Dynamo-electric machine

A motor-generator and stator technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of insufficient contact area, increased vibration and noise, etc., to increase the degree of fixation, reduce vibration and noise, prevent The effect of reducing the axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

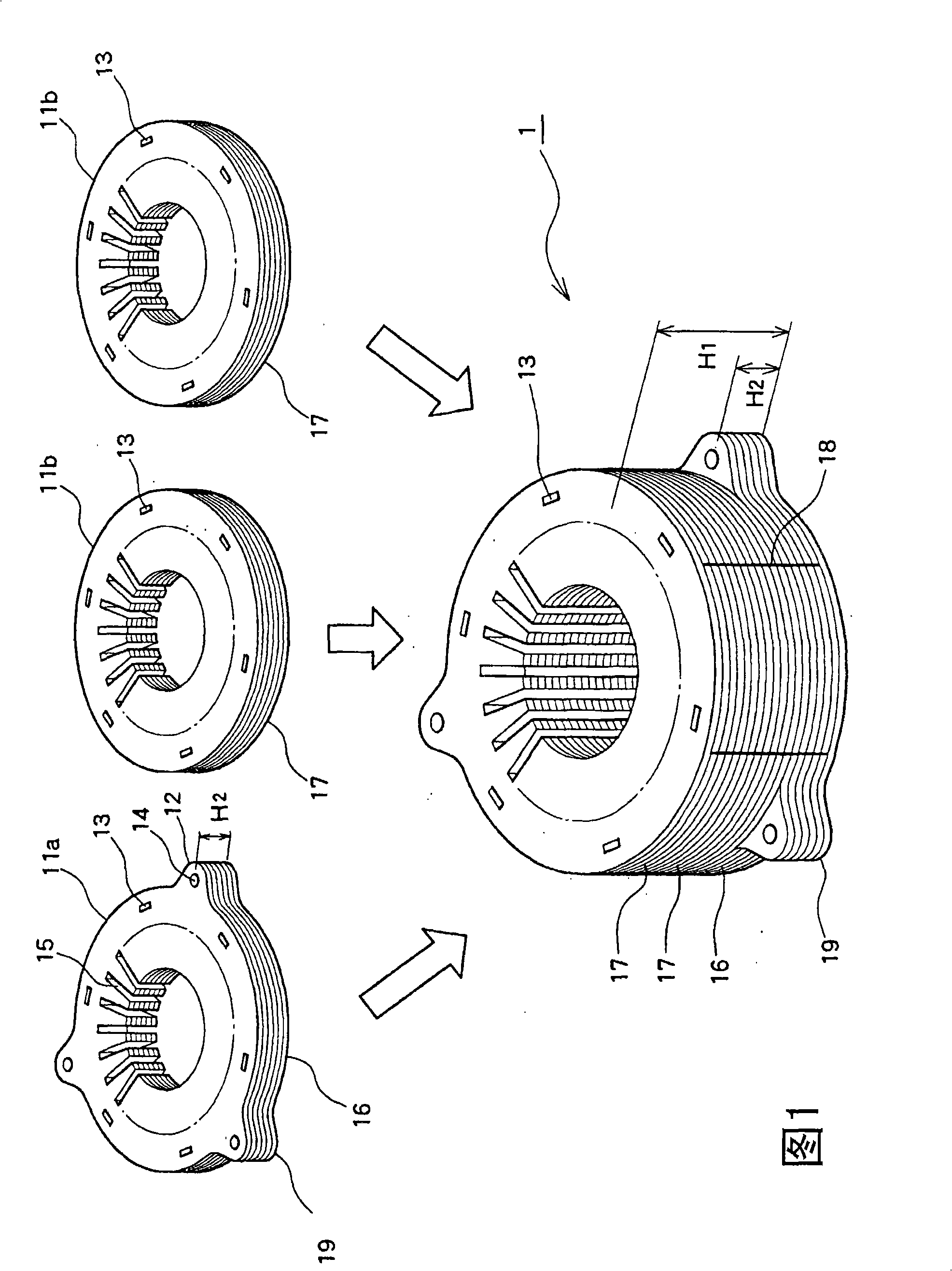

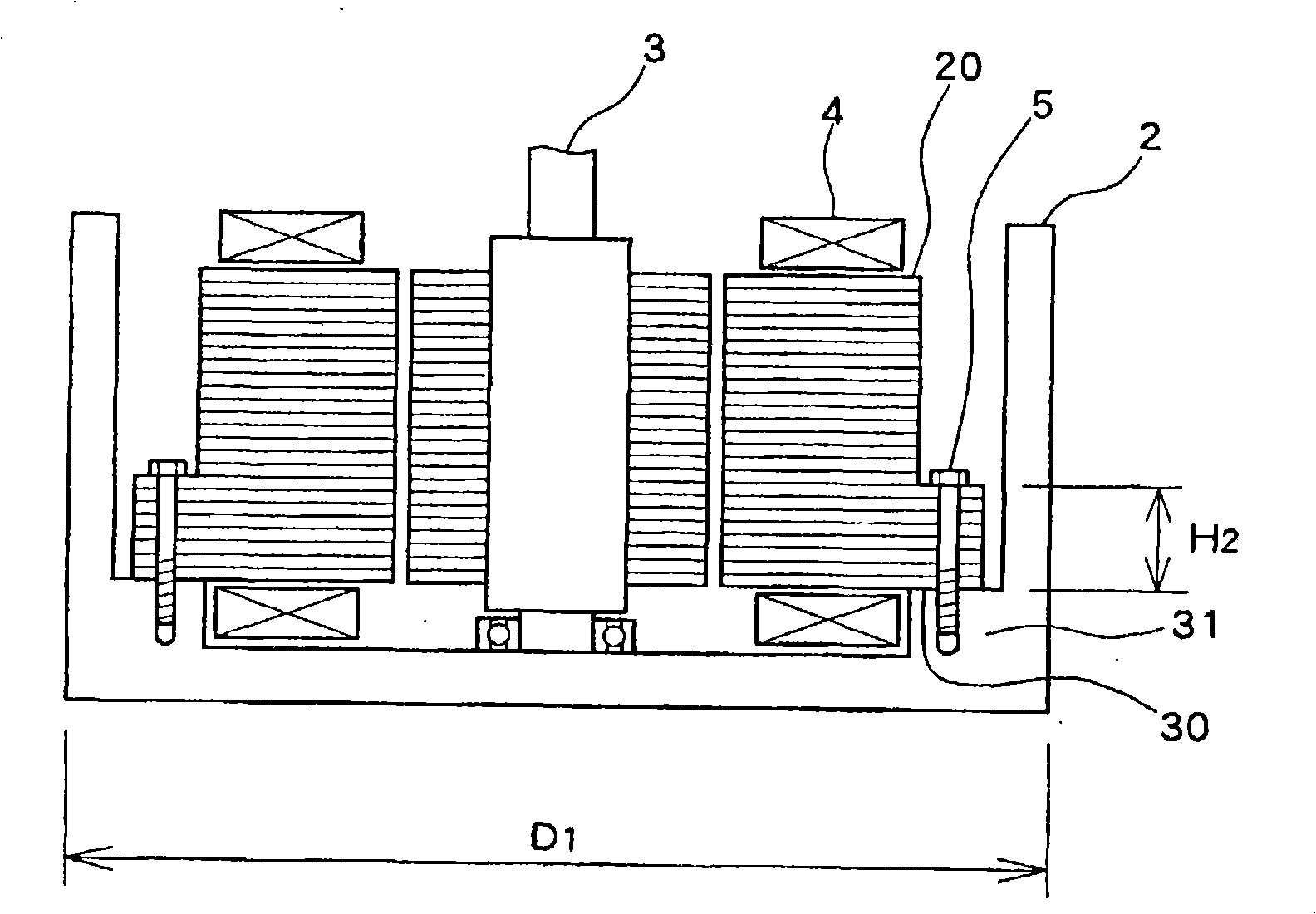

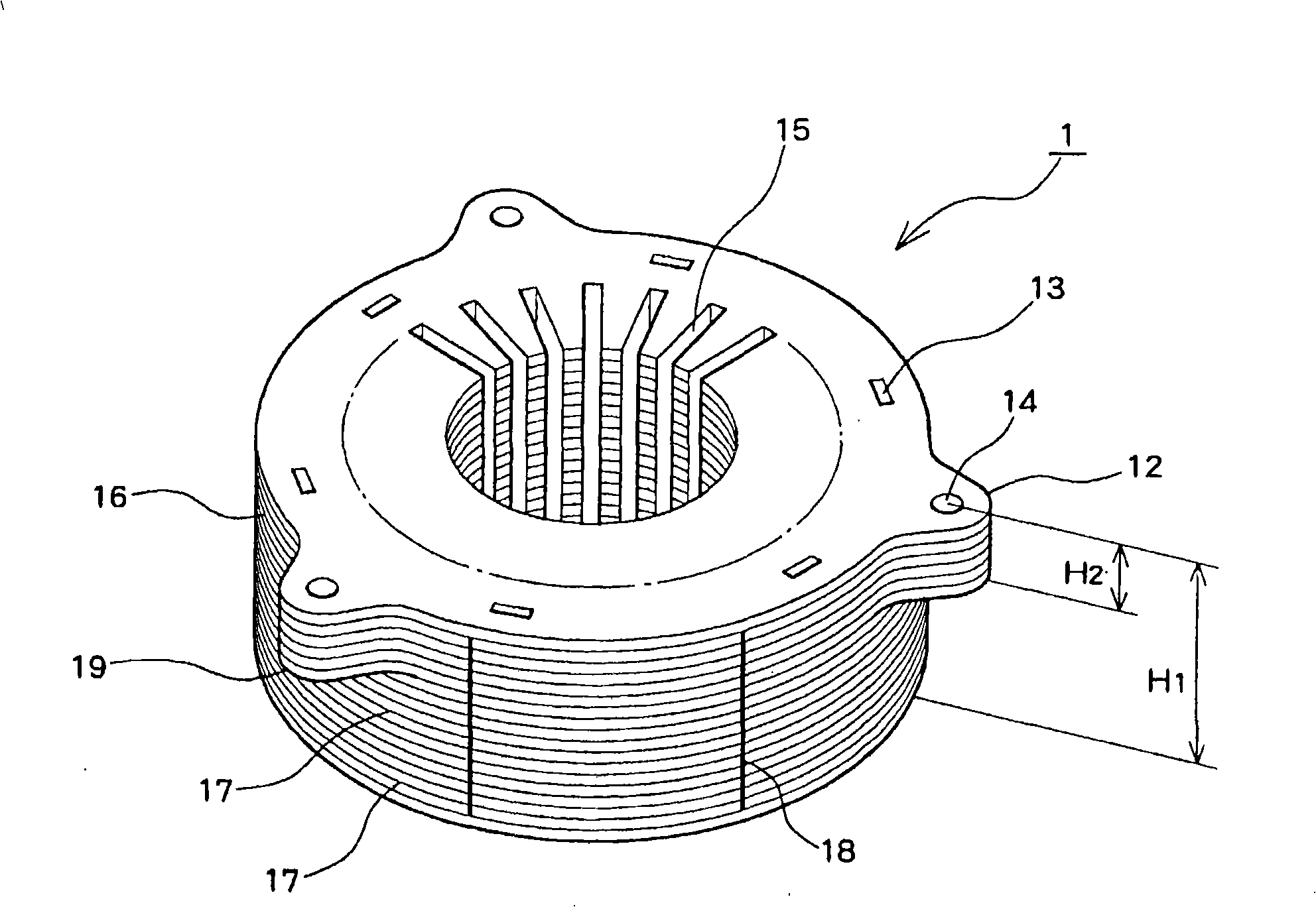

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. 1 and 2 are schematic diagrams of a stator core 1 of a motor generator according to a first embodiment of the present invention, image 3 and 4 is an explanatory diagram of a stator core 1 of an electric motor according to a second embodiment of the present invention, and FIGS. 5 and 6 are schematic views of a stator core 1 of an electric motor according to a third embodiment of the present invention.

[0018] Fig. 1 is a perspective view of a method of manufacturing a stator core 1 in a first embodiment of the present invention. The stator core 1 is constituted by a first lamination block 16 having protrusions 12 in which bolt holes 14 are formed, and a second lamination block 17 having no protrusions 12 . Similar to the prior art described above, the first laminated block 16 is manufactured by punching a fixed-sized electromagnetic steel sheet into the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com