Preparation method of intelligent glass cathode electrochromic layer coating material

An electrochromic layer, smart glass technology, applied in metal material coating process, coating, sputtering and other directions, can solve the problems of abnormal arc and dust, affecting equipment utilization rate, slow coating rate, etc. Density and uniformity prolongation, chemical stability improvement, film roughness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

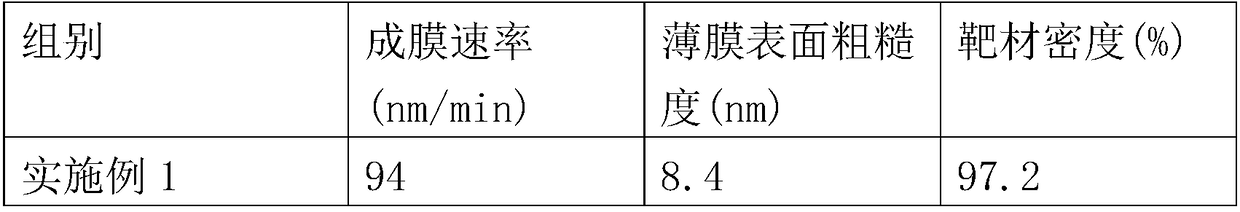

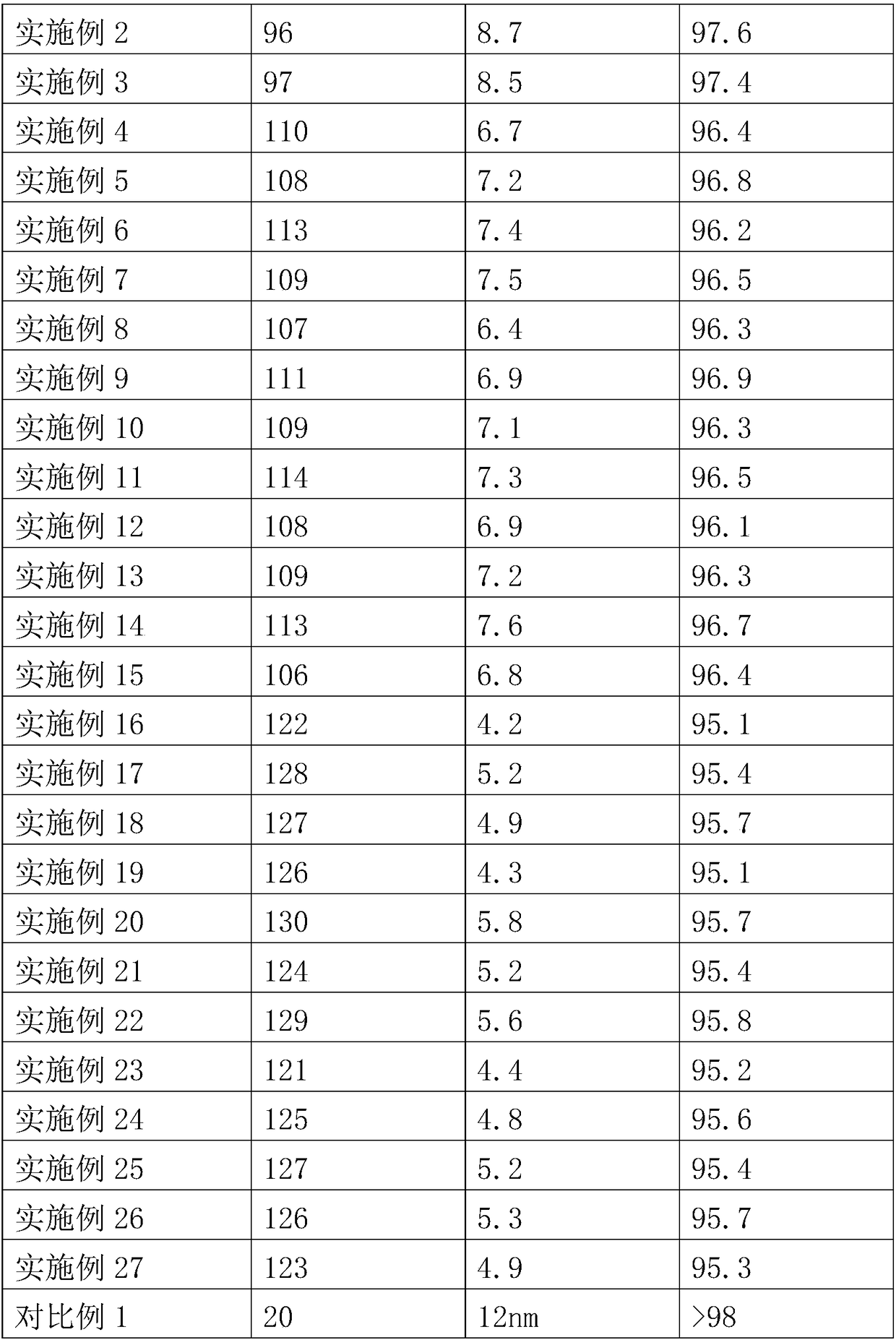

Examples

Embodiment 1

[0015] A preparation method of smart glass cathodic electrochromic layer coating material, using pure tungsten oxide powder, then adding 68wt% zirconia balls, 30wt% pure water and 2wt% dispersant, grinding and mixing sufficiently, the time is 24 hours, Then pour the slurry into a three-inch porous mold, and after 24 hours of drying, the low-density green body of the oxide is formed by demolding, and then sintered in a vacuum sintering furnace at a high temperature of 1100 ° C for 3 hours, and the vacuum degree is 200mmHg , to form a high-density target body for sputtering, which is cut and ground into a three-inch target; then the required coated glass substrate is placed in the sputtering chamber, and the sputtering chamber is vacuumed by a vacuum pumping system. The background pressure was pumped to 0.7×10 -5 After torr, the mixed gas of argon and oxygen is introduced, the volume ratio of oxygen in the mixed gas is 2%, and the working pressure of the sputtering chamber is co...

Embodiment 2

[0017]A preparation method of smart glass cathodic electrochromic layer coating material, using pure tungsten oxide powder, then adding 68wt% zirconia balls, 30wt% pure water and 2wt% dispersant, grinding and mixing fully, the time is 36 hours, Then pour the slurry into a three-inch porous mold, and after 24 hours of drying, the low-density green body of the oxide is formed by demolding, and then sintered in a vacuum sintering furnace at a high temperature of 1200°C for 5 hours, with a vacuum degree of 400mmHg , to form a high-density target body for sputtering, which is cut and ground into a three-inch target; then the required coated glass substrate is placed in the sputtering chamber, and the sputtering chamber is vacuumed by a vacuum pumping system. The background pressure was pumped to 0.8×10 -5 After torr, a mixed gas of argon and oxygen is introduced, the volume ratio of oxygen in the mixed gas is 3%, and the mixed gas is passed through the throttle valve to control the...

Embodiment 3

[0019] A preparation method of smart glass cathodic electrochromic layer coating material, using pure tungsten oxide powder, then adding 68wt% zirconia balls, 30wt% pure water and 2wt% dispersant, grinding and mixing fully, the time is 48 hours, Then pour the slurry into a three-inch porous mold. After 24 hours of drying, the low-density green body of the oxide is formed by demolding, and then sintered in a vacuum sintering furnace at a high temperature of 1400 ° C for 6 hours, and the vacuum degree is 600mmHg. , to form a high-density target body for sputtering, which is cut and ground into a three-inch target; then the required coated glass substrate is placed in the sputtering chamber, and the sputtering chamber is vacuumed by a vacuum pumping system. The background pressure was pumped to 0.9×10 -5 After torr, a mixed gas of argon and oxygen is introduced, the volume ratio of oxygen in the mixed gas is 5%, and the mixed gas is passed through the throttle valve to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com