Method for continuously measuring rotating speed of main heat transfer pump in nuclear island from reverse rotation to forward rotation

A transfer pump, forward rotation technology, applied in the fields of nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve the problems of high price, no analog output, no ability to distinguish between forward rotation signals and reverse rotation signals, etc., to reduce imported products, The effect of increasing the localization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more obvious and comprehensible, preferred embodiments are described in detail below with reference to the accompanying drawings.

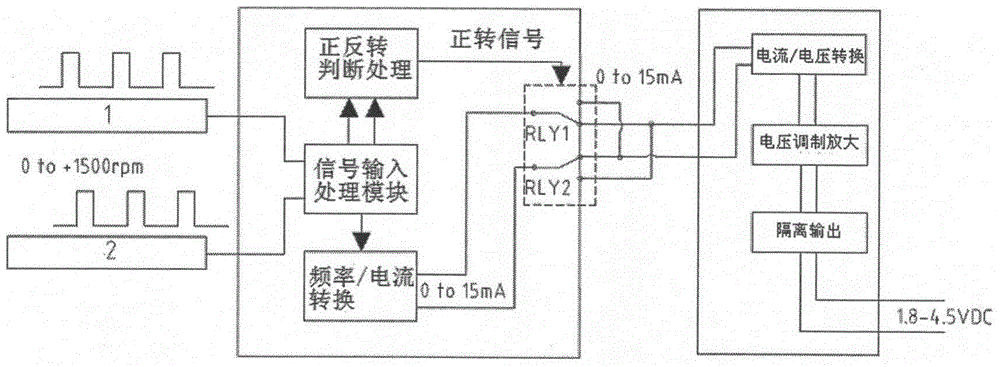

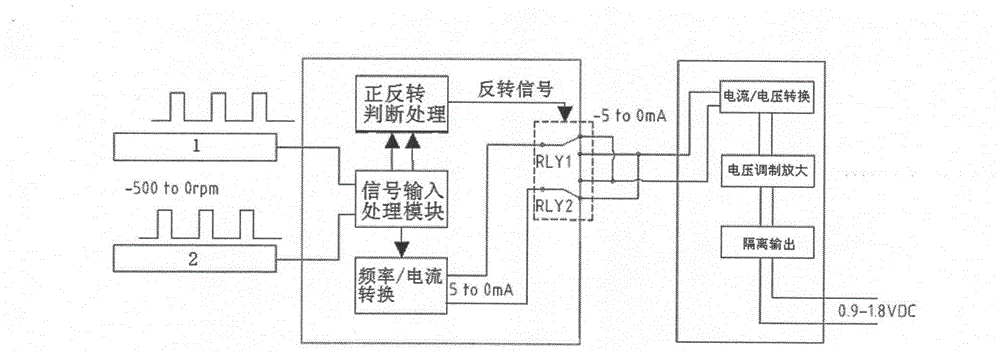

[0022] The method provided by the present invention uses a rotational speed conversion regulator, which includes two inductive proximity switches, a rotational speed signal processing unit and a signal modulator.

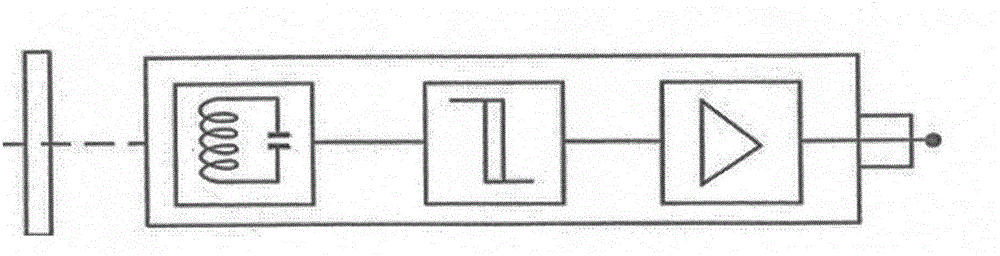

[0023] like figure 1 As shown, the inductive proximity switch consists of three parts: oscillator, switch circuit and amplifier output circuit. The oscillator generates an alternating magnetic field, and when it reaches the sensing distance, an eddy current is generated in the gear disc under test, which causes the oscillation to decay and even stop the vibration. The changes of oscillator oscillation and vibration stop are processed by the post-amplifier circuit and converted into switching signals and input to the rotational speed signal processing unit, so as to achieve the purpose of no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com