Test method of test system for passive hydrogen recombiner

A testing method and a testing system technology are applied in the testing field of a passive hydrogen recombiner testing system, which can solve the problems of no passive hydrogen recombination device testing and other problems, and achieve the effects of simple structure, improved localization rate, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

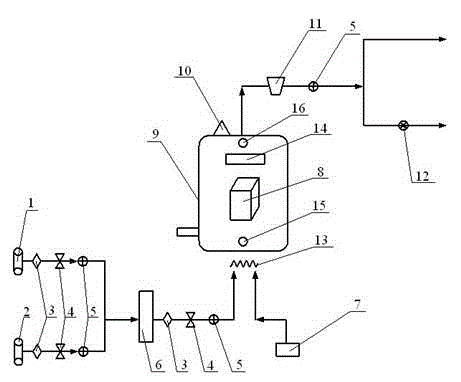

[0050] like figure 1 As shown, the passive hydrogen recombiner test system mainly includes a gas mixing tank 6, a reaction vessel 9 and a sampling unit 12 connected in sequence, and a steam generator 7 is also connected to the inlet end of the reaction vessel 9.

[0051] In order to ensure the accuracy of the detection of the sampling unit, a water eliminator 11 is provided between the reaction vessel 9 and the sampling unit 12, which can remove the reacted water; There is also a flow controller 5 between them; it is convenient for the sampling unit 12 to test the hydrogen concentration of the outlet gas; and the reaction vessel 9 is provided with a safety valve 10 .

[0052] In order to reliably prevent the propagation of flashback and explosion waves, and to quickly discharge the gas into the atmosphere, and to automatically cut off the gas source, a flashback arrestor is arranged between the gas mixing tank 6 and the reaction vessel 9 3; and in order to ensure the one-way ...

Embodiment 2

[0072] Use the passive hydrogen recombiner test system and test method in embodiment 1 to detect the stable reaction performance of the recombiner, and the detection method is as follows:

[0073] When testing a recombiner, at a total intake flow rate of 650m 3 Under the conditions of temperature 350°C and pressure 0.65MPa, 1~4vol% hydrogen and the remaining proportion of oxygen are passed into the reaction vessel. After a period of time, the reaction is stabilized. The same, the hydrogen concentration is also detected by the sampling unit, and the recombination hydrogen amount and recombination efficiency under the detection of this item are calculated through the flow rate displayed on the flow controller. When the recombination hydrogen amount reaches 2.4kg / h or more, the recombination efficiency Reaching more than 90%, the compounder is a qualified product.

[0074] When testing two compounders at the same time, the only difference from testing one compounder is that the ...

Embodiment 3

[0076] Use the passive hydrogen recombiner test system and test method in Example 1 to detect the repeatability of the recombiner. This test mainly examines the repeatability of the recombiner hydrogen content and recombination efficiency in multiple tests to evaluate Reliability and service life of the recombiner. Its detection method is as follows:

[0077] The specific steps of this detection method are the same as the stable reaction performance detection steps and parameters, the only difference is that the test is carried out 5 times in a cycle. When the recombination hydrogen amount of a single recombiner reaches more than 2.4kg / h in each test, the recombination efficiency reaches 90%. Above, it shows that the repeatability of the compounder is qualified.

[0078] When testing two compounders at the same time, the only difference from testing one compounder is that the total intake flow is 1500m 3 / h; when detecting three compounders at the same time, the difference f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com