Antistatic coating, antistatic release film with high adhesion and stability and preparation method of antistatic release film

An antistatic, release film technology, applied in conductive coatings, cellulose coatings, coatings, etc., can solve the problems of unstable release film antistatic performance, peeling failure, poor adhesion, etc., to solve the antistatic effect Bad, contamination reduction, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

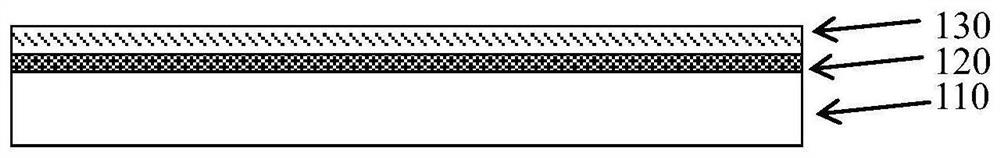

[0058] The antistatic release film to be prepared in this embodiment, such as figure 1 As shown, it includes a PET film base layer 100 (with a thickness of 100 μm), an antistatic layer 120 disposed on the PET film base layer, and a release layer 130 disposed on the antistatic layer.

[0059] In the present embodiment, the antistatic coating, by weight, consists of: 0.05 parts of single-walled carbon nanotube powder (Tuball), 100 parts of deionized water, 0.05 parts of DNA (Sigma), 0.05 parts of cellulose (Acros, MW=100000), 0.05 part of sodium deoxycholate (Acros Organics), 0.05 part of polyvinylpyrrolidone (Damas-beta, MW=10000).

[0060] In the present embodiment, the release coating, in parts by weight, consists of: 100 parts of alkenyl polysiloxane (Zhejiang Yaoyang New Material Technology Co., Ltd.), 2 parts of platinum catalyst (Zhejiang Yaoyang New Material Technology Co., Ltd.), 15 parts of toluene solvent oil (Chengdu Changlian Chemical Reagent Co., Ltd.).

[0061] ...

Embodiment 2

[0094] In the present embodiment, the antistatic coating, by weight, consists of: 0.05 part of multi-walled carbon nanotube powder (Nanocyl NC7000), 100 parts of deionized water, 0.05 part of DNA (Sigma), 0.05 part of cellulose (Acros , MW=100000), 0.05 part of sodium deoxycholate (Acros Organics), 0.05 part of polyvinylpyrrolidone (Damas-beta, MW=10000).

[0095] The preparation steps of the antistatic coating prepared in this example are as follows. Add the multi-walled carbon nanotubes, sodium deoxycholate, DNA, cellulose, and polyvinylpyrrolidone into the spherical kettle, and ball mill for 48 hours to make the single-walled carbon nanotubes uniform. Disperse in deionized water to obtain an aqueous dispersion with a weight percentage of multi-walled carbon nanotubes of about 0.05%, which is an antistatic coating.

[0096] The steps of this embodiment refer to steps (2)-(5) given in Embodiment 1.

[0097] The antistatic release film prepared in this example has an antistat...

Embodiment 3

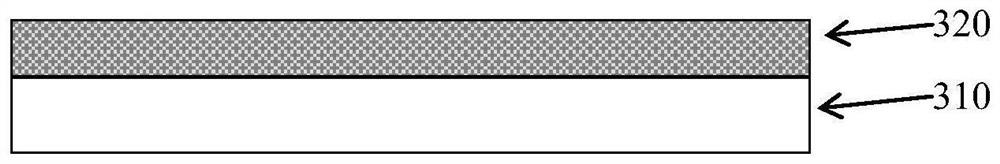

[0109] The antistatic release film to be prepared in this embodiment, such as image 3 As shown, it includes a PET film base layer 310 (with a thickness of 100 μm), and an anti-static release layer 130 disposed on the PET film base layer.

[0110] In the present embodiment, the antistatic coating, in parts by weight, consists of: 0.05 part of multi-walled carbon nanotube powder (Nanocyl NC7000), 100 parts of ethyl acetate (Chengdu Kelong Chemical Co., Ltd.), 0.05 part of dispersant (YIME company, trade mark TNRDIS), 0.05 part of DNA (Sigma), 0.05 part of cellulose (Acros, MW=100000), 0.05 part of sodium deoxycholate (Acros Organics), 0.05 part of polyvinylpyrrolidone (Damas-beta, MW= 10000).

[0111] In the present embodiment, the antistatic release coating, in parts by weight, consists of: 50 parts of antistatic coating, 100 parts of alkenyl polysiloxane (Zhejiang Yaoyang New Material Technology Co., Ltd.), 1.6 parts of platinum catalyst (Zhejiang Yaoyang New Material Techn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com