Pipeline shielding structural electric pump working in manner of internal circulation

A technology of shielding structure and internal circulation, which is applied to the components of pumping devices for elastic fluids, non-variable pumps, pumps, etc., and can solve the problem of reliable operation of the external circulation structure and poor self-adjustment ability of axial force , high wear rate of graphite bearings, etc., to achieve the effect of improving self-adjustment ability, reducing load temperature rise, and reducing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

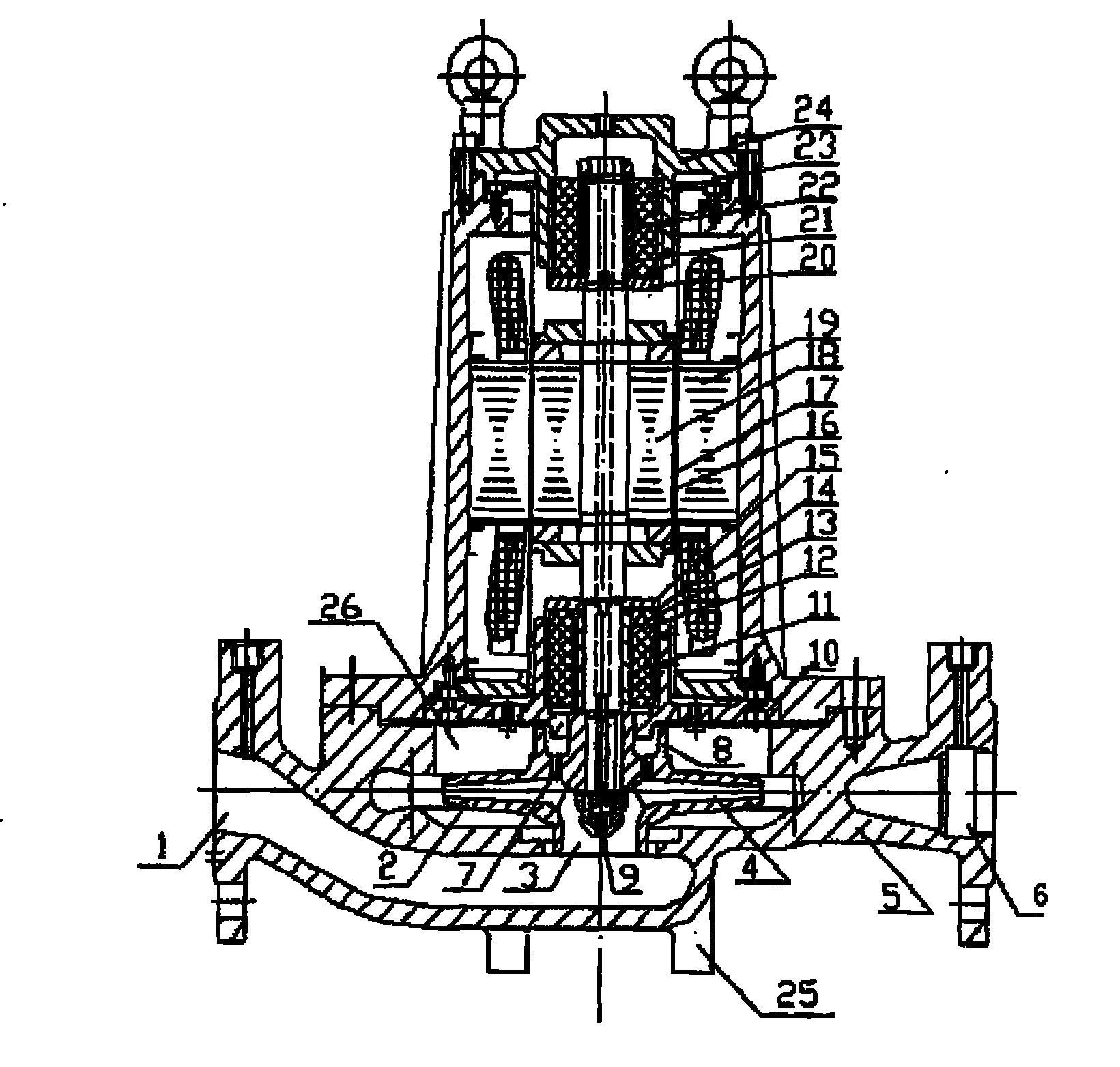

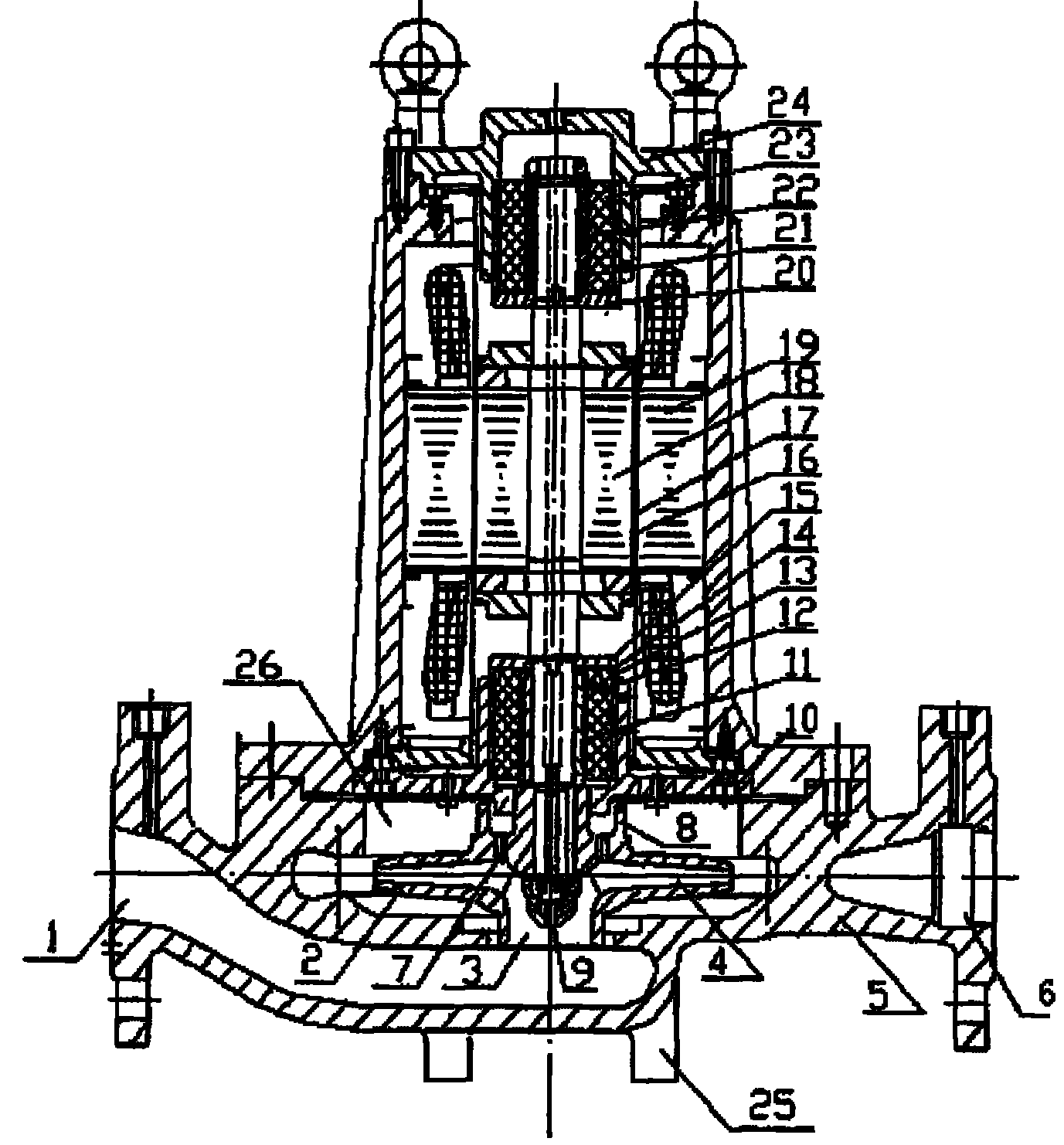

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0018] Due to the characteristics of the pipeline circulating pump: the motor and the pump adopt an integrated structure, all of which are statically sealed, so that the electric pump is completely leak-free; the fully-closed, leak-free structure can transport toxic and harmful liquid substances; The fan makes the pump run with low noise and quietness, which is suitable for occasions with high environmental noise requirements; the use of graphite sliding bearings lubricated by the conveying medium makes the operation noise lower and does not require manual refueling, which reduces maintenance costs; the vertical structure can be like a valve Installed on the pipeline, the installation is convenient and fast, and only the motor and impeller need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com