An electric drive fracturing fluid continuous mixing skid

A fracturing fluid and mixing technology, which is applied in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problem of low automation of mixing skids, difficulty in adjusting the operation of mixing skids and mixing data, and mixing and scheduling. problem of large quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

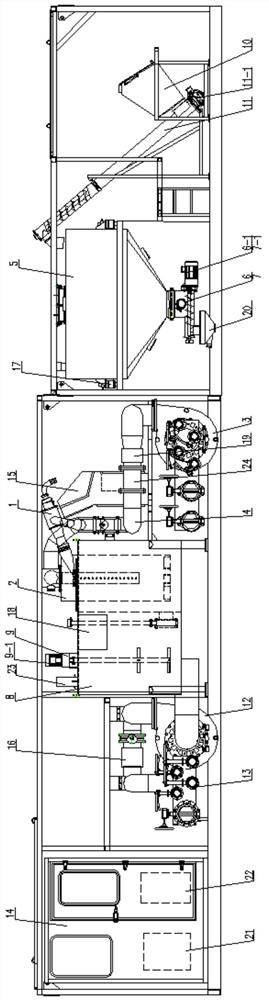

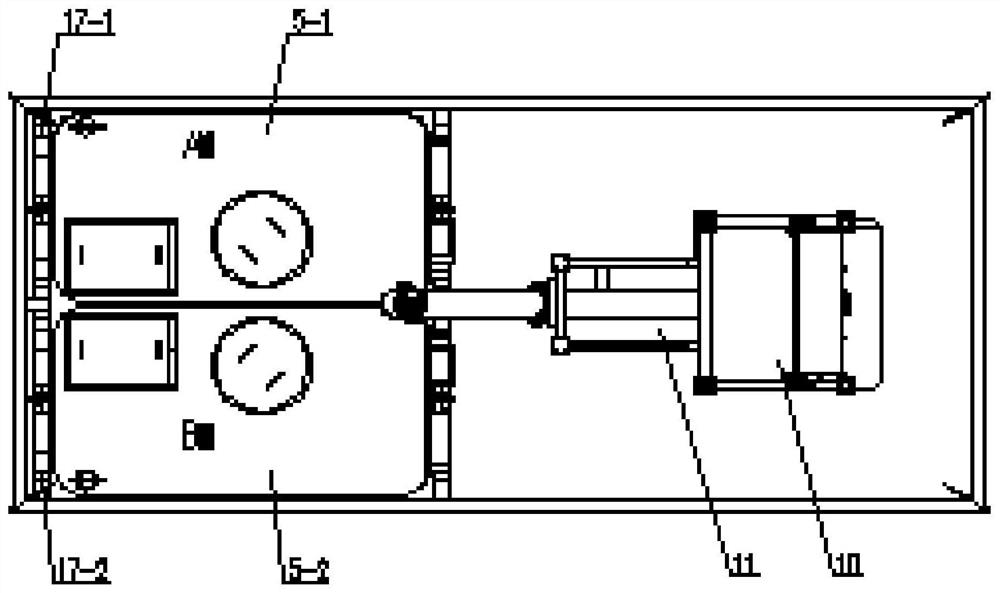

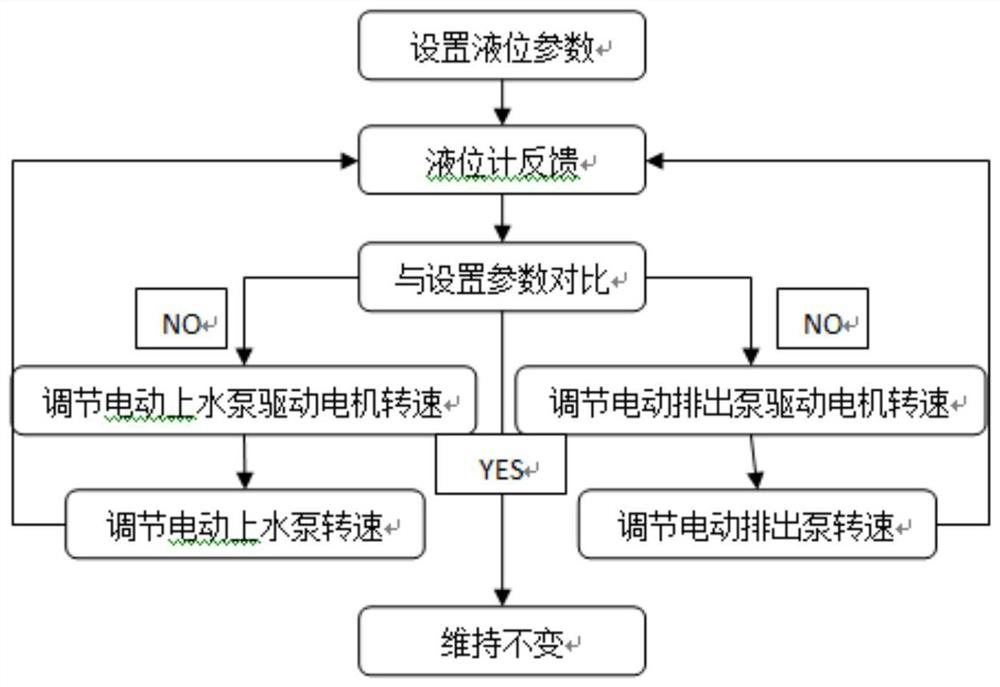

[0029] Please refer to figure 1, an embodiment of the present invention provides an electric drive fracturing fluid continuous mixing skid, including a weight loss metering unit, a hydration unit and a mixing unit connecting the weight loss metering unit and the hydration unit, and also includes a programmable control The mixing unit includes a powder-liquid mixer 1 for mixing powder-liquid into a fluid, and an upper water manifold 4 that is connected to the powder-liquid mixer 1 to inject clean water into it, and to introduce powder into it. pipeline, a centrifugal degassing device 2 to receive the fluid introduced therein, the weight loss metering and feeding unit is provided with a weight loss metering device for measuring its weight loss, and the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com