TBM dual-blade center hobbing cutter and tool

A hob and double-edged technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems that affect the construction progress of tunnel engineering, the limitations of cutting tool performance, and the high cost of imported cutting tools, so as to easily form a stable rolling track , It is not easy to tilt and lose stability, and the effect of preventing tool failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

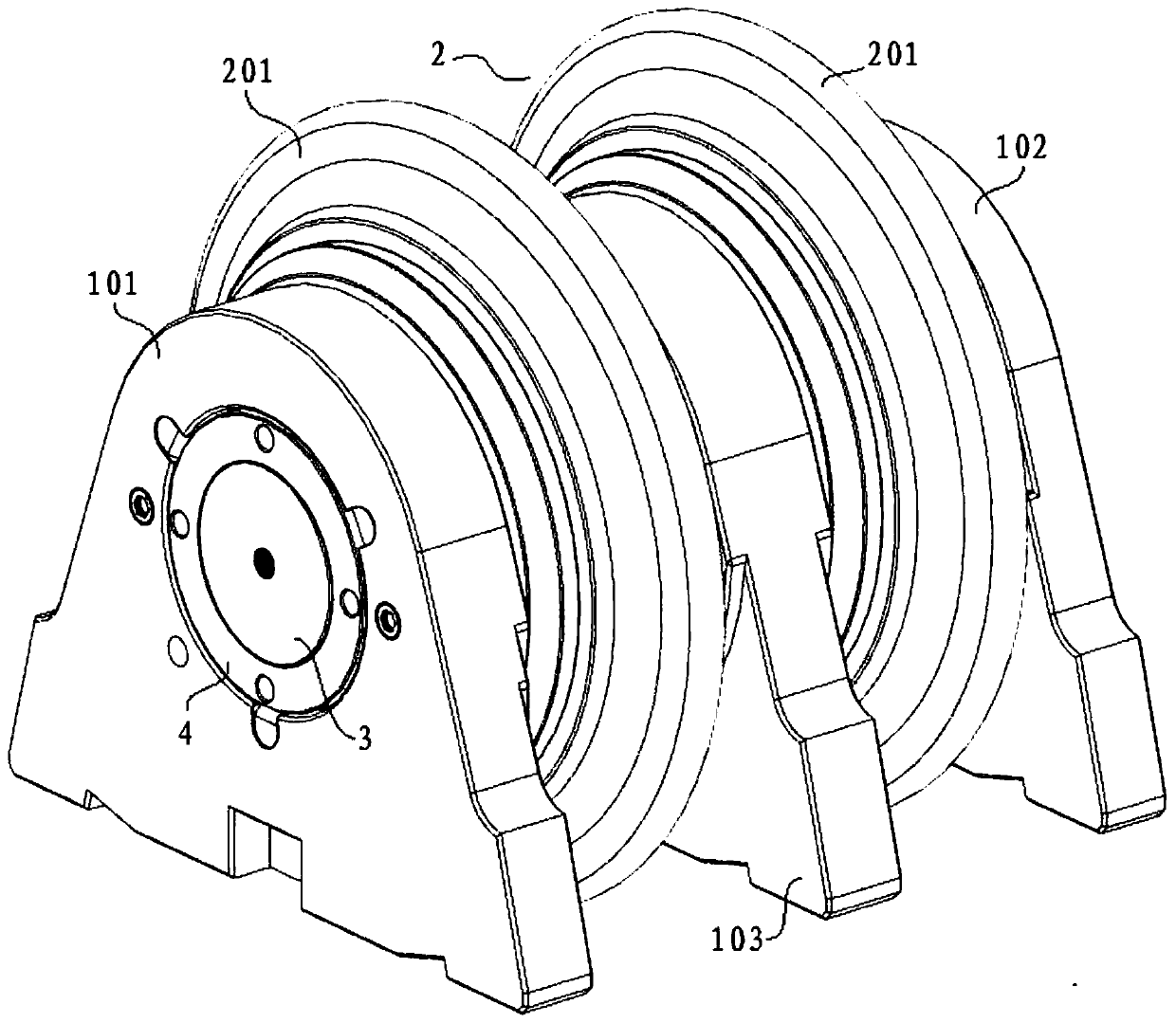

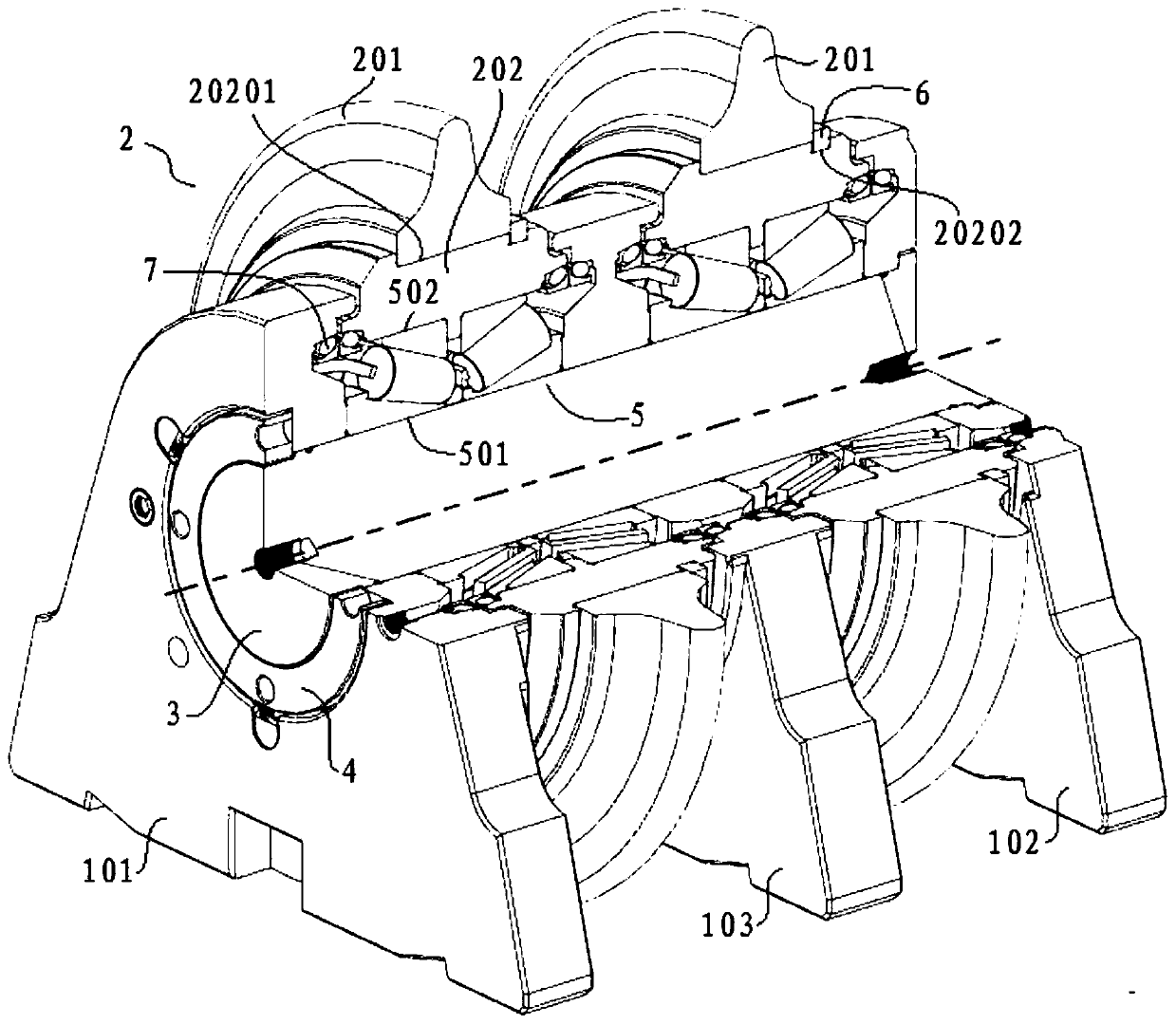

[0063]This embodiment one mainly discloses the structure and working principle of the TBM double-edged center hob of the present invention;

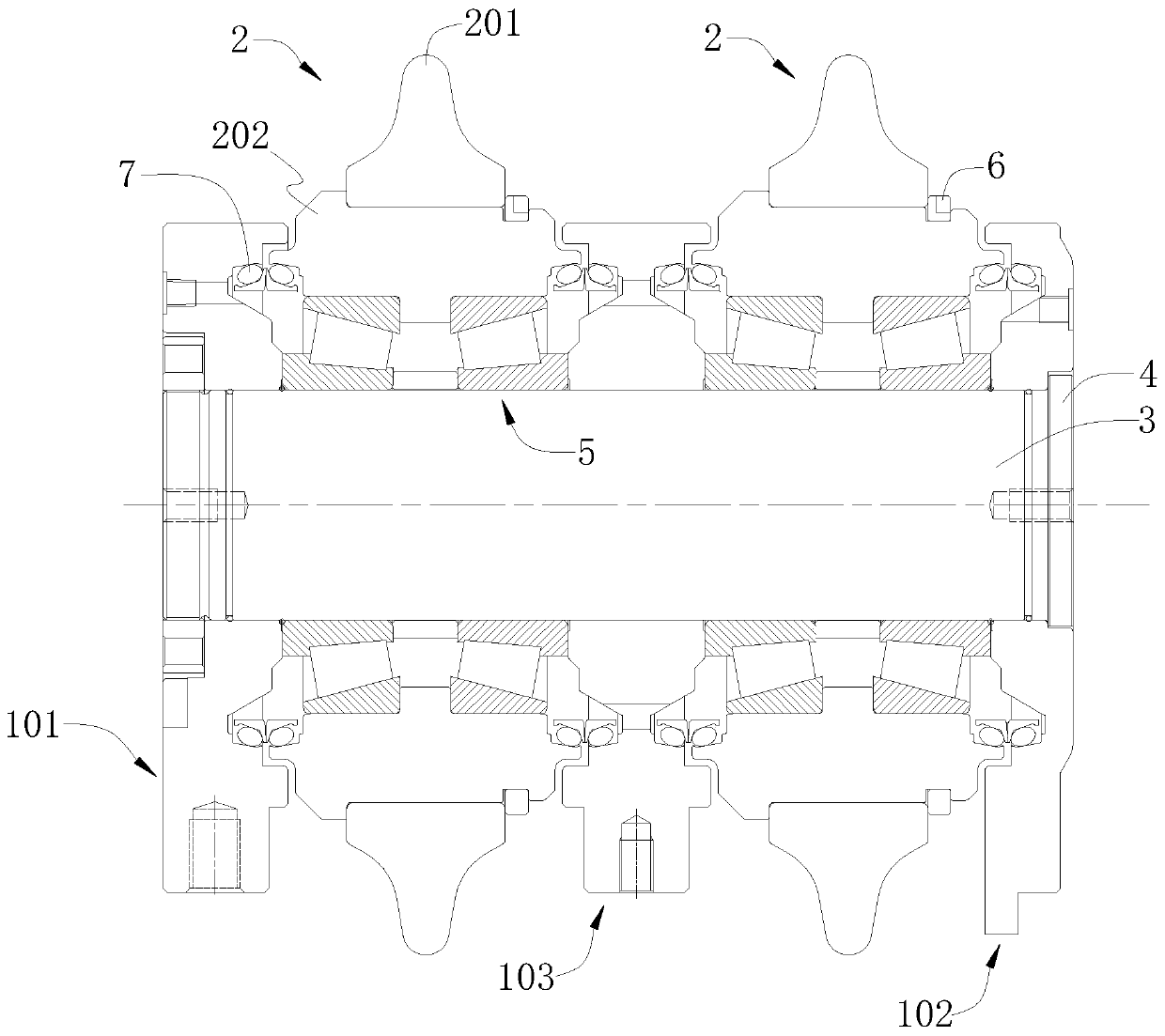

[0064] see Figure 1 to Figure 6 shown.

[0065] Specifically: the TBM double-edged central hob of the present invention, the double-edged central hob comprises:

[0066] end cover assembly;

[0067] a hob unit assembled in the end cover assembly, the hob unit includes two hob bodies 2 arranged at intervals; and

[0068] The bearing 5 assembled on the inner side of the hob body 2;

[0069] This double edge center hob also includes:

[0070] Extending axially along the bearing 5 and passing through the cutter shaft 3 of the end cover assembly;

[0071] The hob body 2 rotates around the axis of the cutter shaft 3 through the bearing 3;

[0072] The bearing 5 is a tapered roller bearing, and the installation taper angle of the tapered roller of the tapered roller bearing relative to the axis of the cutter shaft 3 is θ;

[0073] The i...

Embodiment 2

[0100] A TBM cutter disclosed in Embodiment 2 is integrated with the above-mentioned double-edged central hob.

[0101] In the above technical solution, a TBM double-edged center hob and cutter provided by the present invention have the following beneficial effects:

[0102] The TBM double-edged center hob and cutting tool of the present invention reduce the installation taper angle of the tapered roller of the tapered roller bearing, which can effectively reduce the axial force component of the cutting tool, and the tapered roller bearing adopted by the present invention is more efficient than imported bearings. The width is narrower. Due to the narrower width of the support seat of the inner ring of the bearing and the tapered roller, the force bearing area is reduced and the pressure is increased. It is easier to form a stable rolling ring track under the heavy load pressure of normal work, and it is not easy to tilt and lose stability. ; The installation taper angle is red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com