Multi-step multi-edge gradient micro toothed cutter for drilling carbon fiber reinforced plastics

A composite material, multi-step technology, applied in the direction of tools for lathes, manufacturing tools, accessories of tool holders, etc., can solve the problems of low carbon fiber with interlayer strength, delamination, tearing and burrs, and difficult to guarantee processing quality. , to achieve the effect of improving removal efficiency, improving processing efficiency and reducing axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

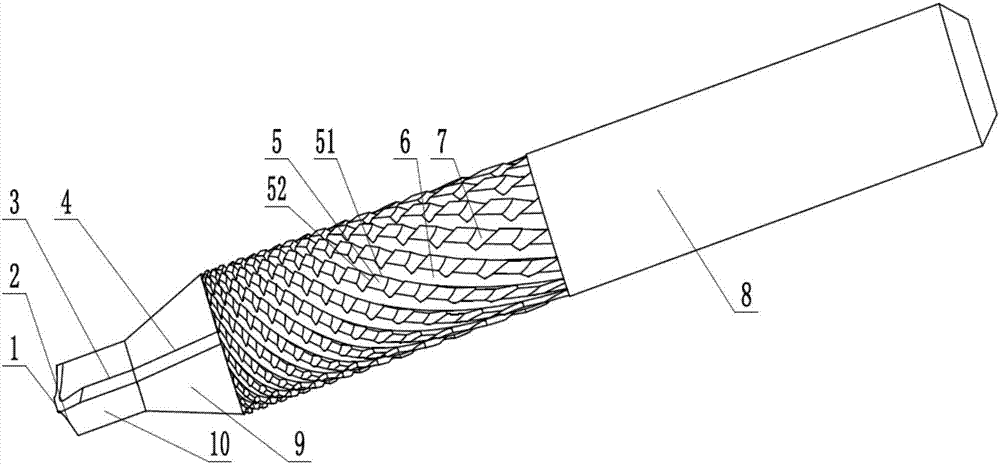

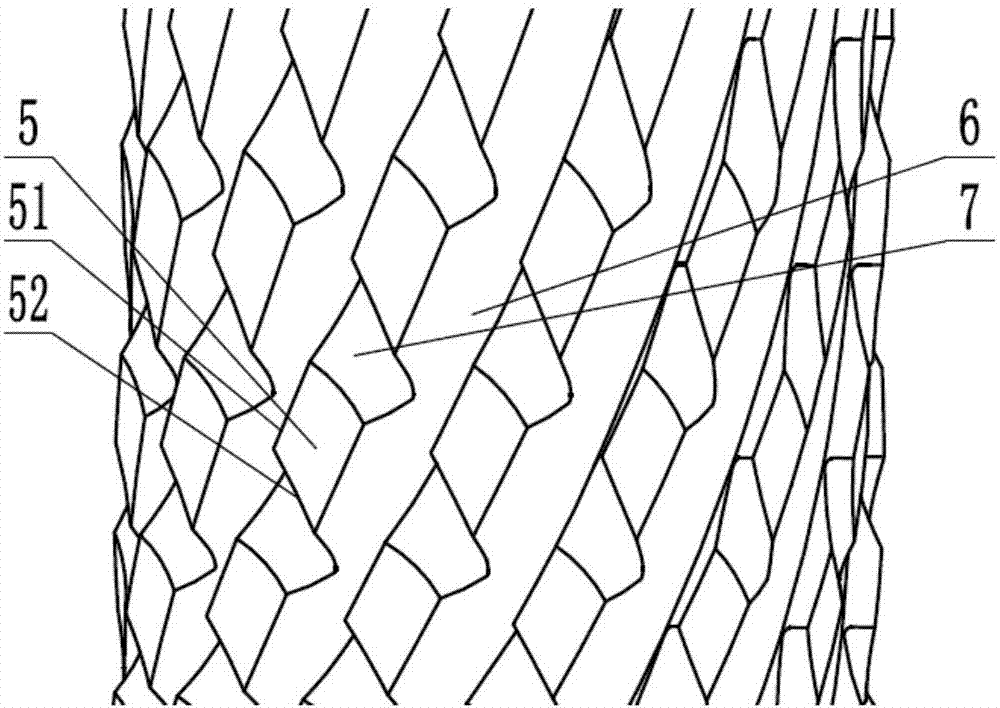

[0019] A multi-step multi-blade gradient micro-tooth tool for hole making of carbon fiber composite materials, including a straight-edged drilling area, a reaming area, a trimming area and a handle 8, the outer diameter of the front end of the reaming area and the straight-edged drilling area The outer diameter of the rear end is the same as that of the trimming area;

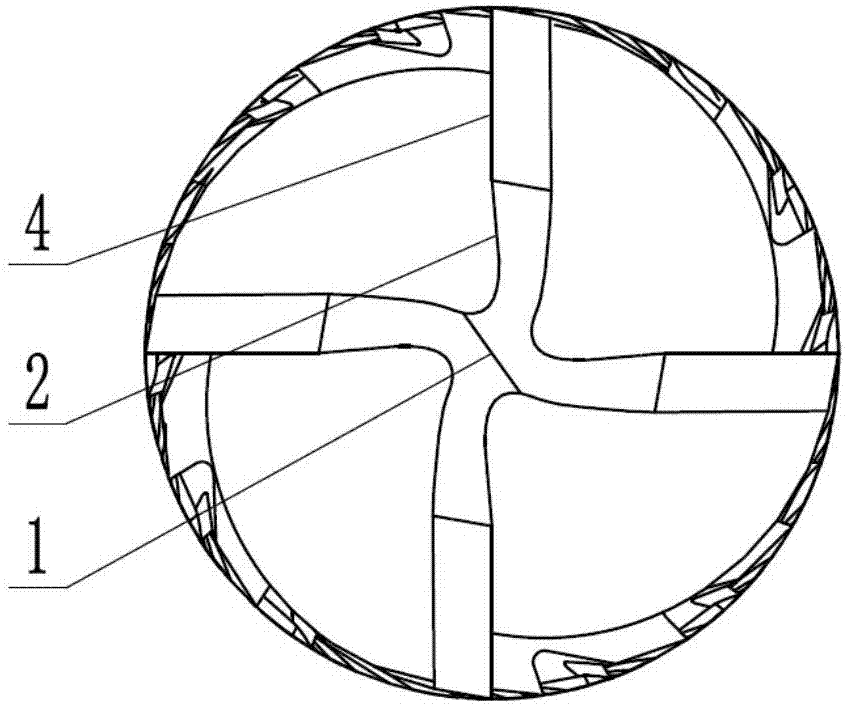

[0020] The straight edge drilling area has four parts: chisel edge 1, main cutting edge 2, minor cutting edge 3 and drilling flute 10, and the two ends of chisel edge 1 are respectively connected with two main cutting edges 2; Four minor cutting edges 3 are evenly distributed in the circumferential direction, two of which are respectively connected to the outer endpoints of the two major cutting edges 2, and there are drilling chip removal grooves 10 between adjacent two minor cutting edges 3;

[0021] The reaming area has two parts, the reaming cutting edge 4 and the reaming chip removal groove 9. Along the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com