Uncured rubber asphalt waterproof coating, preparation method thereof and waterproof reflecting film

A kind of asphalt waterproof coating and non-curing rubber technology, applied in the direction of asphalt coating, coating, etc., can solve the problems of increasing manufacturing cost, complicated production process, increasing component cost, etc., and achieve improved chemical crosslinking degree, high chemical stability, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

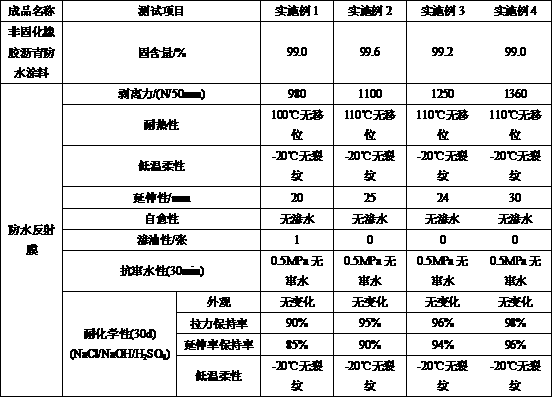

Examples

Embodiment 1

[0039] A kind of non-curing rubber asphalt waterproof coating, its raw material formula is calculated by mass parts, comprises 30 parts of petroleum asphalt; 3 parts of tackifier; 15 parts of softening agent; 10 parts of rubber powder; ; Catalyst 1 part.

[0040] Among them, petroleum asphalt has a penetration of 7mm, a softening point of 48°C, a ductility of 160cm at 10°C, a dynamic viscosity of 180Pa.s at 60°C, and a wax content of 1%. The tackifier is alkylphenolic resin, and the softener is coal. The tar, the rubber powder are montmorillonite, the anionic dispersant is sodium oleate, the thickener is petroleum resin, and the catalyst is dicumyl oxide.

[0041] The above-mentioned non-cured rubber asphalt waterproof coating is prepared according to the following steps:

[0042] Step 1: Heat the petroleum asphalt to 135°C and pour it into a stirring device, stir at a stirring rate of 800 rpm, add softener, rubber powder, and anionic dispersant in proportion, and stir at a c...

Embodiment 2

[0050] A kind of non-curing rubber asphalt waterproof coating, its raw material formula is calculated by mass parts, comprises petroleum asphalt 35 parts; Tackifier 8 parts; Softening agent 10 parts; Rubber powder 15 parts; Anionic dispersant 1 part; Thickener 10 parts ; Catalyst 2 parts.

[0051] Among them, petroleum asphalt has a penetration of 9.5mm, a softening point of 50°C, a ductility of 155cm at 10°C, a dynamic viscosity of 150Pa.s at 60°C, and a wax content of 2%. The tackifier is terpene resin, and the softener is appropriate Er oil, rubber powder is kaolin, anionic dispersant is sulfate ester salt, thickener is coumarone resin, catalyst is triallyl isocyanurate.

[0052] The above-mentioned non-cured rubber asphalt waterproof coating is prepared according to the following steps:

[0053] Step 1: Heat the petroleum asphalt to 138°C and pour it into a stirring device, stir at a stirring rate of 900 rpm, add softener, rubber powder, and anionic dispersant in proporti...

Embodiment 3

[0061] A kind of non-curing rubber asphalt waterproof coating, its raw material formula is calculated by mass parts, including 50 parts of petroleum asphalt; 3 parts of tackifier; 15 parts of softening agent; 10 parts of rubber powder; 2 parts of anionic dispersant; 15 parts of thickener ; Catalyst 0.5 parts.

[0062] Among them, petroleum asphalt has a penetration of 8mm, a softening point of 62°C, a ductility of 161cm at 10°C, a dynamic viscosity of 155Pa.s at 60°C, and a wax content of 0.5%. Alkanes, rubber powder is talc powder, anionic dispersant is sulfonate, thickener is carbon five resin, catalyst is bis-tert-butylperoxycumene.

[0063] The above-mentioned non-cured rubber asphalt waterproof coating is prepared according to the following steps:

[0064] Step 1: Heat the petroleum asphalt to 140°C and pour it into a stirring device, stir at a stirring rate of 1000 rpm, add softener, rubber powder, and anionic dispersant in proportion, and stir at a constant temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com