Color polytetrafluoroethylene release film and preparation method thereof

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the field of mechanical peeling film and electronics, can solve problems such as single color and limited application range, and achieve the effects of convenient operation, wide application range, excellent anti-sticking performance and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

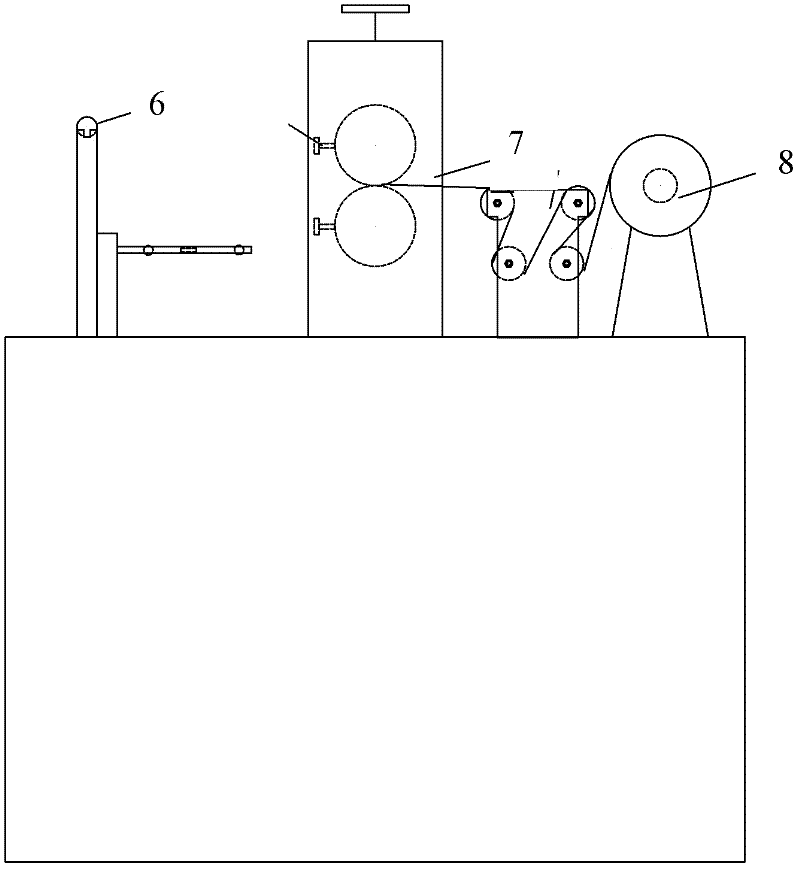

[0021] like figure 1 , figure 2 , image 3 As shown, the manufacturing method of the colored polytetrafluoroethylene release film provided in this embodiment includes the following steps in order:

[0022] 1) Blend polytetrafluoroethylene resin and green titanium-based inorganic pigments as filler materials (special pigments for polytetrafluoroethylene, products of Changzhou Caiyi Chemical Co., Ltd., Jiangsu Province) in a blender at a weight ratio of 100:5 1 minute to make the mixed ingredients;

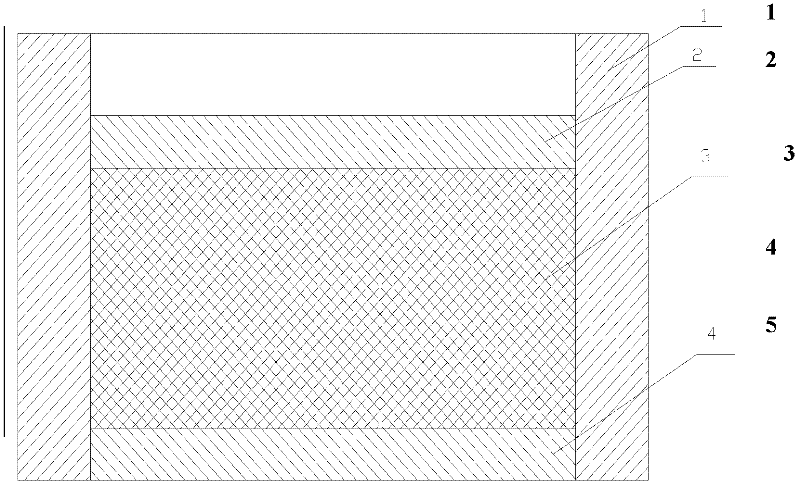

[0023] 2) Put the above-mentioned mixed material 3 in the inner space of the common mold consisting of the outer mold 1, the upper mold 2, the center core 4 and the lower mold 5, and then keep the mixture under the pressure of 20Mpa and the pressurization rate of 16mm / min. Press for 6 minutes to complete the press molding, then release the pressure and release the mold to obtain a semi-finished blank;

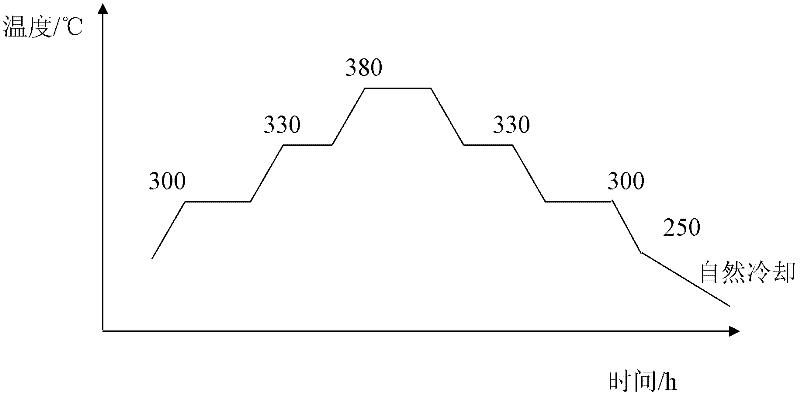

[0024] 3) Put the above-mentioned semi-finished blank into the sintering fu...

Embodiment 2

[0028] like figure 1 , figure 2 , image 3 As shown, the manufacturing method of the colored polytetrafluoroethylene release film provided in this embodiment includes the following steps in order:

[0029] 1) Blend polytetrafluoroethylene resin and red titanium-based inorganic pigments as filler materials (special pigments for polytetrafluoroethylene, products of Changzhou Caiyi Chemical Co., Ltd., Jiangsu Province) in a blender at a weight ratio of 100:3 1 minute to make the mixed ingredients;

[0030] 2) Put the above-mentioned mixed material 3 in the inner space of the common mold consisting of the outer mold 1, the upper mold 2, the center core 4 and the lower mold 5, and then keep the mixture under the pressure of 15Mpa and the pressurization rate of 20mm / min. Press for 6 minutes to complete the press molding, then release the pressure and release the mold to obtain a semi-finished blank;

[0031] 3) Put the above-mentioned semi-finished blank into the sintering furn...

Embodiment 3

[0035] like figure 1 , figure 2 , image 3 As shown, the manufacturing method of the colored polytetrafluoroethylene release film provided in this embodiment includes the following steps in order:

[0036] 1) Put polytetrafluoroethylene resin and blue titanium-based inorganic pigments (special pigments for polytetrafluoroethylene, products of Changzhou Caiyi Chemical Co., Ltd., Jiangsu Province) as filler materials in a blender at a weight ratio of 100:5. Mix for 1 minute to make the mix;

[0037] 2) Put the above-mentioned mixed material 3 in the inner space of the common mold composed of the outer mold 1, the upper mold 2, the center core 4 and the lower mold 5, and then keep it under the pressure of 15Mpa and the pressurization rate of 18mm / min. Press for 6 minutes to complete the press molding, then release the pressure and release the mold to obtain a semi-finished blank;

[0038] 3) Put the above-mentioned semi-finished blank into the sintering furnace, such as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com