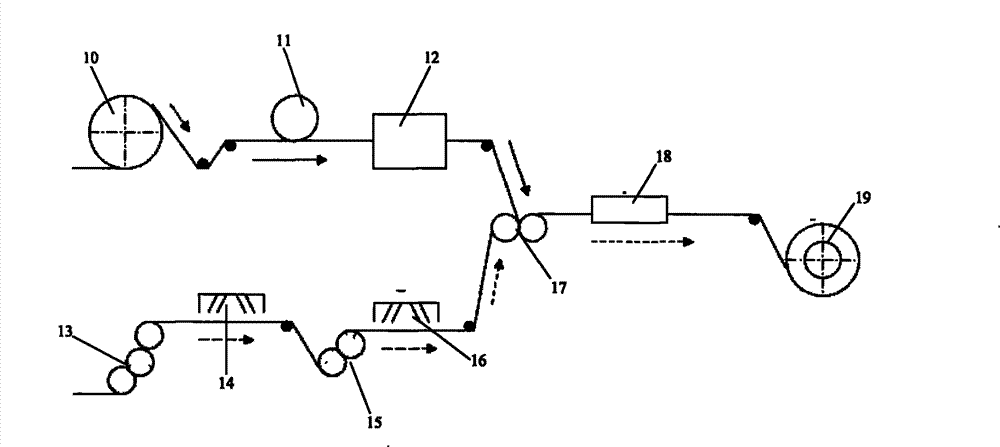

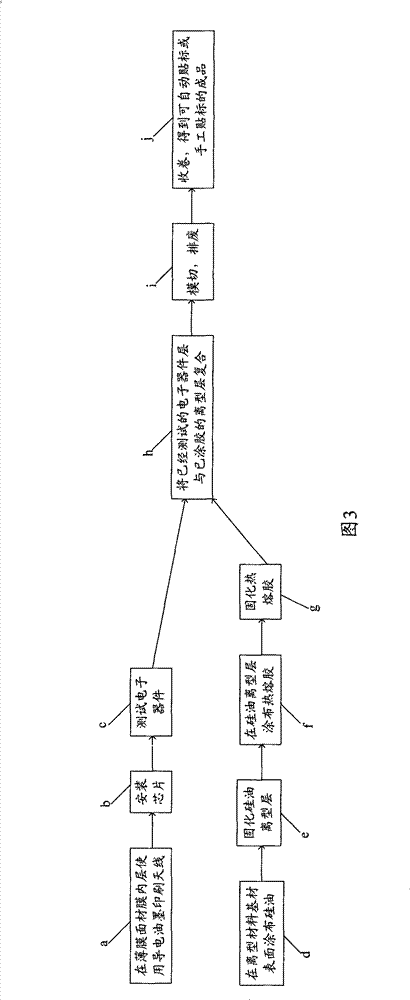

Manufacturing method and system of radio frequency self-adhesive label

ActiveCN101877072AAvoid scratchesPrevent oxidationSemiconductor/solid-state device manufacturingRecord carriers used with machinesEngineeringSilicone oil

The invention relates to a manufacturing method and a system of a radio frequency self-adhesive label, and the manufacturing method of the radio frequency self-adhesive label comprises the following steps: a) using conductive ink to print an antenna on an inner layer of a surface material film of a thin film; b) mounting a chip; c) testing an electronic device; d) coating silicone oil on the surface of a release material substrate; e) curing a silicone oil release layer; f) coating hot melt adhesive on the silicone oil release layer; g) curing the hot melt adhesive; h) compounding the tested electronic device layer with the release layer coated with the adhesive; i) carrying out die cutting and waste discharge; and j) taking up and obtaining a finished product which can be stuck automatically or manually. The manufacturing method of the radio frequency self-adhesive label can meet the technical requirements of the market on the radio frequency self-adhesive label, has significant advantages in the aspects of manufacturing efficiency, product yield, durability and economy, and can solve the shortcomings of the existing process, and the popularization of the manufacturing method of the radio frequency self-adhesive label is conductive to the wide applications of the radio frequency technology.

Owner:浙江龙游道明光学有限公司

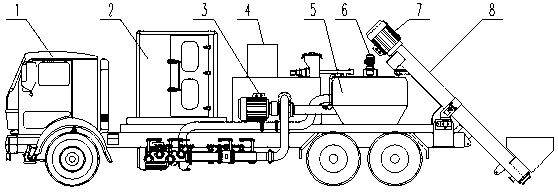

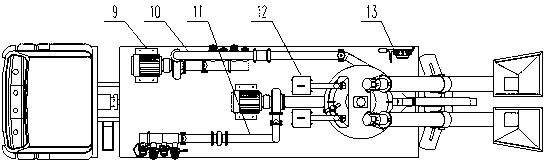

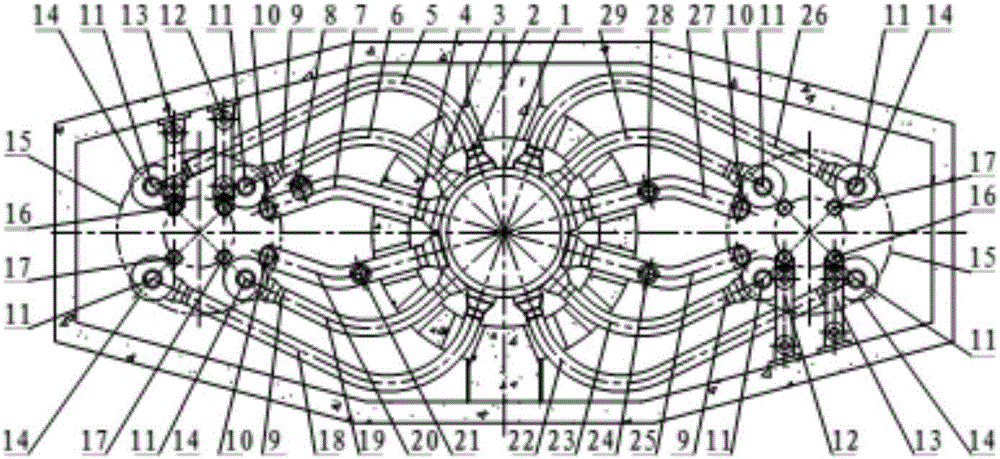

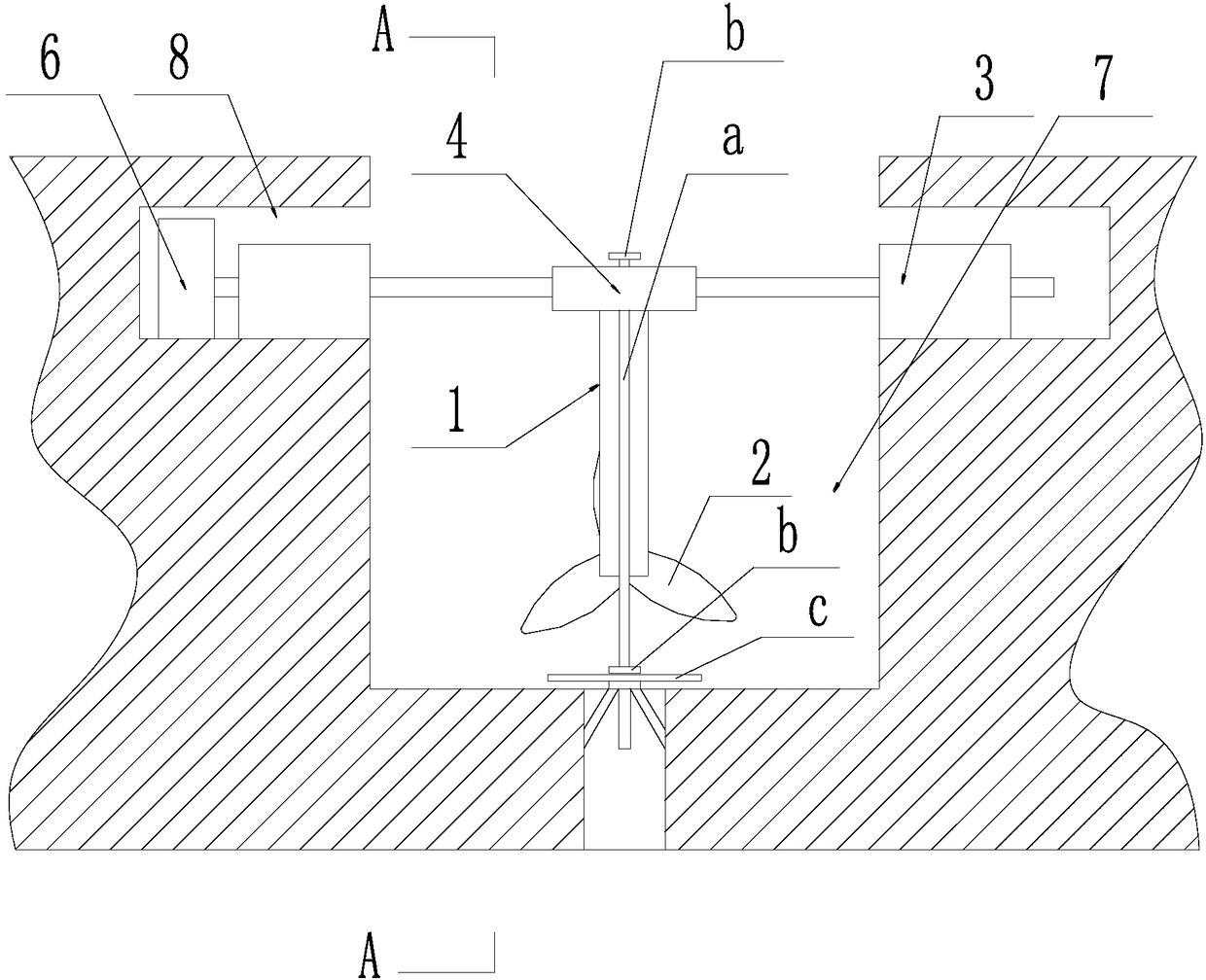

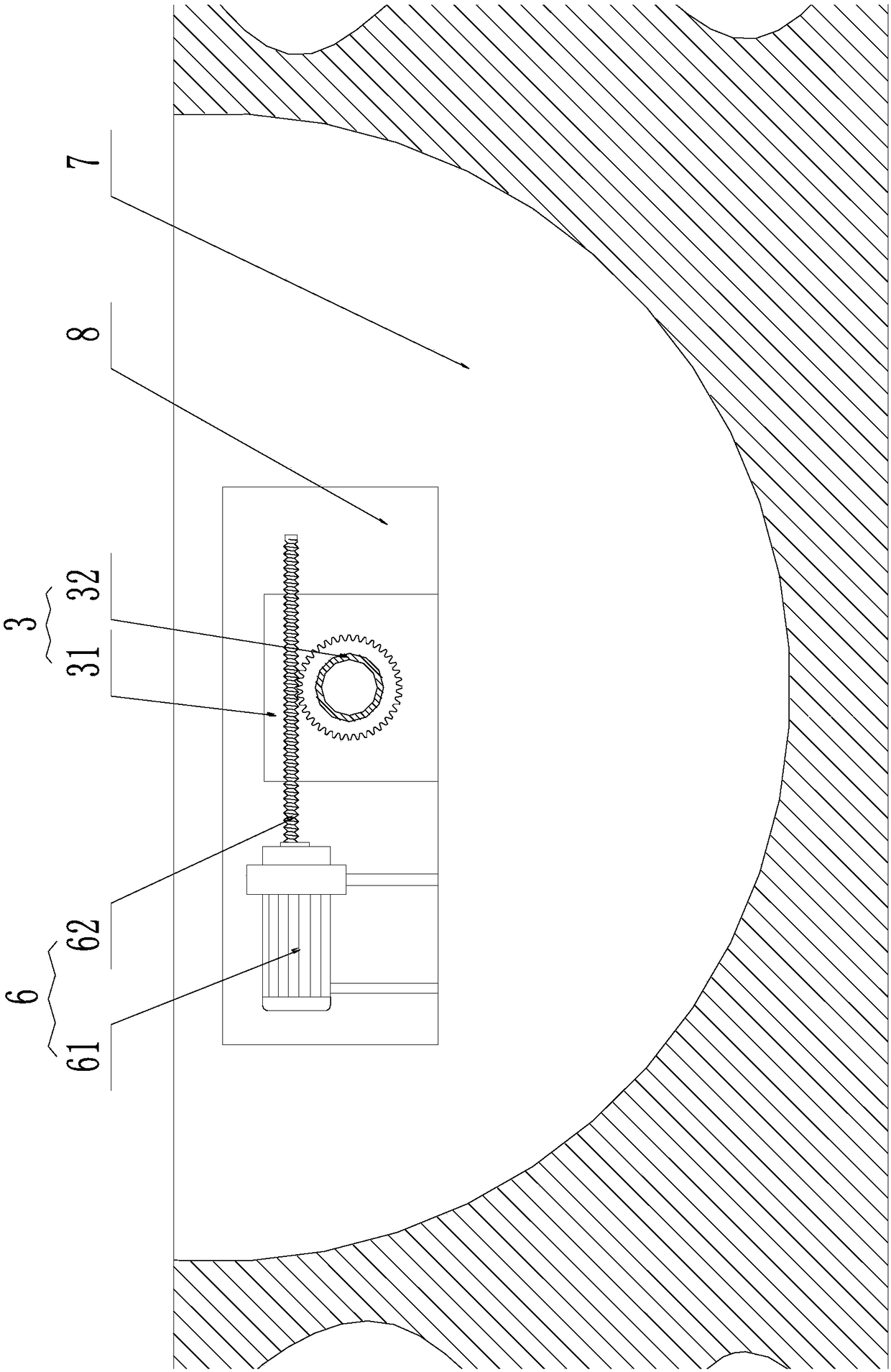

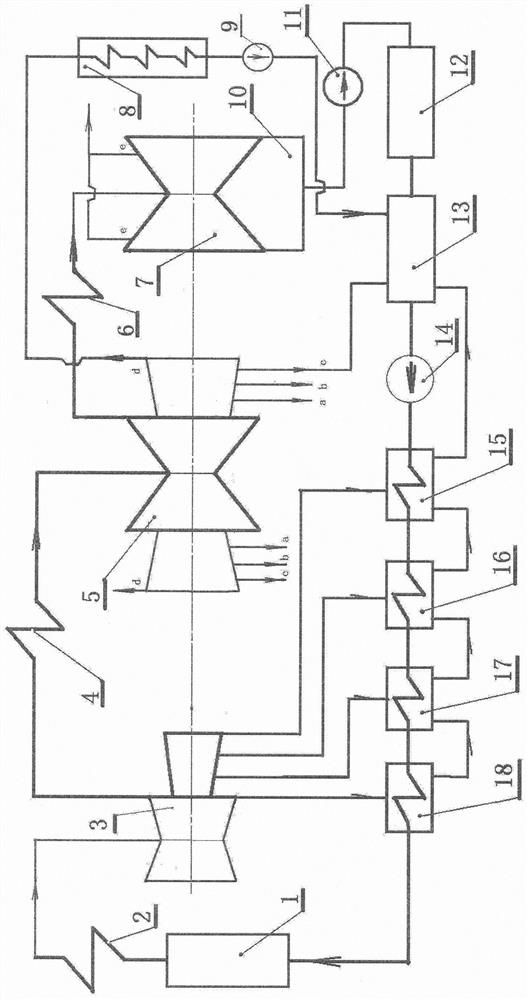

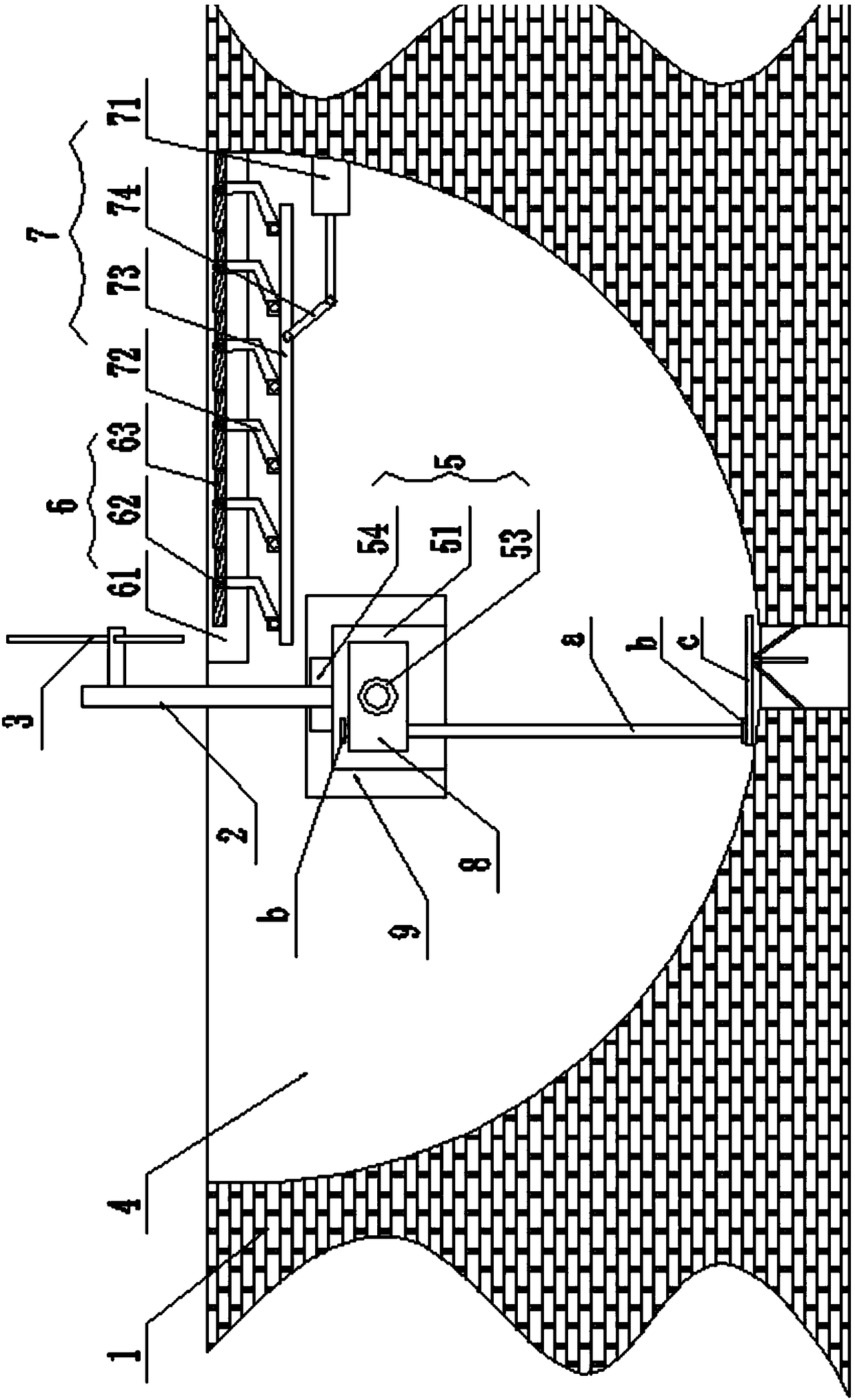

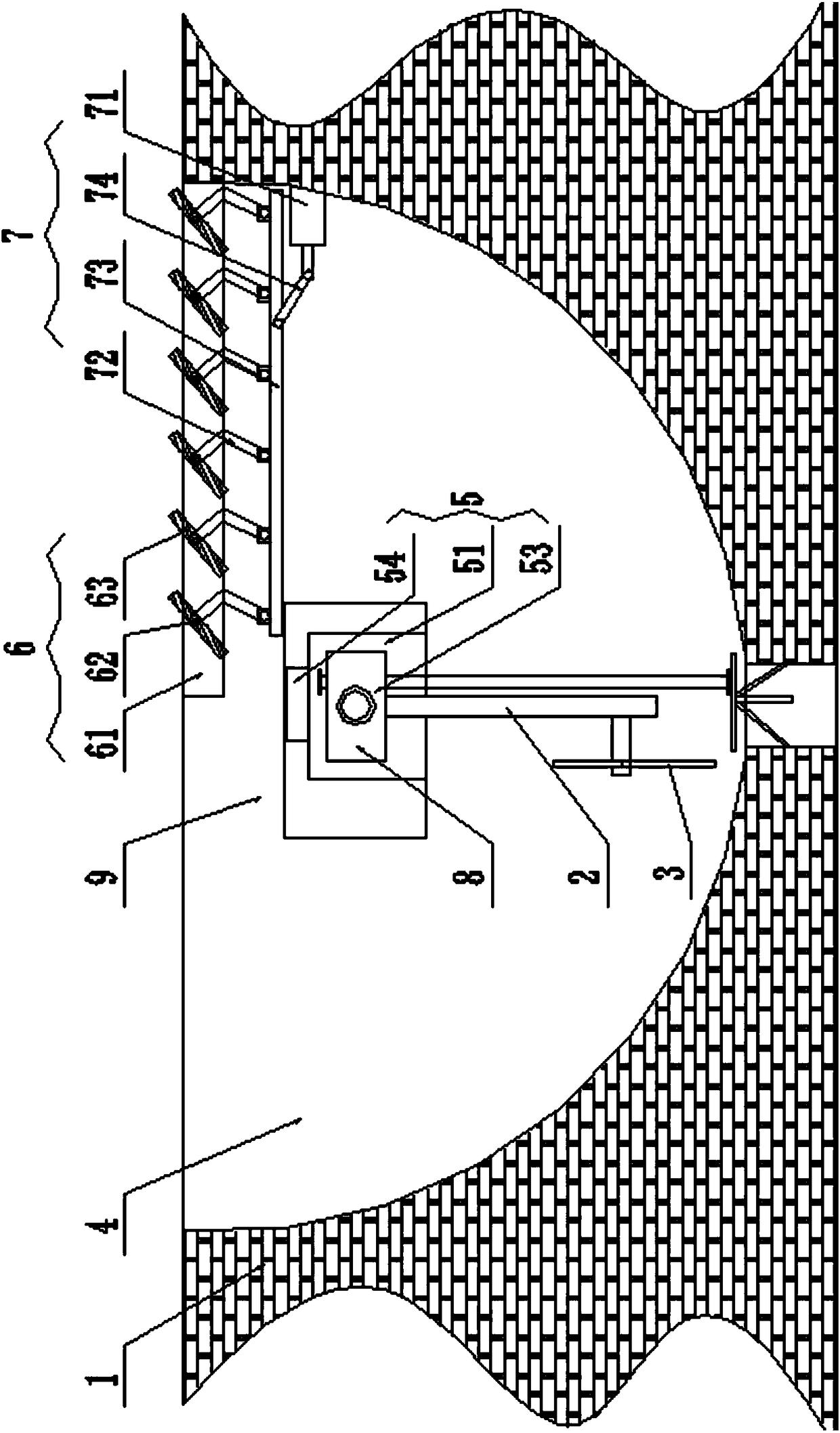

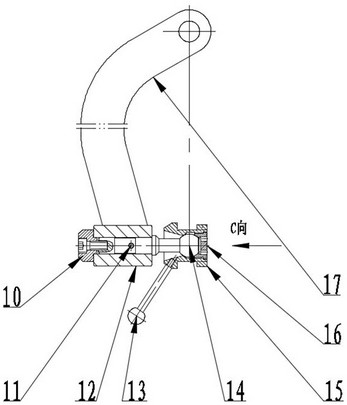

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

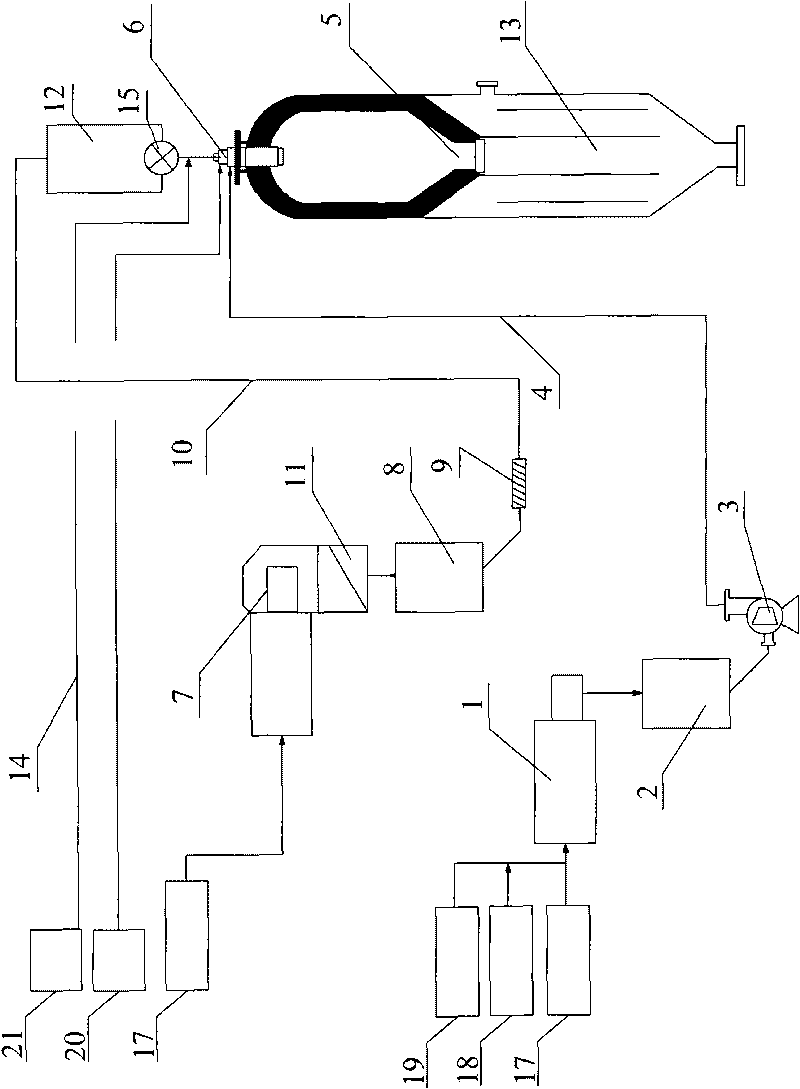

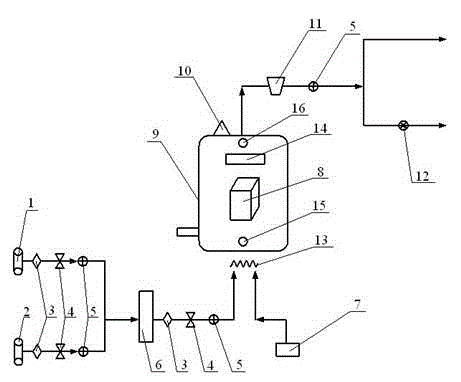

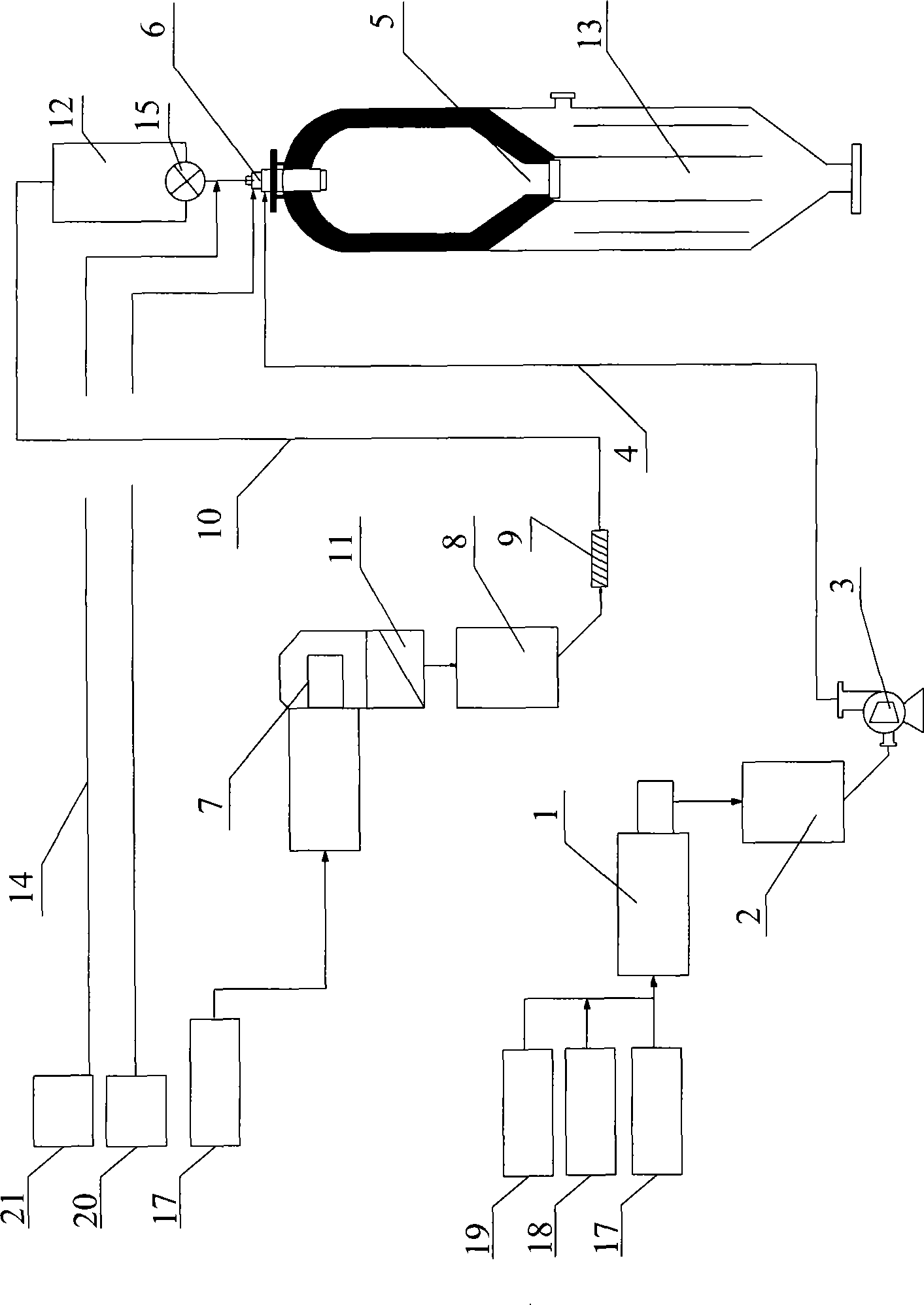

Three-phase multi-raw-material pressurized coal gasification device and process thereof

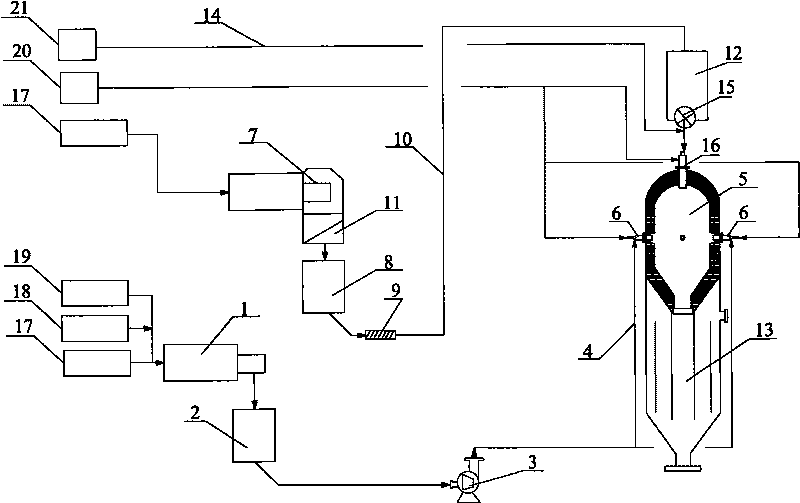

ActiveCN101760244AIncrease contentReduce contentGranular/pulverulent flues gasificationCombustion chamberEngineering

The invention discloses a three-phase multi-raw-material pressurized coal gasification device and a process thereof, which comprises a coal slurry preparing and conveying mechanism, a dry coal powder preparing and conveying mechanism and a pressurized gasification mechanism, wherein the coal slurry preparing and conveying mechanism consists of a coal mill, a coal slurry groove, a high-pressure coal slurry pump, and a high-pressure coal slurry pipeline; the dry coal powder preparing and conveying mechanism consists of a dry powder preparer, a dry powder storage groove, a screw conveyor, a coal powder pipeline and a nozzle feeding bin; and the pressurized gasification mechanism consists of a combustion chamber and a quench chamber. The high-pressure coal slurry pipeline and the nozzle feeding bin are respectively connected with a mixing nozzle which is arranged on the combustion chamber and is communicated with the interior of the combustion chamber. By the combination of multiple phases and multiple raw materials, the pressurized coal gasification device increases the content of carbon in the reactants and increases reacting efficiency and production intensity, and the contents of carbon monoxide and hydrogen in the active ingredients are increased from 80% to 84%-88%, thereby improving the comprehensive utilization ratio of the coal resource and reducing the discharge amount of carbon dioxide.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

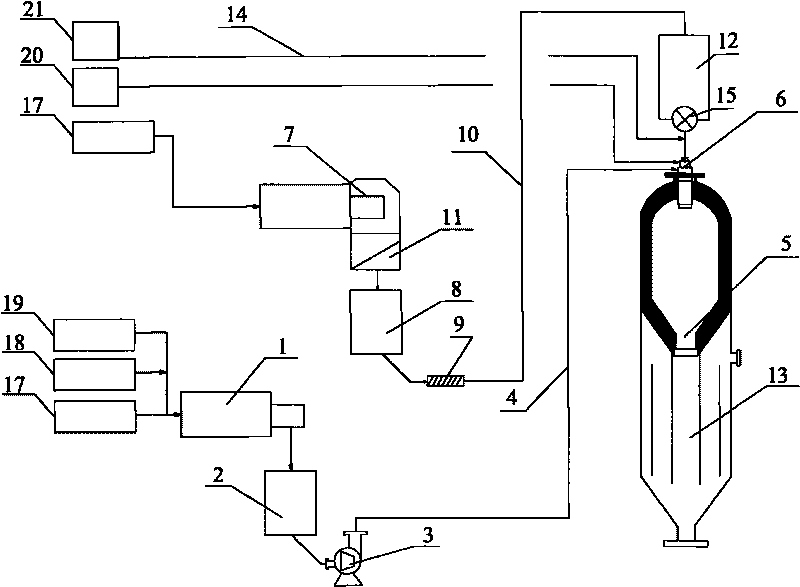

Three-phase multi-material three-dimensional pressurized clash coal gasification device and process thereof

ActiveCN101760243AReduce water contentReduce heat lossGranular/pulverulent flues gasificationMulti materialCarbon dioxide

The invention discloses a three-phase multi-material three-dimensional pressurized clash coal gasification device and a process thereof, which comprises a coal slurry preparing and conveying mechanism, a dry coal powder preparing and conveying mechanism and a pressurized gasification mechanism, wherein the coal slurry preparing and conveying mechanism consists of a coal mill, a coal slurry groove, a high-pressure coal slurry pump and a high-pressure coal slurry pipeline; the dry coal powder preparing and conveying mechanism consists of a dry powder preparer, a dry powder storage groove, a screw-rod conveyer, a coal powder pipeline and a nozzle feeding bin; and the pressurized gasification mechanism comprises a combustion chamber and a quench chamber. A water-coal slurry nozzle and a dry coal powder nozzle are arranged on the combustion chamber and are respectively communicated with the interior of the combustion chamber; and the dry coal powder nozzle and the water-coal slurry nozzle are also connected with a high-pressure gas pipeline. The dry coal powder nozzle arranged at the top reduces the damages of the returned air current mixture to the vault and the blind-head firebricks, thereby improving the utilization rate of the equipment. The injection mode of the dry powder and the carbon dioxide at the top increases the content of carbon in the reactants, and the active ingredients in the coal gas are increased to 85% above, thereby improving the utilization ratio of the coal resource and reducing the discharge amount of carbon dioxide.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

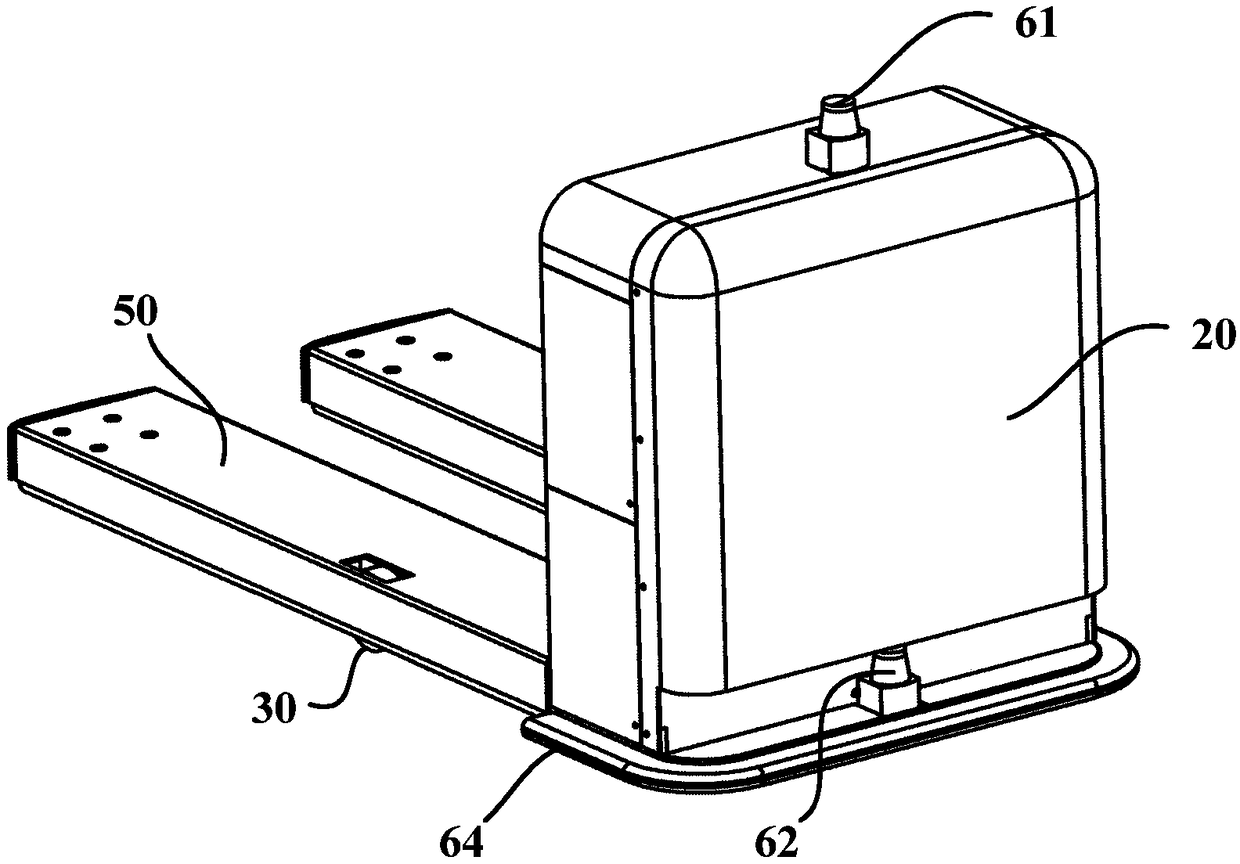

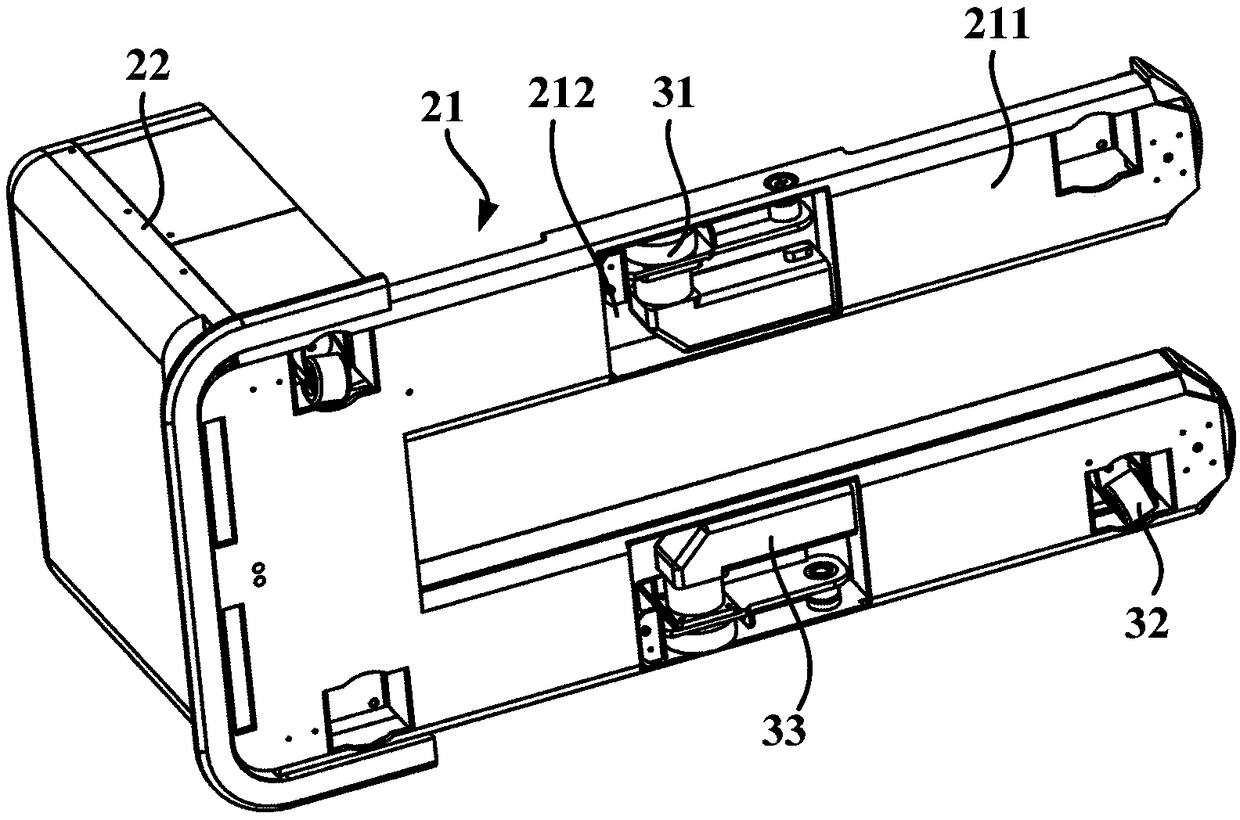

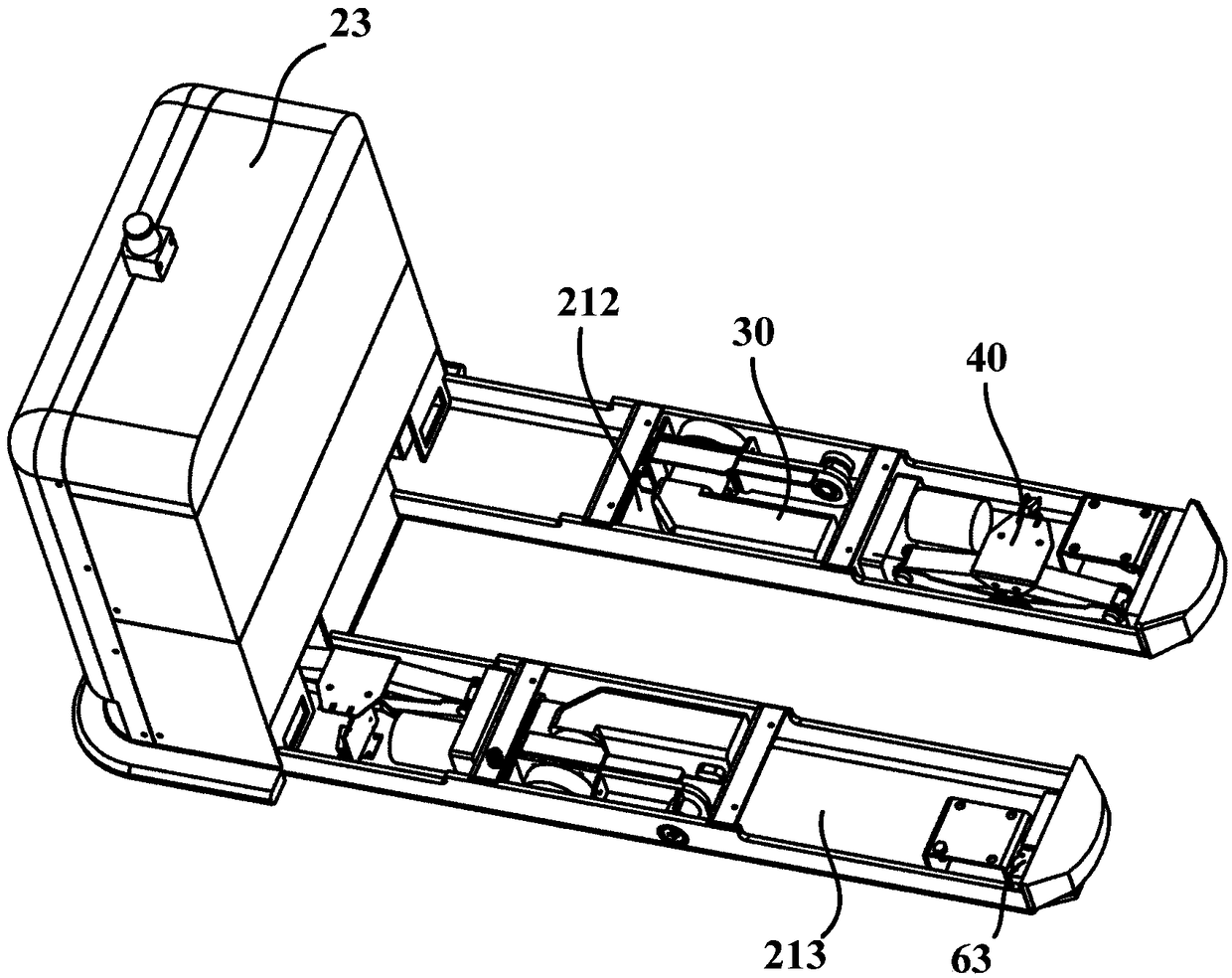

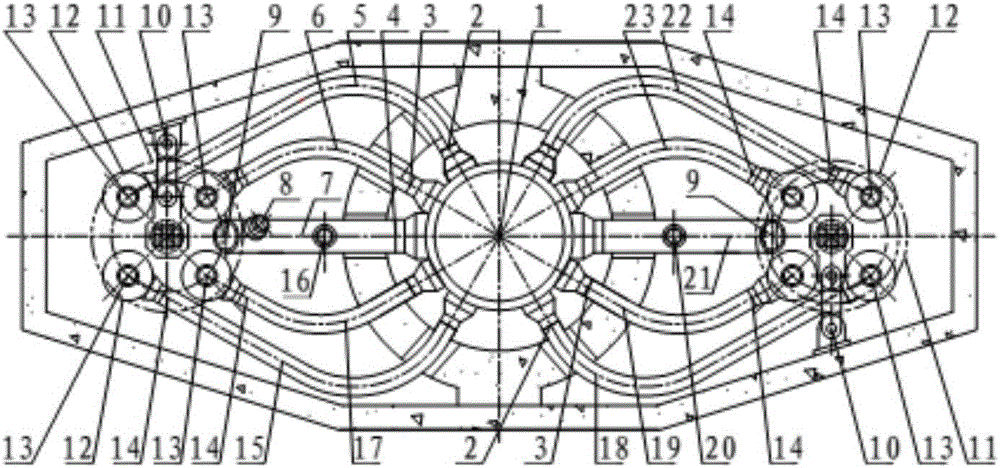

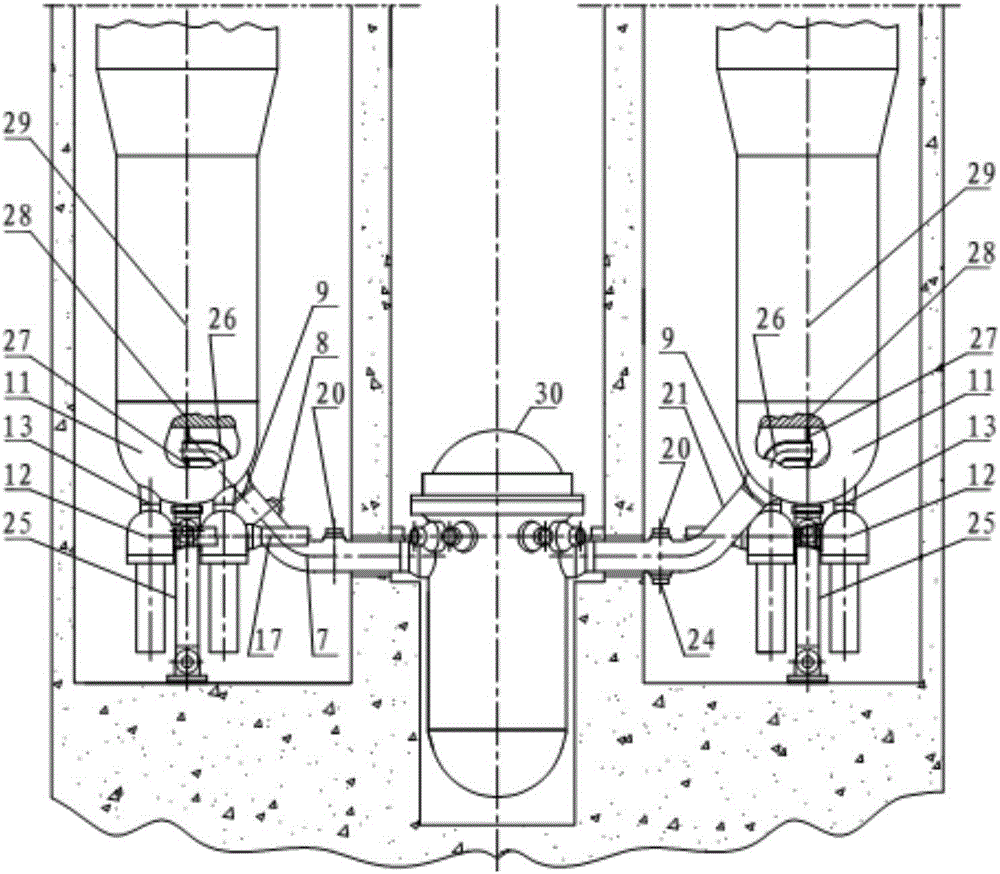

Multifunctional automatic guide transport vehicle

The invention relates to a multifunctional automatic guide transport vehicle. The multifunctional automatic guide transport vehicle comprises a vehicle body, a vehicle driving system, a multi-point jacking device, two supporting plates, a bus system and a safety guide device, wherein the vehicle body is provided with a chassis, and the chassis is provided with two fork foot base frames which are arranged in parallel; the vehicle driving system is provided with two driving wheels, a plurality of universal wheels and two first driving devices used for correspondingly driving the two driving wheels to rotate; the two driving wheels are arranged on the lower portions of the two sides of the middle of the chassis in the front-back direction correspondingly; the multi-point jacking device is provided with a plurality of lifting devices and second driving devices used for correspondingly driving the plurality of lifting devices to perform lifting motion; each supporting plate is provided withat least two lifting devices; the bus system synchronously controls the plurality of second driving devices; and the safety guide device is provided with a solid state laser radar, a laser obstacle avoidance sensor, a contact type sensor, a mechanical anti-collision strip arranged in the vehicle body, a sound-light alarm and an emergency stop button. According to the multifunctional automatic guide transport vehicle, the height of a cargo fork can be reduced to the largest extent, and turning can be realized at the minimum radius.

Owner:ZHEJIANG FIELD INTELLIGENT EQUIP CO LTD

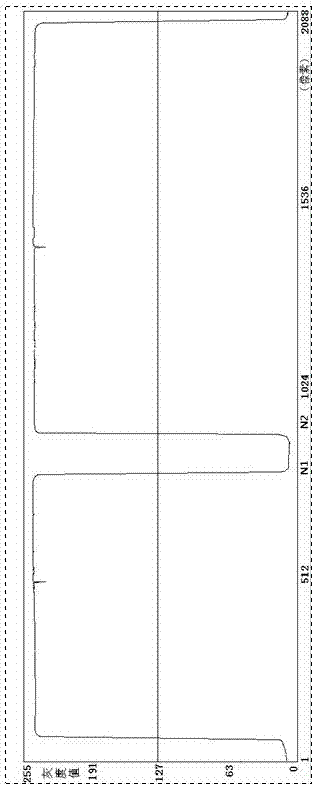

Synchronous display device and method for double-independent graphics card of Feiteng platform

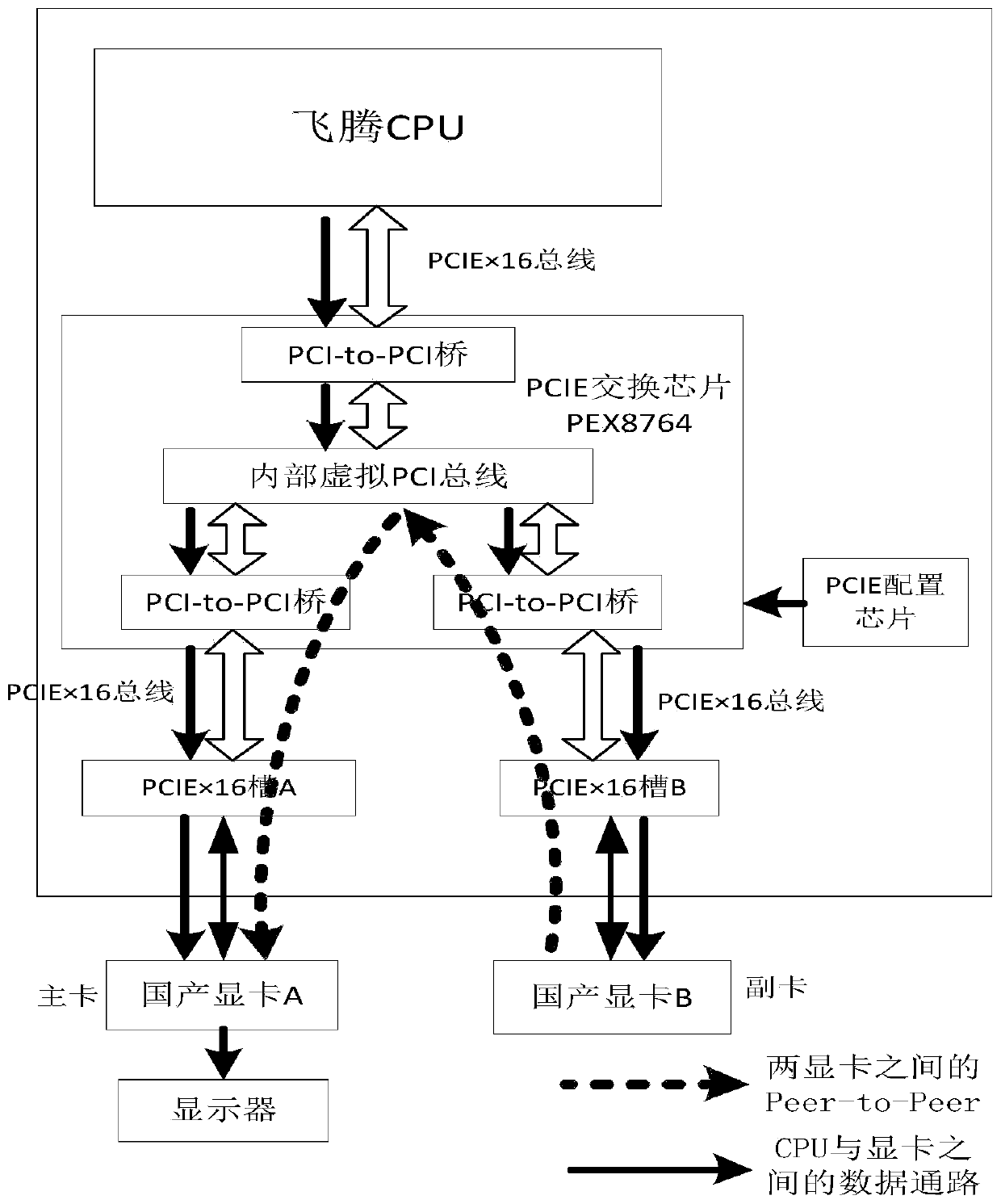

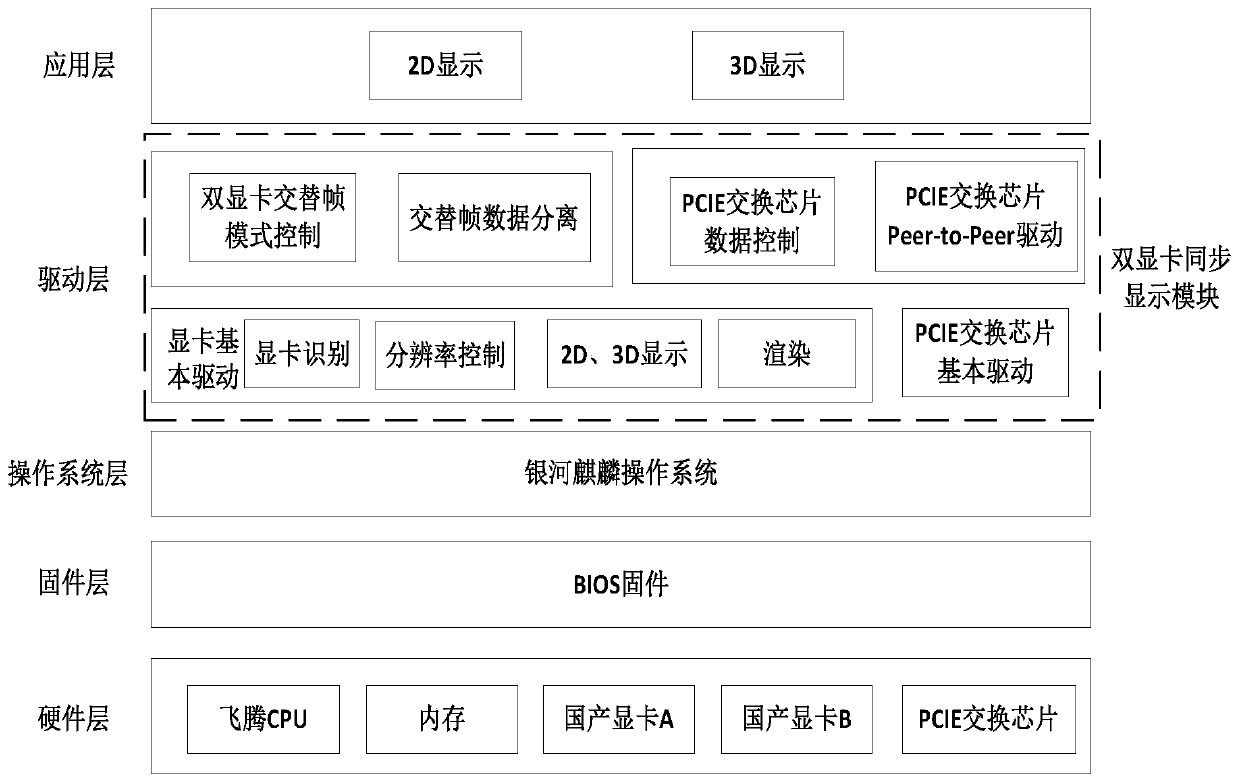

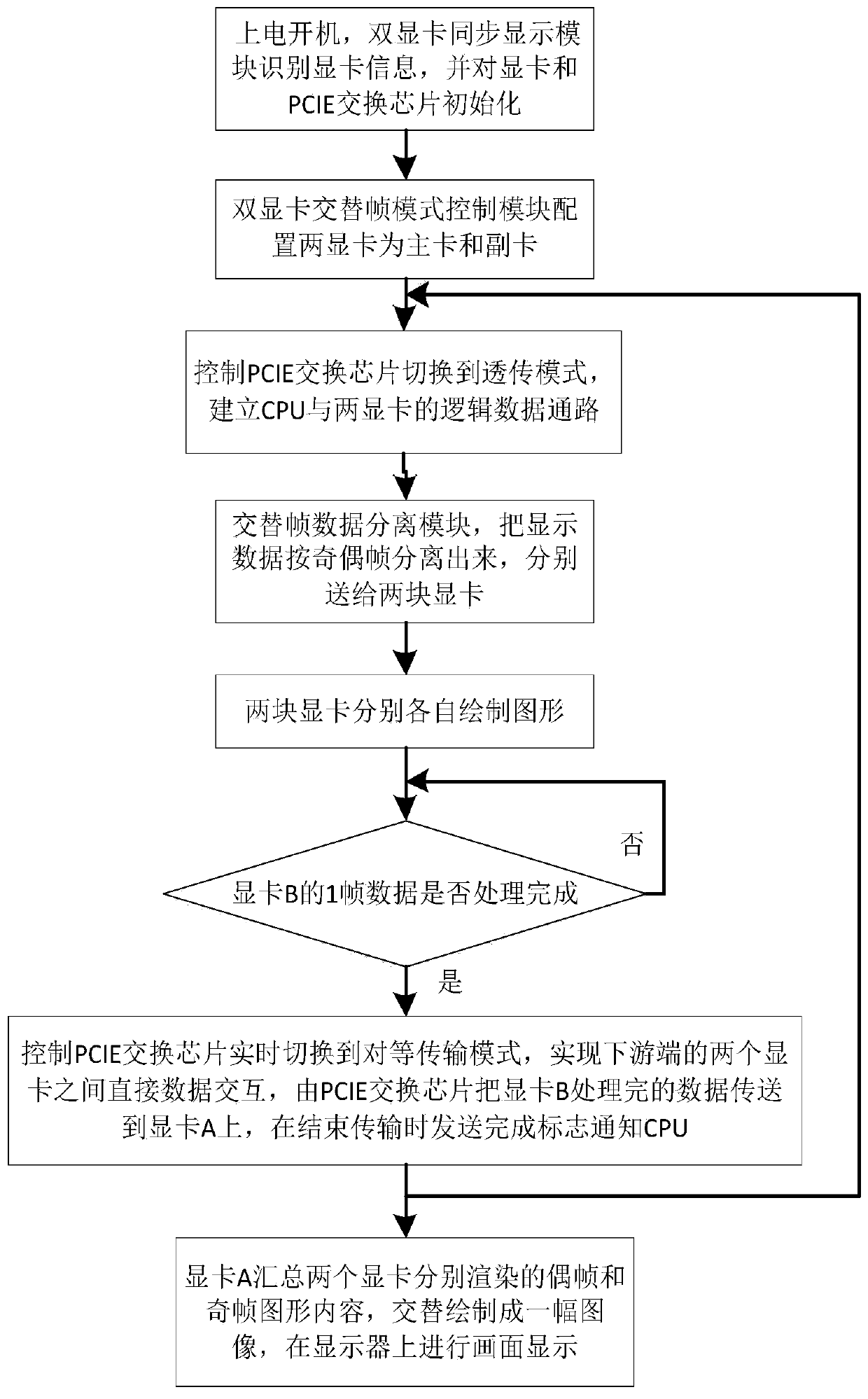

PendingCN111142951AMeet the needs of self-controlHigh localization rateBootstrappingExecution for user interfacesGraphicsGraphic card

The invention provides a Feiteng platform-based double-independent graphics card synchronous display device. The device comprises a system mainboard, two domestic independent graphics cards and a double-graphics card synchronous display module, the system mainboard comprises a domestic Feiteng CPU, Kunlun BIOS firmware, a Kylin operating system, a general PCIE switching chip, a PCIE configurationchip, two PCIE * 16 slots, namely a PCIE * 16 slot A and a PCIE * 16 slot B, wherein the PCIE * 16 slot A and the PCIE * 16 slot B are used for being connected with independent graphics cards in an inserted mode; a display card A on the PCIE * 16 slot A is a main card and is connected with a display to provide display information to the outside; and a display card B on the PCIE * 16 slot B is an auxiliary card and does not directly output display information to the outside. The invention provides a double-graphics-card synchronous display method of a domestic Feiteng platform. The number of primitives rendered by a single display card is reduced, the rendering time is shortened, the rendering speed is finally increased, the graphic performance of the whole machine is remarkably improved, the fluency under the condition that multiple videos are played at the same time is improved, the target scaling roaming response time of a situation system is shortened, and the fluency and user experience are improved.

Owner:NO 15 INST OF CHINA ELECTRONICS TECH GRP

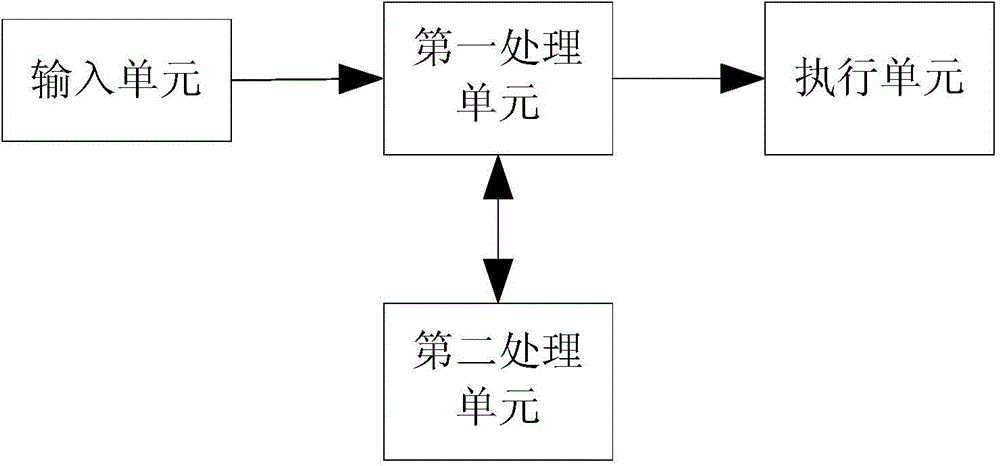

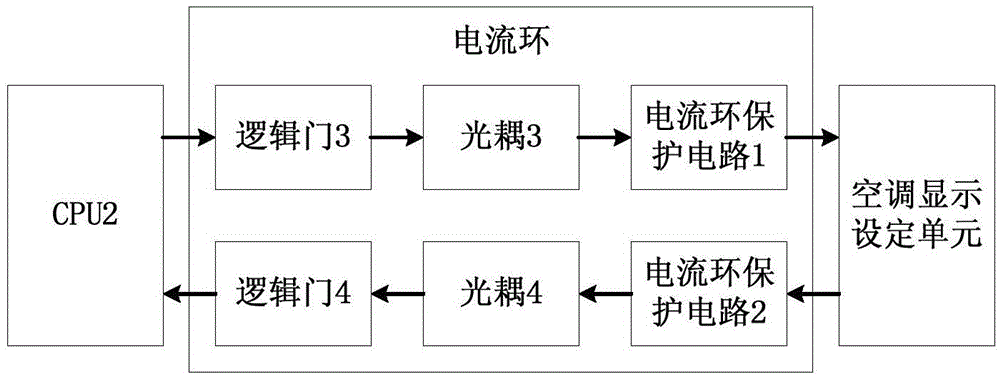

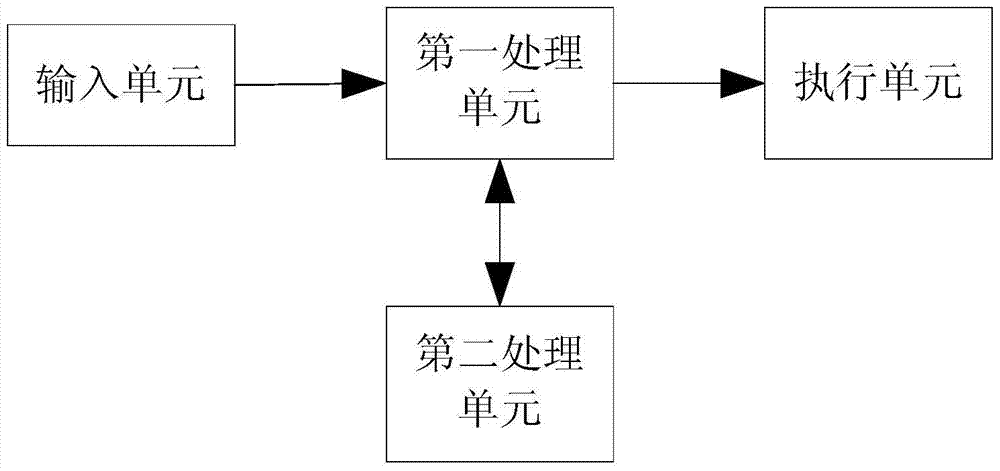

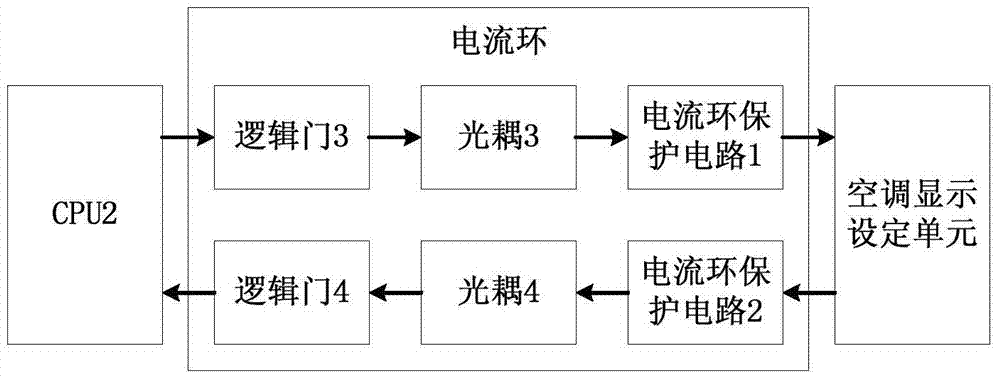

Air conditioner system control device

ActiveCN104633858AImprove reliabilityGood maintainabilityMechanical apparatusSpace heating and ventilation safety systemsDual coreVoltage

The invention discloses an air conditioner system control device. The air conditioner system control device comprises an input unit, a first processing unit and an executing unit and further comprises a second processing unit, wherein the input unit is used for converting external temperature signals into voltage signals, the first processing unit is used for receiving running state information of an air conditioner system and the voltage signals outputted by the input unit and generating control signals on the basis of the running state information and the voltage signals, the executing unit is used for controlling the air conditioner system on the basis of the control signals, the second processing unit is used for helping the first processing unit complete a communication and clock synchronization function, and the input unit collects the running state information and conveys the running state information to the first processing unit. A simple double-core hardware framework is adopted, the complex air conditioner control and protection function is achieved, high reliability and high maintainability are achieved, and the manufacturing cost of a high speed train is reduced.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

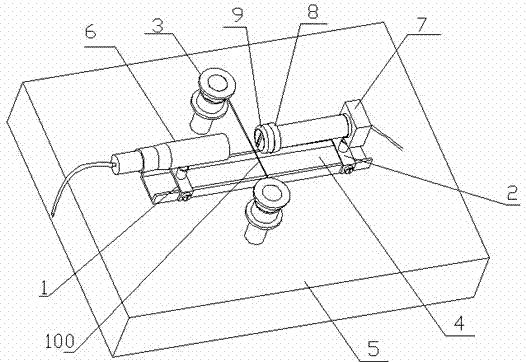

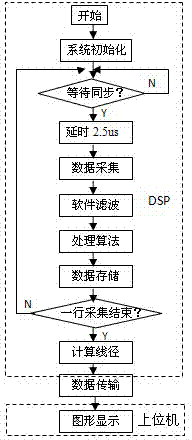

Digital signal processor (DSP) based linear array charge coupled device (CCD) online detection system for absorbable suture line diameter

InactiveCN104121860AAchieving precise measurementsImprove uniformityUsing optical meansClosed loopAbsorbable suture

The invention relates to a digital signal processor (DSP) based linear array charge coupled device (CCD) online detection system for absorbable suture line diameter. The DSP based linear array CCD online detection system for absorbable suture line diameter comprises structural members and a system circuit. The structural members include a light source support, a CCD support, guide wheels and a guide rail. The guide wheels and the guide rail are fixed to the surface of a platform of a wet spinning machine. A linear array CCD comprises a linear array CCD module and a casing; a plug rod B is arranged at the bottom of the casing and is in close fit with a central slot of a holder B. A telecentric lens is mounted at the front end of the linear array CCD and provided with a shading device. The shading device consists of a lens hood and a shade piece. The system circuit consists of an optical imaging module, a linear array CCD drive module, a high-speed analog / digital (A / D) data acquisition and DSP digital signal processing module. Compared with the conventional measurement method, the DSP based linear array CCD online detection method for the absorbable suture line diameter has the advantages that the line diameter can be detected in real time accurately during production and twisting of absorbable sutures, a DSP controller output end provides detection data for a spinneret mechanism and a tension control system to realize closed-loop control of spinneret pressure and stretch tension, thus the produced sutures have good uniformity.

Owner:TIANJIN POLYTECHNIC UNIV

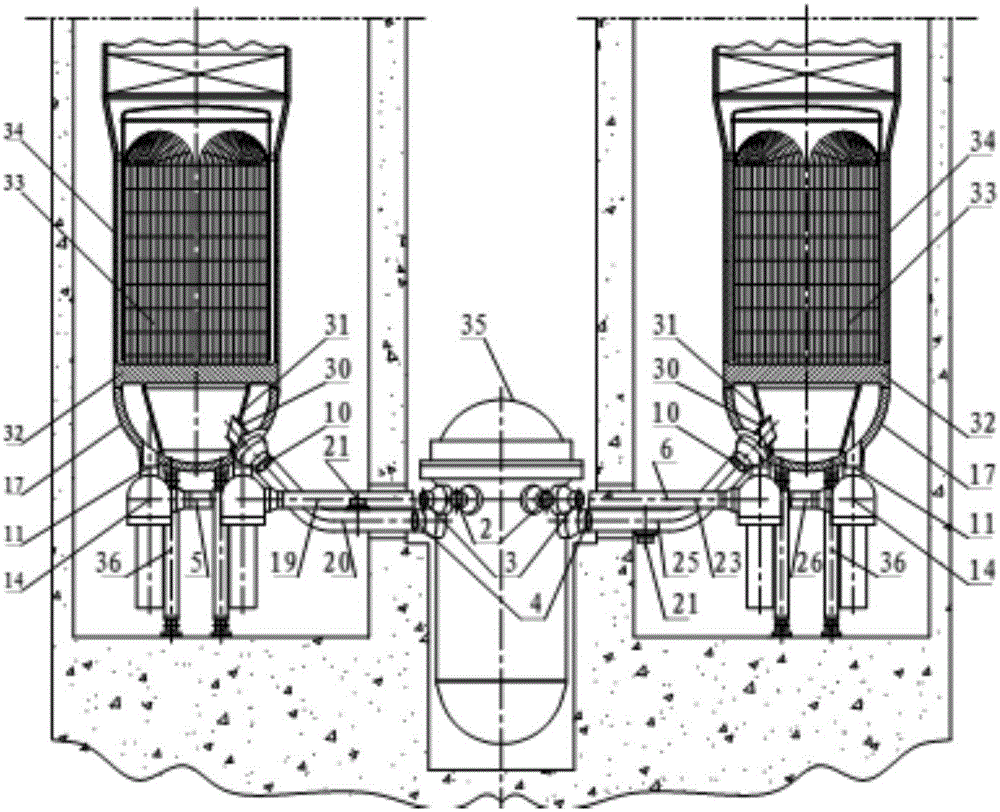

Reactor coolant loop arrangement of passive pressurized water reactor nuclear power plant

PendingCN106098120ABreaking the technical bottleneck of the main pumpBreaking the bottleneck of manufacturing technologyNuclear energy generationSteam generator primary sideVapor generatorPressurized water reactor

The invention provides a reactor coolant loop arrangement of a passive pressurized water reactor nuclear power plant. The reactor coolant loop arrangement comprises a reactor pressure vessel and vapor generators; the reactor pressure vessel is provided with a pipe-connection section barrel which is provided with reactor coolant outlet pipe-connection nozzles and reactor coolant inlet pipe-connection nozzles, and the vapor generators are connected with the reactor pressure vessel through main pipelines. According to the reactor coolant loop arrangement of the passive pressurized water reactor nuclear power plant, design improvement is conducted on a reactor main coolant loop, the technical bottleneck problem of large CAP series nuclear power plant main pumps is broken through, and meanwhile the technical bottleneck problem of large CAP series nuclear power plant main pipeline hot section manufacturing is broken through.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Brewage method of wine

InactiveCN105969563AHigh localization rateHighlight the characteristics of the terroirWine preparationEconomic benefitsFermentation

The invention discloses a brewage method of wine. The method mainly comprises the following steps: raw material preparation, impregnation, pressing, clarifying, fermentation, standing, aging and the like. In the raw material preparation step, 1 part by weight of stem-removed Hetian red grapes, 1.5-3.5 parts by weight of Turpan red grapes and 1-3 parts by weight of Riesling grapes are selected, and 30-50ppm SO2 is added at the stem-removal crushing part. In the impregnation step, after 0.1-1 part by weight of grape juice is added, cold impregnation is carried out at 5-10 DEG C for 8-16 hours, wherein the grape juice is prepared by mixing and crushing the Hetian red grapes, Turpan red grapes and Riesling grapes. Compared with the prior art, the method disclosed by the invention has the advantages of simple technique and high grape variety localization rate, is natural and pollution-free, has the climate characteristics in Xinjiang, and enhances the economic benefit.

Owner:SHIHEZI UNIVERSITY

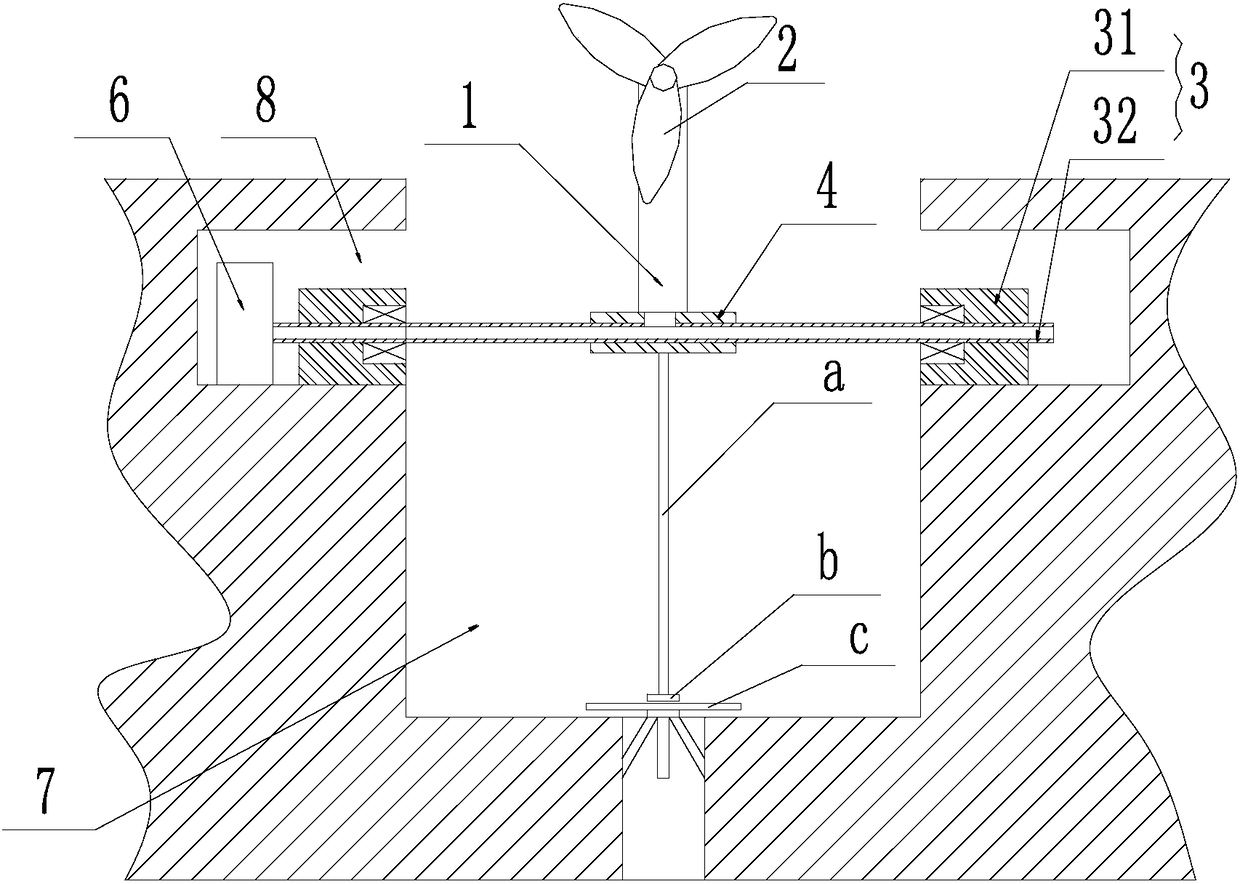

Intelligent island wind driven generator

InactiveCN108317050APrevent collapseSimple structureWind motor supports/mountsMachines/enginesWind drivenTower

The invention discloses an intelligent island wind driven generator. The wind driven generator comprises a tower frame and a draught fan arranged on the upper portion of the tower frame; the lower portion of the tower frame is connected with a tower frame turnover device. Compared with the prior art, the intelligent island wind driven generator has the beneficial effects that the structure is simple and practical, the generator is suitable for the weather abnormal area with strong wind blown, wind pressures of the strong winds to the draught fan and the tower frame can be effectively avoided,the phenomenon that the tower frame bears too strong wind pressure, and the tower frame collapses is avoided, engineering building cost is reduced, and the import substitution rate and the large-scaleproduction are facilitated.

Owner:CHONGQING YIYAO TECH CONSULTATION CO LTD

Loop layout of reactor coolant for passive pressurized water reactor nuclear power plant

PendingCN106098116AHigh localization rateLoop Design ImprovementsNuclear energy generationSteam generator primary sideReactor pressure vesselPressurized water reactor

The invention provides a loop layout of a reactor coolant for a passive pressurized water reactor nuclear power plant. The loop layout comprises a reactor pressure vessel and a vapor generator, wherein the reactor pressure vessel comprises a pipe connecting section cylinder, and the pipe connecting section cylinder is provided with a reactor coolant outlet pipe connecting mouth and a reactor coolant inlet pipe connecting mouth; and the vapor generator is connected with the reactor pressure vessel through a main pipeline. According to the loop layout, the design of a reactor coolant loop is improved, so that the difficulty of the technological development bottleneck of large-scale main pumps of large-scale CAP series nuclear power plants is broken through, two main coolant loops are realized under the condition that a main pump with the power higher than that of a CAP1000 nuclear power plant is not utilized and even the main pump with the power lower than that of the CAP1000 nuclear power plant is used, and meanwhile, CAP series passive pressurized nuclear power plants with power higher than that of the CAP1000 nuclear power plant are realized.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

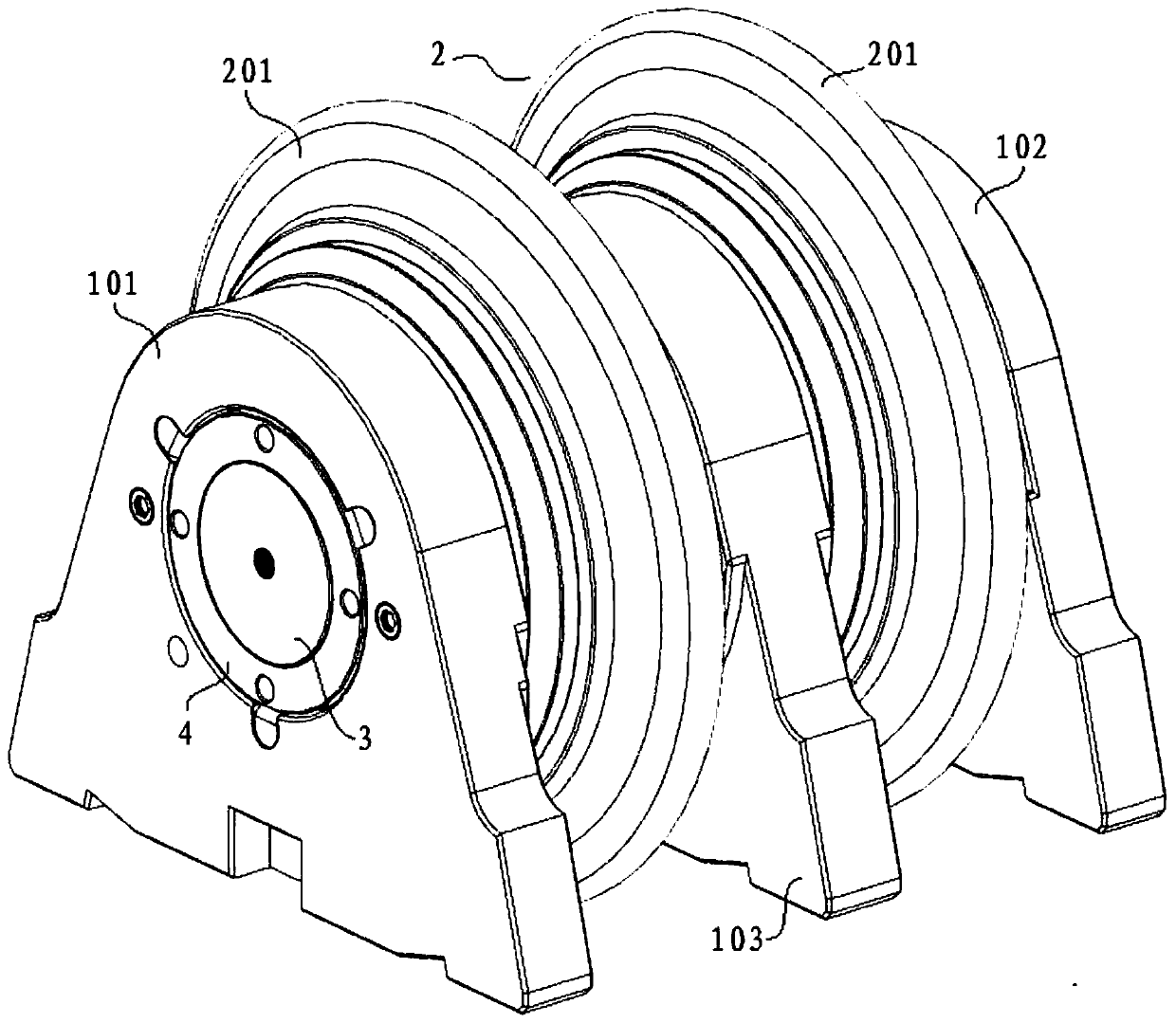

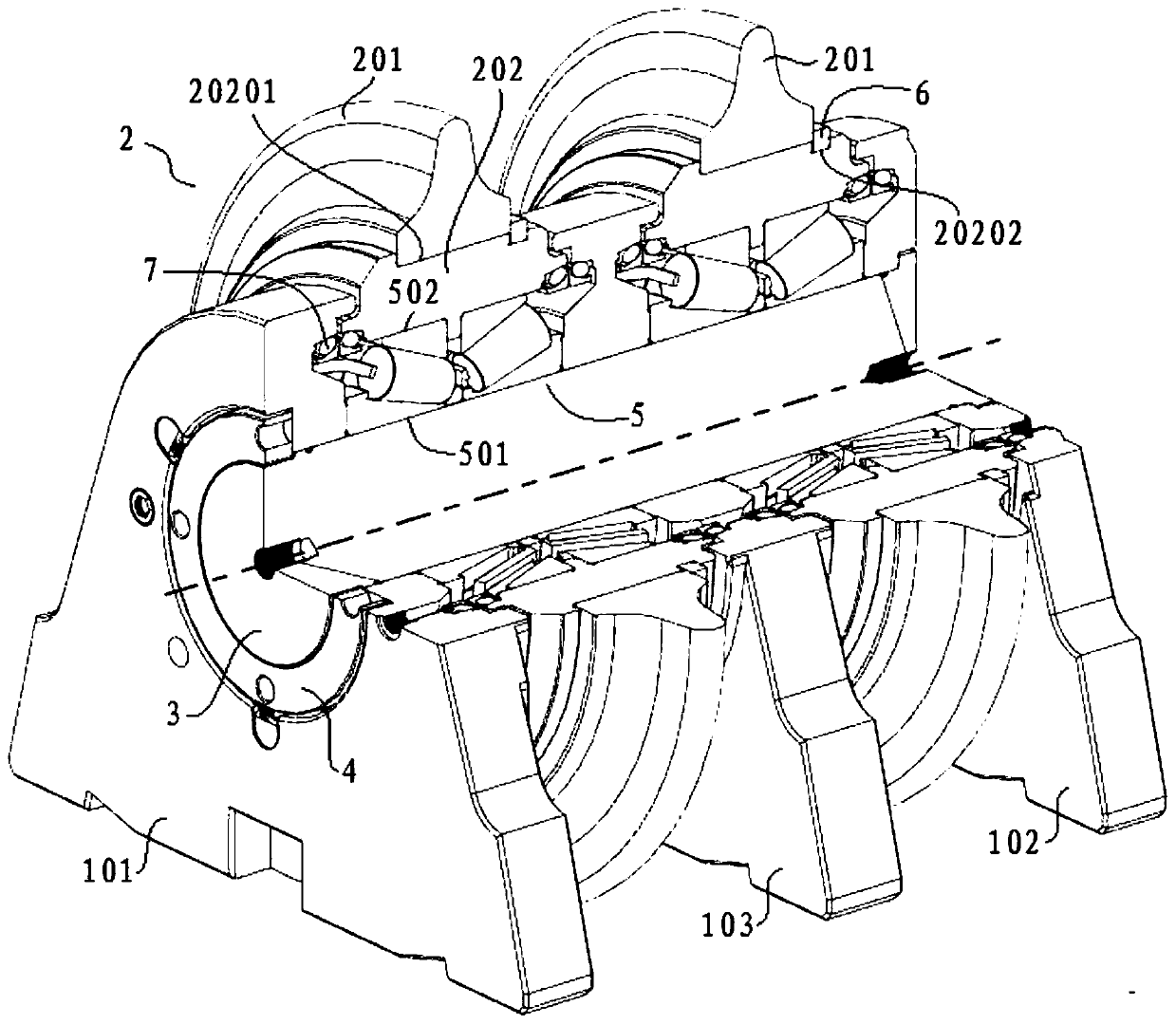

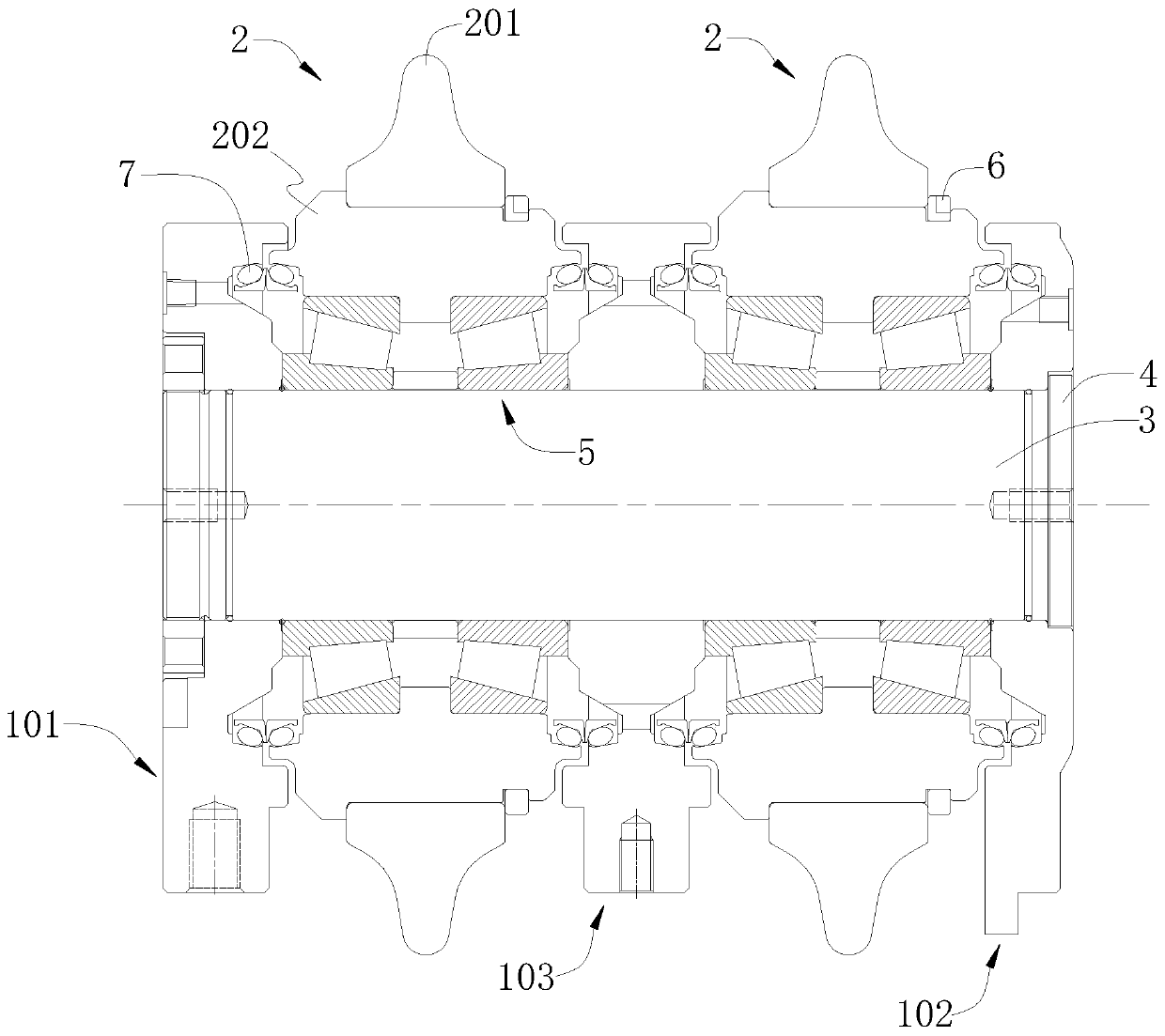

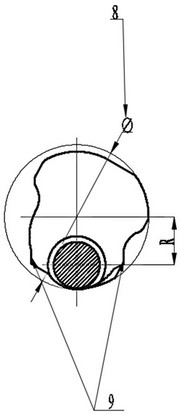

TBM dual-blade center hobbing cutter and tool

The invention discloses a TBM dual-blade center hobbing cutter and a tool. The center hobbing cutter comprises an end cover assembly and a hobbing cutter set assembled in the end cover assembly, the hobbing cutter set comprises two hobbing cutter bodies mounted in a spaced manner, and bearings assembled on the inner sides of the hobbing cutter bodies, the dual-blade center hobbing cutter further comprises a cutter shaft extending in the axial direction of the bearings and penetrating through the end cover assembly, the bearings are conical roller bearings, the mounting taper angle of conical rollers of the conical roller bearings relative to the axis of the cutter shaft is theta, the mounting taper angles of the conical rollers relative to the axis of the cutter shaft is theta and smallerthan 12 degrees, according to the TBM dual-blade center hobbing cutter and the tool, the mounting taper angles of the conical rollers of the conical roller bearings are reduced, the tool axial component force can be effectively reduced, compared with an imported bearing, the conical roller bearings are narrower, due to the fact that a bearing inner ring supporting base and the conical rollers arenarrower, the stress area is reduced, the pressure intensity is increased, under the heavy load pressure of normal work, a stable roller ring track is more easily formed, and the inclination to lose stability is not prone to happening.

Owner:凌远科技股份有限公司

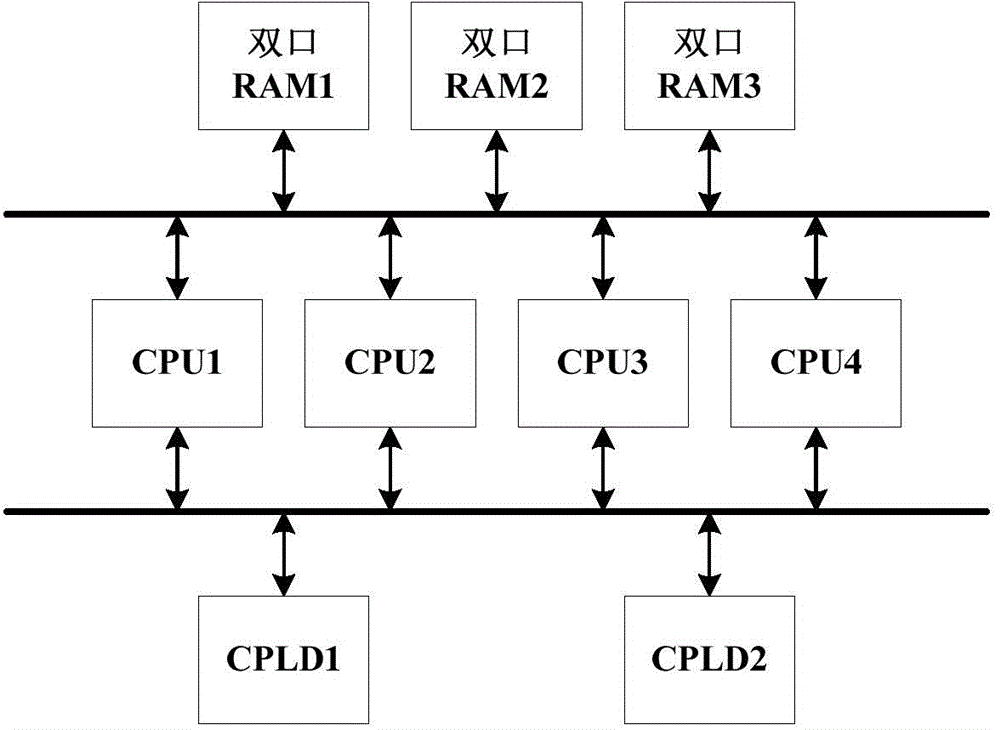

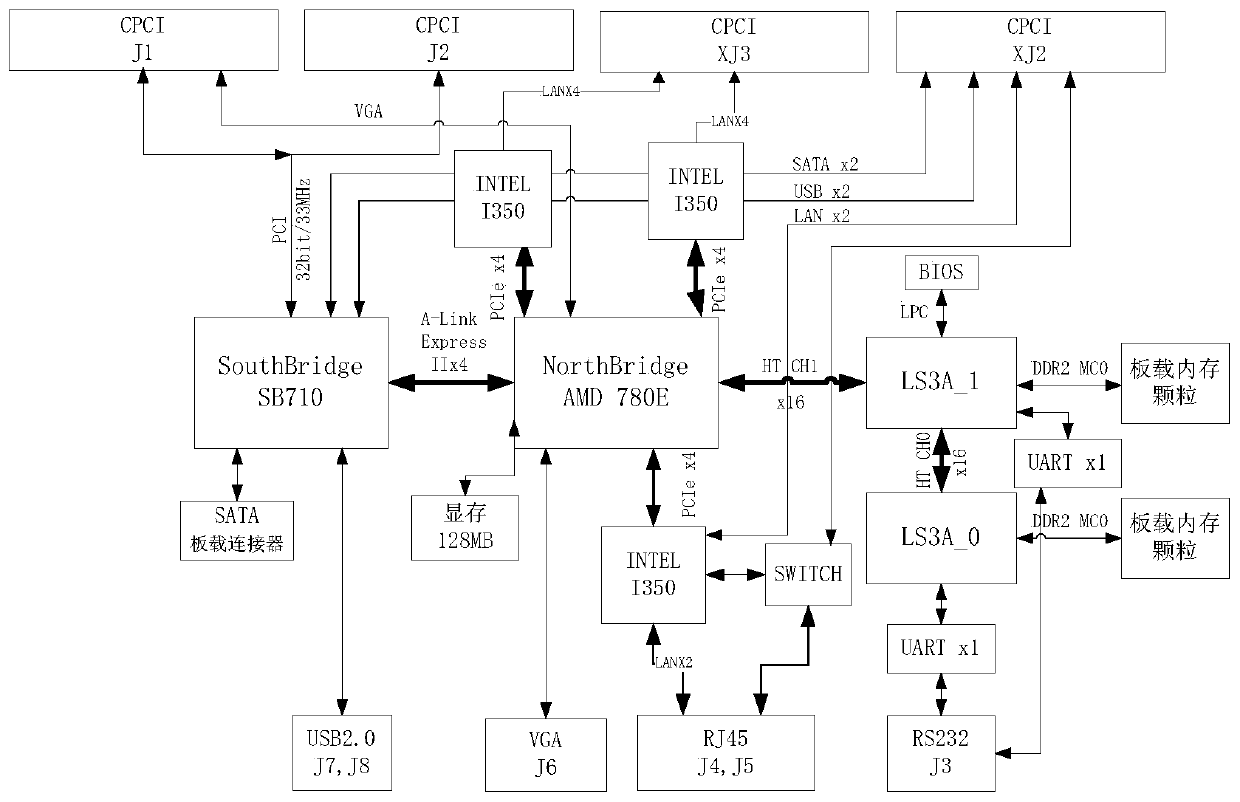

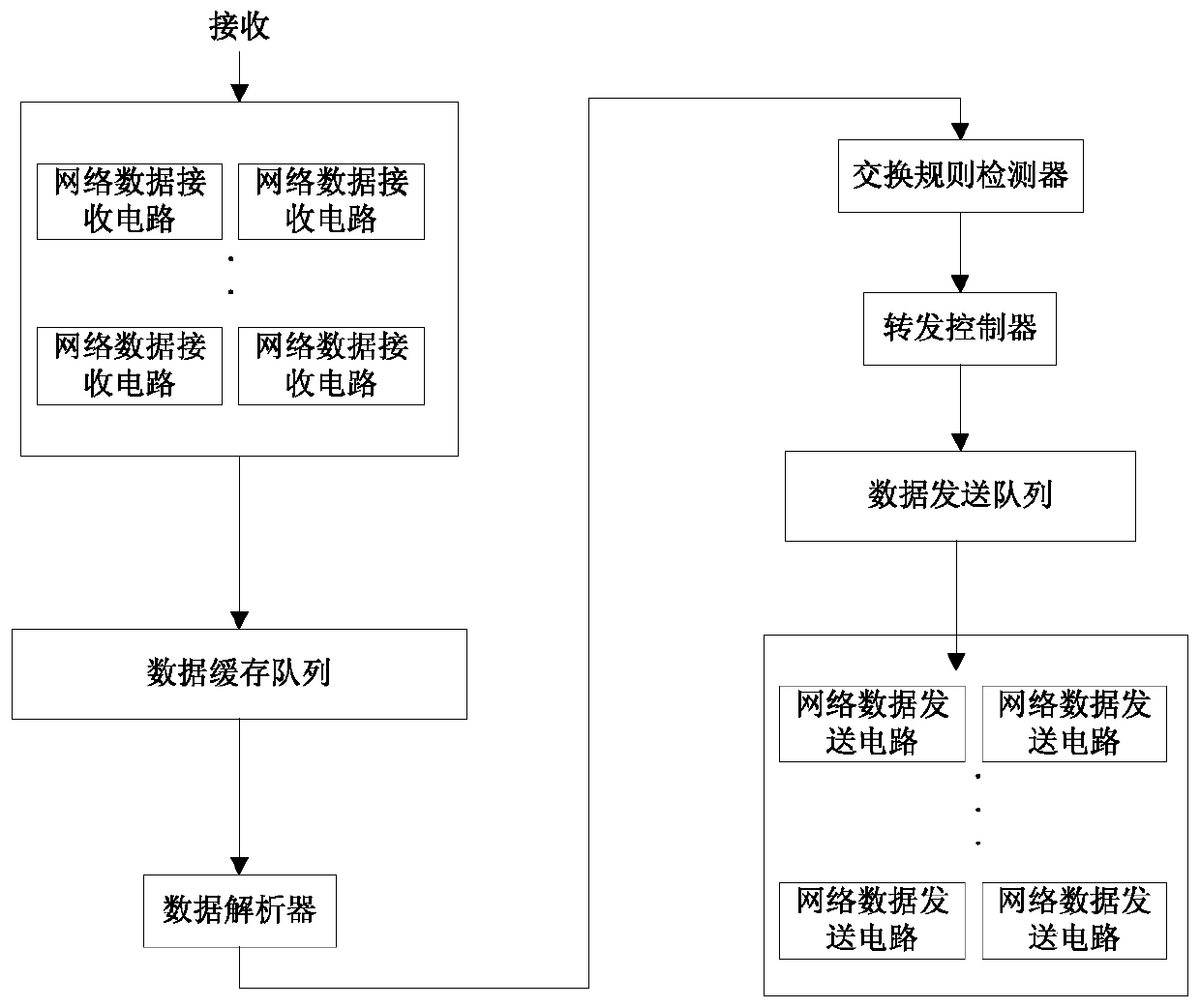

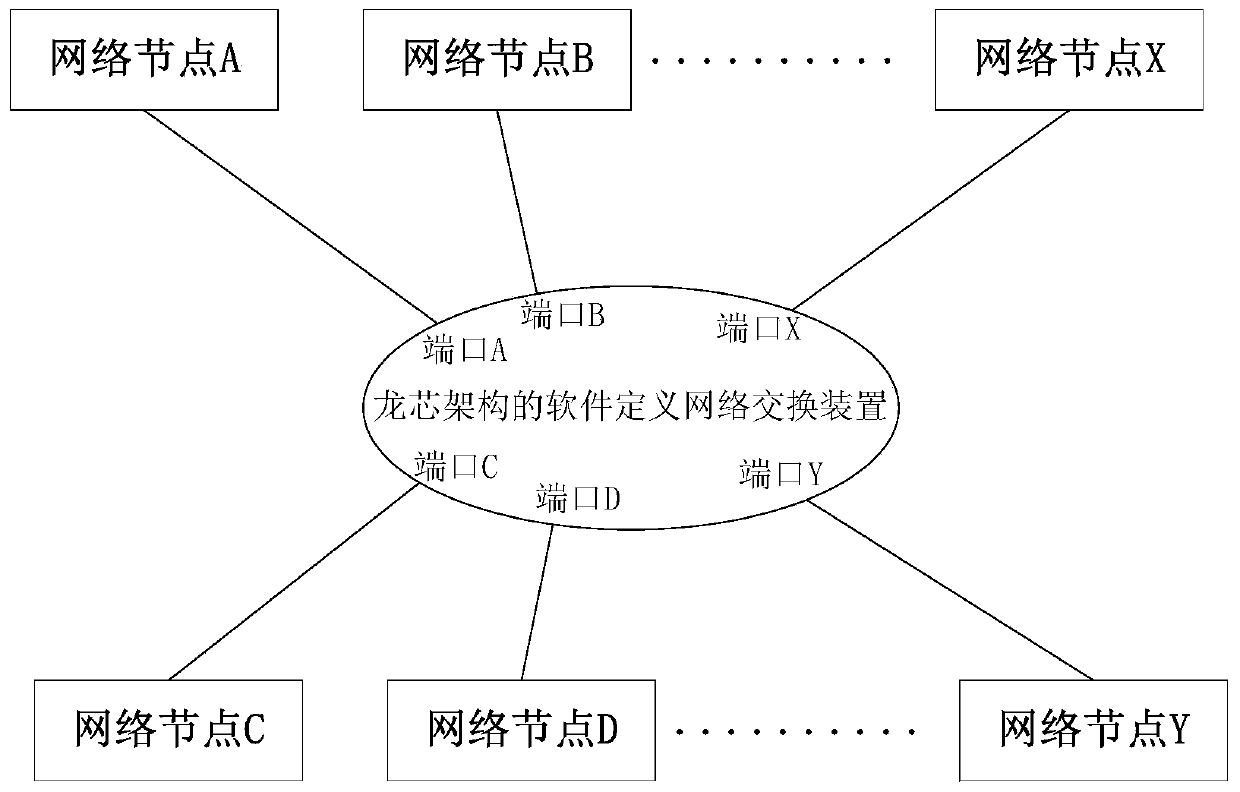

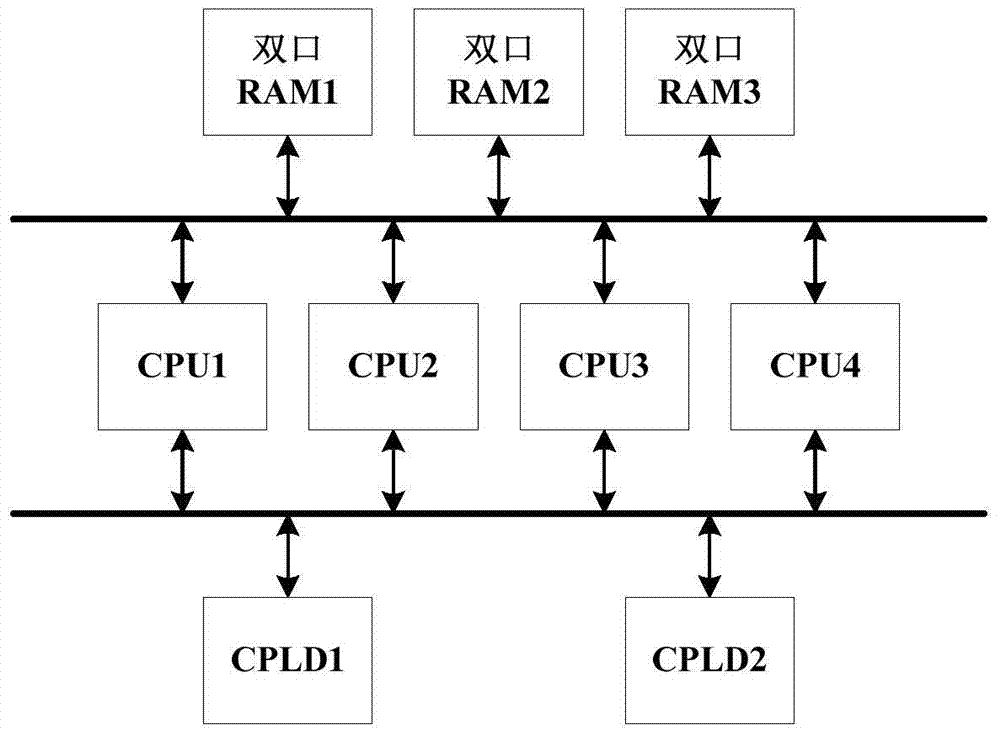

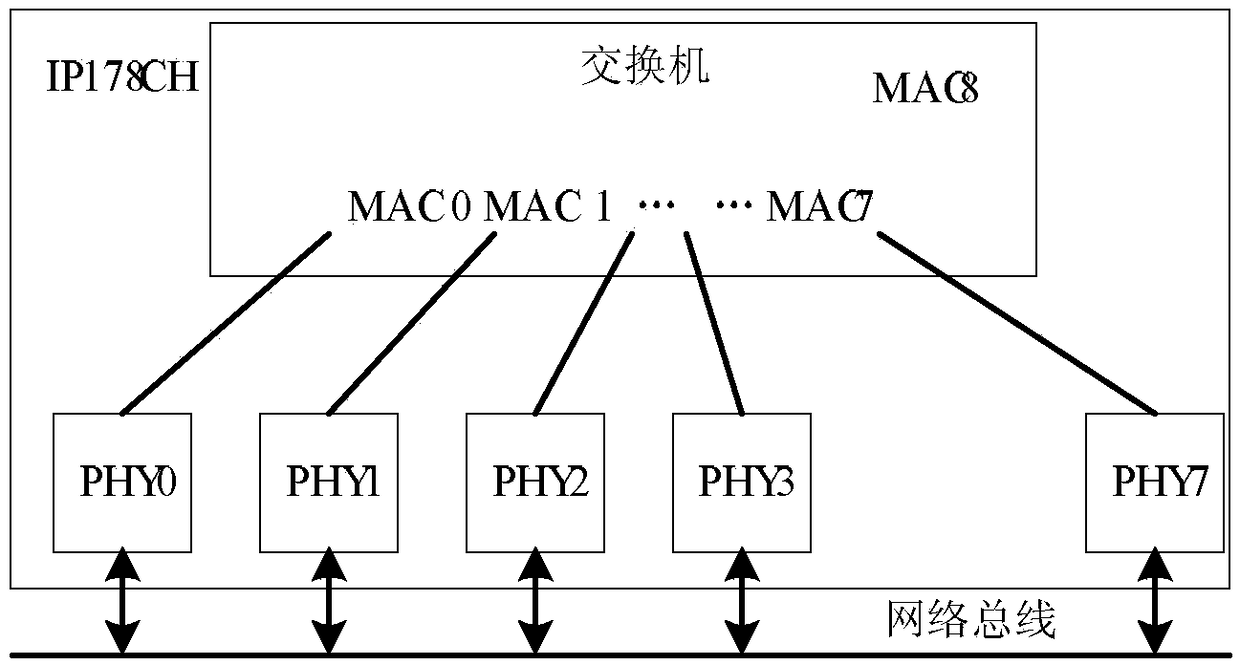

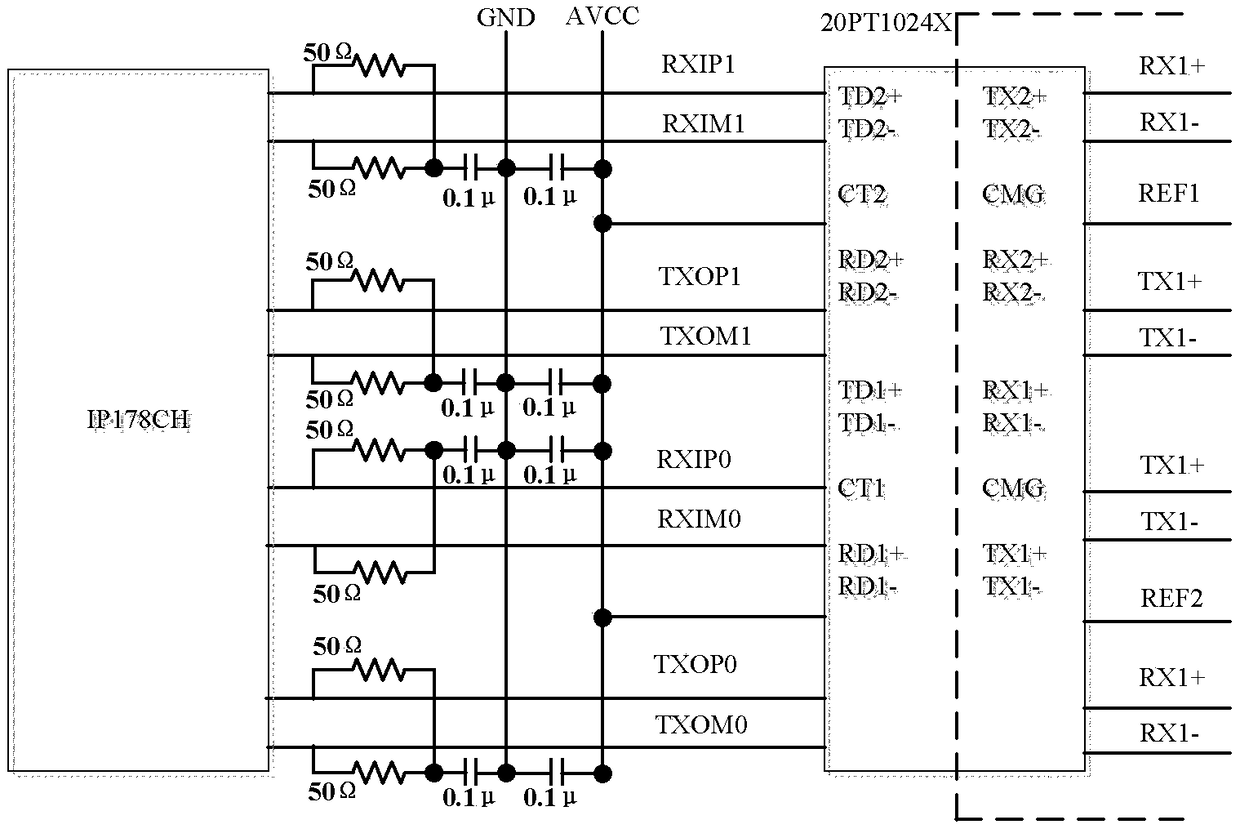

A software-defined network switching device and data switching method based on Loongson architecture

ActiveCN108040011BFast forwardHigh localization rateData switching networksOperational systemConfigfs

The invention discloses a software-defined network switching device and a data switching method based on the Godson architecture, including a control processor part, the control processor part is connected with a north bridge chip by using an HT bus, and the north bridge chip is configured with at least 3 x4 PCIe ports , each x4 PCIe port is connected to an Ethernet network card, each Ethernet network card is provided with at least 2 Ethernet ports, and the Ethernet port is externally connected to a CPCI port and an RJ45 port; the north bridge chip is connected to the south bridge chip through the A-Link bus, and the south bridge chip is connected to the south bridge chip The bridge chip is connected to the CPCI port through the PCI bus, and the south bridge chip is connected to the hard disk on the carrier board. The hard disk on the carrier board is used to install the Linux operating system. The configuration file of the Linux operating system is pre-configured with user-defined data exchange rules.

Owner:中国兵器装备集团自动化研究所有限公司

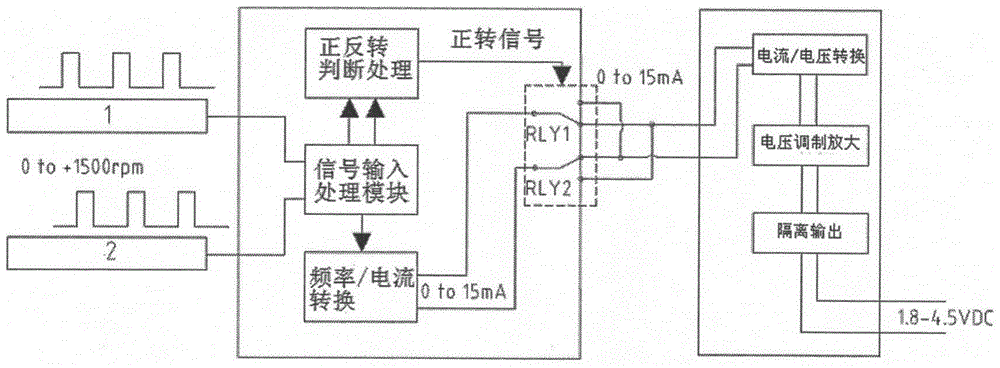

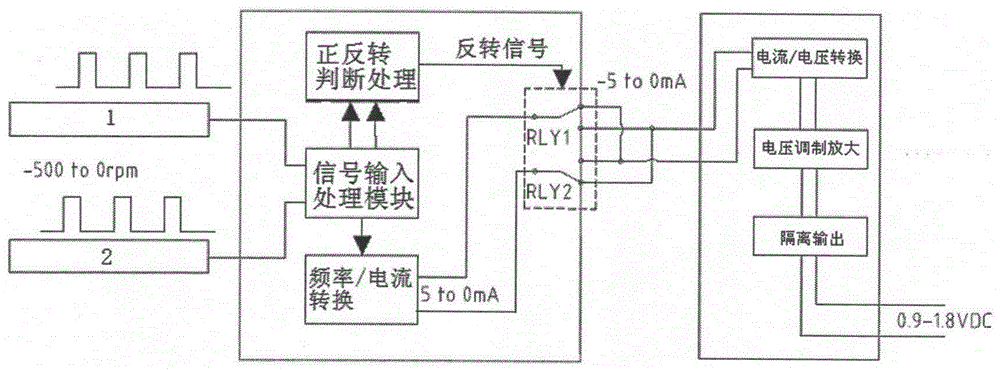

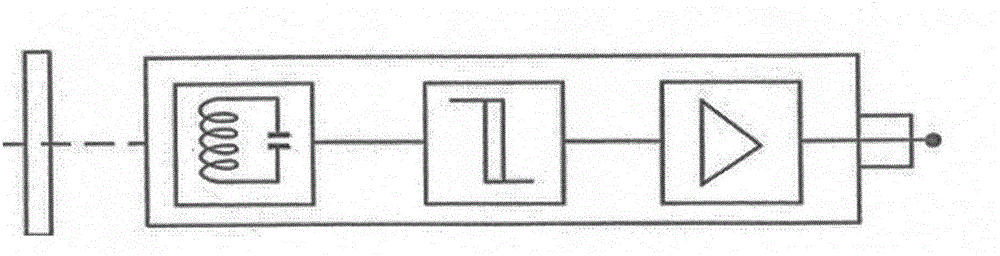

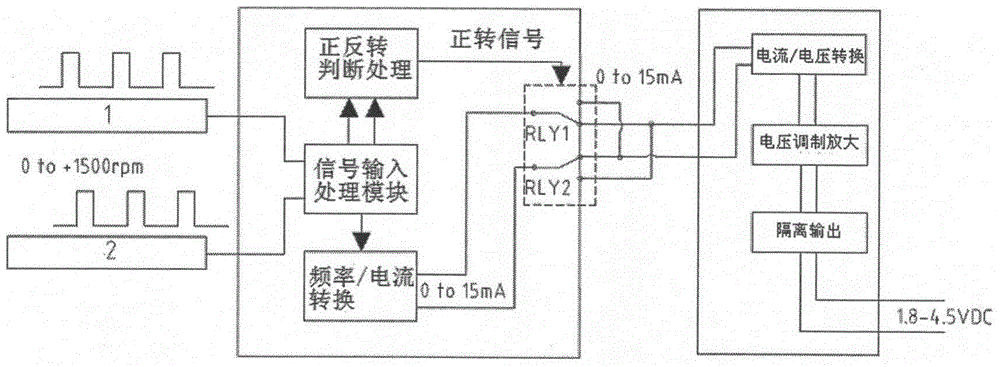

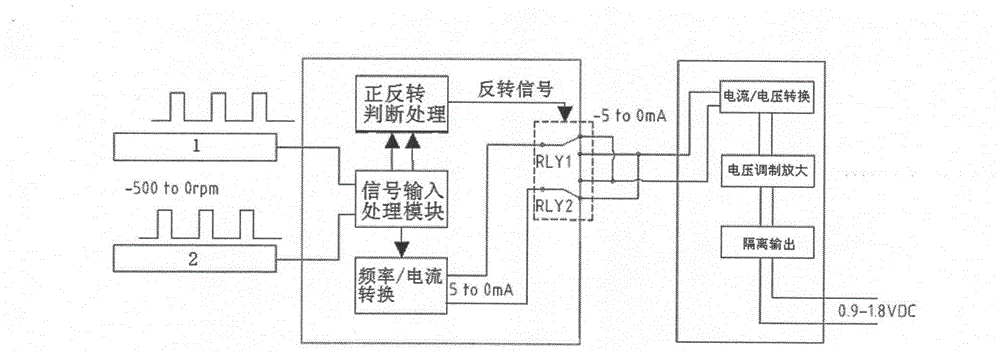

Method for continuous measurement of rotational speed of main heat transfer pump in nuclear island from reverse to forward rotation

ActiveCN104538066BHigh localization rateSolve nuclear controlNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention relates to a method for continuously measuring the rotating speed of a main heat transfer pump in a nuclear island from reverse rotation to forward rotation. N inductance approach switches, a rotating speed signal processing unit and a signal modulator are used in the invention. The nuclear control of large foreign companies to the nuclear power field in China and the technology and price monopoly of key products are solved. The method can be popularized in the measurement of the rotating speed of other similar pump shaft pump groups to reduce imported products and improve the localization rate of nuclear power stations.

Owner:SHANGHAI POWER EQUIP RES INST +1

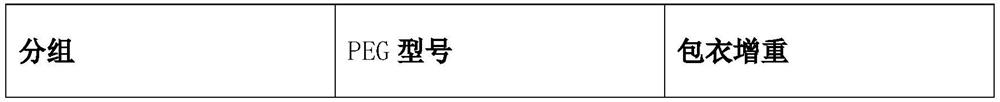

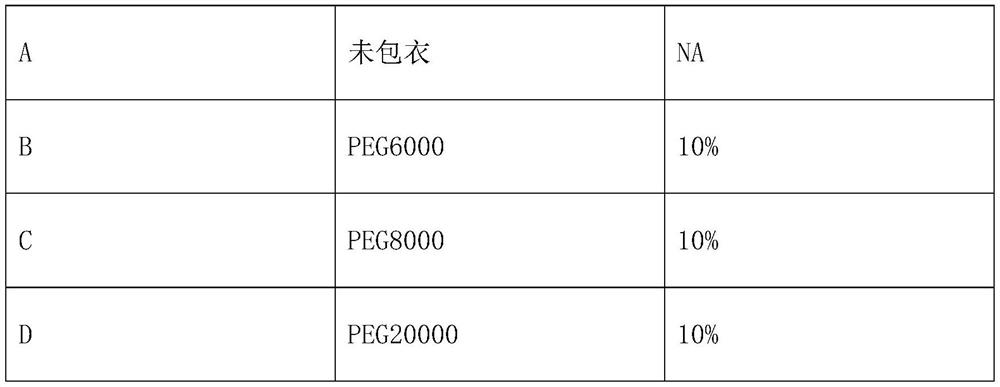

A traditional Chinese medicine moisture-proof coating agent

ActiveCN107875137BAchieve the effect of moisture-proof coatingDissolve fastPharmaceutical non-active ingredientsMicrocapsulesCellulosePolyethylene glycol

The invention discloses a moisture-proof coating agent for traditional Chinese medicine, which mainly contains 78-98% by mass of medicine, 1-11% of macromolecular skeleton auxiliary materials that are easily soluble in water and have poor hygroscopicity and other auxiliary materials, wherein the macromolecular skeleton auxiliary materials One or any combination of two or more selected from polyethylene glycol 1000-20000, solid poloxamers, and other excipients selected from one of lactose, mannitol and a small amount of low-substituted cellulose Or any two or any combination of two or more, the moisture-proof coating agent for traditional Chinese medicine has obvious moisture-proof effect, dissolves quickly, has no insoluble suspended matter, and can still maintain the powder of granules or powders under normal temperature conditions with a relative humidity below 75%. Physical characteristics, convenient for industrial application.

Owner:TIANJIN TASLY PHARMA CO LTD

An air conditioning system control device

ActiveCN104633858BReduce manufacturing costImprove the level of information designMechanical apparatusSpace heating and ventilation safety systemsMaintainabilityDual core

The invention discloses an air conditioner system control device. The air conditioner system control device comprises an input unit, a first processing unit and an executing unit and further comprises a second processing unit, wherein the input unit is used for converting external temperature signals into voltage signals, the first processing unit is used for receiving running state information of an air conditioner system and the voltage signals outputted by the input unit and generating control signals on the basis of the running state information and the voltage signals, the executing unit is used for controlling the air conditioner system on the basis of the control signals, the second processing unit is used for helping the first processing unit complete a communication and clock synchronization function, and the input unit collects the running state information and conveys the running state information to the first processing unit. A simple double-core hardware framework is adopted, the complex air conditioner control and protection function is achieved, high reliability and high maintainability are achieved, and the manufacturing cost of a high speed train is reduced.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

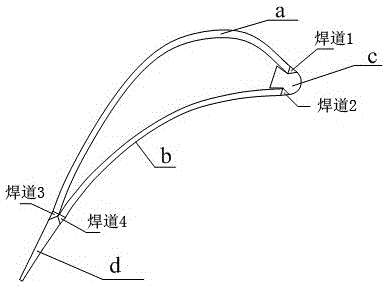

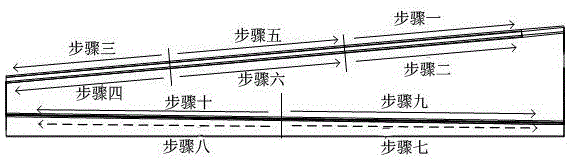

A Three-stage Welding Method for Cold Metal Transition of Hollow Stationary Blade of Steam Turbine

ActiveCN103480973BLow heat inputReduce the numberSoldering apparatusArc welding apparatusWelding residual stressTrailing edge

The invention relates to the field of steam turbines, in particular to a three-stage cold metal transfer welding method for steam turbine hollow static blades. The method includes performing spot welding on a leading edge, performing spot welding on a trailing edge, cooling to the room temperature, performing full welding on the leading edge and performing full welding on the trailing edge. The full welding are performed on the leading edge and the trailing edge by the cold metal transfer method, welding joints on the back arc of the leading edge and welding joints on the inner arc of the leading edge are welded in a three-stage manner, and welding joints on the back arc of the trailing edge and welding joints on the inner arc of the trailing edge are welded in a two-stage manner. By the aid of the method, heat input during welding a steam turbine hollow blade can be reduced, welding residual stress and distortion can be controlled effectively, cooling time is reduced, the number of the welding joints is decreased, welding operation is simplified, and quality stability of welded parts is improved; technical requirements on welders are low correspondingly, production of domestic enterprises are facilitated, and technology level and localization rate of steam turbine core equipment are improved; the cold metal transfer method is adopted, and the three-stage method and relative welding sequence of 'three-segment + three-segment + two-segment + two-segment' and the welding method for each segment are adopted.

Owner:DONGFANG ELECTRIC CORP LTD

Test method of test system for passive hydrogen recombiner

InactiveCN102682860BThe test data is close to the actual situationAccurate test evaluation meansNuclear energy generationNuclear monitoringHydrogenWater vapor

The invention discloses a test system for a passive hydrogen recombiner, and solves the problem that a system for testing the complete machine of a passive hydrogen recombiner is unavailable in the prior art. The test system mainly comprises a mixed gas tank, a reaction vessel and a sampling unit which are connected in sequence, wherein the reaction vessel is communicated with a water vapor generator. The invention also provides a test method of the test system for the passive hydrogen recombiner. The test system provided by the invention has the advantages of simple structure, convenience in operation and suitability for popularization and application.

Owner:SICHUAN INST OF MATERIALS & TECH +2

Manufacturing method and system of radio frequency self-adhesive label

ActiveCN101877072BAvoid scratchesPrevent oxidationSemiconductor/solid-state device manufacturingRecord carriers used with machinesEngineeringSilicone oil

The invention relates to a manufacturing method and a system of a radio frequency self-adhesive label, and the manufacturing method of the radio frequency self-adhesive label comprises the following steps: a) using conductive ink to print an antenna on an inner layer of a surface material film of a thin film; b) mounting a chip; c) testing an electronic device; d) coating silicone oil on the surface of a release material substrate; e) curing a silicone oil release layer; f) coating hot melt adhesive on the silicone oil release layer; g) curing the hot melt adhesive; h) compounding the tested electronic device layer with the release layer coated with the adhesive; i) carrying out die cutting and waste discharge; and j) taking up and obtaining a finished product which can be stuck automatically or manually. The manufacturing method of the radio frequency self-adhesive label can meet the technical requirements of the market on the radio frequency self-adhesive label, has significant advantages in the aspects of manufacturing efficiency, product yield, durability and economy, and can solve the shortcomings of the existing process, and the popularization of the manufacturing method of the radio frequency self-adhesive label is conductive to the wide applications of the radio frequency technology.

Owner:浙江龙游道明光学有限公司

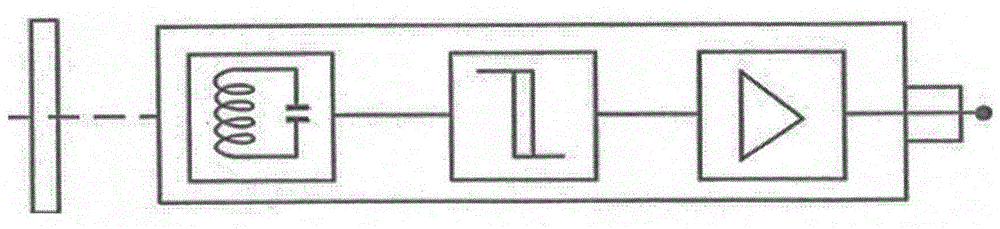

Method for continuously measuring rotating speed of main heat transfer pump in nuclear island from reverse rotation to forward rotation

ActiveCN104538066AReduce imported productsHigh localization rateNuclear energy generationNuclear monitoringNuclear engineeringInductance

The invention relates to a method for continuously measuring the rotating speed of a main heat transfer pump in a nuclear island from reverse rotation to forward rotation. N inductance approach switches, a rotating speed signal processing unit and a signal modulator are used in the invention. The nuclear control of large foreign companies to the nuclear power field in China and the technology and price monopoly of key products are solved. The method can be popularized in the measurement of the rotating speed of other similar pump shaft pump groups to reduce imported products and improve the localization rate of nuclear power stations.

Owner:SHANGHAI POWER EQUIP RES INST +1

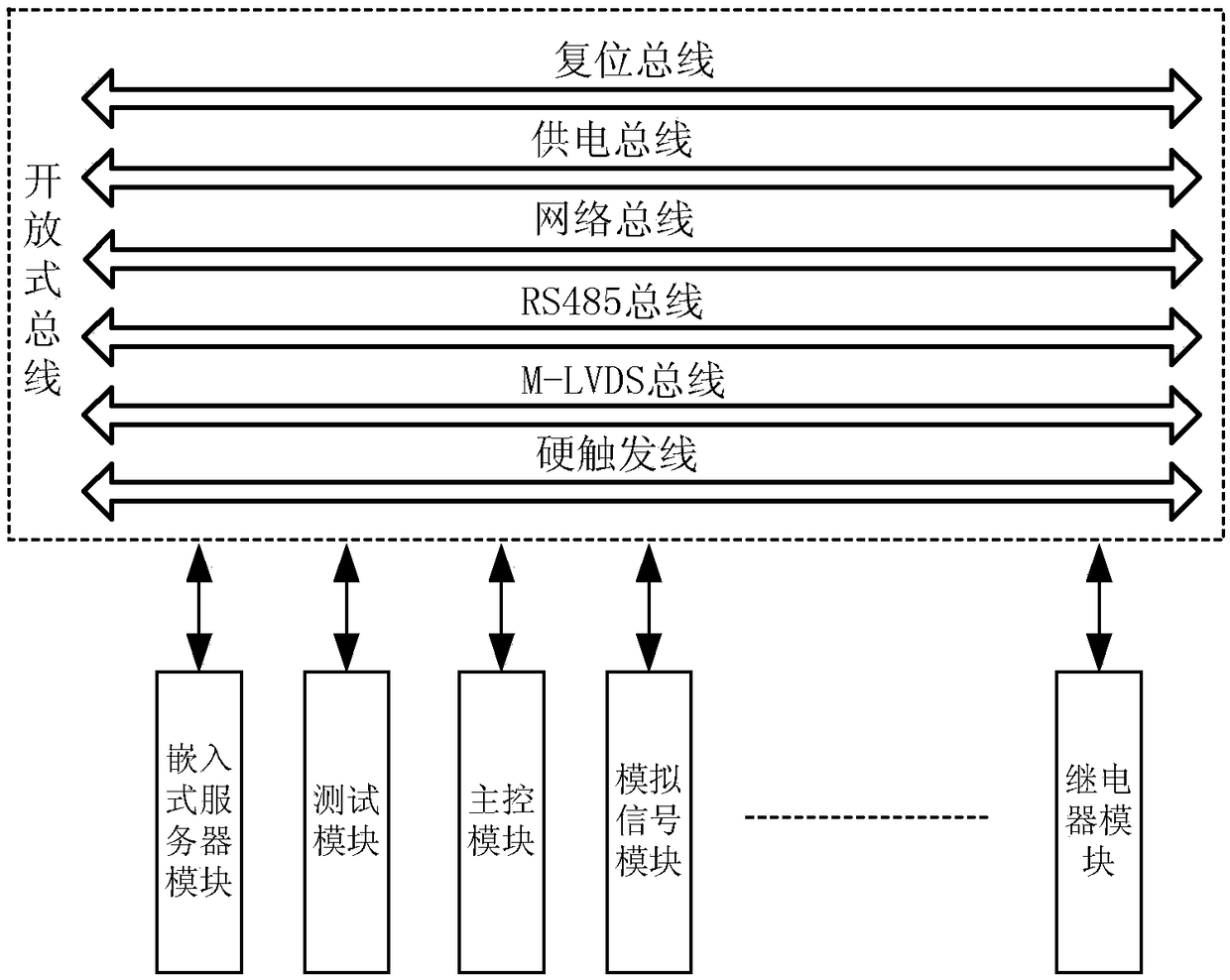

A user-defined serial open bus

ActiveCN108984458AIncrease autonomySave resourcesElectric digital data processingEmbedded technologyNetwork connection

The invention provides a serial open bus with a self-customized bus structure, which relates to bus design. The open bus of the invention is used for completing communication between a main control module and each functional module. The serial open bus comprises: a reset bus, which is used for sending unified instructions to each module, so that all modules are restored to initial state value at the same time; a power supply bus connected with a power supply for supplying a desired voltage to each module; a network bus, which is used for providing network connection for each module and is alsoused for debugging a module separately; and a user-defined bus, used to add the corresponding functional bus according to the requirements. With embedded technology and computer technology as the core, a DSP, an ARM, a single-chip microcomputer, an FPGA and other high-performance devices are used to construct the user-defined bus, which exhibits high autonomy. Each module can customize the bus structure according to the specific military test requirements, resources are saved, the environmental test can be past, and the localization rate of the equipment is improved.

Owner:哈尔滨诺信工大测控技术有限公司

Efficient low-carbon ultra-supercritical secondary reheating combined heat and power generation unit

PendingCN114483229AReduce steam leakageReduced potential for frictionSteam engine plantsUltra high pressureCogeneration

The invention discloses an efficient low-carbon ultra-supercritical secondary reheating cogeneration unit, and relates to a coal-fired power plant ultra-supercritical grade secondary reheating cogeneration unit which is provided with a double-flow ultrahigh pressure cylinder with an additional heat regeneration stage on one side and a double-flow high-medium pressure cylinder with an additional heat supply stage on two sides. The power generation heat consumption of the ultra-supercritical grade secondary reheating cogeneration unit can be remarkably reduced, greenhouse gas emission is remarkably reduced, a huge amount of industrial heat load is connected according to needs, and a large amount of heating heat load is connected according to seasonal needs; the condensing part is provided with an intelligent backpressure adjusting system for measuring the instant temperature of circulating water entering the condenser and adjusting the steam consumption of heating steam 1 and heating steam 2 in real time, so that the volume flow of the steam entering the tail blade of the medium-low pressure cylinder adapts to the backpressure which can be achieved by the circulating water temperature, the effective enthalpy drop of the tail blade of the medium-low pressure cylinder is maximized, and the energy consumption of the tail blade of the medium-low pressure cylinder is reduced. And meanwhile, the steam does not flow back at the blade root to scour the blade root.

Owner:章礼道

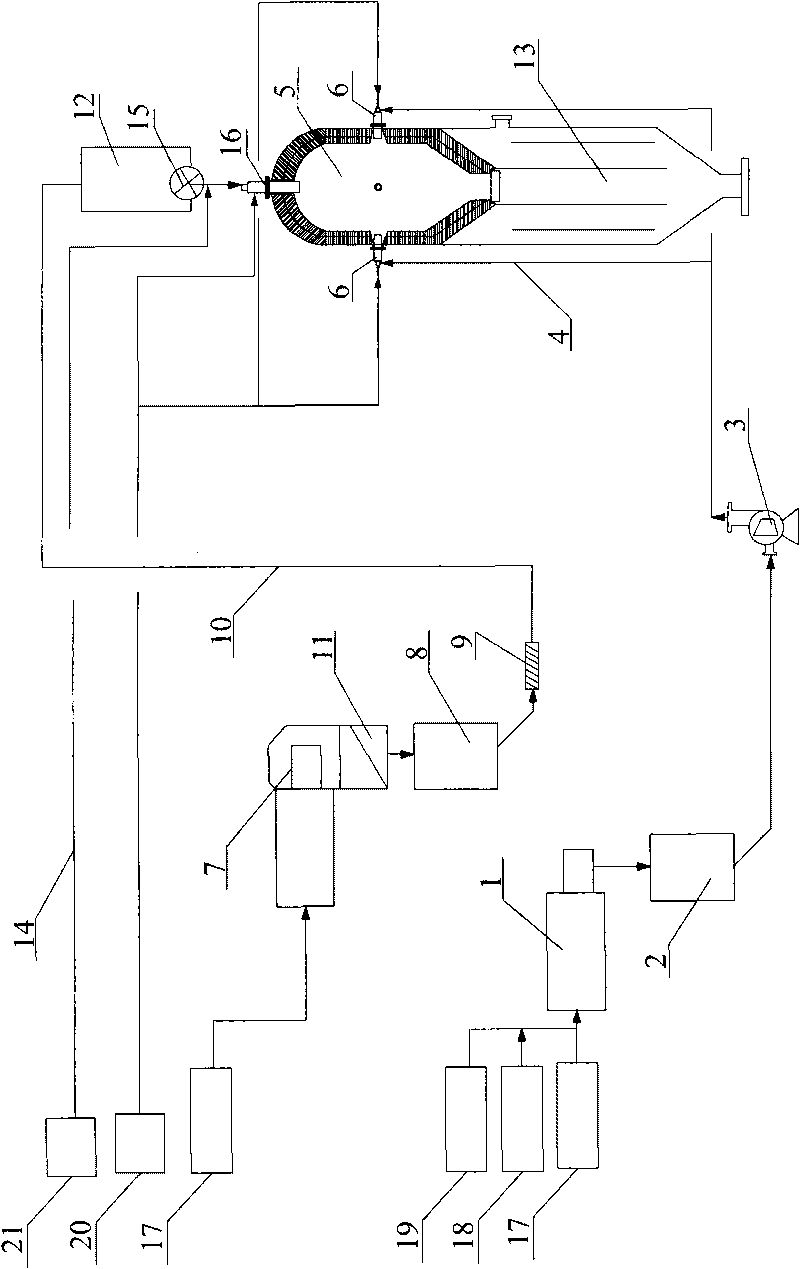

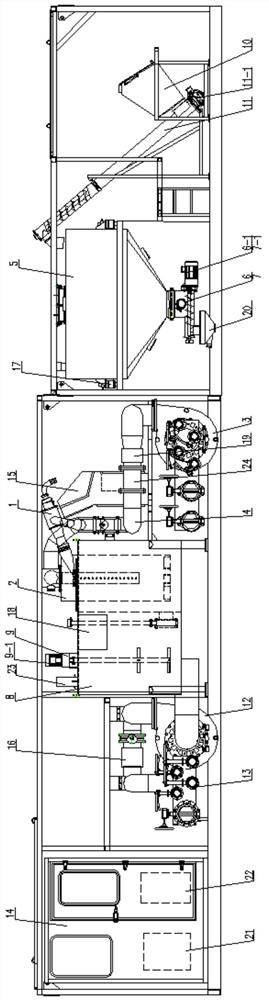

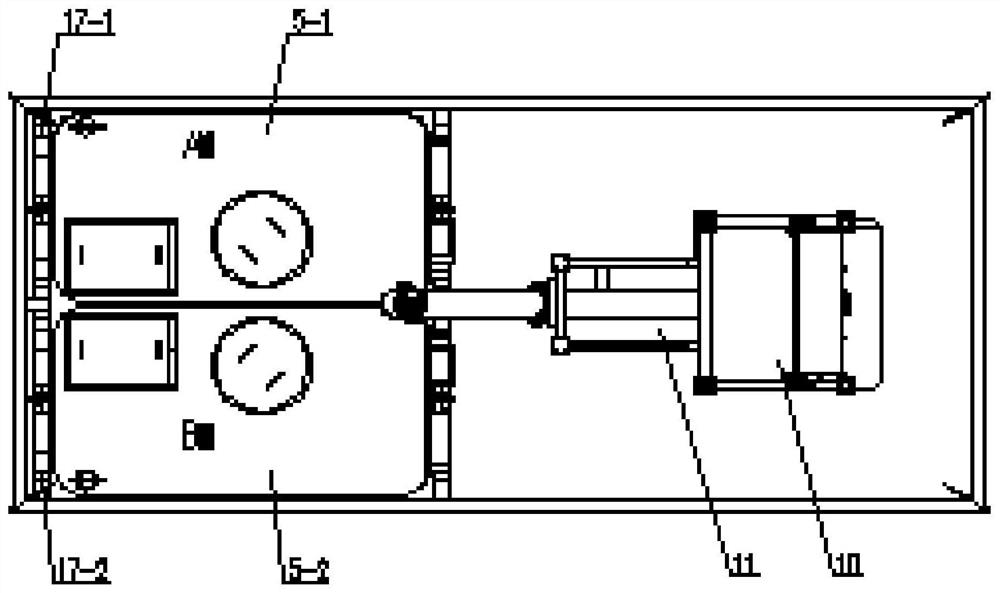

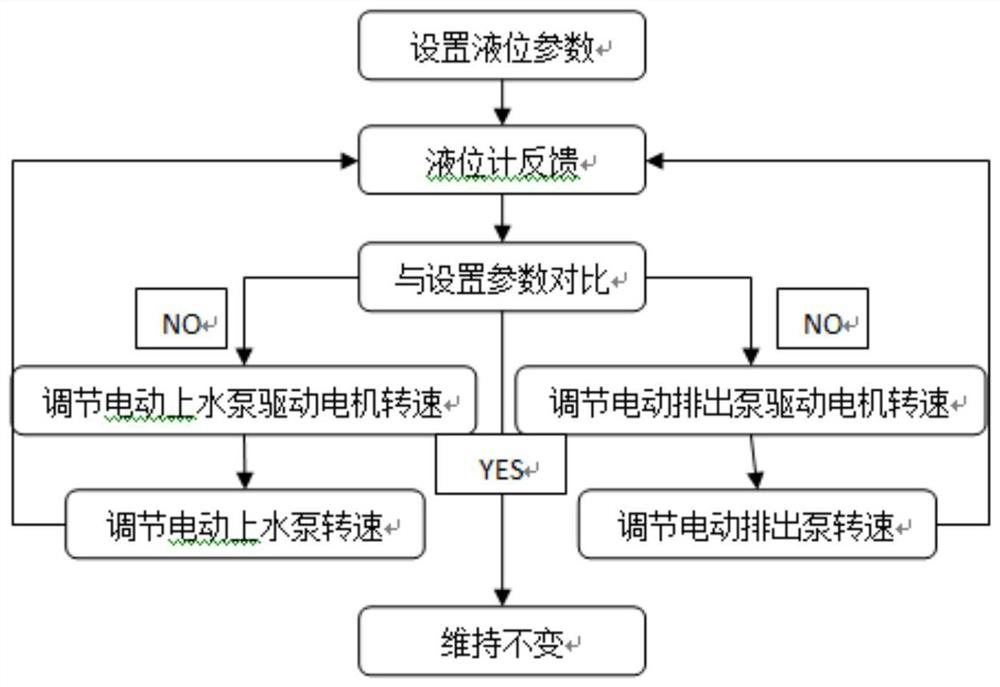

An electric drive fracturing fluid continuous mixing skid

ActiveCN109796956BSimple structureReasonable designMixer accessoriesDrilling compositionElectric dischargeFracturing fluid

Owner:四机赛瓦石油钻采设备有限公司 +1

Intelligent urban wind driven generator

InactiveCN108317049APrevent collapseWon't hitFinal product manufactureWind motor supports/mountsWind drivenTower

The invention discloses an intelligent urban wind driven generator. The wind driven generator comprises a base, a tower frame is arranged on the base, a wind driven generator body is arranged on the upper portion of the tower frame, an arc tower frame turnover groove is formed in the base, a tower frame turnover device is arranged between two groove walls of the arc tower frame turnover groove, and is connected with the lower portion of the tower frame, and an induced air device is arranged on a groove opening of the arc tower frame turnover groove in a covering manner. Compared with the priorart, the intelligent urban wind driven generator has the beneficial effects that the structure is simple and practical, the generator is suitable for the weather abnormal area with strong wind blown,wind pressures of the strong winds to the wind driven generator body and the tower frame can be effectively avoided, the phenomenon that the tower frame bears too strong wind pressure, and the towerframe collapses is avoided, reliability of the generator is improved, the service life of the generator is prolonged, the wind driven generator can continuously generate power, the use rate of the wind driven generator is improved, cost is reduced, and the import substitution rate and the large-scale production are facilitated.

Owner:CHONGQING YIYAO TECH CONSULTATION CO LTD

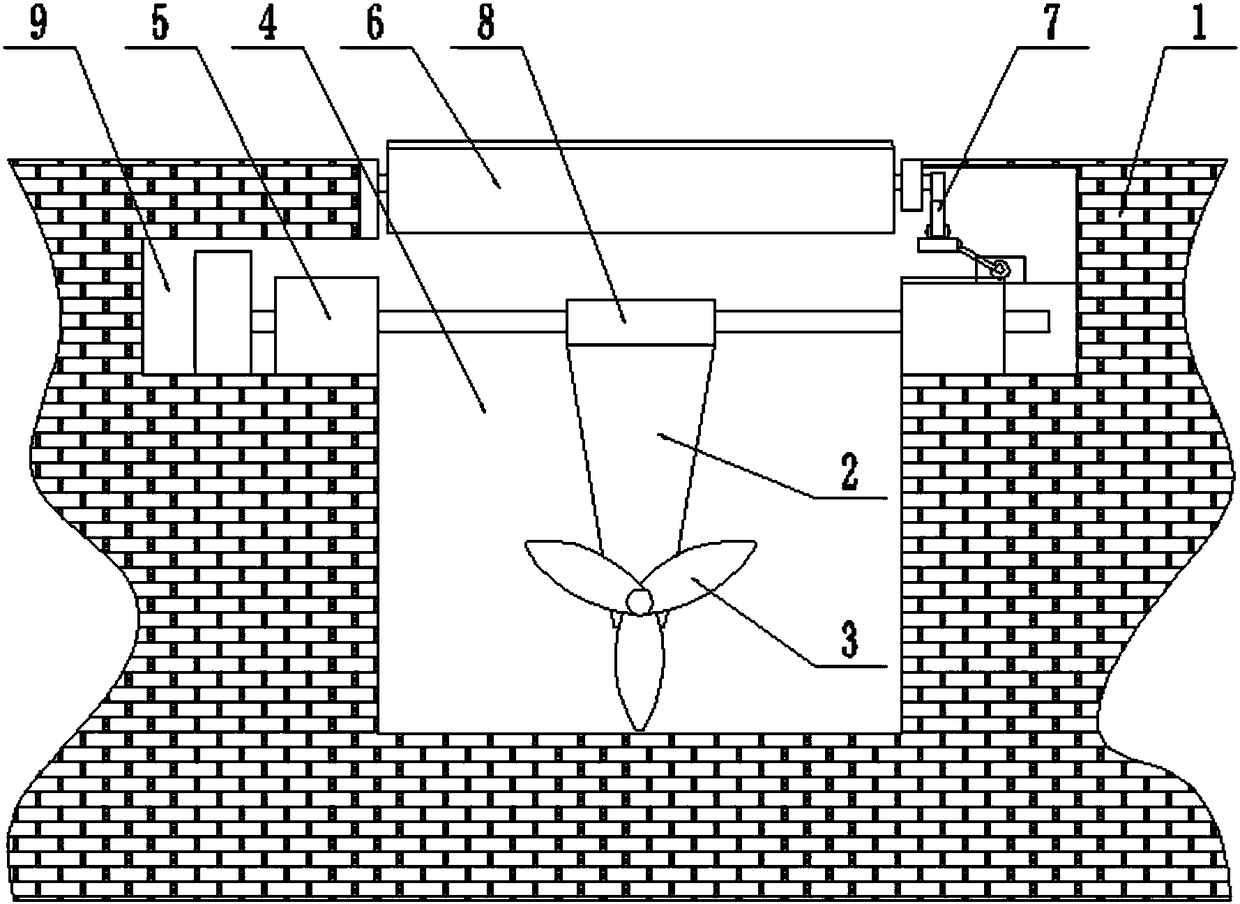

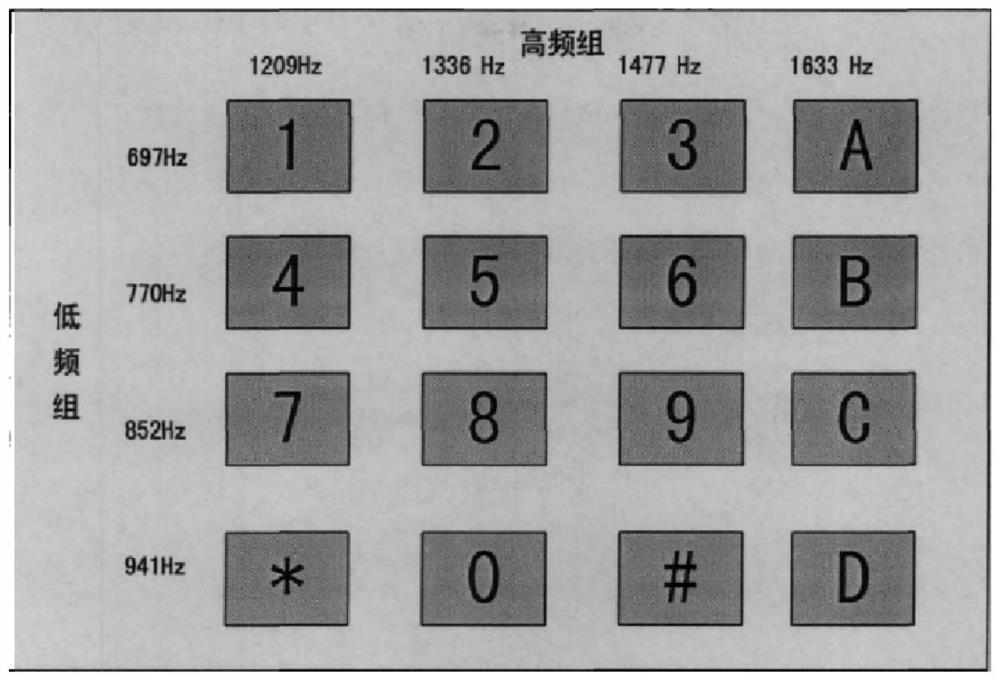

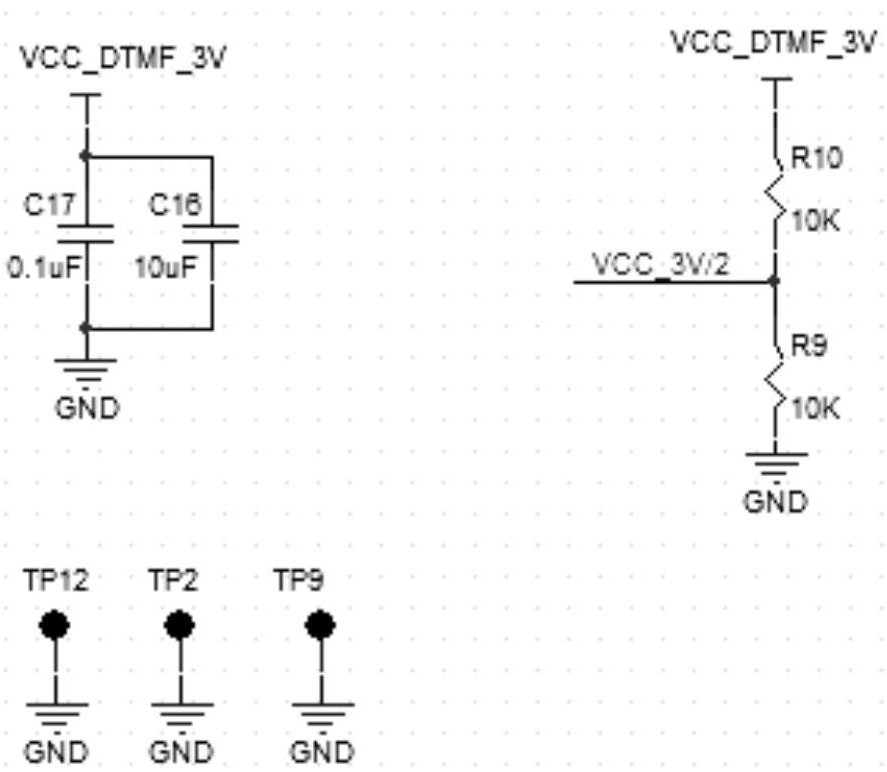

Implementation method for DTMF code transmission of airborne telephone

ActiveCN113556434AResolve dependenciesAddressing the need to reduce power consumptionInterconnection arrangementsBroadcast specific applicationsCapacitanceDirect memory access

The invention provides an implementation method for DTMF code transmission of an airborne telephone, which comprises the following steps of: loading data for generating sine waves into a DMA (direct memory access) module of a single chip microcomputer module, adjusting the conversion rate of two channels of a DAC (digital-to-analog conversion) module by using a timer (TIM) module so as to generate eight sine waves with different frequencies, and outputting the signals from two DAC module ports of the single chip microcomputer; connecting an adder module built based on an operational amplifier, synthesizing two sine waves into a DTMF signal of a fixed frequency group, sending the DTMF signal through the output end of the DAC module, connecting an access selection module, controlling the on-off of the access selection module through the single chip microcomputer, then connecting a signal coupling module, couplingly connecting the signal coupling module to an external power supply line after direct current filtering, impedance matching and capacitance matching, and sending the DTMF signal to a broadcast interphone system. The problem that an existing telephone depends on a DTMF coding chip is solved, power consumption of a system is reduced, and cost is saved.

Owner:SHAANXI BAOCHENG AVIATION INSTR

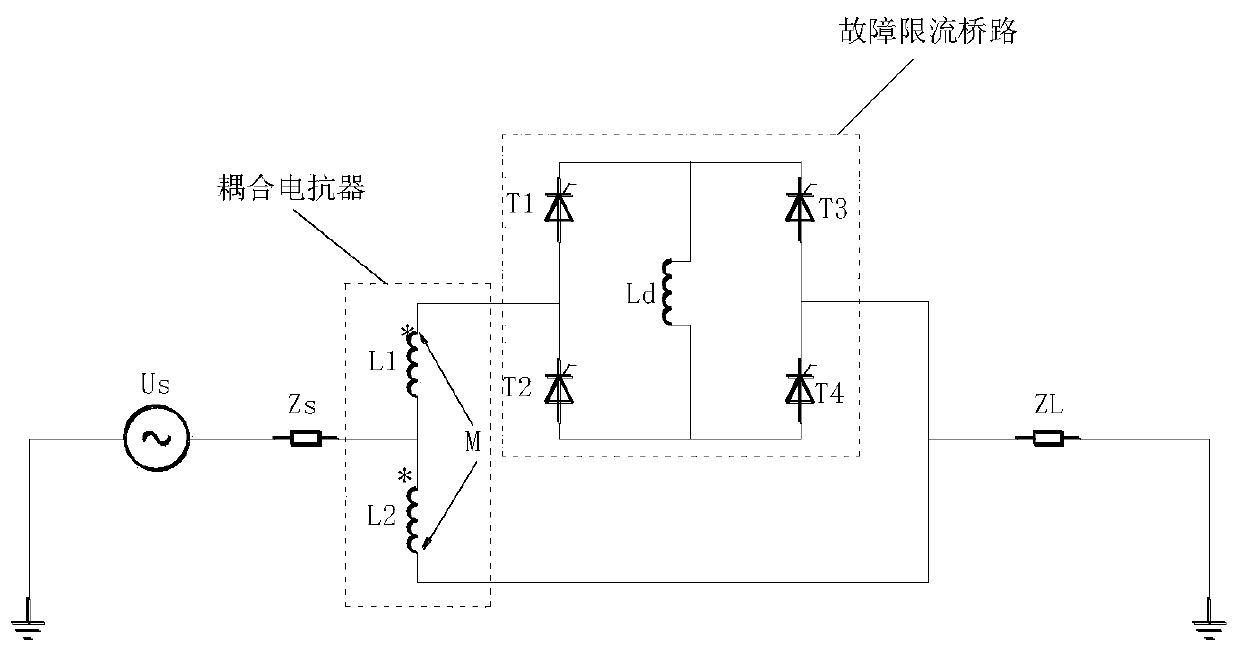

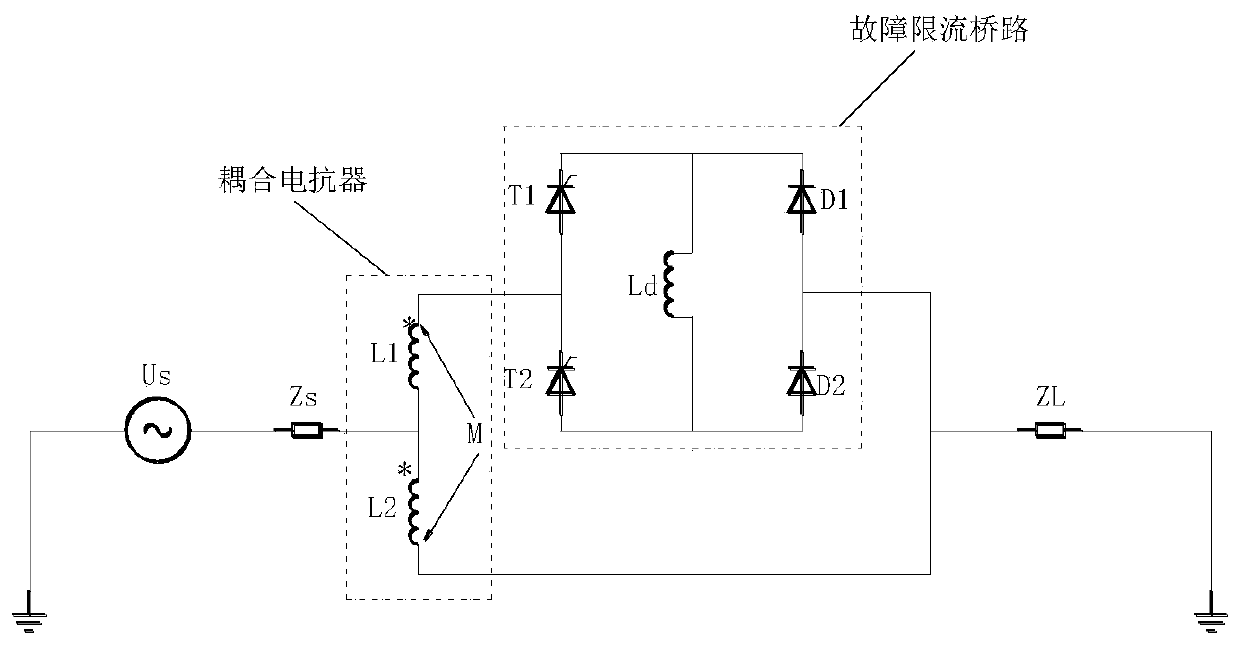

Economical bridge type fault current limiter

InactiveCN111431153ALower impedanceReduce voltage lossTransformers/inductances coils/windings/connectionsAc-dc conversionBridge typeFault current limiter

The invention discloses an economical bridge type fault current limiter. The economical bridge type fault current limiter comprises a coupling reactor and a fault current-limiting bridge circuit. Thefault current-limiting bridge circuit is composed of a single-phase rectifier bridge circuit and a direct-current reactor, the single-phase rectifier bridge circuit is composed of four thyristors or two thyristors and two diodes, and the direct-current reactor is connected to the direct-current output end of the single-phase rectifier bridge circuit in parallel. The coupling reactor is formed by concentrically arranging two sets of windings wound in opposite directions, one winding is connected with the alternating current side of the fault current-limiting bridge circuit in series and then isconnected with the other winding in parallel, and the two windings are connected through a synonym end. According to the invention, the influence on the system during the normal operation of the current limiter is effectively reduced, the fault current-limiting response speed of the current limiter is improved, and the economy and reliability of the current limiter are improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

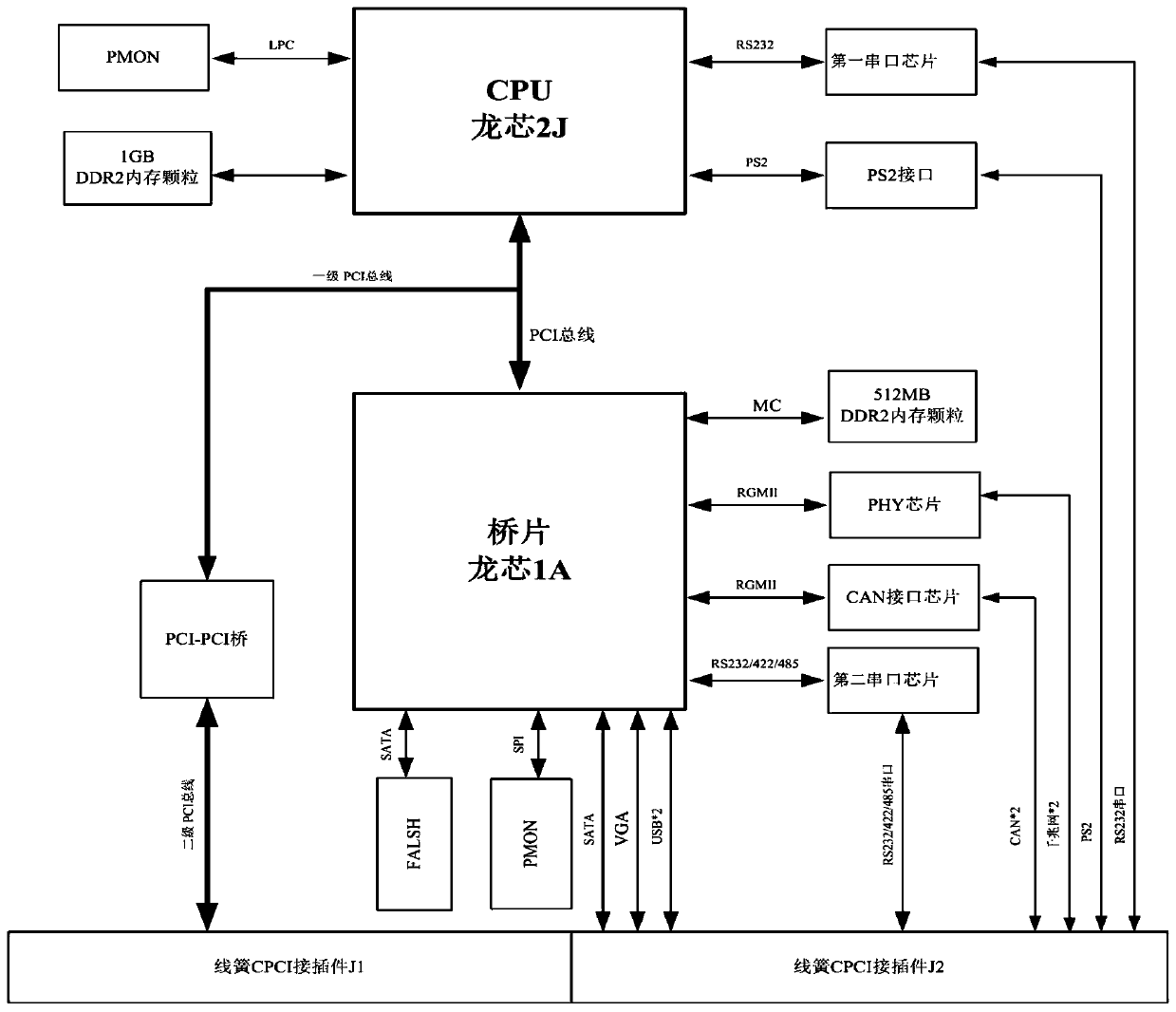

Main board based on wire spring CPCI bus

InactiveCN109783422AImprove the independent and controllable process of localizationImprove reliabilityElectric digital data processingComputerized systemEngineering

The invention discloses a main board based on a wire spring CPCI bus, a Loongson 2J processor is mainly responsible for executing operation and control in a system, a matched bridge chip Loongson 1A is used for managing various peripheral interfaces, the adaptability of the main board is improved, and the main board is used for providing CPCI bus control for the outside through PCI-PCI bridge chip, an imported CPU board card conforming to the CPCI standard can be replaced, and the localization autonomous controllable process of key products of the embedded computer system is improved. The uselevel reaches the military product level, and the device can be used in various severe environments and can be widely applied to various control fields with domestic requirements.

Owner:XIAN MICROELECTRONICS TECH INST

Three-phase multi-raw-material pressurized coal gasification device and process thereof

ActiveCN101760244BIncrease contentReduce contentGranular/pulverulent flues gasificationCombustion chamberHigh pressure

Owner:SHANDONG HUALU HENGSHENG CHEM IND

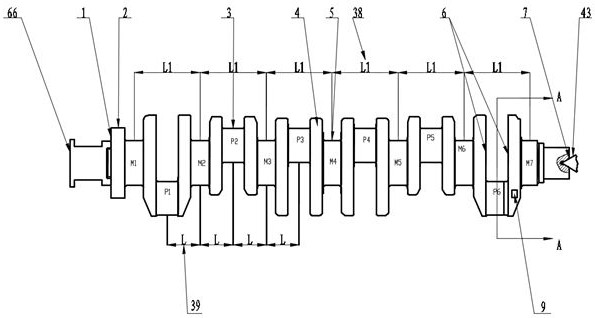

Equipment for machining main connecting journal of crankshaft and end surface of balancing block

PendingCN112296412AEasy to changeHigh degree of automationMilling equipment detailsPositioning apparatusEngineeringMachine tool

The invention relates to equipment for machining a main connecting journal of a crankshaft and an end surface of a balancing block, which is used for machining the crankshaft automatically. A fixed bracket is fixed to the left end of a machine tool body, a movable bracket is slidably connected to the right end of the machine tool body and is connected to a right sliding table through a connectingrod, clamping apparatuses are mounted at the front ends of the two brackets, and an angular positioning device is arranged on an angular positioning clamping apparatus; a cutterhead is driven by a cutterhead spindle to rotate and is fed in perpendicular, vertical and transverse direction; and a milling head box is mounted on a frame, the frame is connected to a sliding table, the sliding table isconnected to a guide rail of the machine tool body, a center rack is connected to a left sliding table, and a skipping distance L between the center rack and the cutterhead on the left side is a center distance between the main journal and an adjacent connecting rod neck. The equipment further comprises a lug type follow-up lifting tool and a cutterhead debugging worktable. It is only needed to detach the crankshaft manually and the crankshaft is clamped automatically by using a hydraulic clamping apparatus, so that the main journal, the connecting journal and the end surface of the balancingblock of the crankshaft can be machined at one time automatically. The equipment can be suitable for machining various crankshafts, and it is convenient to replace the machine tool in type and the equipment is very high in degrees of automation and flexibility.

Owner:XIANGYANG FUDA DONGKANG CRANKSHAFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com